Right/left independent action column type vulcanization machine

An independently operated and equipped technology, applied in the field of vulcanizers, which can solve problems such as large installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

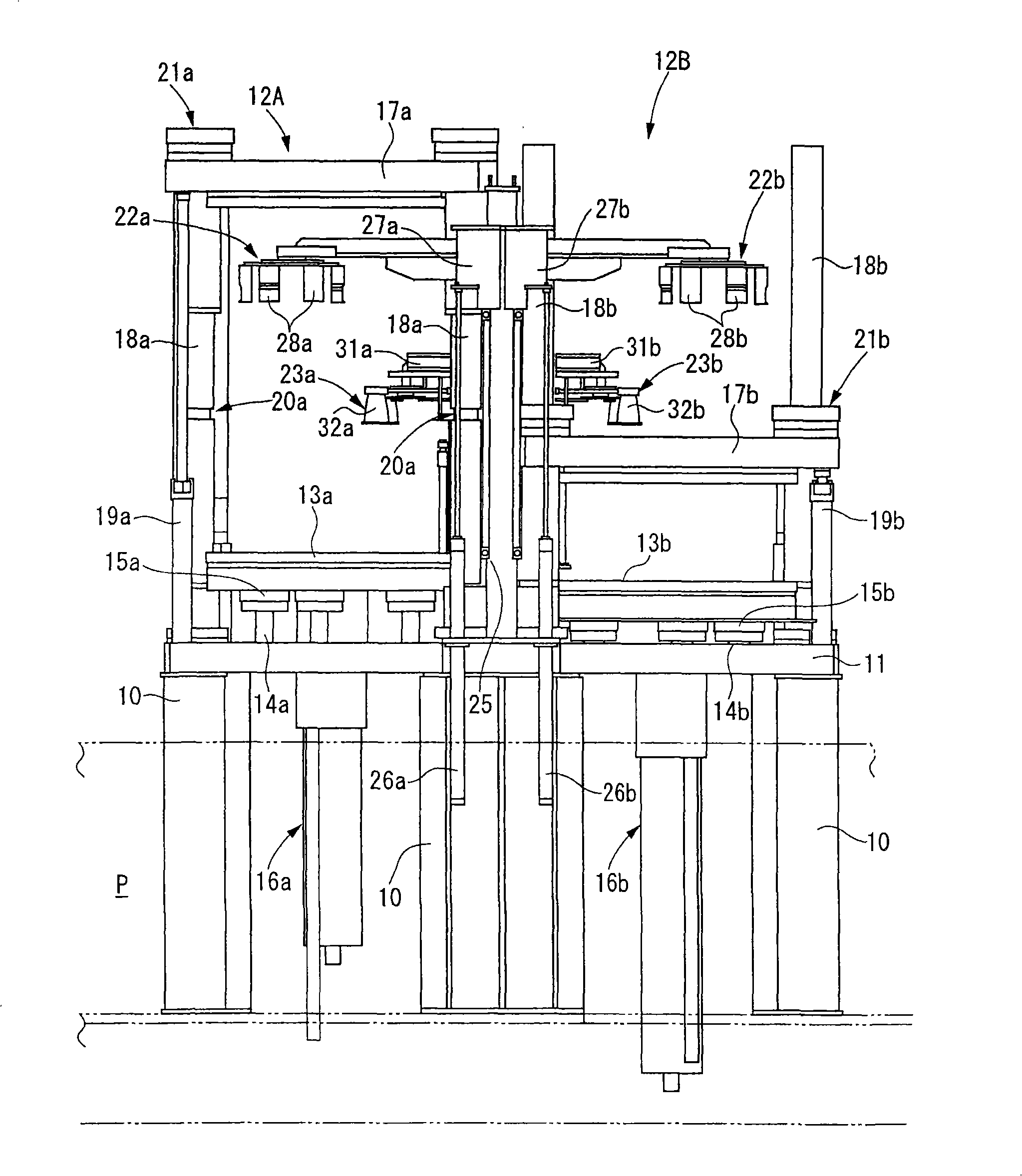

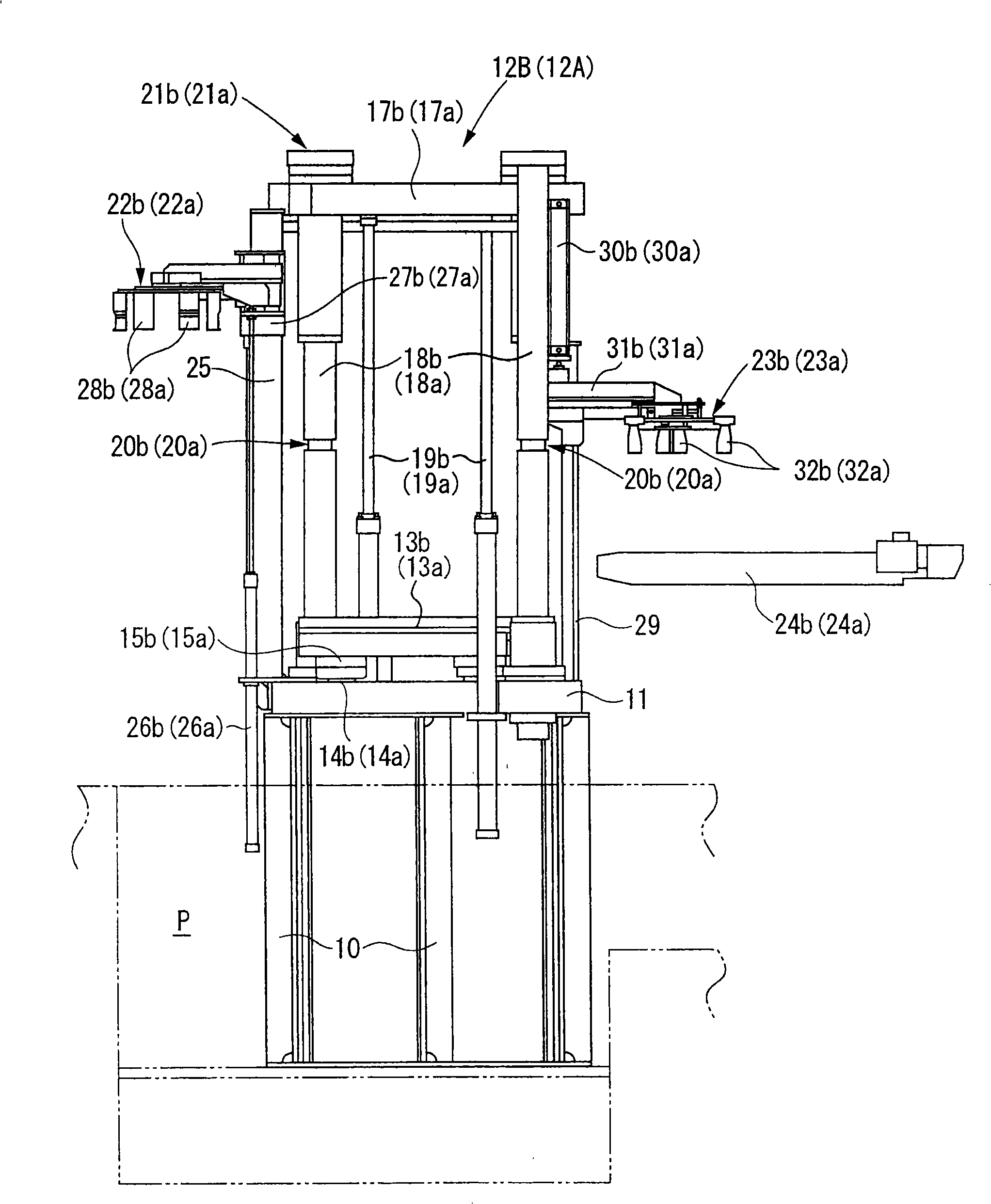

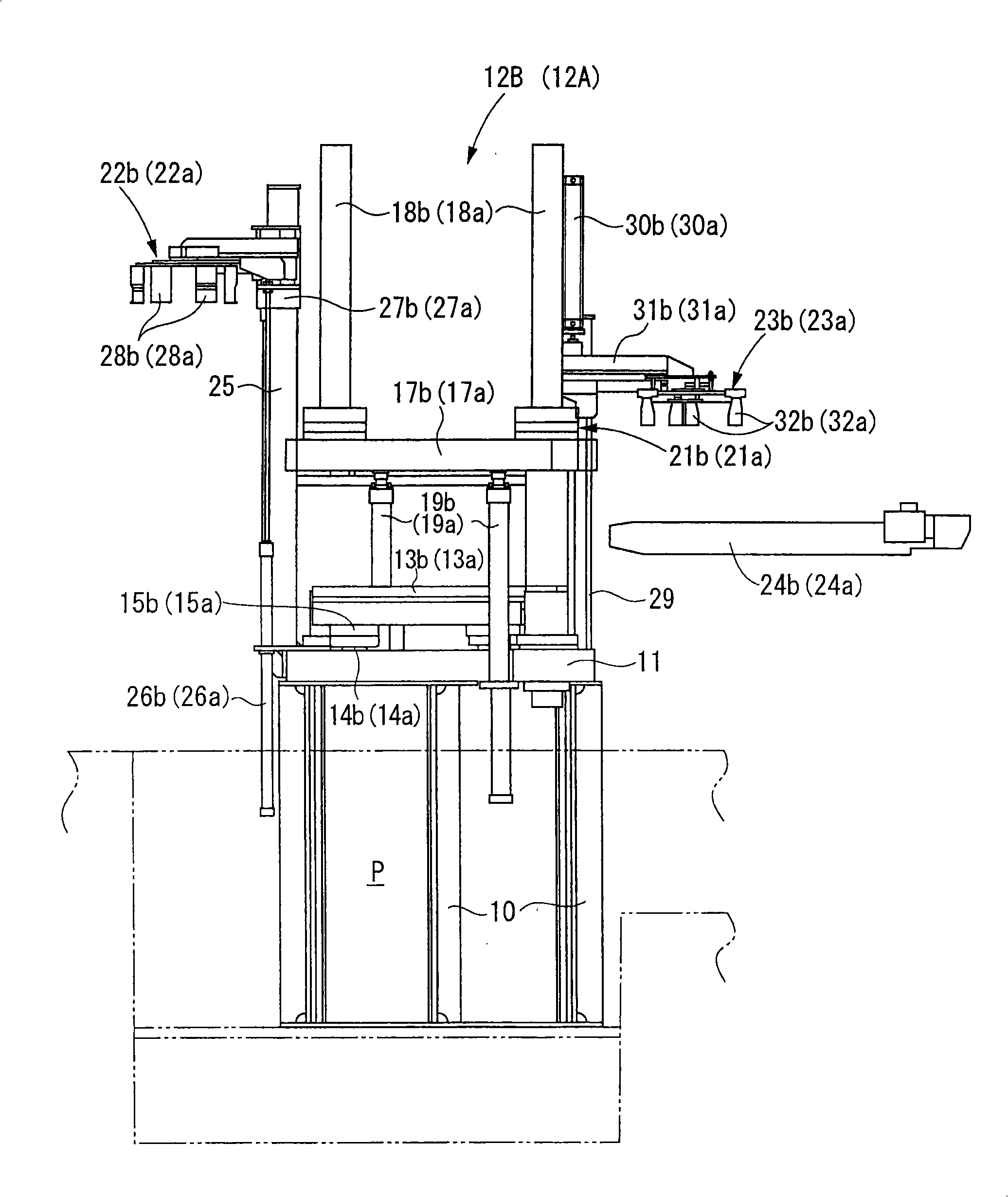

[0052] figure 1 is a front view of a laterally independently operated column equipped curing press showing an embodiment of the present invention. figure 2 is a side view of a laterally independently operated column-equipped press with the upper mold mounting member raised, image 3 is a side view of a laterally independently operated column-equipped press with the upper mold mounting member lowered, Figure 4 It is a plan view of a column-equipped vulcanizing press operated independently laterally.

[0053] As shown in the figure, a base plate 11 is horizontally supported by a plurality of brackets 10 erected in a pit P of a factory, and a left-hand mold opening and closing device 12A and a right-hand mold opening and closing device 12B are mounted on the base plate 11 so as to be operable independently of each other.

[0054] The left-hand mold switch device 12A and the right-hand mold switch device 12B respectively have a lower mold mounting member ( Lower mold supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com