Bevel wedge type screw distributing mechanism

A material-distributing mechanism and screw technology, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of unreliable insertion of blocking plates and smaller screw gaps, so as to achieve higher efficiency, higher reliability of material distribution, and improved material distribution. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

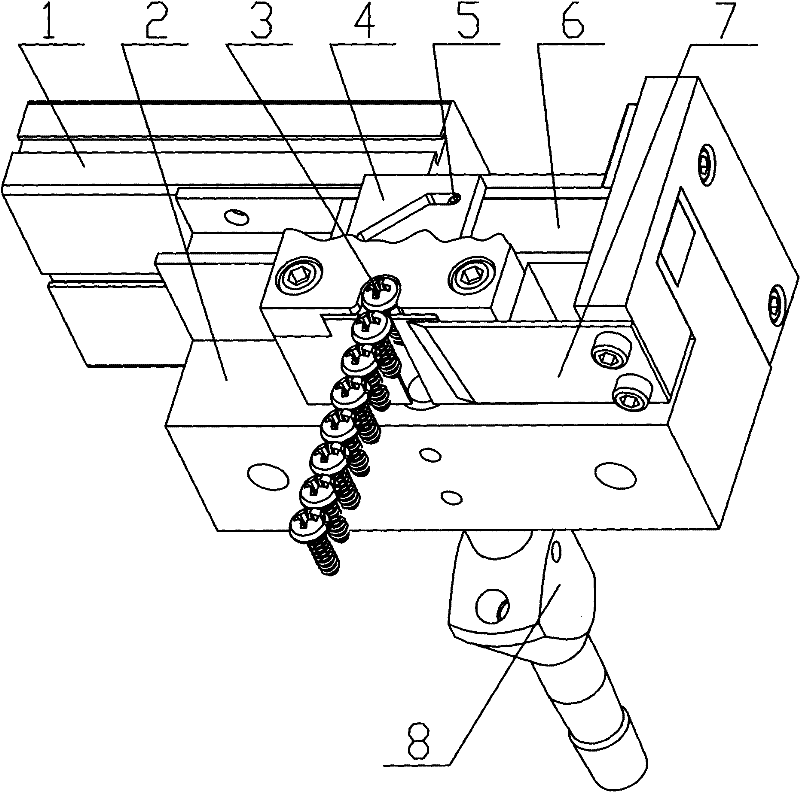

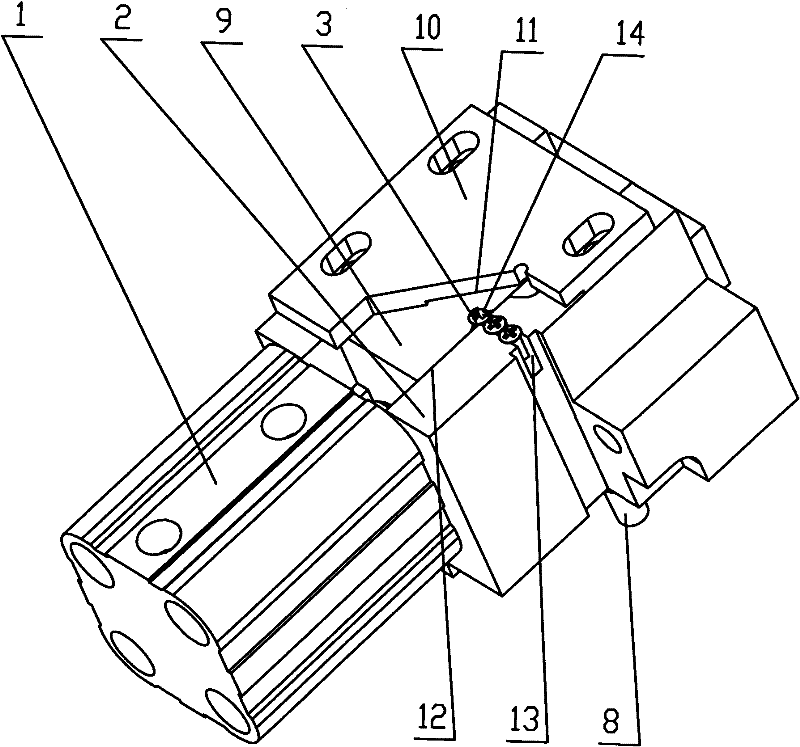

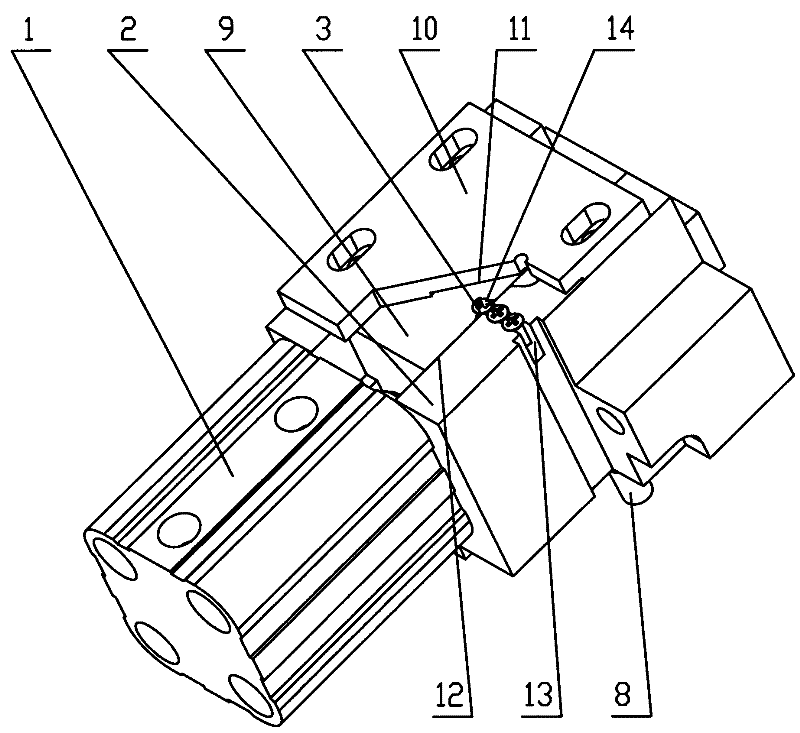

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] A wedge-type screw material distribution mechanism, comprising a power head 1, a guide block 2, and a blowing pipe 8, the guide block 2 is provided with a guide groove 13, and the inner surface 12 of the guide block 2 is provided with a pusher block 9, and the pusher The block 9 is provided with a material holding chamber 14 suitable for the screw, the guide groove 13 on the guide block 2 communicates with the material holding chamber 14 on the pushing block 9, and the top of the pushing block 9 is provided with a slope 11. The material guide plate 10 , the slope 11 of the material guide plate 10 ends above the inner surface 12 of the guide block 2 . .

[0013] The blow tube 8 is arranged on the guide block 2 . The power head 1 is a cylinder.

[0014] When working, the screws are arranged in the guide groove 13 on the guide block 2, the screw head is supporte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap