Hammer type crusher internally provided with feeding fan and rotary screen

A hammer mill and rotary screen technology, used in pharmaceutical, feed, chemical, and food fields, can solve the problems of increasing the total installed capacity, increasing energy consumption, and high manufacturing costs, and improving the probability of shearing and hammering , reduce noise and dust pollution, avoid the effect of idling energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

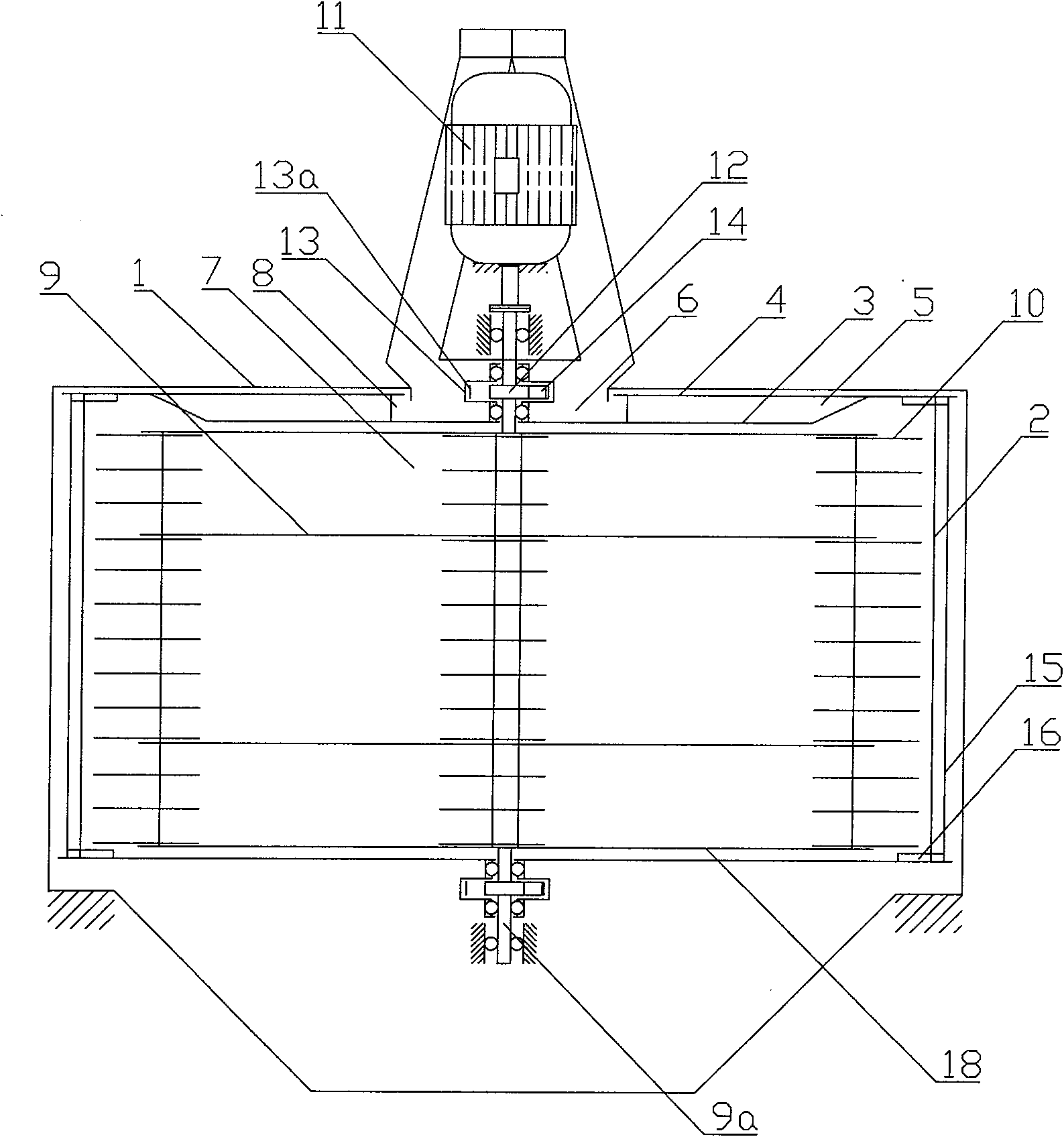

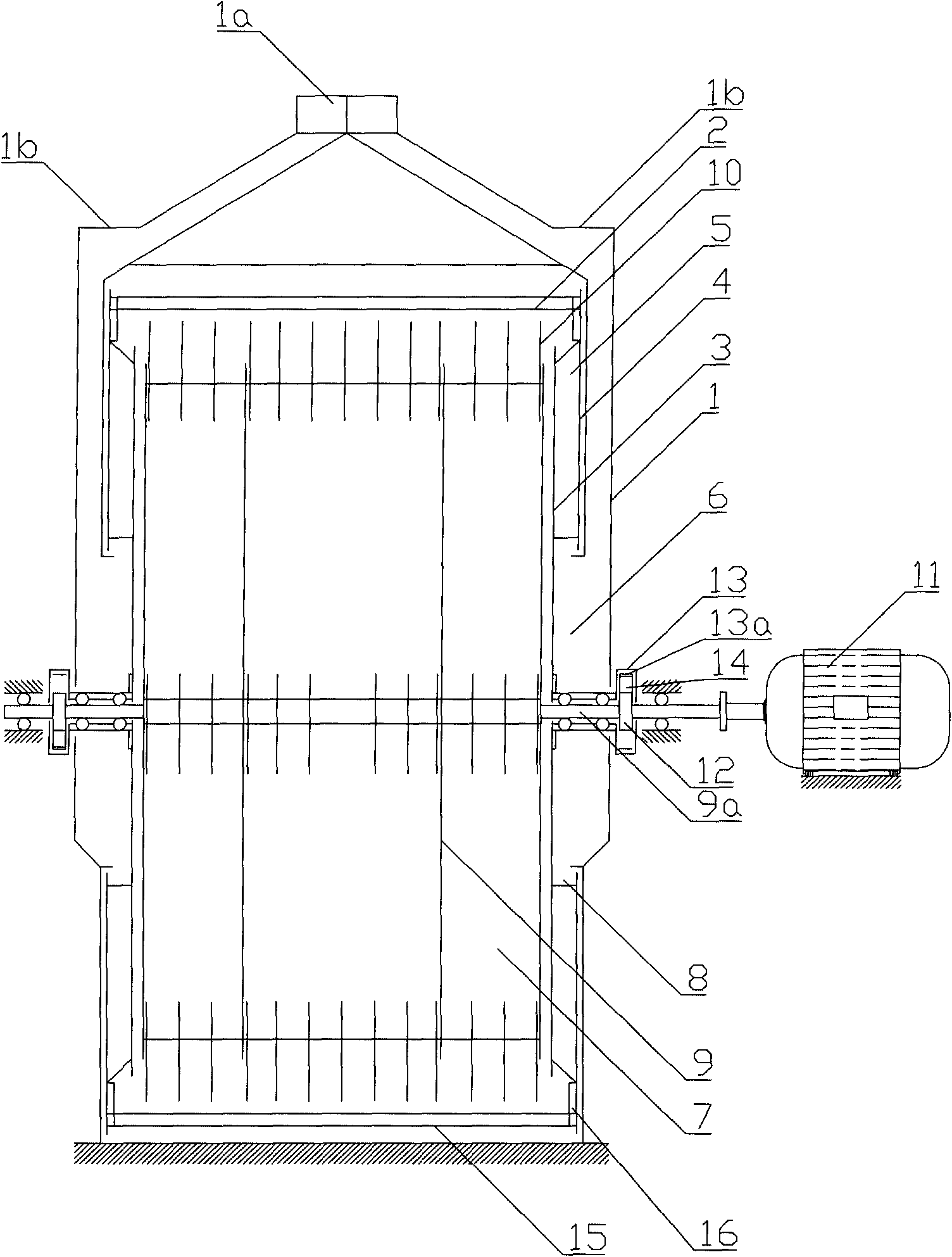

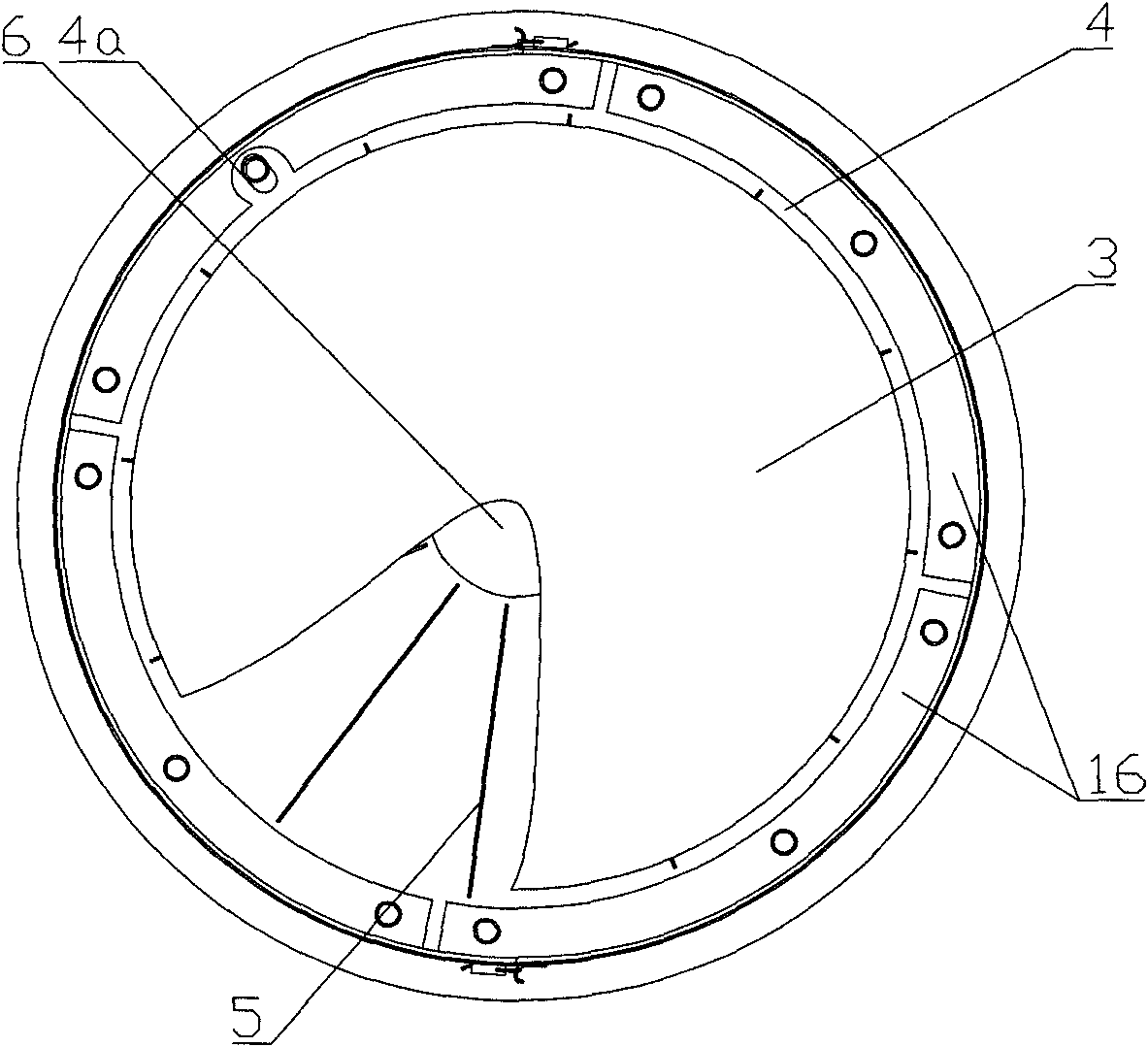

[0033] figure 1 It is a structural schematic diagram of the horizontal built-in feeding fan rotary screen hammer mill of the present invention, figure 2 It is a schematic structural diagram of a vertical built-in feeding fan rotary screen hammer mill, image 3 is the front view of the rotary screen assembly, Figure 4 It is a schematic diagram of the structure of the rotary screen assembly, as shown in the figure: the hammer mill with built-in feeding fan and rotary screen in this embodiment includes a casing 1, a driving device, and a rotary screen assembly arranged in the casing 1 and rotor assembly; the rotary sieve assembly includes a fan and a cylindrical filter screen 2, the fan includes a circular inner plate 3 and a circular outer plate 4 arranged parallel to each other, and the inner plate 3 can be wound around itself The way of axis rotation is matched with the rotation of the shell 1. The inner plate 3 and the outer plate 4 are fixedly connected by the blades 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com