Rotary type cylindrical drying device

A cylinder drying and rotary technology, applied in drying, drying machines, progressive drying machines, etc., can solve the problems of affecting the quality of textiles, reducing drying efficiency, textiles being damp and hardened, etc., and achieve the effect of water vapor emission Good, avoid impurity clogging, facilitate the effect of water vapor distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

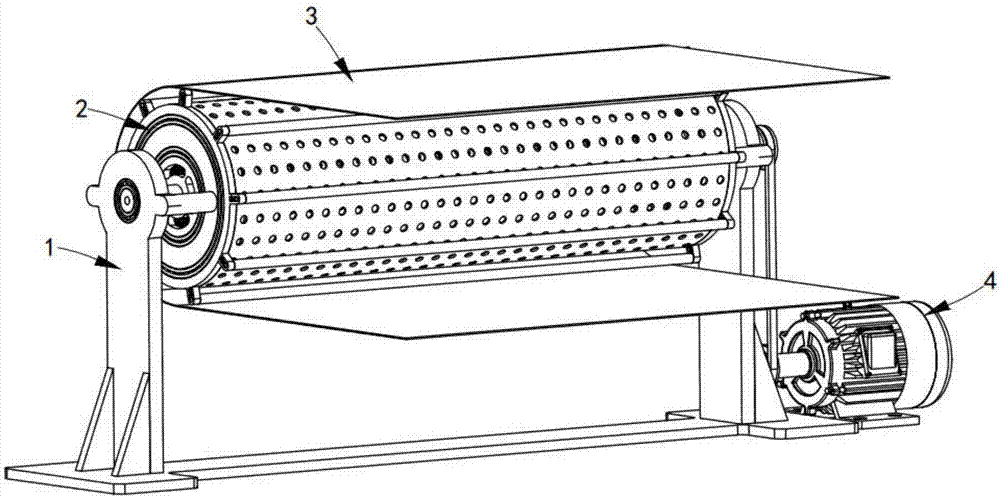

[0052] Such as figure 1 and figure 2 As shown, a rotary drum drying device, including a frame 1, also includes:

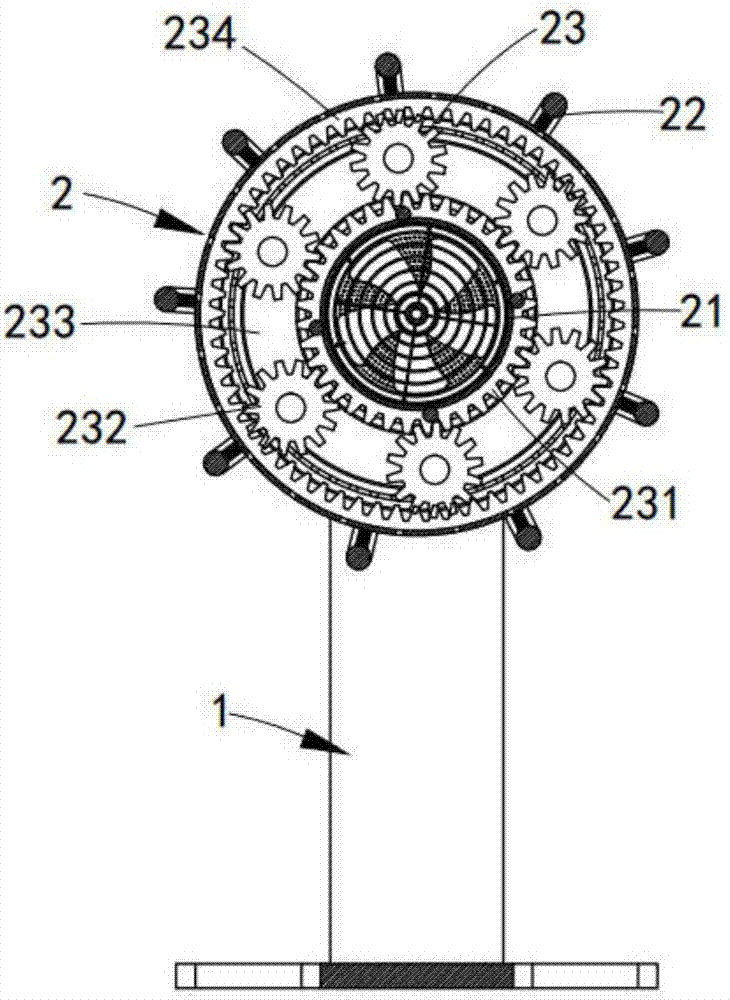

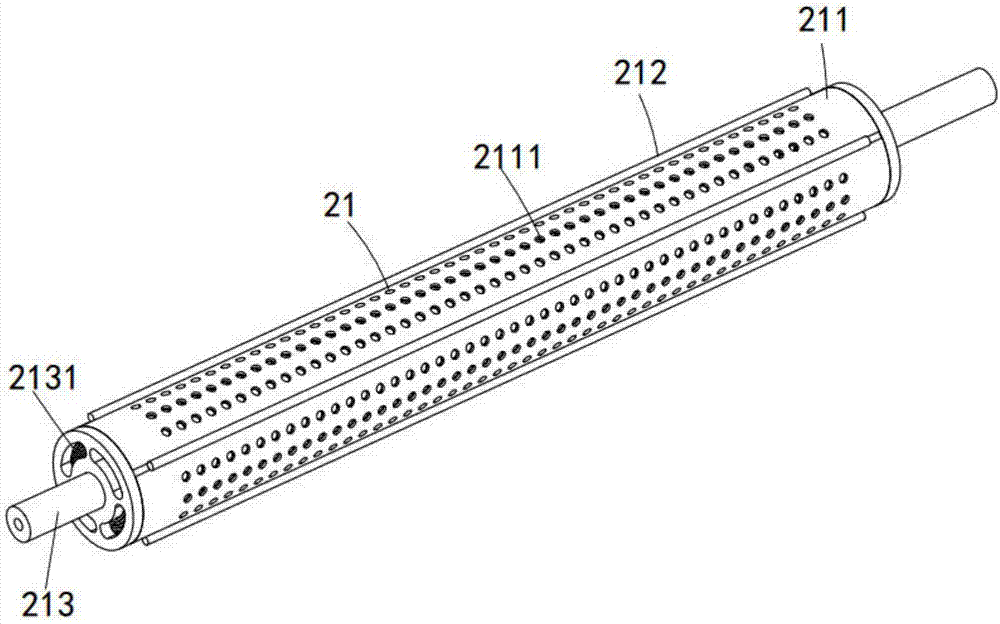

[0053] Drying mechanism 2, the drying mechanism 2 is a cylindrical arrangement, its two ends are rotatably arranged on the frame 1, the cloth 3 is arranged around the drying mechanism 2, and the drying mechanism 2 includes an inner cylinder assembly 21. The outer cylinder assembly 22 and the gear assembly 23 connecting the inner cylinder assembly 21 and the outer cylinder assembly 22;

[0054]A driving mechanism 4, the driving mechanism 4 is arranged on one side of the frame 1, and drives the drying mechanism 2 to rotate through a belt drive.

[0055] It should be noted that the driving mechanism 4 drives the cylindrical drying mechanism 2 to rotate. During the rotation, the inner cylinder assembly 21 rotates clockwise, and the outer cylinder assembly 22 rotates counterclockwise. The inner cylinder assembly 21 generates hot air. The cloth 3 is dried, and the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com