Convenient and fast constant-resistance type temporary support strut

A temporary support, constant resistance technology, applied in pillars/supports, mining equipment, earthwork drilling, etc., can solve the problems of long disassembly and assembly time, complicated operation, bulky volume, etc., and achieve fast support and easy operation. , to ensure the effect of construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

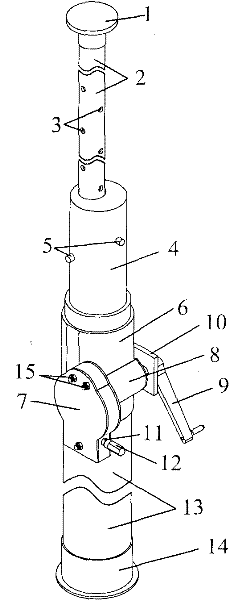

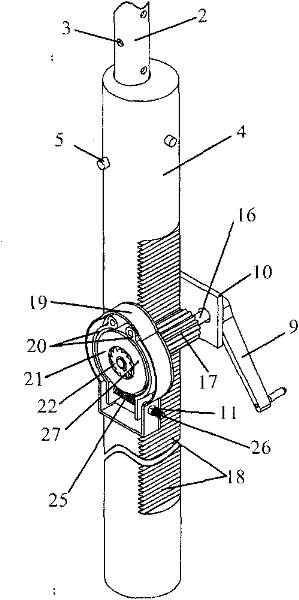

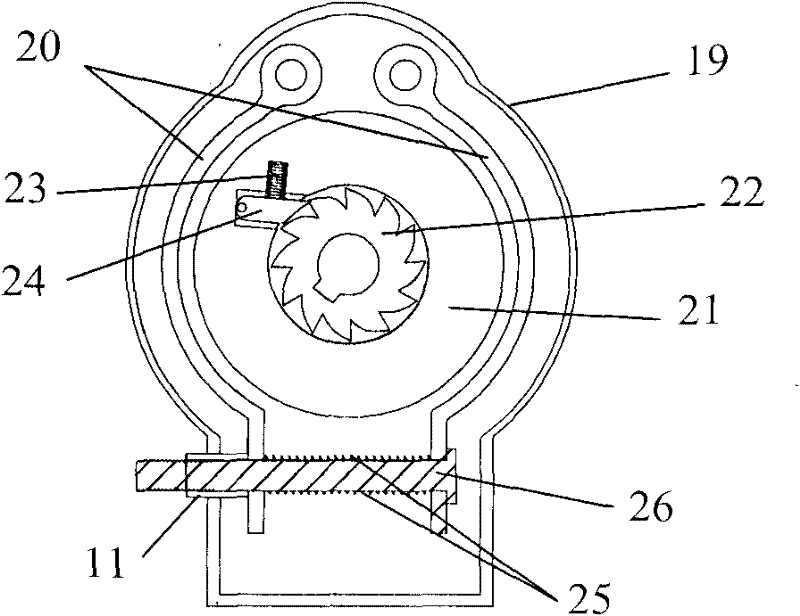

[0012] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] Depend on Figure 1-5 Shown, the present invention comprises outer column, sleeve, rack column and interior active column, and inner active column 2 upper end has top plate 1, and the column body of inner active column 2 has fixed hole 3, and inner active column 2 is contained in the gear In the bar column 4, pin holes are arranged on the outer wall of the rack column 4, and the pin 5 crosses in a cross shape through the pin hole and the fixing hole 3 on the inner column 2 to fix the inner column 2 and the rack column 4 together. The bar column 4 passes through the sleeve 6 and is installed in the outer column 13. The lifting mechanism for lifting the rack column 4 is fixed on the sleeve 6. The sleeve 6 is fixed on the outer column 13. There is a chassis 14 at the bottom of the outer column 13, and the outer column 13 A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com