Cement product setting accelerating method and device

A cement product and microwave technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of long time and restrict the production of cement products, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and examples of implementation.

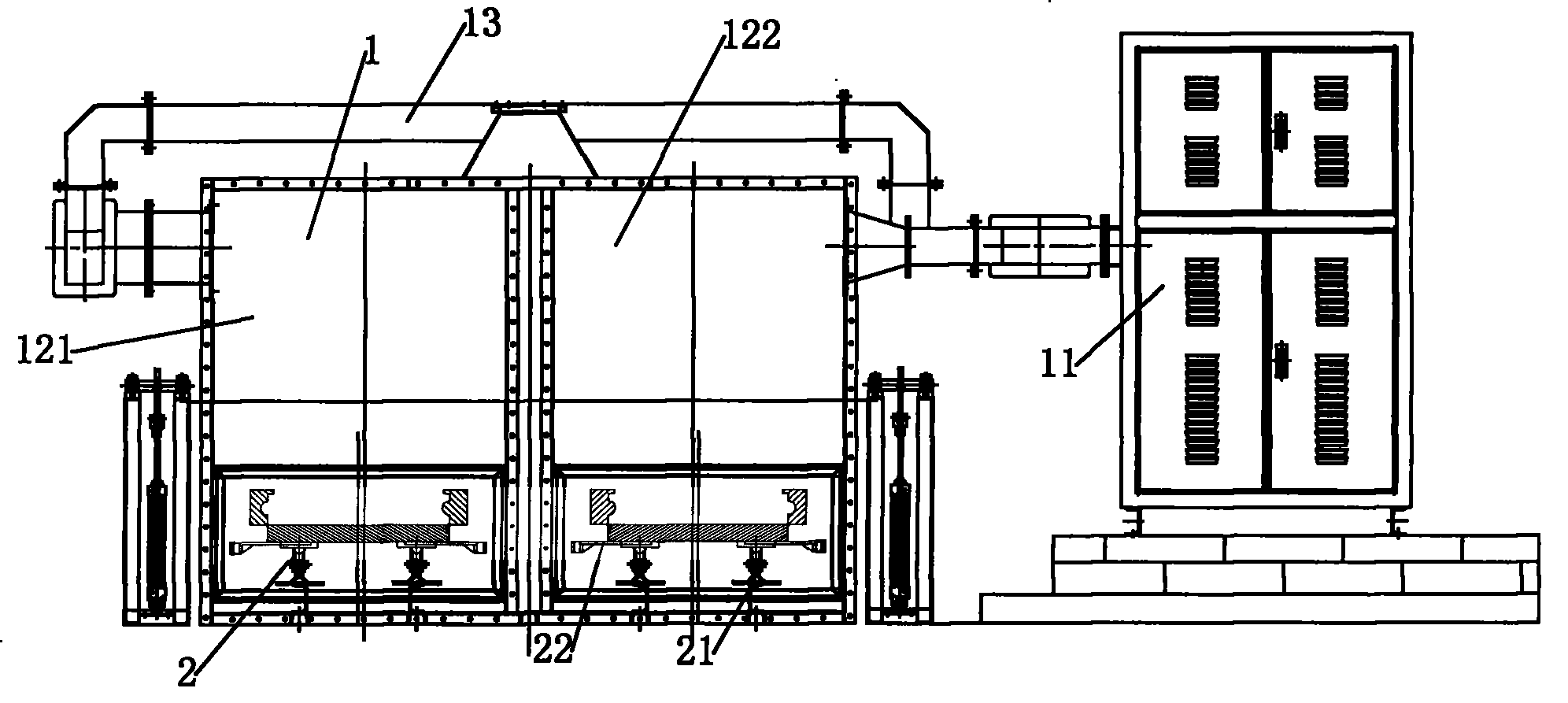

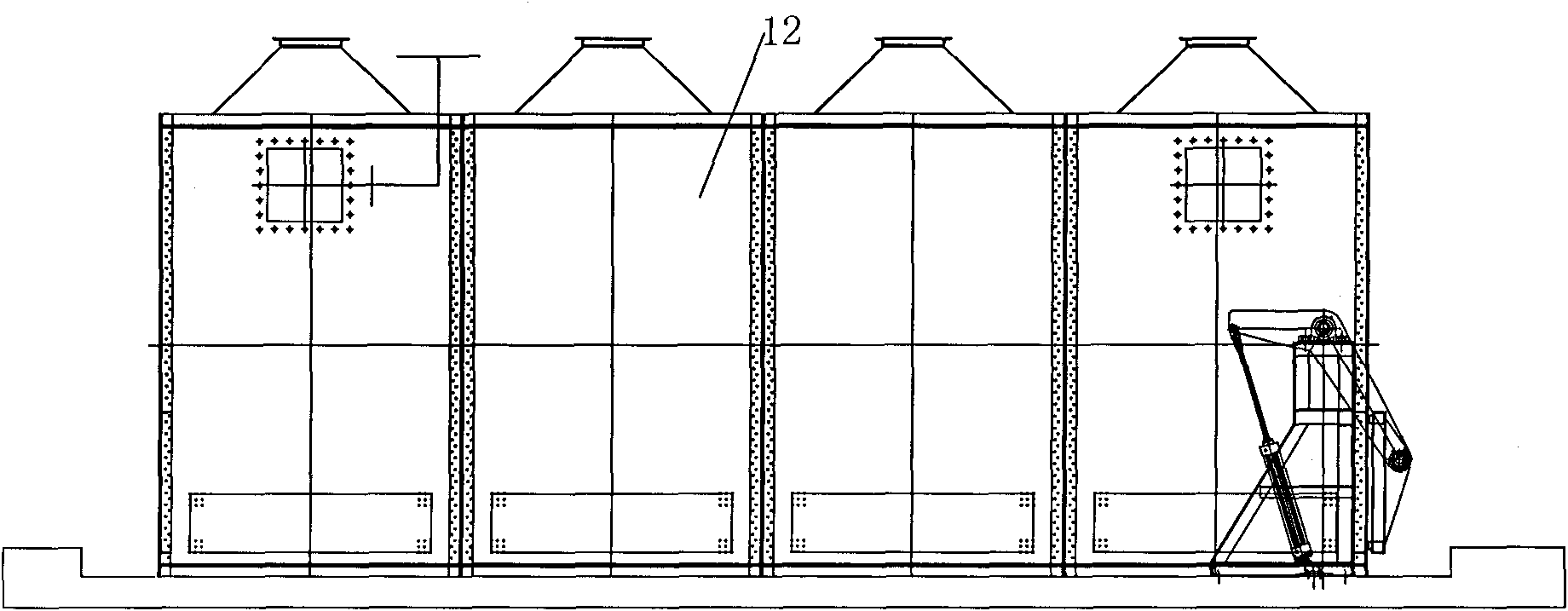

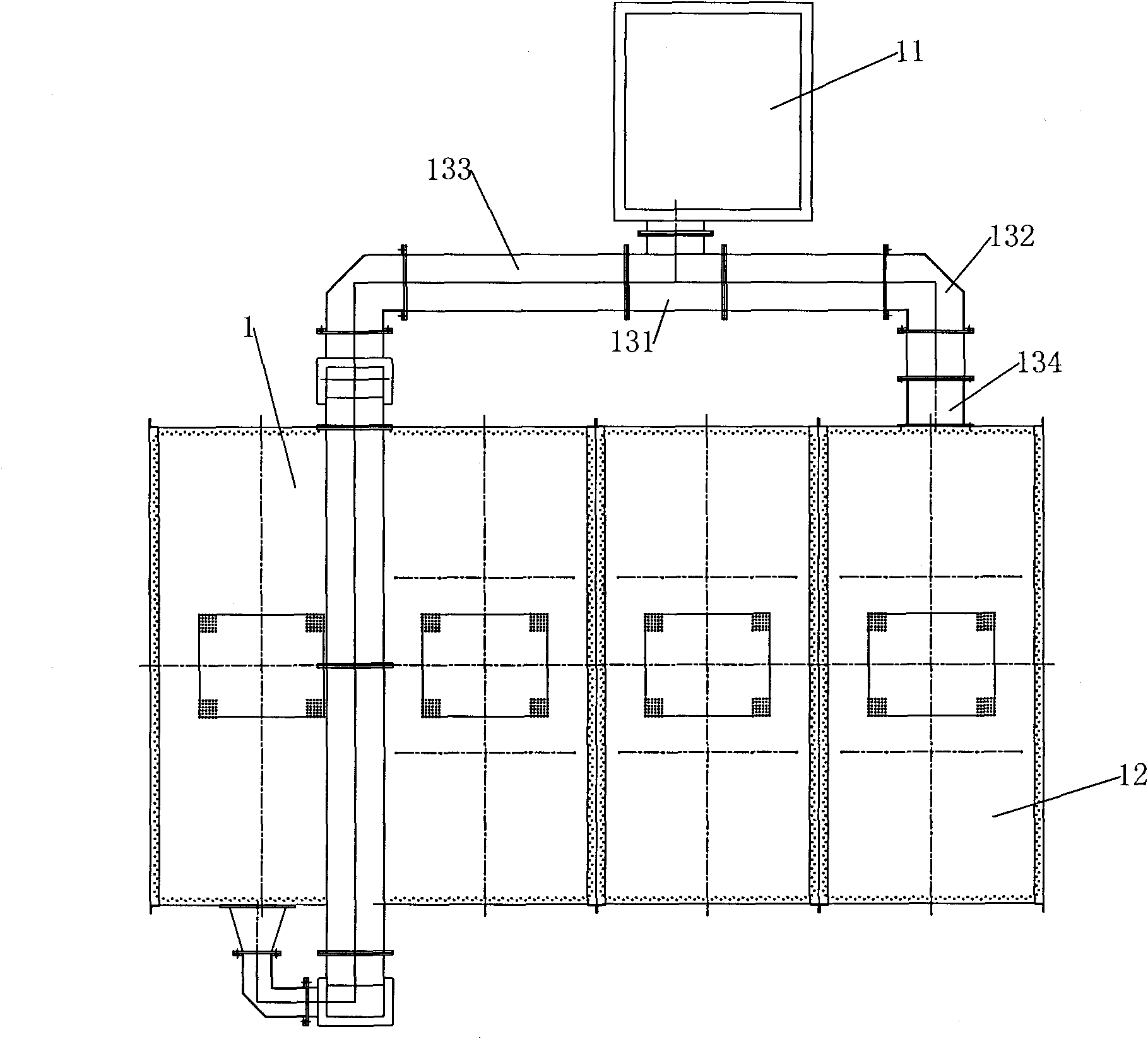

[0016] Referring to Figure 1-3, the coagulation accelerator 1 for cement products includes a microwave source 11 and a resonant cavity 12, and the resonant cavity 12 includes a left resonant cavity 121 and a right resonant cavity 122. A waveguide 13 that connects the microwave source with the left resonant cavity and the right resonant cavity respectively. There are many kinds of waveguides 13 , such as T-shaped waveguides 131 , H-plane waveguides 132 , straight waveguides 133 , E-plane waveguides 134 and so on. The pulling device 2 includes rails 21 passing through the left resonant cavity and the right resonant cavity respectively, and a walking trolley 22 arranged on the rails. The transmitting power of the microwave source is 20-40 kilowatts, and the frequency is 4000-6000 MHz.

[0017] The microwave source emits microwaves, enters ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap