Necessity automatic speed control lifting device

A lifting device and emergency avoidance technology, applied in life-saving equipment, building rescue, etc., can solve problems such as loss of balance, easy to panic, unsafe, etc., and achieve the effect of simple and practical structure, good economic benefits, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

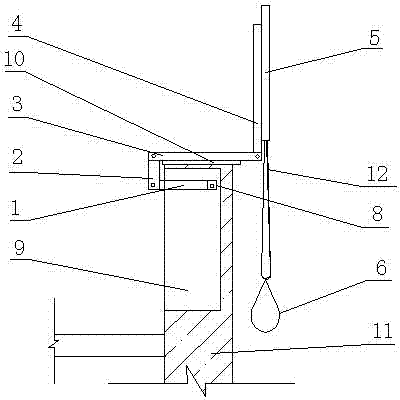

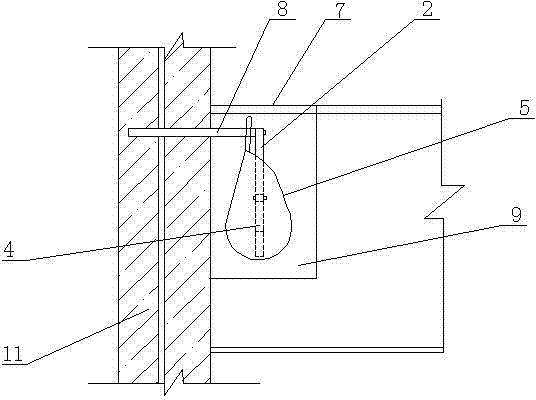

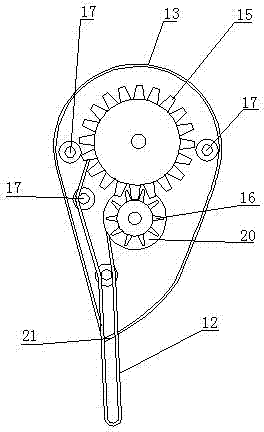

[0028] by attached figure 1 , figure 2 , image 3 , Figure 4 As shown, an emergency avoidance self-controlled speed lifting device is characterized in that it includes a force arm 8, most of which are fixed in a reinforced concrete column 11, a small part is suspended in a wall cabinet 9, a force arm 8, a telescopic arm I1 , telescopic arm II2, telescopic arm III3, and telescopic arm IV4 are hinged sequentially, and telescopic arm IV4 is fixedly equipped with rope box 5; The journal at the end is respectively connected with the upper box body 14 and the lower box body 13 through the bearing 22, a large gear 15 is arranged on one side of the runner 18, and a pinion 16 is arranged on the same side of the rotating shaft 19 relative to the runner 18, and the gearwheel 15 has a large number of teeth. The pinion gears 16 mesh with each other and have the same modulus. A baffle plate 20 is set inside the pinion gear 16. A movement gap is set between the outer circular surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com