Roof cracking method and device for coal mining

A technology for cracking and roofing, applied in the field of roof cracking methods and devices, can solve the problems of the old roof failing to collapse in an orderly manner, the existence of mining process, potential safety hazards, etc., and achieve a significant decrease in the mine pressure, reduce the mine pressure, and increase the production capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be further described below in conjunction with the drawings and specific embodiments.

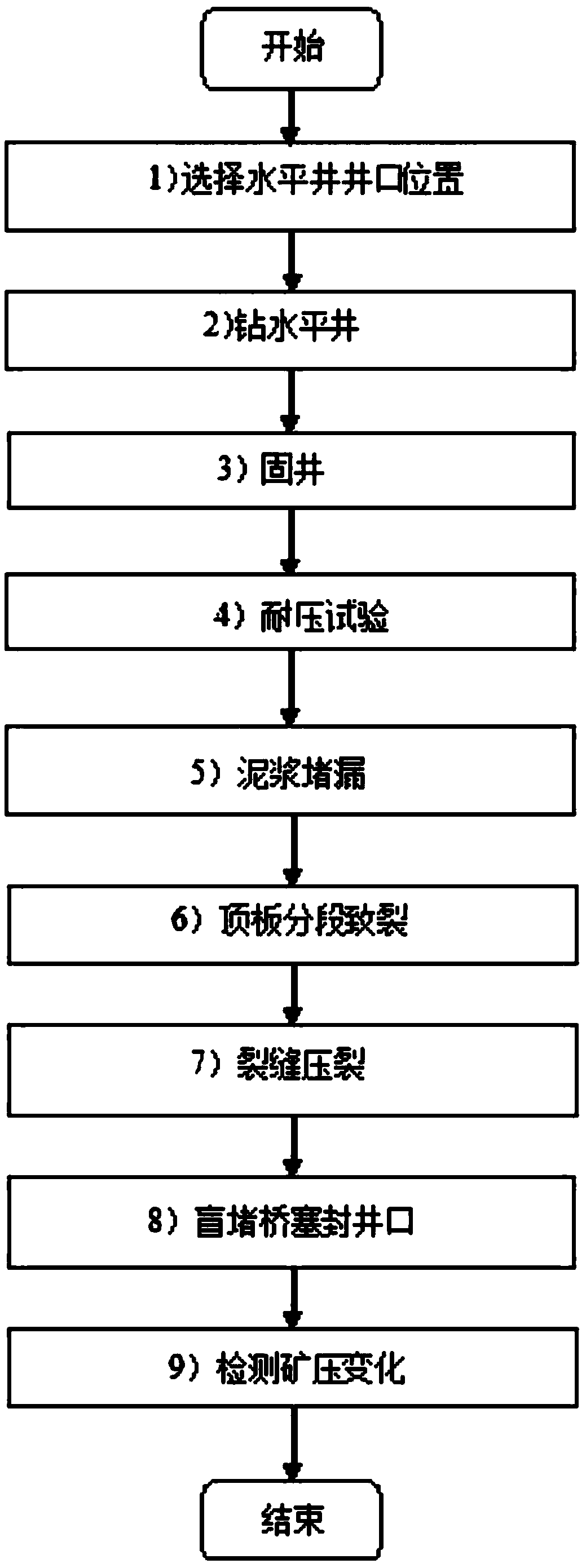

[0066] Reference figure 1 :

[0067] A roof cracking method used in coal mining includes the following steps:

[0068] 1) Select the location of the horizontal well head:

[0069] On the ground, according to the lateral position of the working face and the direction of working face extension, determine the position of the wellhead through the comparison chart of downhole and ground position. At the same time, the layout of the site should be considered. The general construction site area is 2500m 2 ~4000m 2 . After the rig is erected, the GPS measurement system is used for fixed measurement, and a retest is performed before the completion of the drilling.

[0070] 2) Drilling horizontal wells:

[0071] The horizontal well in this example is an "L" type horizontal, which is characterized by short vertical well sections and long horizontal sections. Generally, horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com