A coke oven automatic heating optimization system

An automatic heating and coke oven technology, applied in coke oven heating, coke oven, automatic control, etc., can solve the problems of frequent coke oven heating control, coke oven heating control lag, frequent personnel flow, etc., and achieve the elimination of coke oven smoke Gas NOX rising phenomenon, eliminating black smoke from pushing coke, stabilizing and improving coke quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The coke oven automatic heating optimization system of the present invention will be further described below.

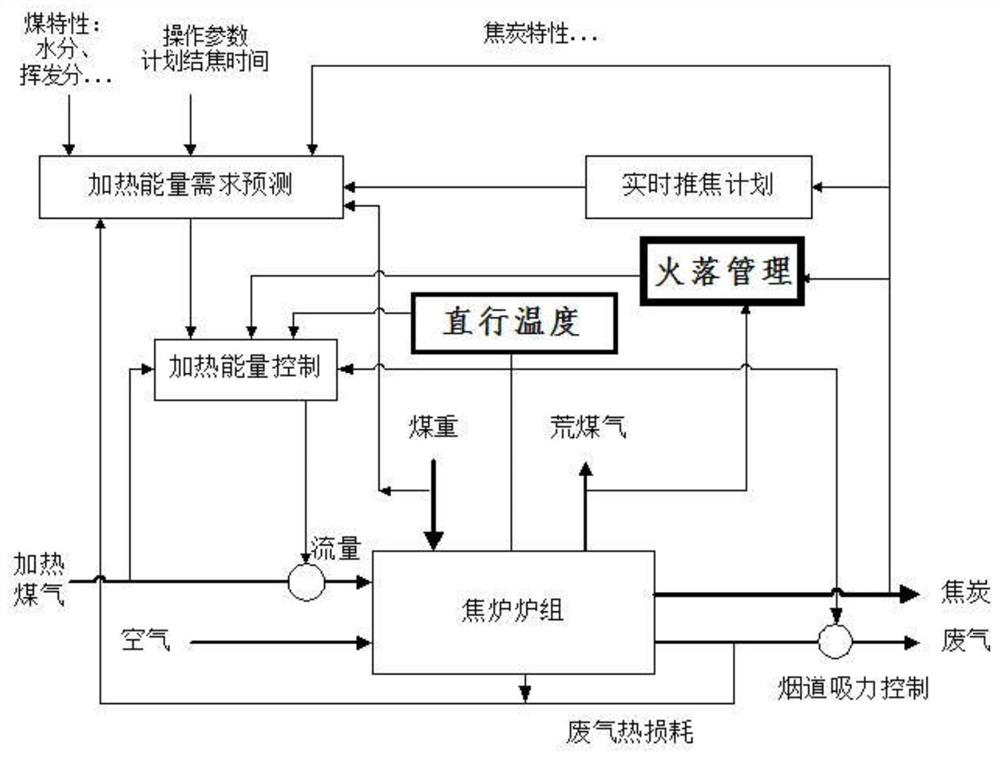

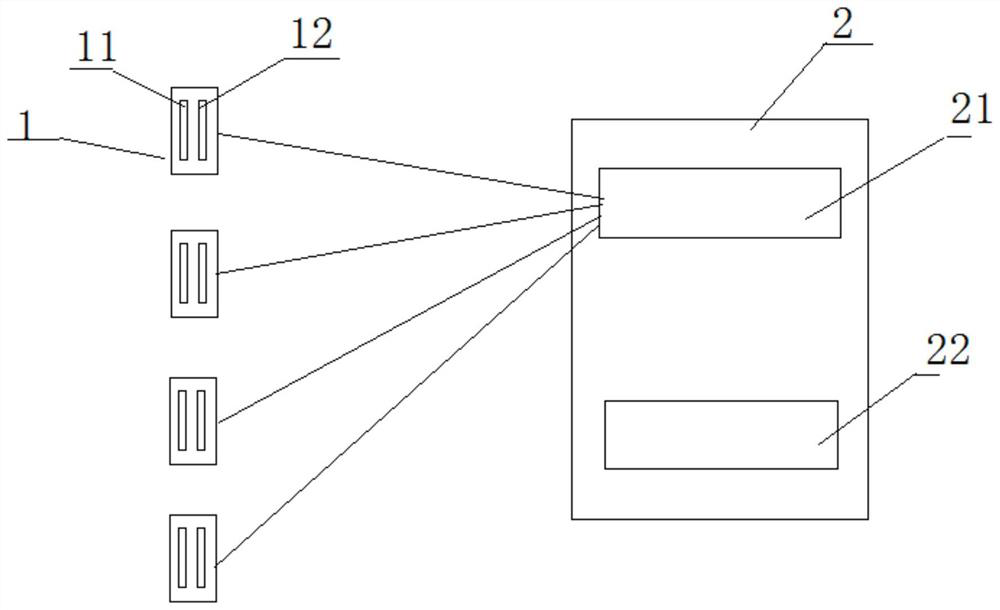

[0044] Coke oven automatic heating optimization system, including feed-forward control system and feed-back control system.

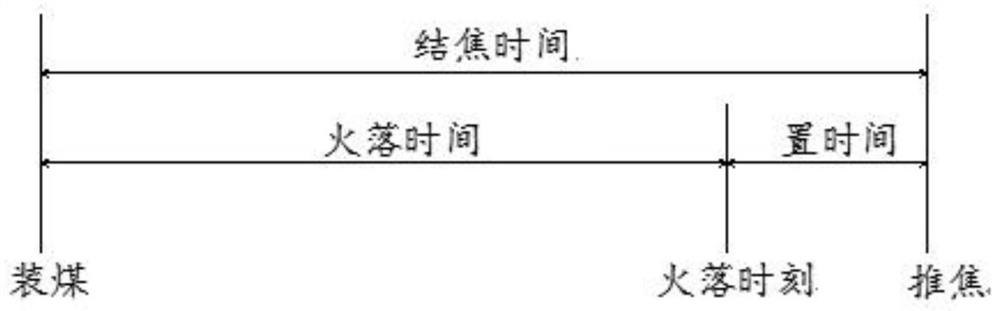

[0045] The feed-forward control system is used to collect real-time data of coke oven production, calculate the set value of the control parameter through the energy prediction model, and send the set value to the coke oven control system to realize feed-forward rough adjustment; the said The real-time data of coke oven production includes gas pressure, flow, calorific value, temperature, mixed coal moisture, heating gas composition, and coke pushing operation plan.

[0046] The energy prediction model is:

[0047] Q 需 =f 1 (G,W,V);

[0048] Q 供 =f 2 (q,q,t);

[0049] T 1 =f3 (Q 需 , Q 供 );

[0050] Among them, Q is heat, G is coal loading, W is moisture, V is volatile matter, q is gas calorific value, Q is gas flow rate, t is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com