Automatic screw buckle assembling operation system

An automatic assembly and operating system technology, applied in control/adjustment systems, mechanical control devices, instruments, etc., can solve problems such as inability to meet high-efficiency processing and low efficiency, and achieve the effect of improving efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

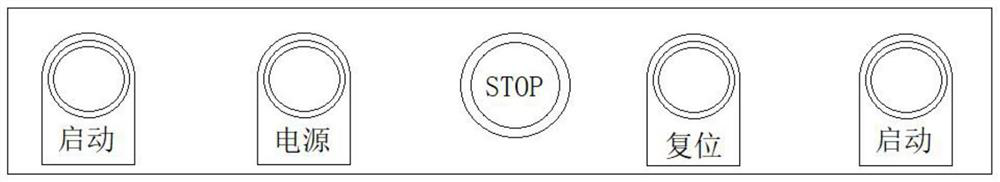

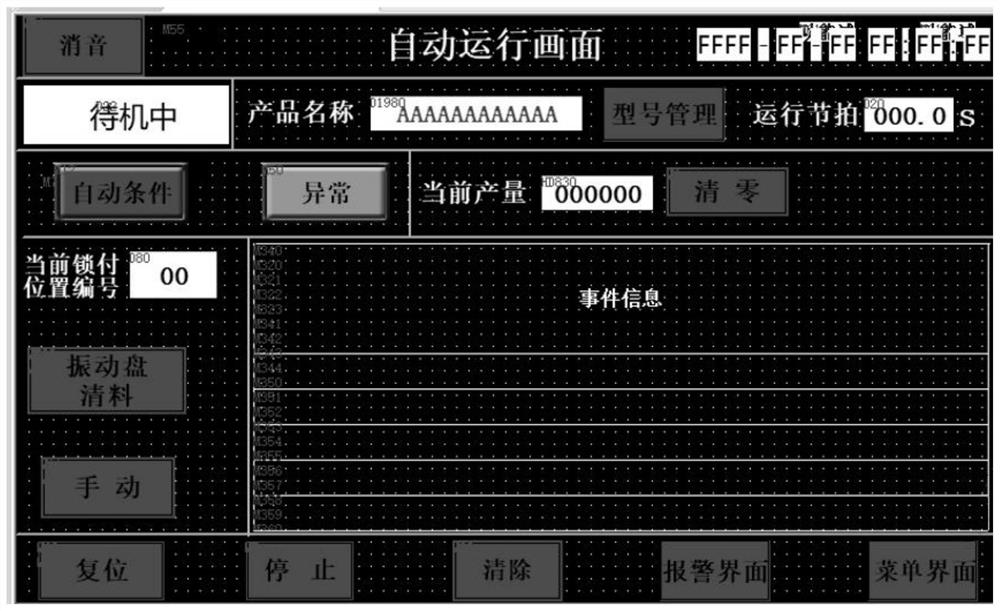

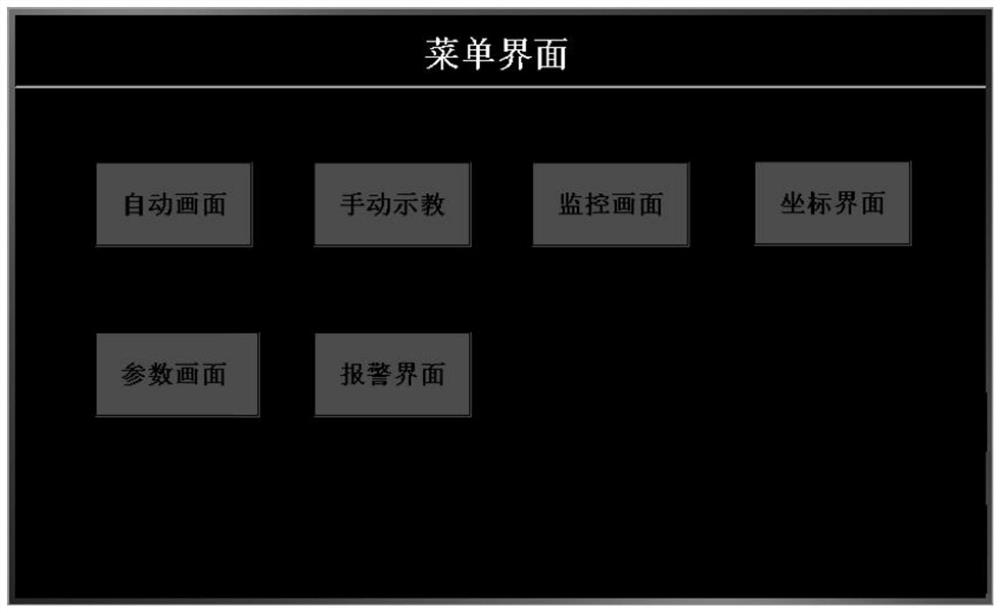

[0022] as attached figure 1 , 2 As shown, an automatic assembly operating system for screw snaps includes two parts, an operating device and an operating interface. The operating device includes two start buttons, a power button and a reset button, and the two start buttons are respectively arranged There is a power button and a reset button, and the power button is set on the left side of the reset button; the operation interface includes an operation status display column, a product model display column, an equipment operation tempo display column, an equipment automatic operation condition button, and an equipment abnormality indication button , output display column, current locking position number column, vibration plate cleaning button, manual / automatic switching button, reset button, stop button, alarm clear button, alarm interface, menu interface and event information display column, the operation status display column, product model display column, and equipment oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com