Evaluation and regulation method for internal quality of tobacco leaf formulation module

A leaf group formula, tobacco leaf technology, applied in the direction of tobacco, tobacco preparation, application, etc., can solve the problems of negative impact on internal quality, lack of guidance basis for sensory and chemical evaluation, unfavorable effective maintenance and continuation, etc., to achieve stable product quality, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

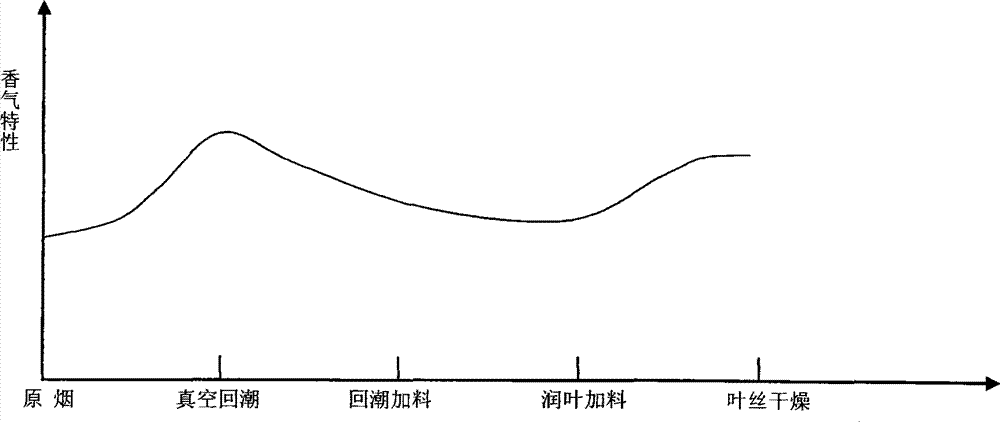

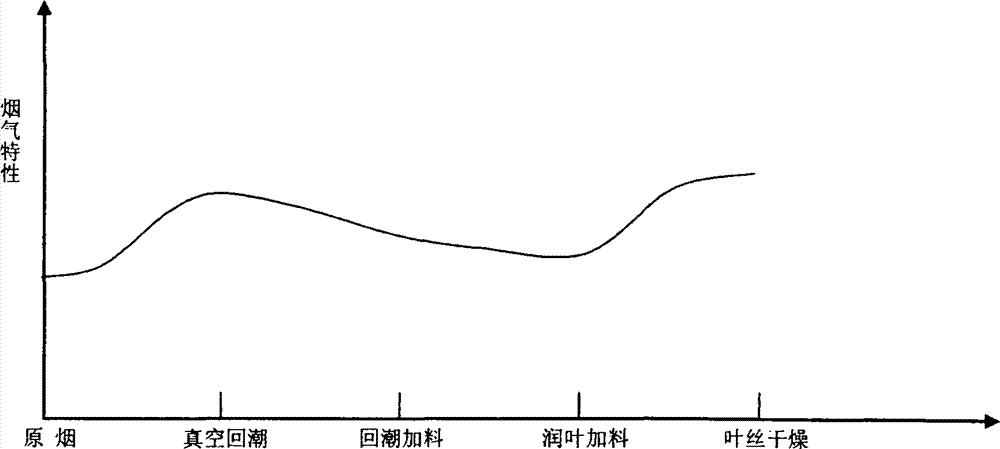

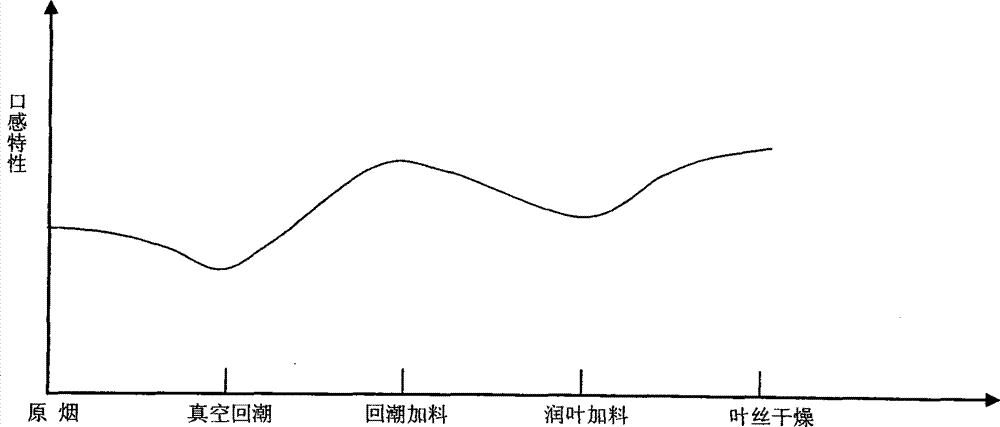

[0042] The improved internal quality evaluation and control methods of the leaf group formula module include:

[0043] 1. Determine the "compatibility principle" of the leaf group formula module

[0044] Combining the characteristics of each process, the characteristics of the leaf group formula module, the style characteristics of cigarette products and the research results of related silk processing, the processing technology concept of "segmented processing" is proposed: different processing targets are designed for each process. Each process is required to improve the overall sensory properties of tobacco leaf raw materials, but to selectively regulate part of the sensory properties of tobacco leaf raw materials in each process. The processing target is the "compatibility principle" of the combination of leaf group formula modules after processing in each process;

[0045] (1) Compatibility principle of the vacuum rehydration process: After targeted grouping processing in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com