Bottom dead center adjusting mechanism for high-speed press

A technology for adjusting mechanisms and presses, which is applied in the field of presses, and can solve the problems that the disc motor cannot realize the controllable inching function, the bottom dead point cannot be adjusted in inchings, and precision stamping cannot be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

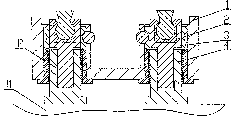

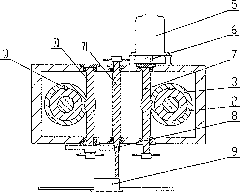

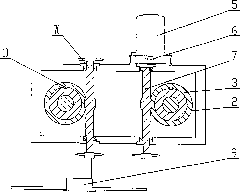

[0013] The present invention as figure 1 , 2 As shown, the top of the press slide block 11 is connected with a pair of connecting rod devices, and the connecting rod device includes a ball joint rod, a ball bowl, an adjusting screw 2, a worm wheel 3, a worm, a worm drive mechanism, a guide post 4 and a guide post Bearing; the guide post bearing is fixedly connected to the fuselage 1, and the guide post 4 is connected to the guide post bearing; the guide post 4 is provided with a threaded hole toward the direction of the ball joint rod, and the lower part of the adjustment screw 2 is provided with A threaded connection section 12, the adjusting screw 2 is connected to the threaded hole through the threaded connecting section 12 at its lower part; the top of the adjusting screw 2 is provided with a bowl connection hole, and the ball bowl is arranged in the bowl connection hole Inside, the ball-joint connecting rod is connected with the adjusting screw 2 through the ball bowl; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com