Optima design method of hydraulic support based on beam-free end distance high-strength protection side

A hydraulic support and optimized design technology, which is applied in the optimized design of hydraulic supports and the field of hydraulic supports with large mining heights, can solve the problems of short telescopic beams of hydraulic supports, insufficient upward support force, and large empty roof distance, etc., to achieve enhanced The effect of increasing the horizontal supporting force of the side protection, increasing the stretchability, and improving the initial supporting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the present invention, the present invention will be further clearly and completely described below in conjunction with reference to the accompanying drawings and in conjunction with embodiments. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

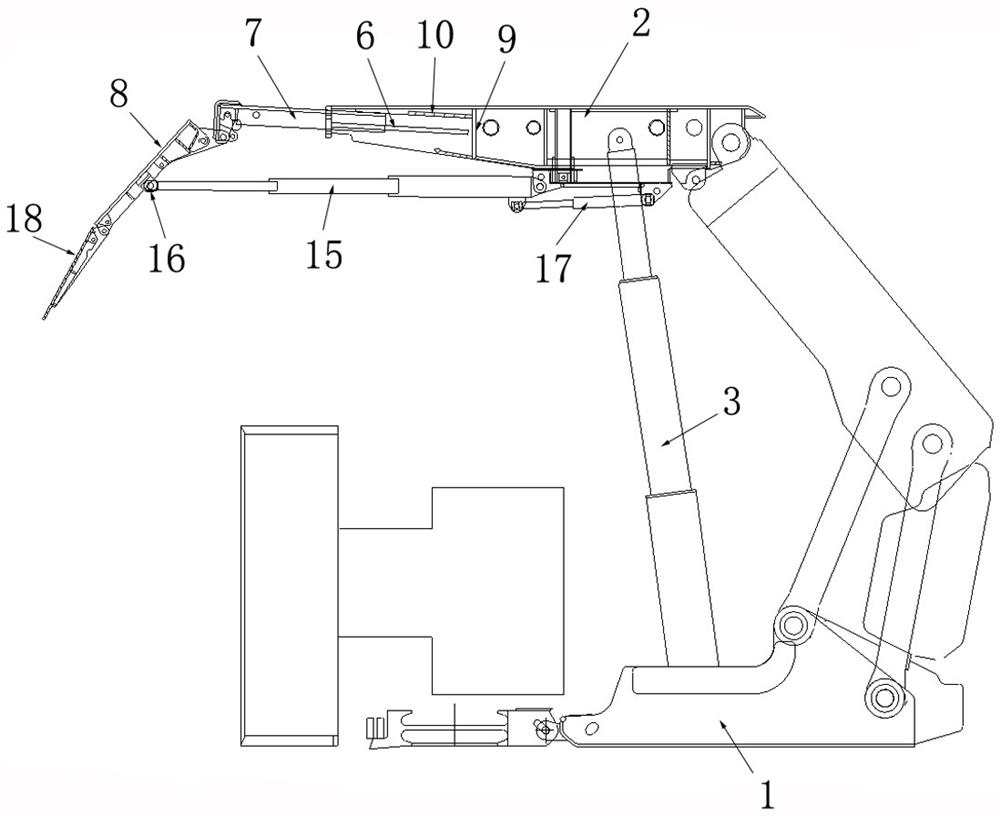

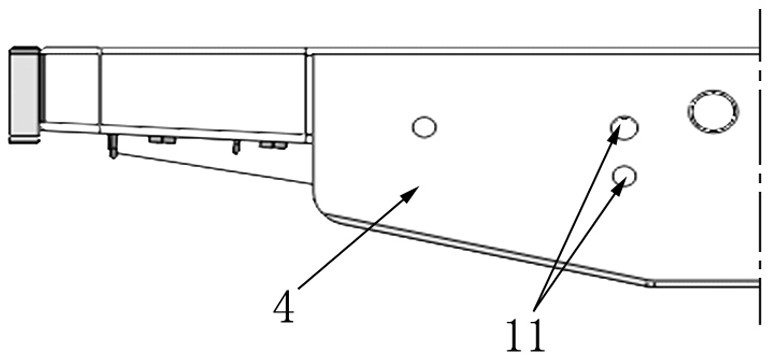

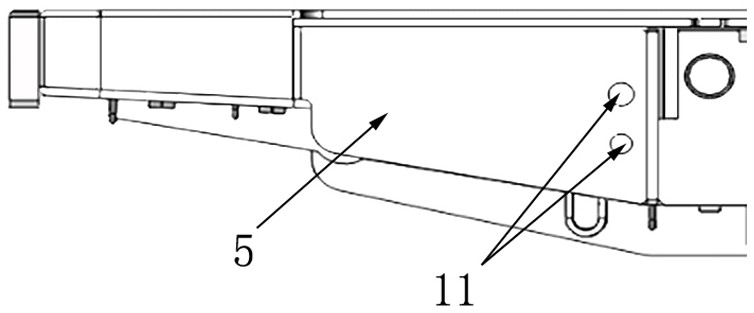

[0030] An optimal design method of a hydraulic support based on beamless end distance and high-strength side protection. The hydraulic support adopts a cover-type hydraulic support with a large mining height as an optimization model. The cover-type hydraulic support with a large mining height includes a base 1, a top beam 2 and a connecting The column jack 3 between the two; one side of the top beam 2 is provided with a fixed side guard plate 4, and the other side is provided with a movable side guard plate 5; the top beam 2 is provided with a slidewa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com