Micro speaker semi-finished automatic assembly equipment

A micro-speaker, automatic assembly technology, applied in the direction of sensors, electrical components, etc., can solve the problems of complex structure of assembly equipment, low processing efficiency, low processing accuracy, etc., and achieve the effect of simplifying the structure, improving efficiency, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

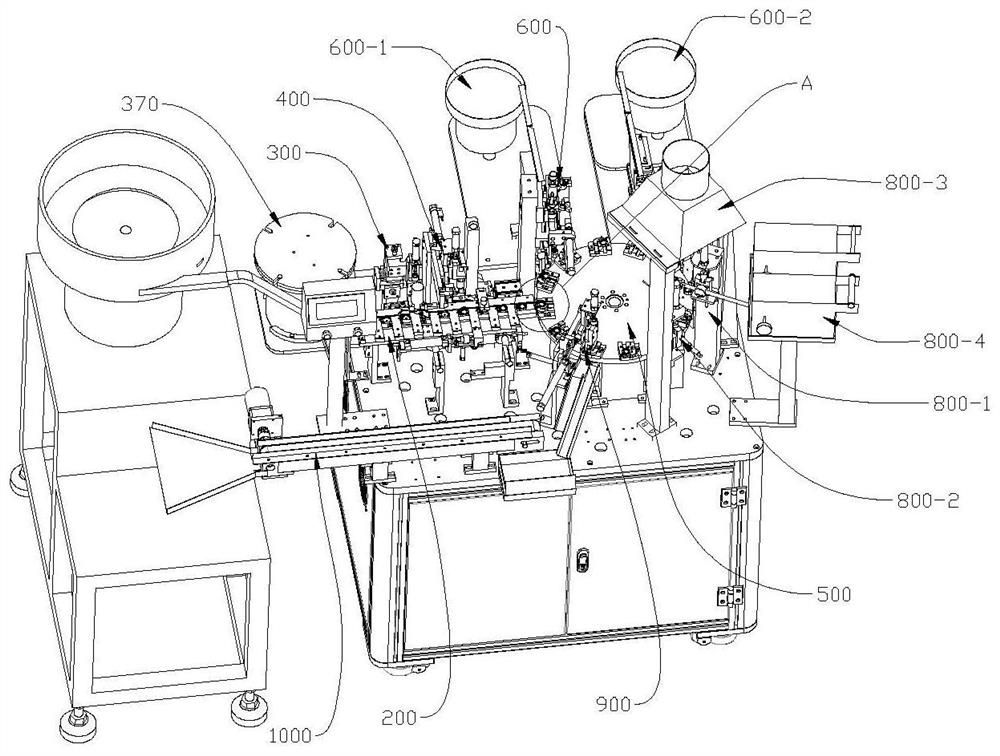

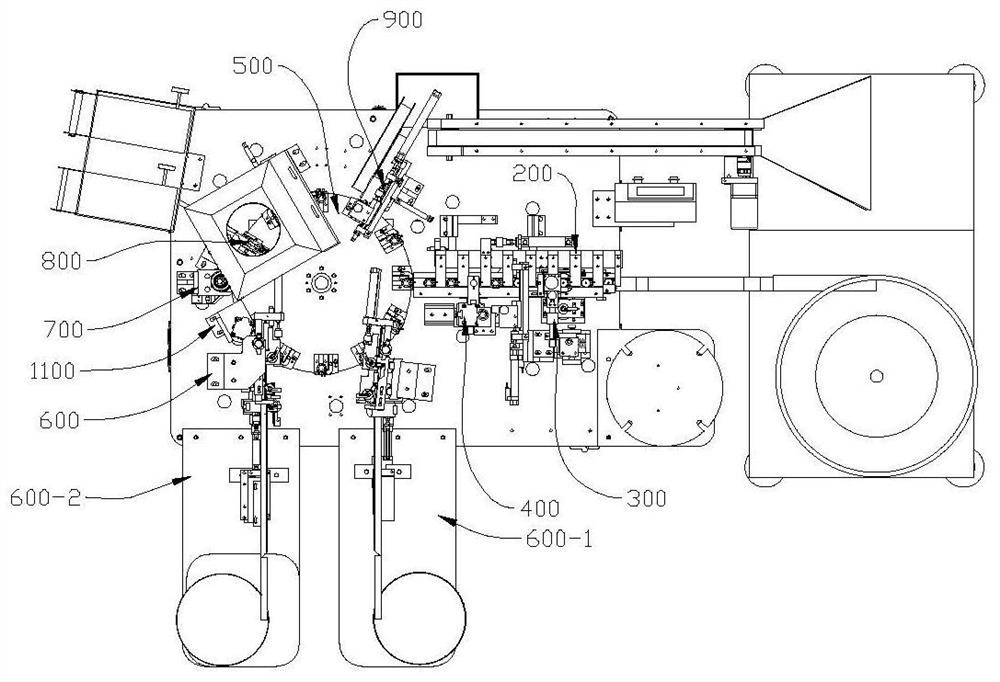

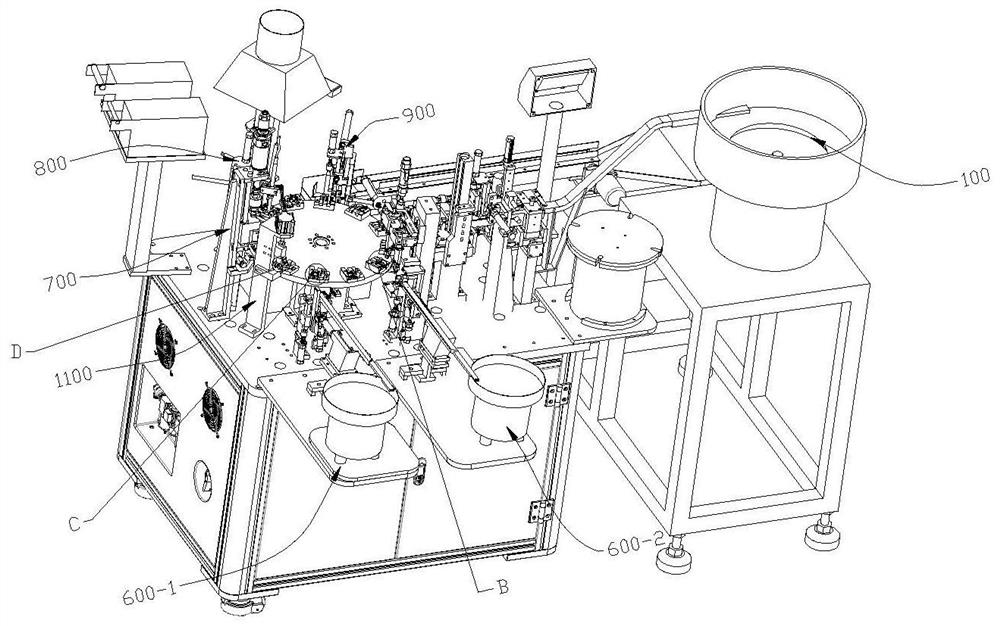

[0081] Such as Figure 36 As shown, this embodiment provides a kind of automatic assembly equipment for semi-finished products of micro-speakers, which involves a total of four parts for the plastic casing 1, the vibrating diaphragm 2, and the two terminals of terminal one 301 and terminal two 302, combined with Figure 1-Figure 3 As shown, the processing process includes feeding plastic shell 1, dispensing glue, upper vibrating diaphragm 2, pressure gluing, upper terminal 1 301 and terminal 2 302, terminal pressing and positioning, terminal heat riveting, terminal spot welding, taking out materials and other steps. In order to simplify the automatic assembly production line and improve the smoothness of the connection between each processing procedure, so that each processing procedure can be kept at the same working rhythm, this embodiment divides the specific processing steps in the above-mentioned processing process into two major processes. The first station includes pla...

Embodiment 2

[0112] Such as Figure 29 As shown, the difference between this embodiment and the above-mentioned embodiments is that in this embodiment, a flattening and fitting mechanism 1100 is provided after the terminal is loaded and between hot riveting processing. The flattening and fitting mechanism 1100 includes a seat body 1120, The vertical movement cylinder five 1110 and the guide seat 1121 fixedly installed on the seat body 1120, and a flattening joint head 1130 is slid through the guide seat 1121, between the flattening joint head 1130 and the piston rod of the longitudinal movement cylinder five 1110 Fixedly connected by a clamping block 1101 , a position sensor is fixedly installed under the guide seat 1121 and on the seat body 1120 for detecting the descending height of the flattening head 1130 . combine Figure 30 As shown, the bottom of the flattened abutting head 1130 is provided with two abutting parts corresponding to the two metal positioning pins 101 on the plastic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com