Punching method of tube hole set and stamping die thereof

A technology for stamping dies and pipes, used in perforating tools, manufacturing tools, forming tools, etc., can solve the problems of difficulty in ensuring the coaxiality of the holes on the upper surface of the pipe and the holes on the lower surface, low production efficiency, etc., and achieve high precision and uniformity. Axiality, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the accompanying drawings.

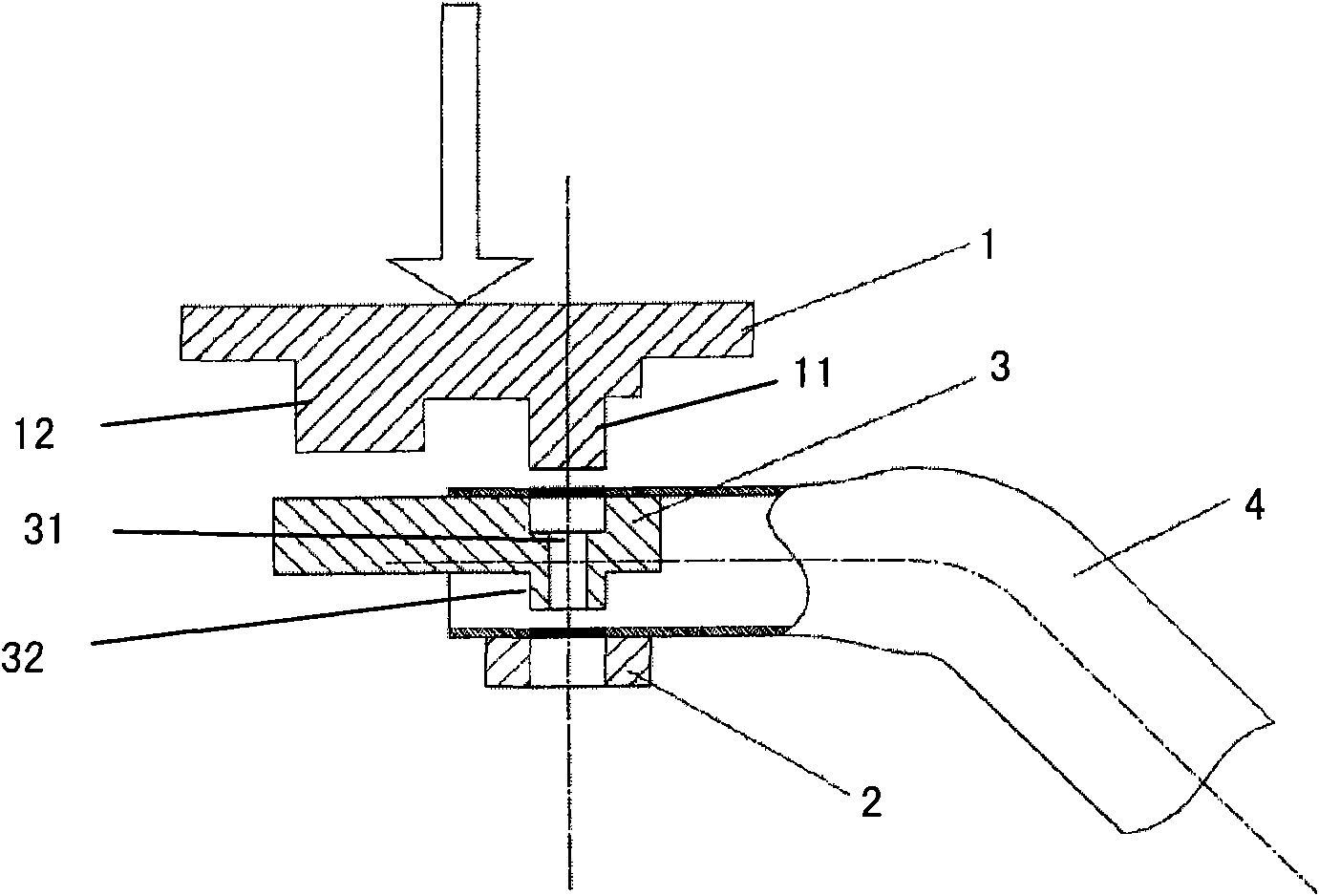

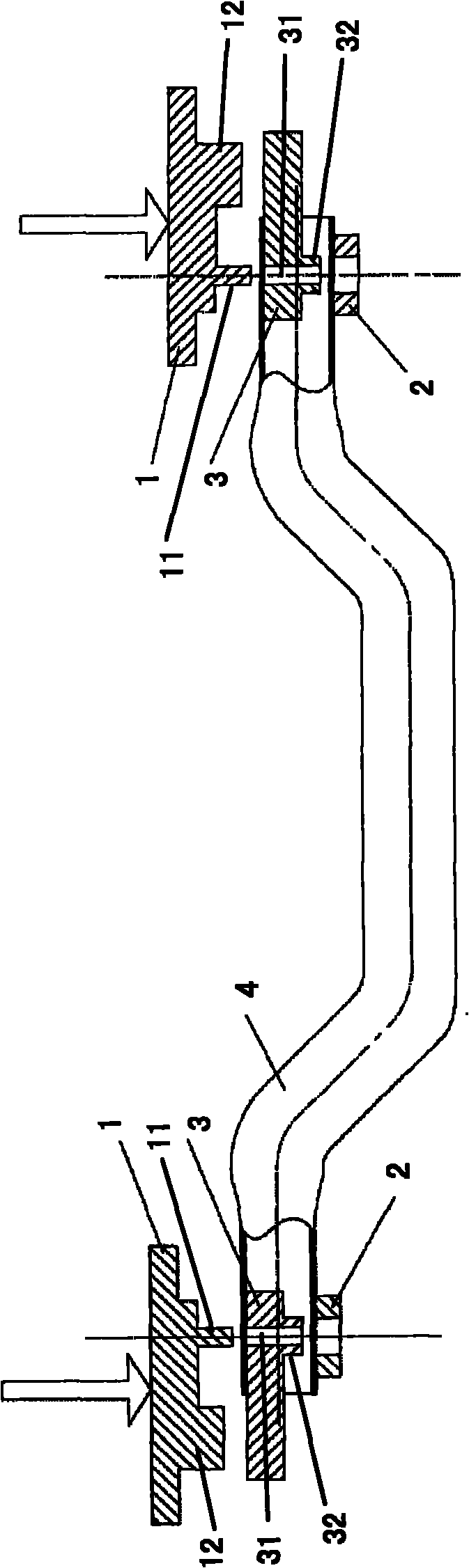

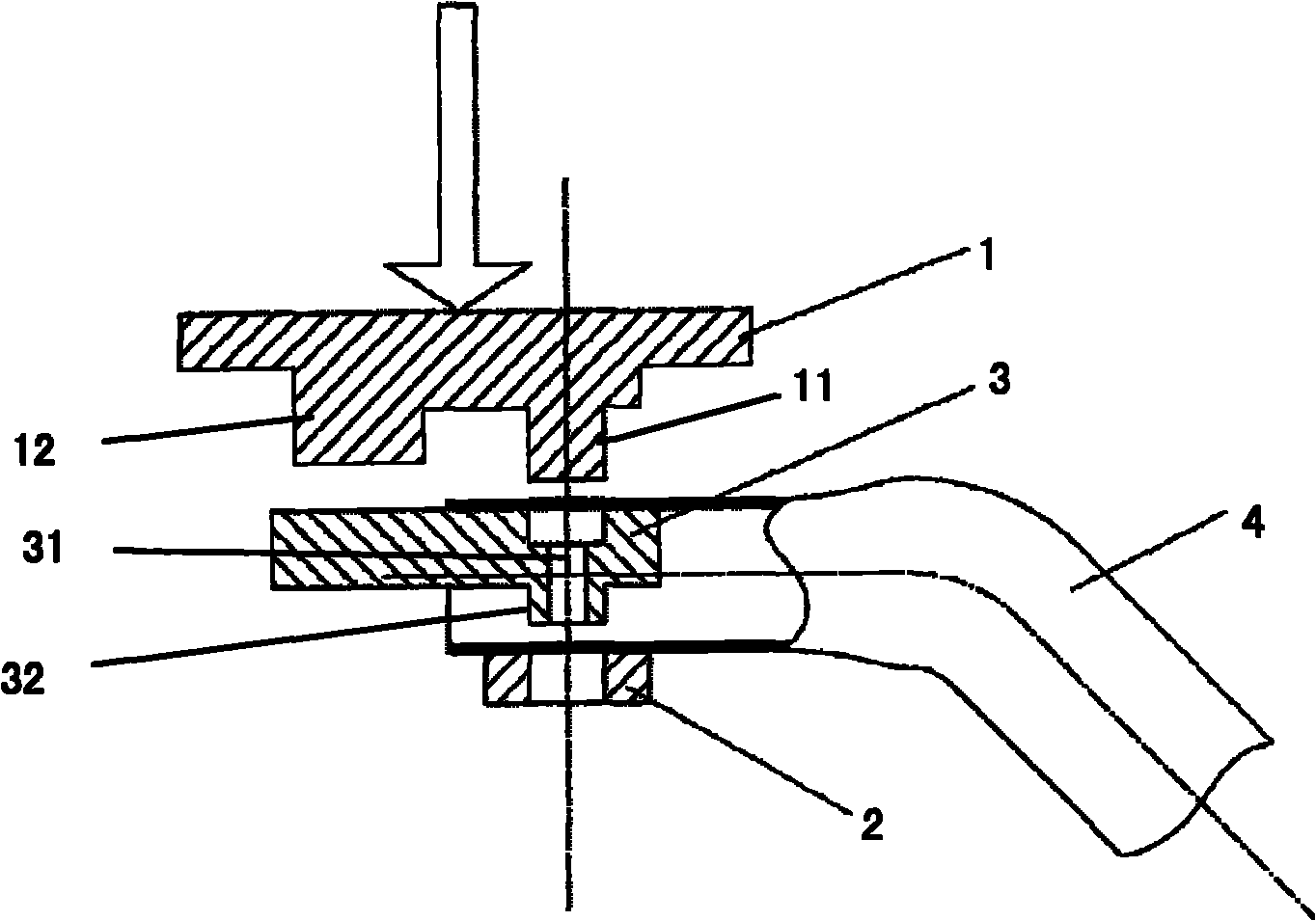

[0018] FIG. 1 shows a first embodiment of the stamping die of the present invention. The stamping die of the present invention includes an upper die 1, a lower die 2 and a step die 3 that can move up and down. The upper die 1 is provided with a first punch 11 for punching holes. The upper die 1 and the lower die 2 are the dies on the existing punching machine, and the stepped die 3 can be arranged on a guide rail mechanism, or can be connected to a lever 5 as shown in Figure 6, and the stepped die 3 is driven by the lever 5 to achieve up and down. move. The stepped die 3 is arranged between the upper die 1 and the lower die 2, the side of the stepped die opposite to the first punch 11 is provided with a lower die opening 31, and the side opposite to the lower die 2 is provided with a first punch for punching holes. Two punches 32. The bottom of the upper die 1 is als...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap