Compressing device of optical inspection instrument

A technology of optical detector and pressing device, which is applied in measuring devices, optical testing flaws/defects, scientific instruments, etc. It can solve problems such as low detection accuracy and easy shaking of various components of PCB boards, and achieve the effect of improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

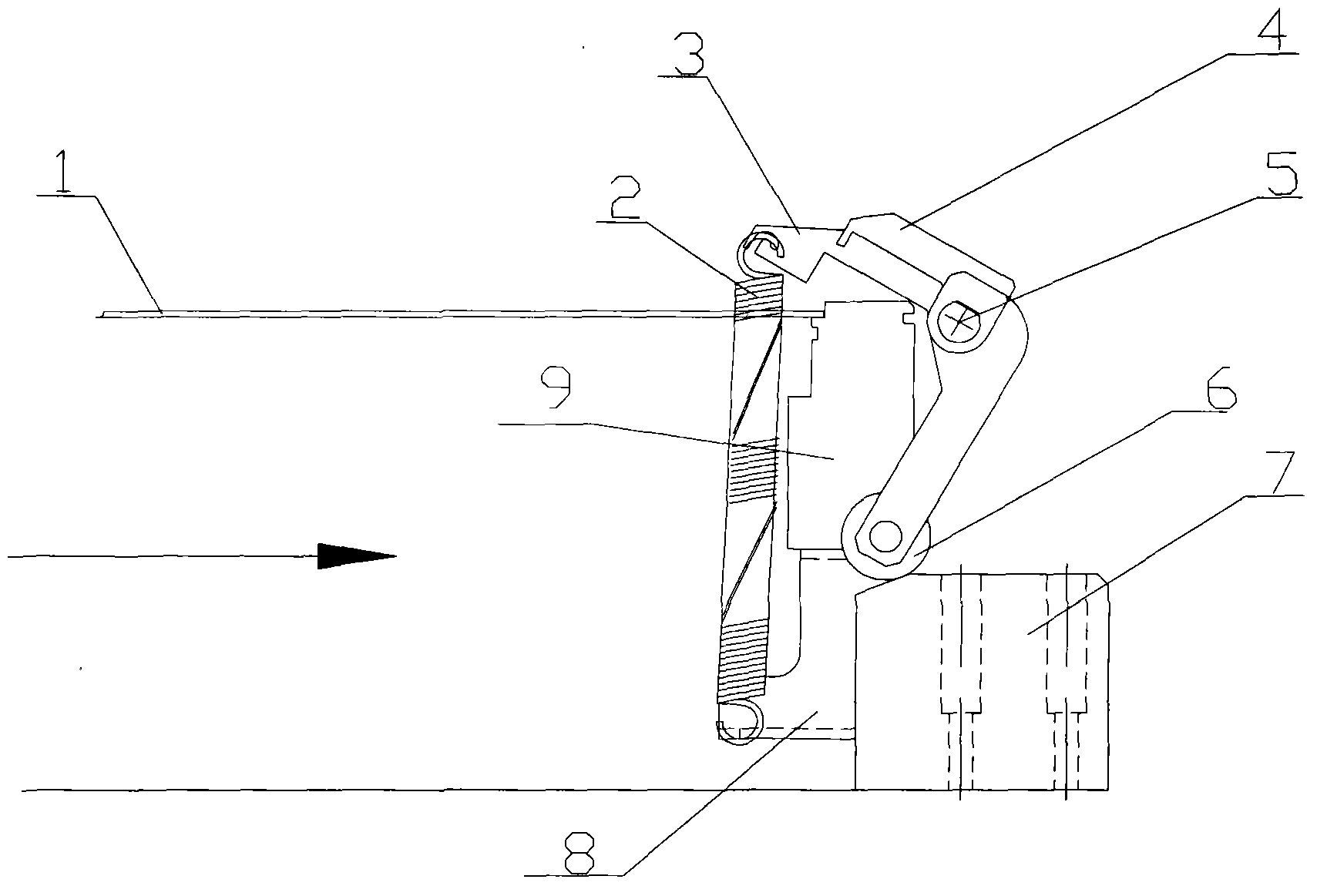

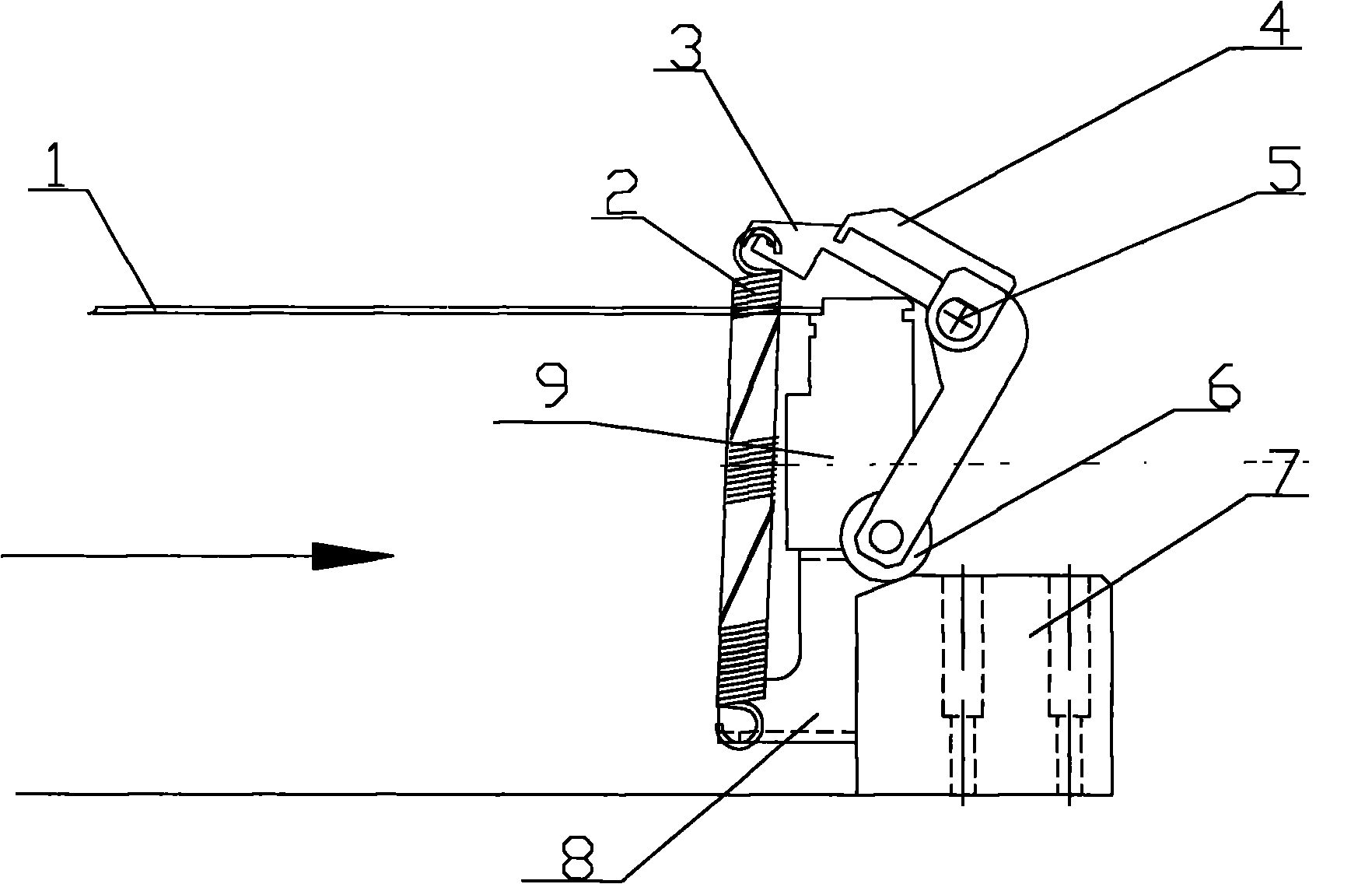

[0013] As shown in FIG. 1 , it is a structural schematic view of the pressing device of the optical detector of the present invention when pressing the PCB board.

[0014] In the figure, one side of the PCB board 1 is fixed by the claws 4 of the pressure plate, and the claws 4 of the pressure plate are rigidly and fixedly connected with an "L"-shaped bar 3, and the "L"-shaped bar 3 is rotatably connected to the fixture through the rotating shaft 5 at its turning point. On platform 9, rolling bearing 6 is fixed on the bottom end of "L" shaped bar 3, and there is fixed seat 7 on the horizontal tabletop in front of rolling bearing 6, and extension spring 2 is connected with one end of "L" shaped bar 3 without rolling bearing 6 and is located in the fixture. Extension spring fixed plate 8 on the platform 9.

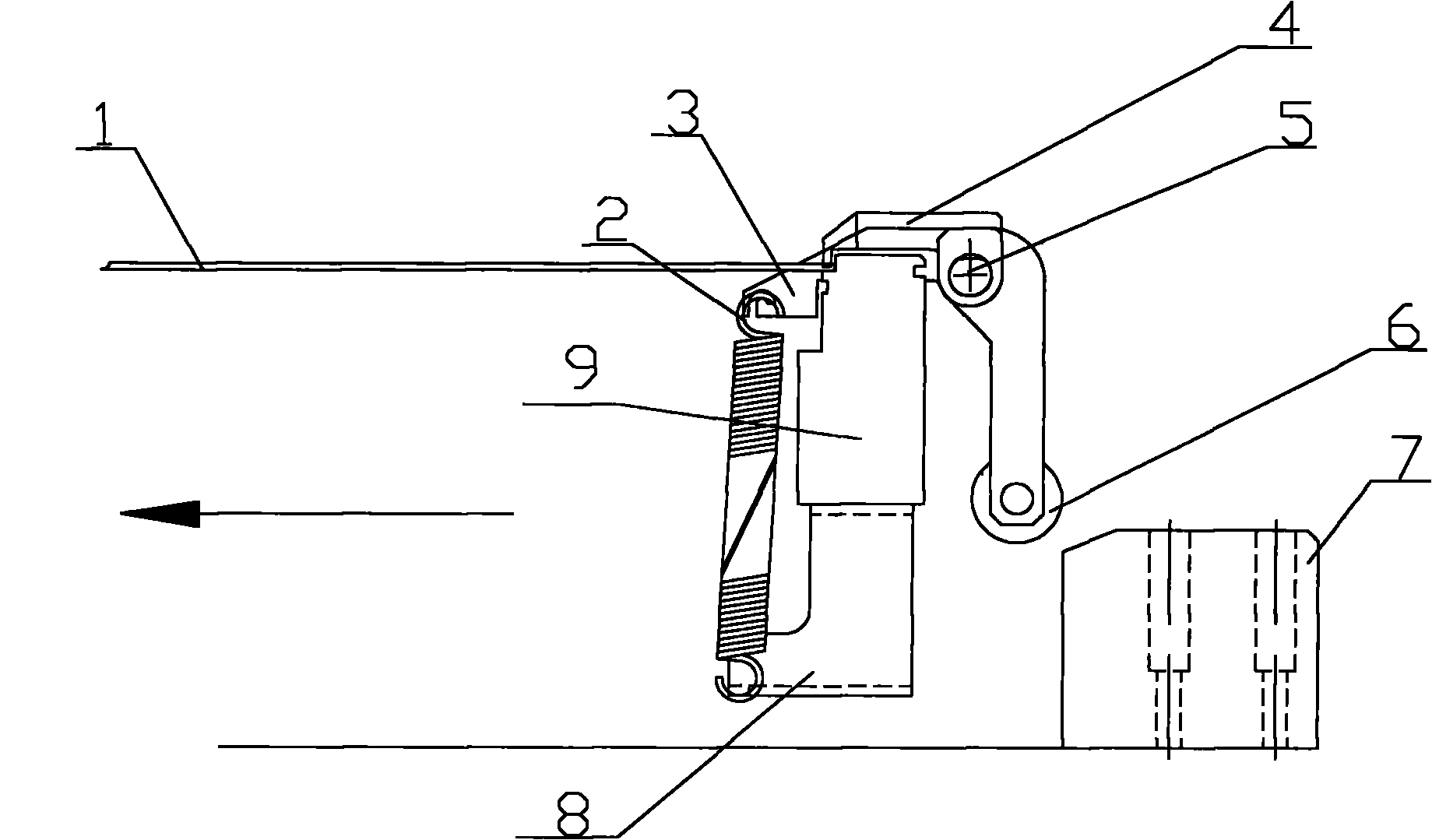

[0015] As shown in FIG. 2 , it is a structural schematic view...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com