Vacuum-hammock shock-proof sleeve

An anti-vibration sleeve and hammock type technology, applied in the field of packaging sleeves, can solve problems such as poor protection effect of packaging, gas puncture by the anti-vibration sleeve, leakage and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

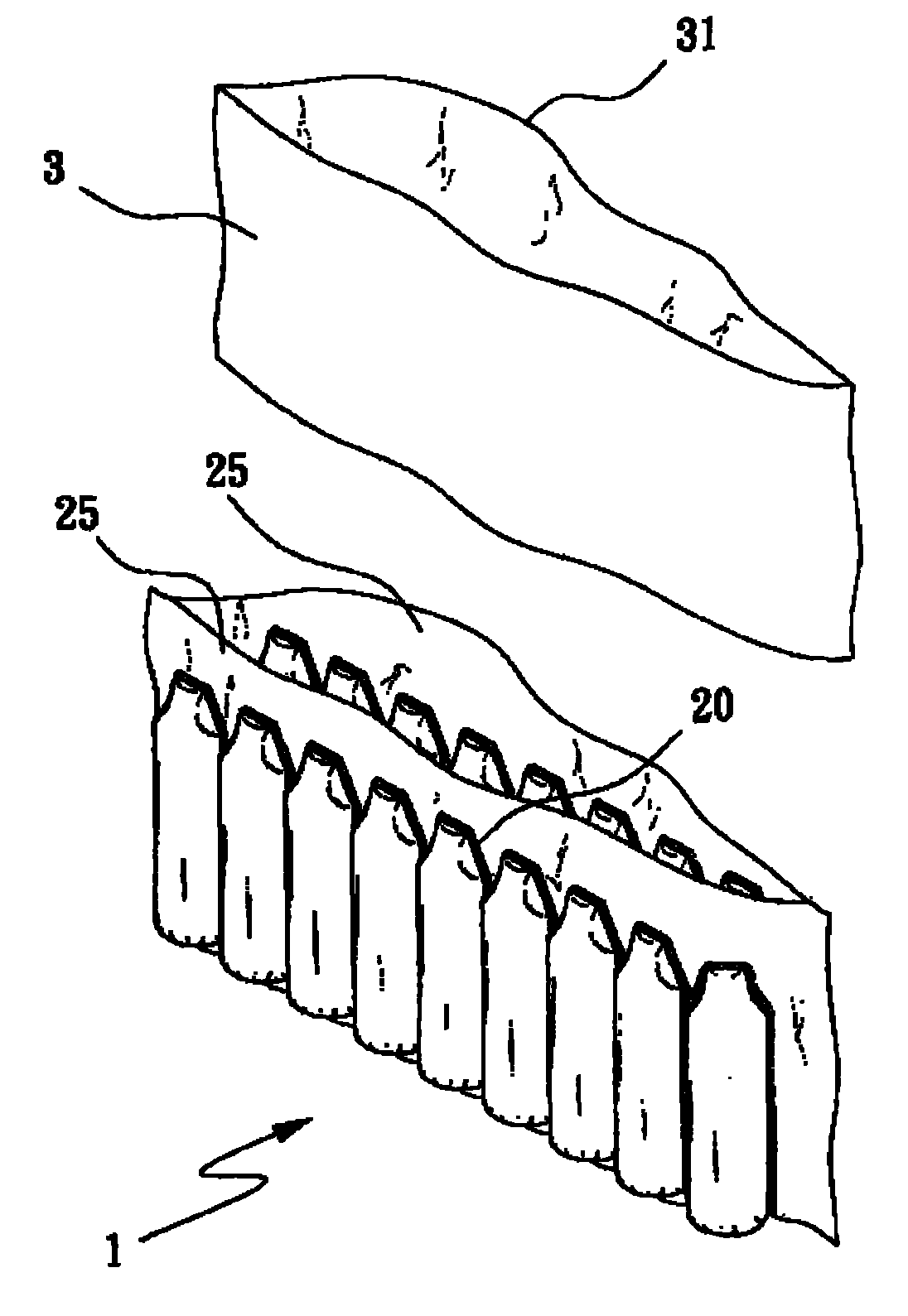

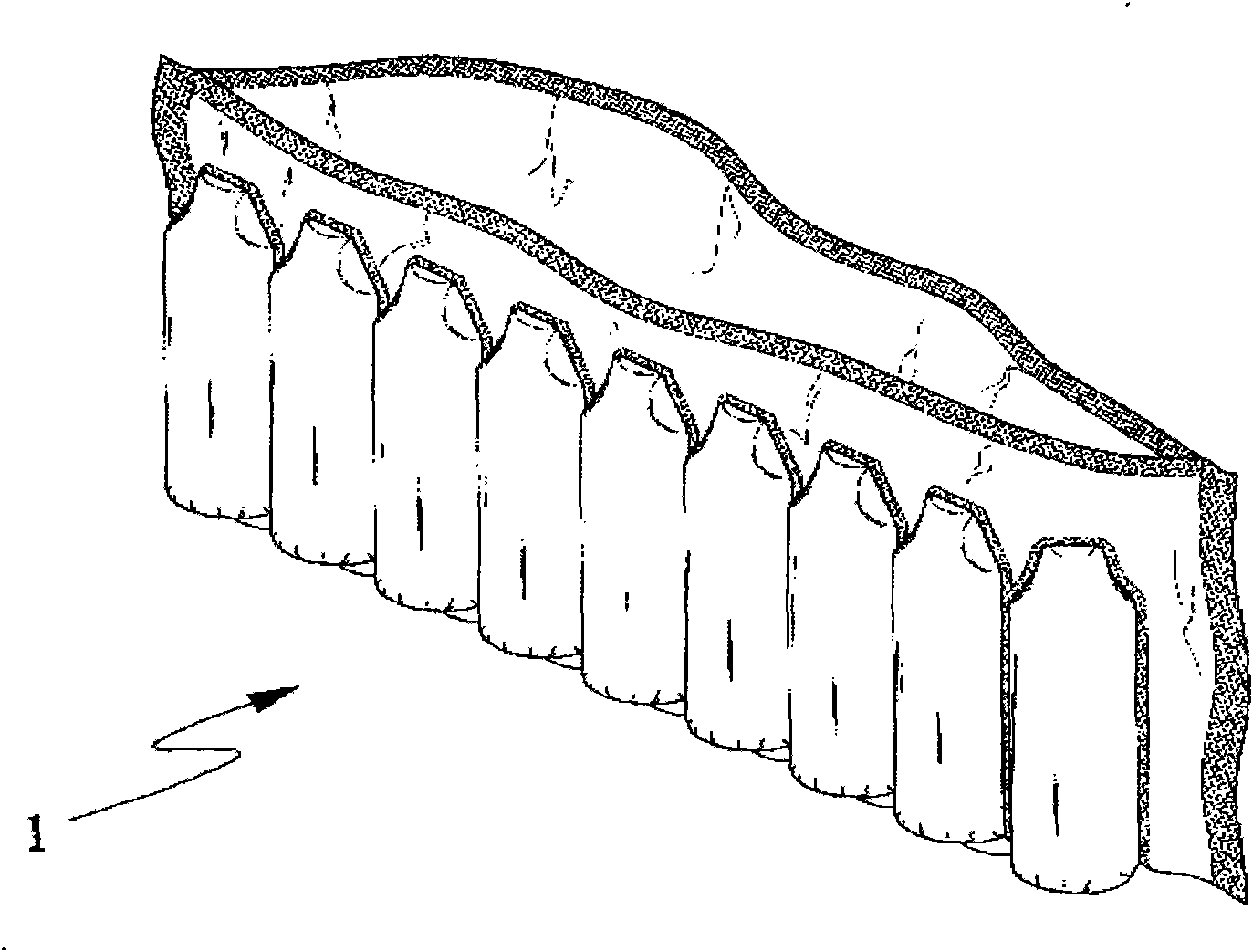

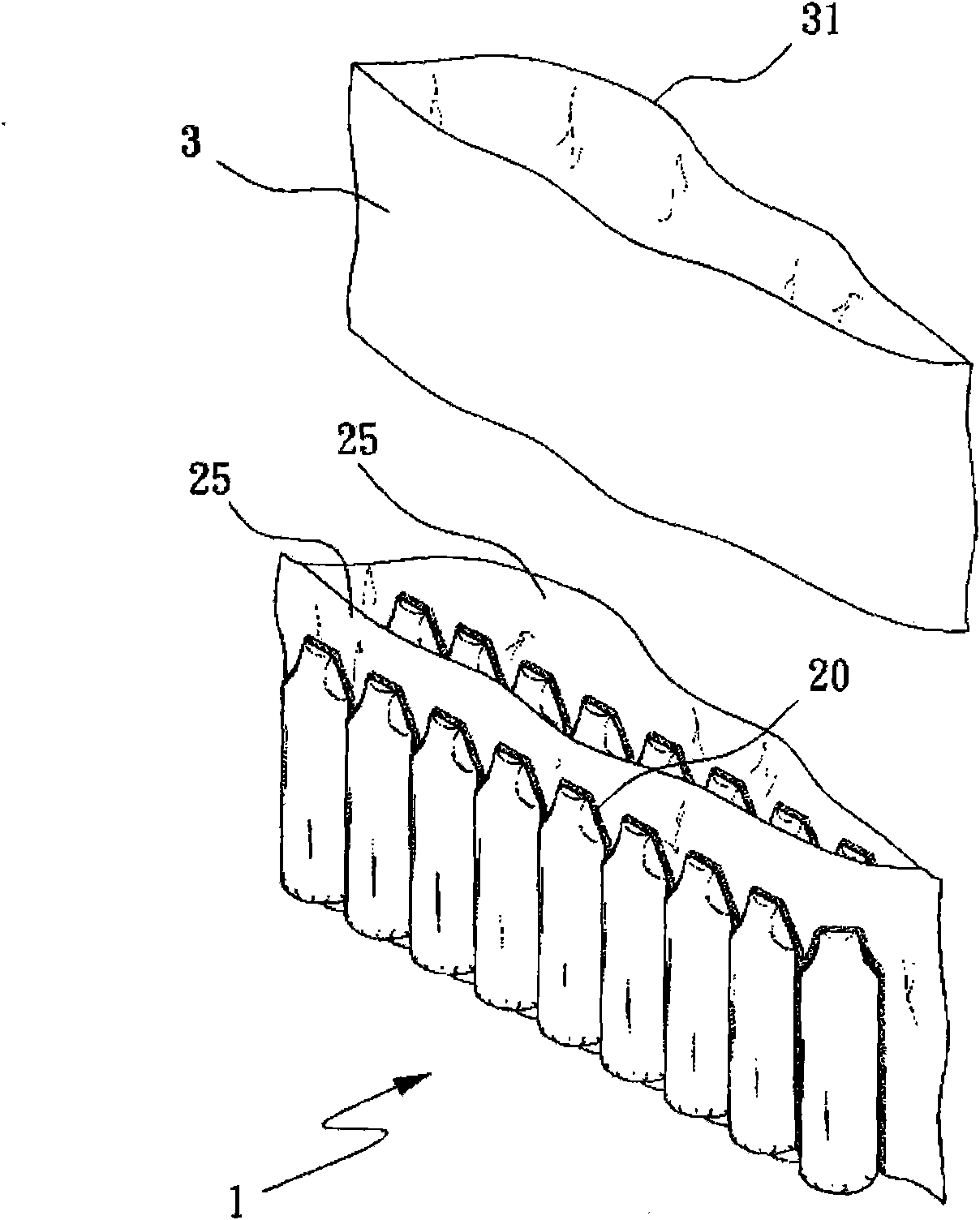

[0030] The vacuum hammock type anti-vibration cover described in the specific embodiment of the present invention has two layers of protection. Specifically, the anti-vibration cover includes:

[0031] The buffer wall is composed of multiple air columns arranged;

[0032] an accommodating space, wherein a plurality of said buffer walls are connected and combined to form said accommodating space in a closed state;

[0033] The packaging inner film is used to cover the package by vacuuming, and is arranged in the accommodating space and suspended on the buffer wall.

[0034] Among them, the buffer wall composed of air columns in the shockproof sleeve can absorb and buffer the impact and vibration of the outside world, so it plays a first layer of pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com