Device and method for automatically adjusting the horizontal ride level of a utility vehicle

An automatic adjustment, truck technology, applied in vehicle parts, transportation and packaging, elastic suspension, etc., can solve the problem of not being noticed by the vehicle driver

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

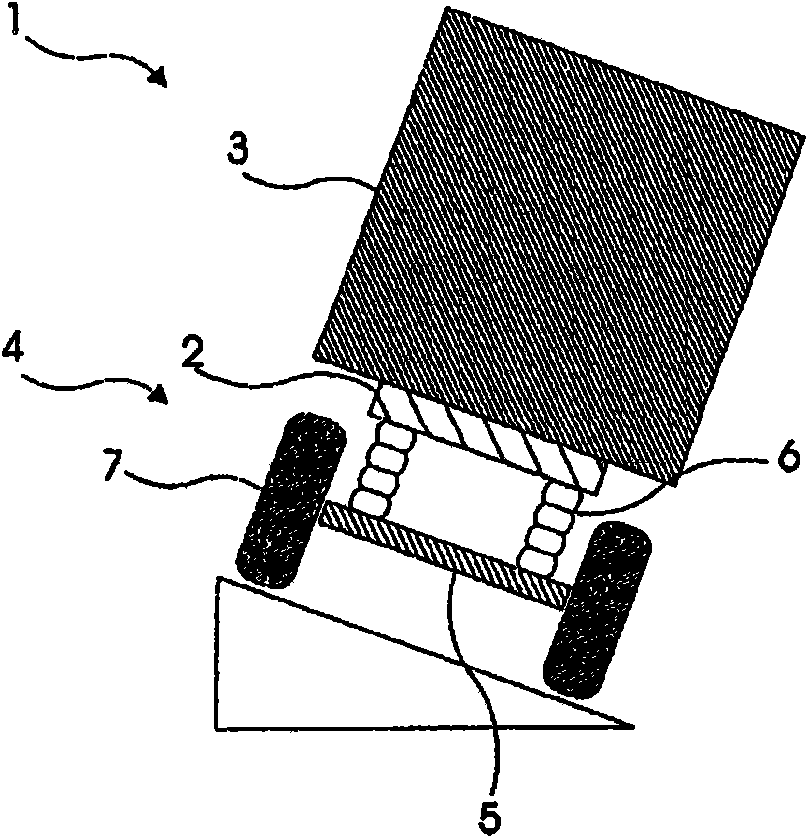

[0033] exist figure 1 A truck 1 with a device 8 according to the invention is shown in simplified form in . The vehicle shown has a vehicle body 2 on which a pivotable body 3 is mounted. The vehicle body 2 is connected to a chassis 4 which, in this illustration, includes an axle 5 , spring elements 6 and wheels 7 . figure 1 The position of the vehicle corresponds to driving or parking on a sloping ground with an inclination angle α, and the spring element 6 has a length suitable for driving operation. In view of the method according to the invention, this location is assumed to be the starting point for starting the method.

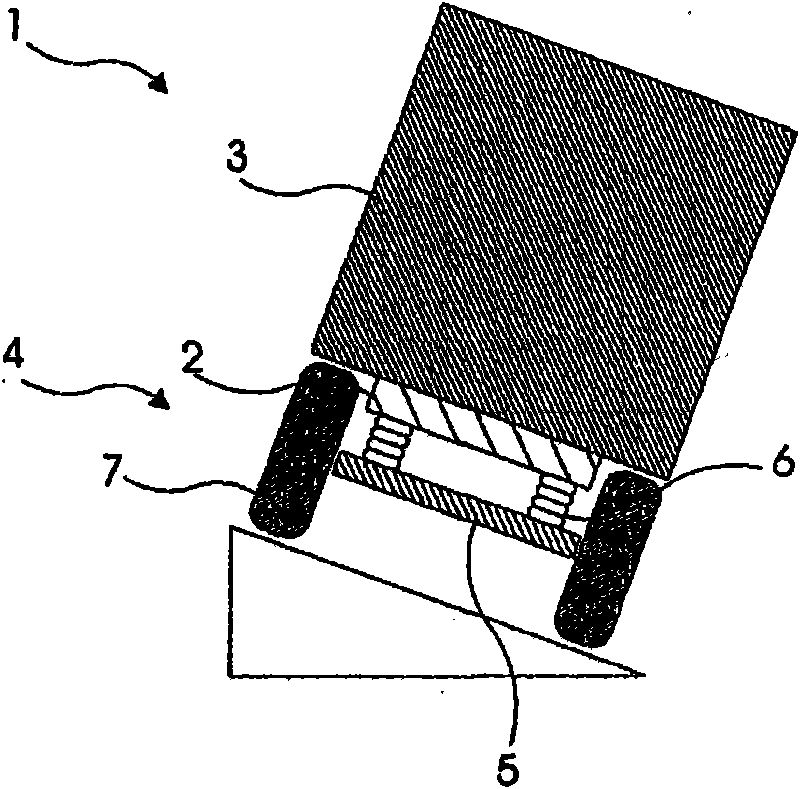

[0034] exist figure 2 shown in figure 1 The same vehicle as in . In this illustration, the spring element 6 is lowered to a minimum length x 0 . In this way, the center of gravity of the vehicle 1 is then shifted as close as possible in the direction of the axle 5 of the vehicle 1 and as close as possible to the center of the support surface. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com