Watertight seal lighting equipment

A lighting device, waterproof sealing technology, applied in the direction of lighting devices, fixed lighting devices, lighting auxiliary devices, etc., can solve the problems of damage to the sealing degree of equipment, difficulty in cleaning the maintenance of lighting devices, deposition of dirt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

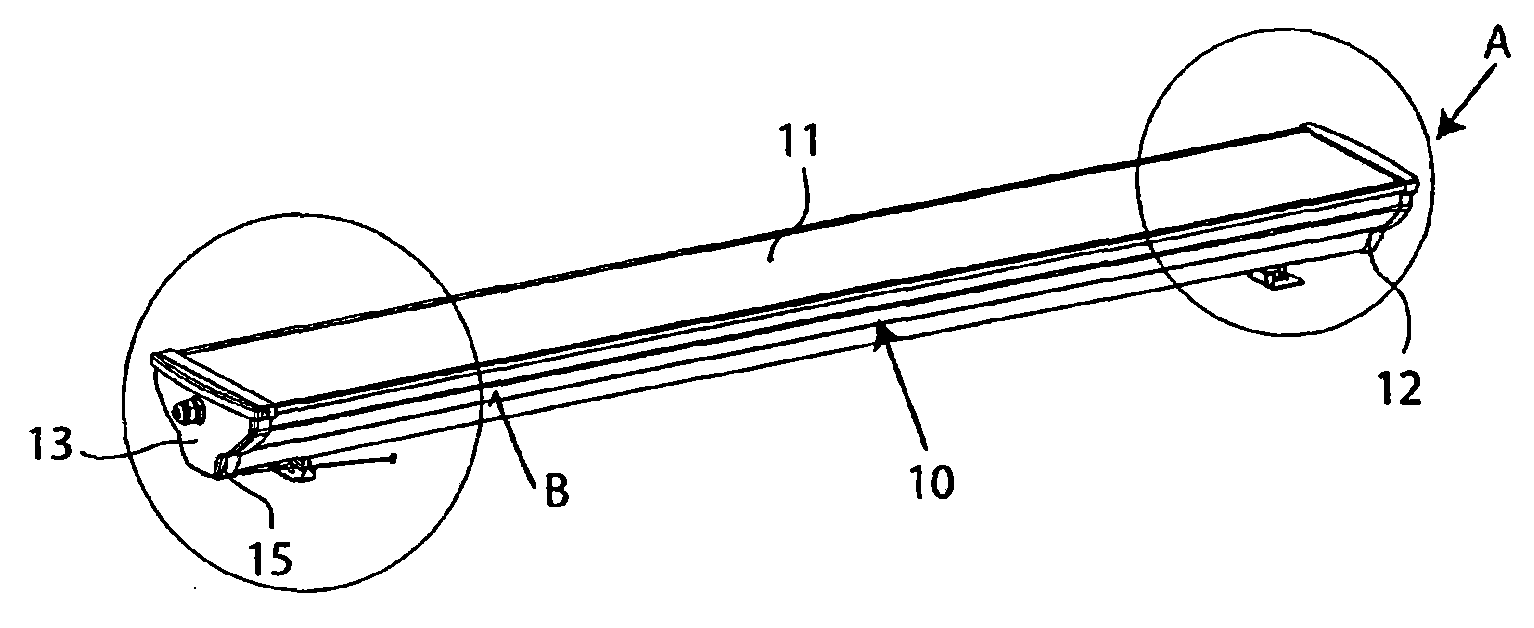

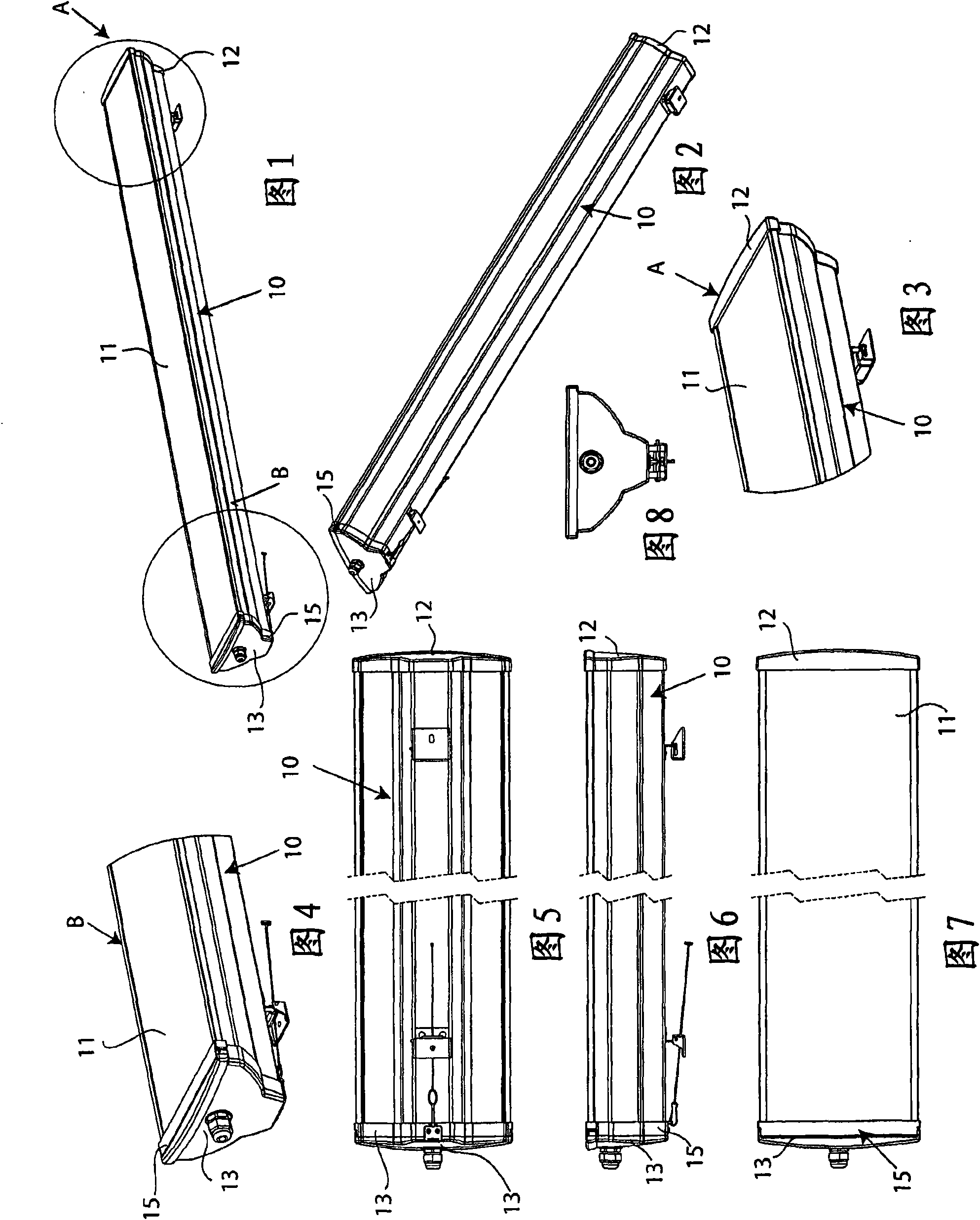

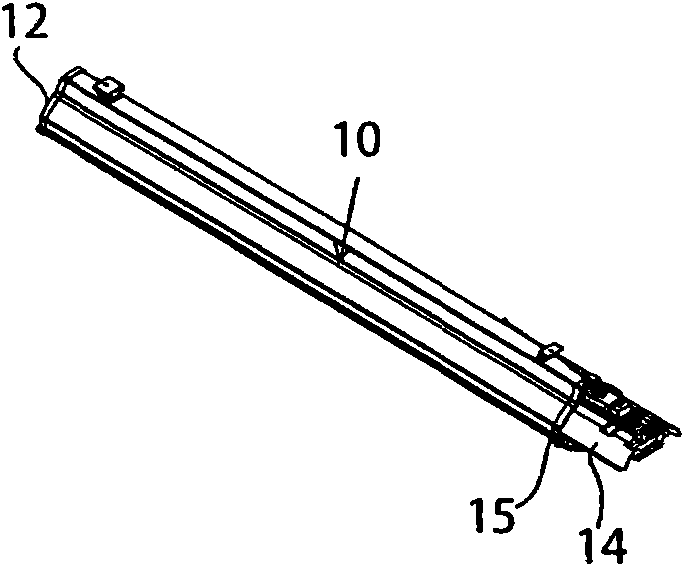

[0038] Referring to the accompanying drawings, the waterproof and sealed lighting device as the object of the present invention includes: a main body 10, which is made of a thin slab formed in one piece, and coated with epoxy polyester powder; a top closing partition 11, which is made of tempered The glass plate is composed of; the first closed head 12, which is formed by die-casting aluminum and seals the main body 10 and the partition 11; the second movable head 13, which is formed by die-casting aluminum and which can be opened relative to the main body 10 (as shown in Figures 9, 17, 18 and 21).

[0039] In the main body 10, there is also a withdrawable support part 14, on which there are light sources and feeders connected by wires, and a luminous flux recycler or reflector is arranged above, so that the outgoing light has stronger scattering.

[0040] The main body 10 is fitted to the tempered glass closing partition 11 by means of mechanical crimping, and has a silicone-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com