Patents

Literature

90results about How to "Appropriate pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

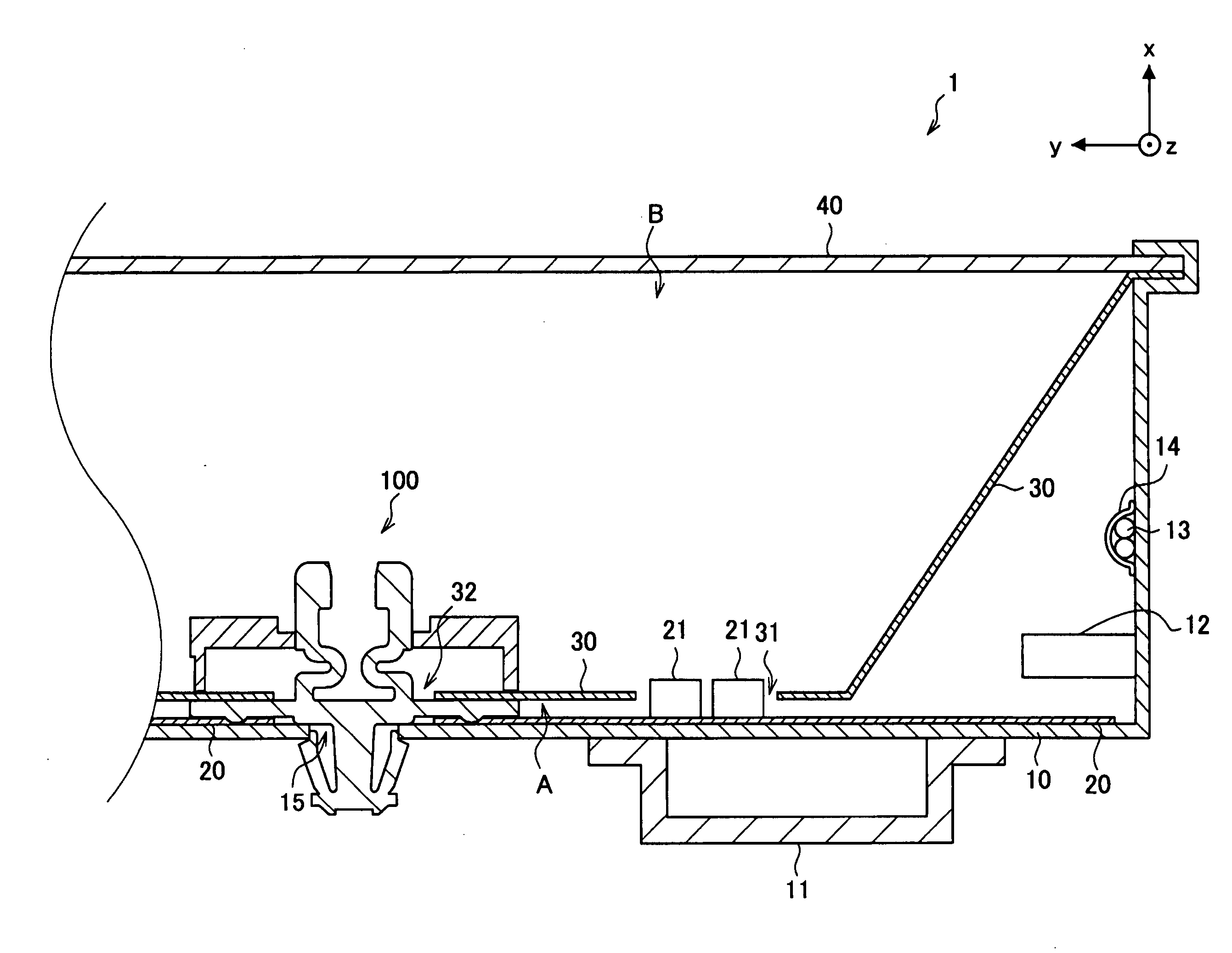

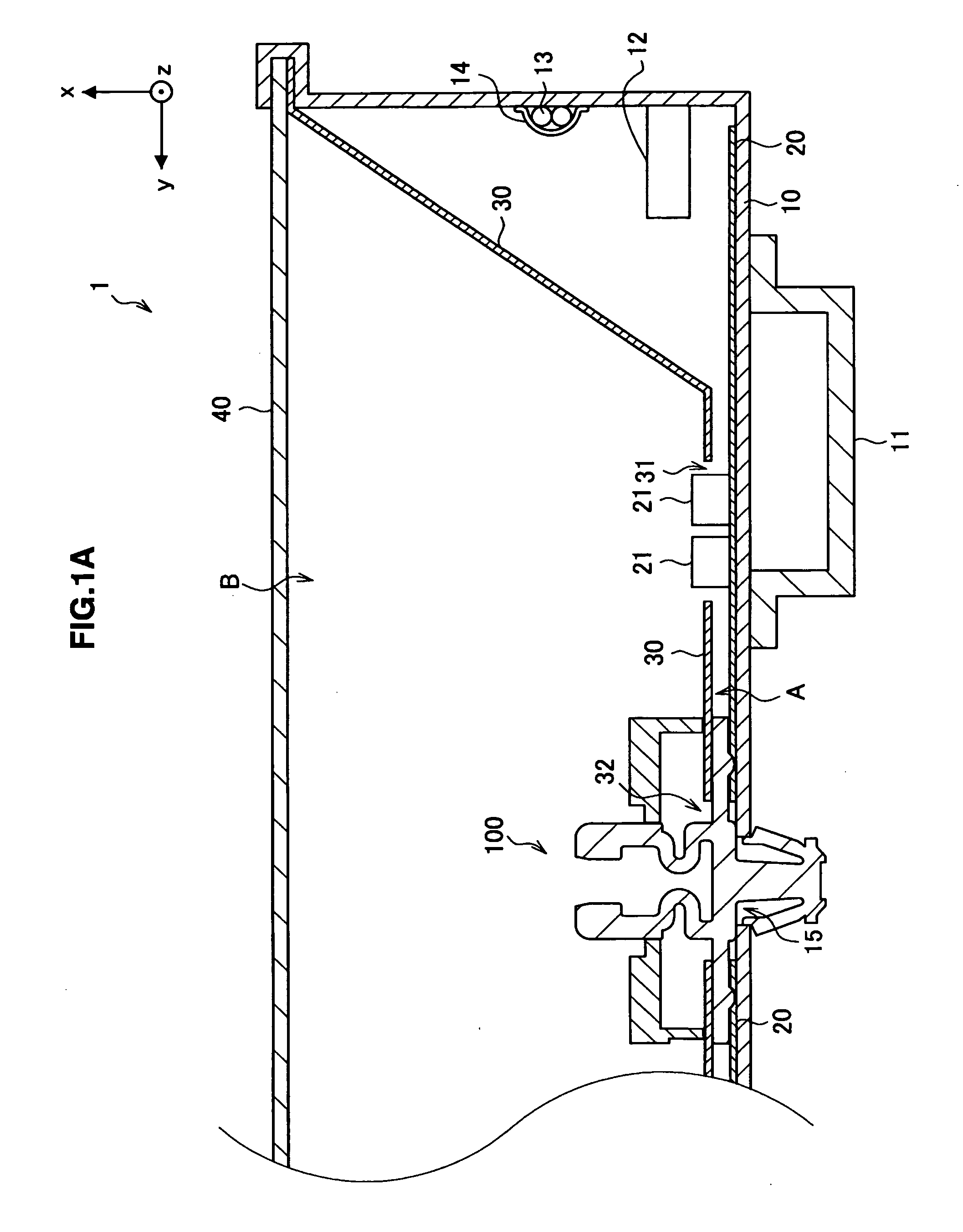

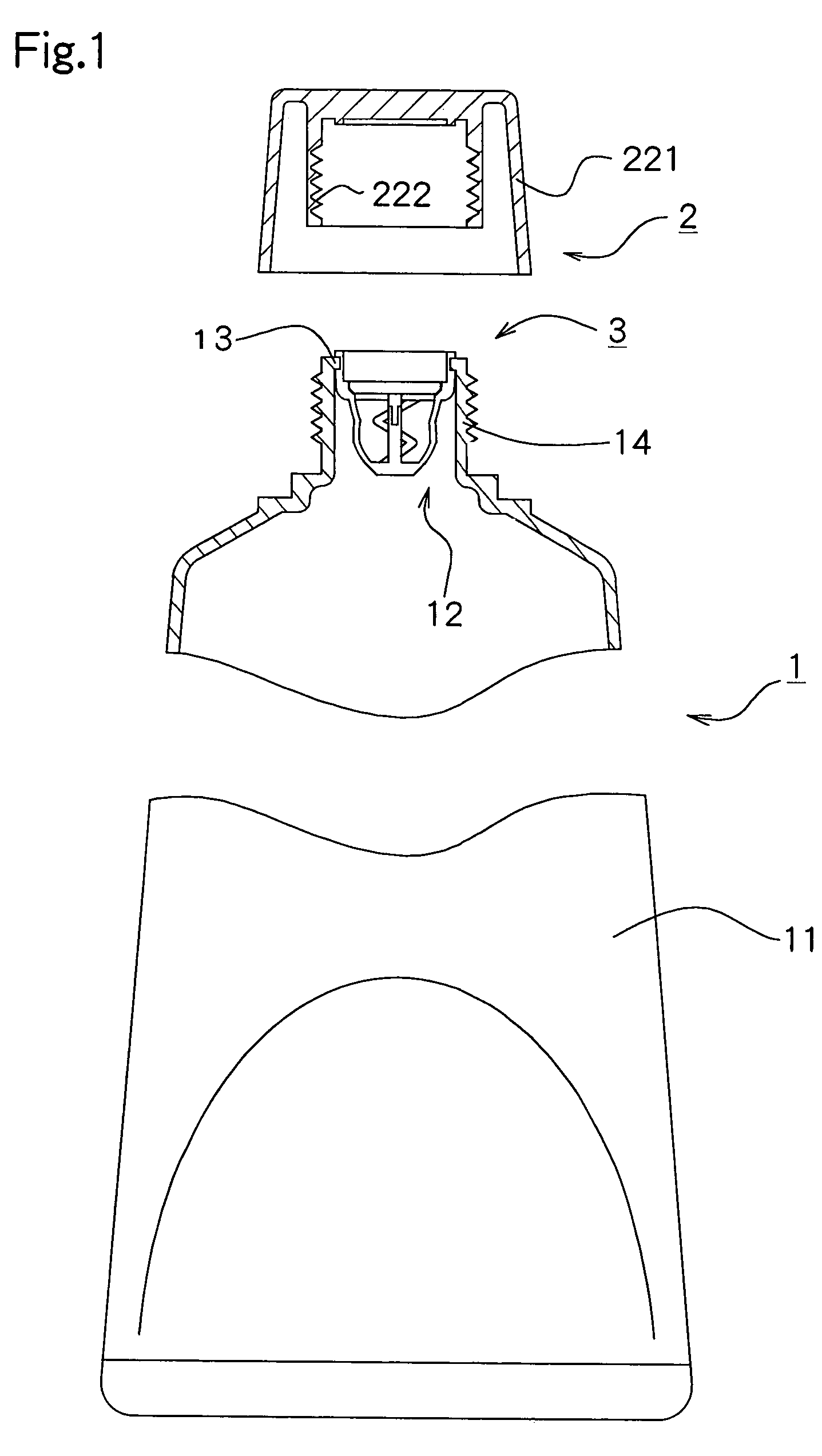

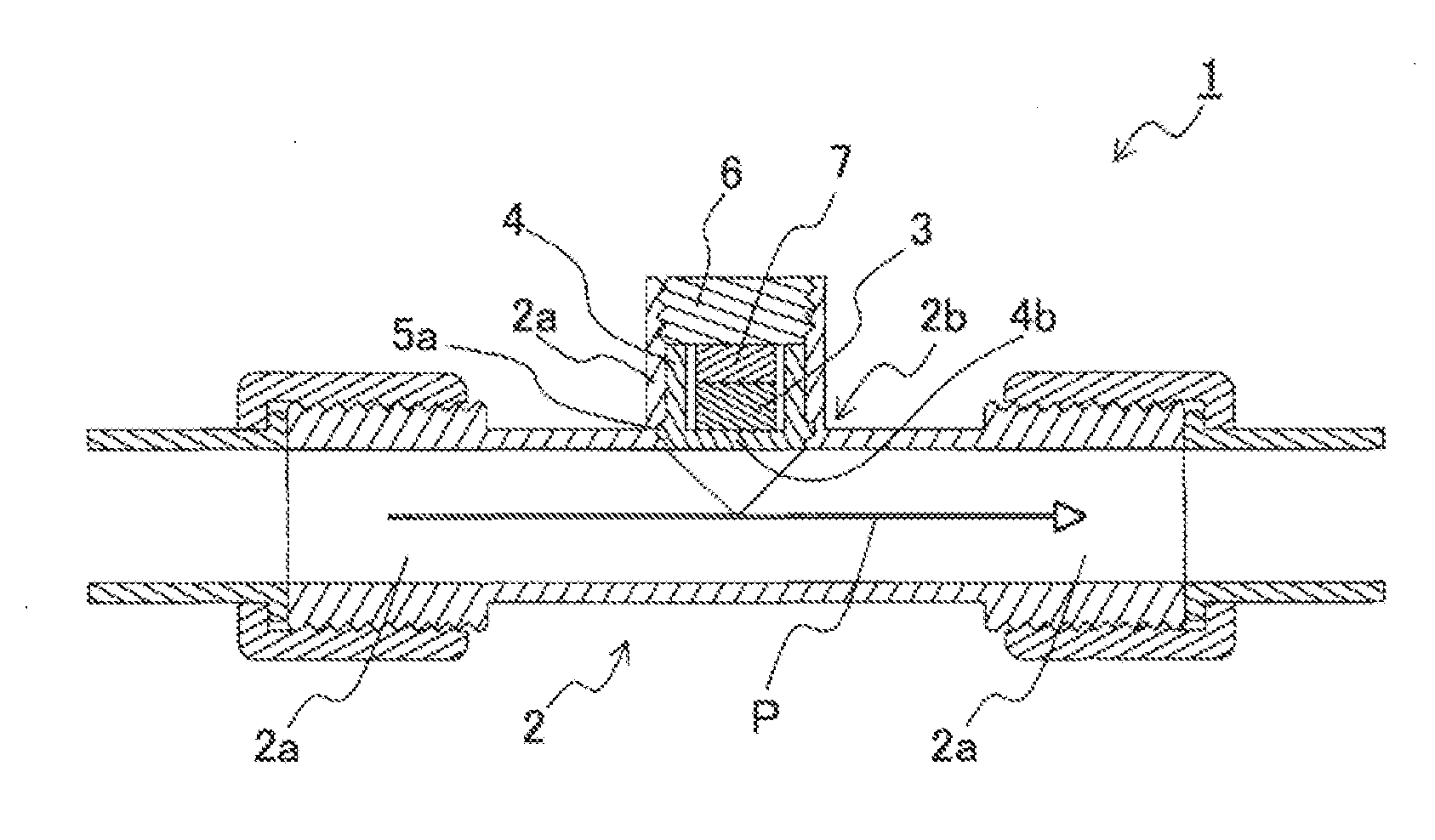

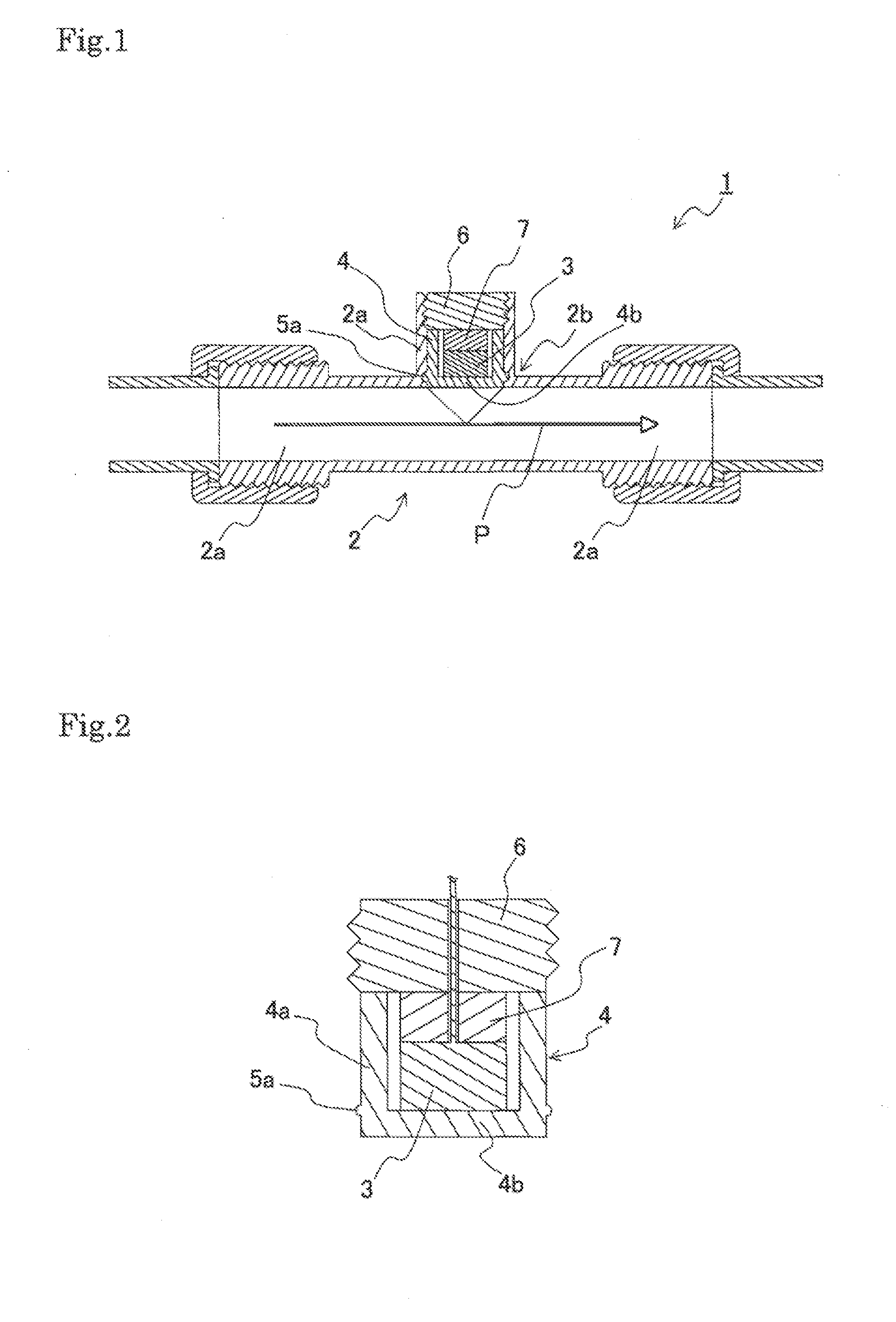

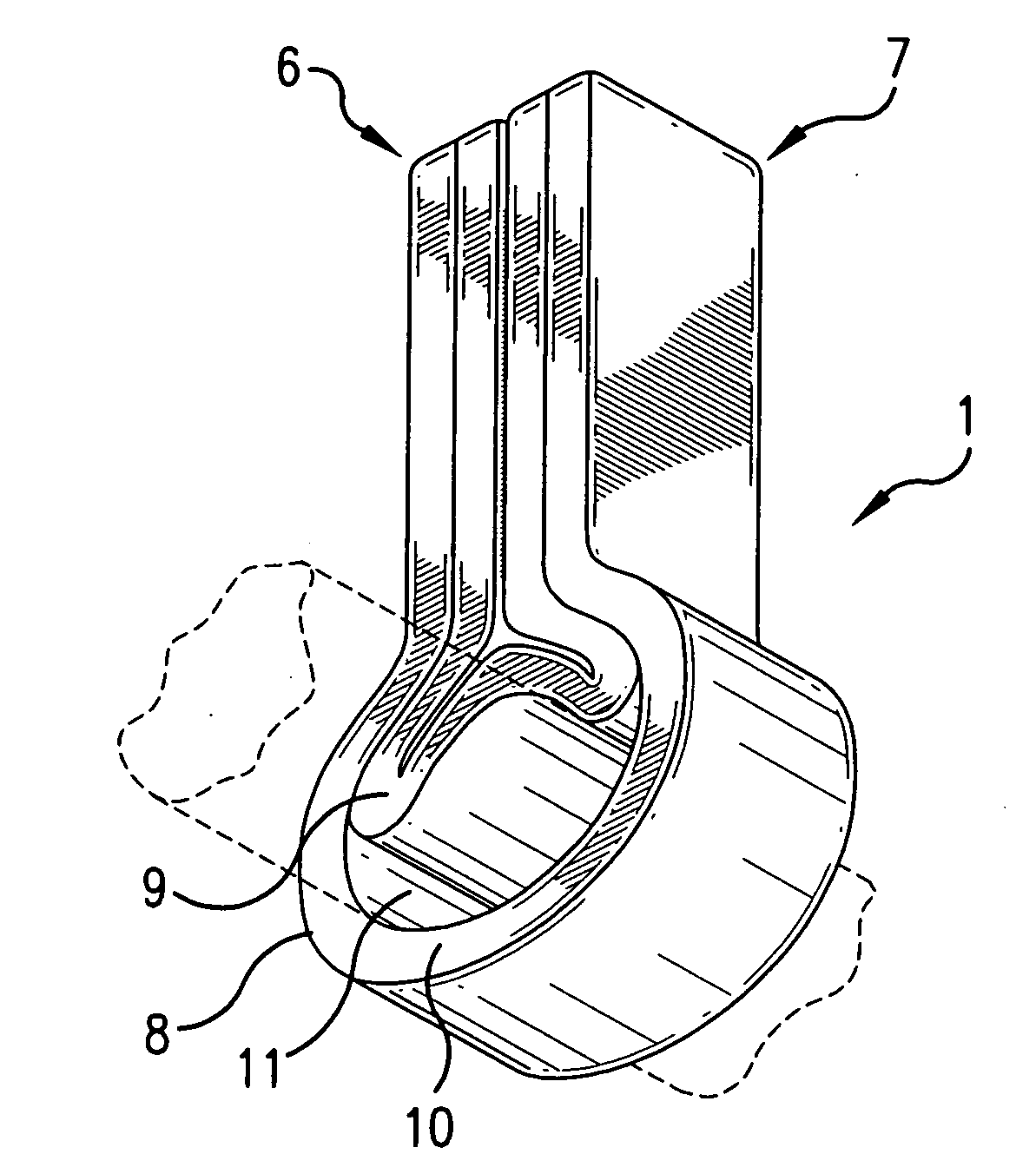

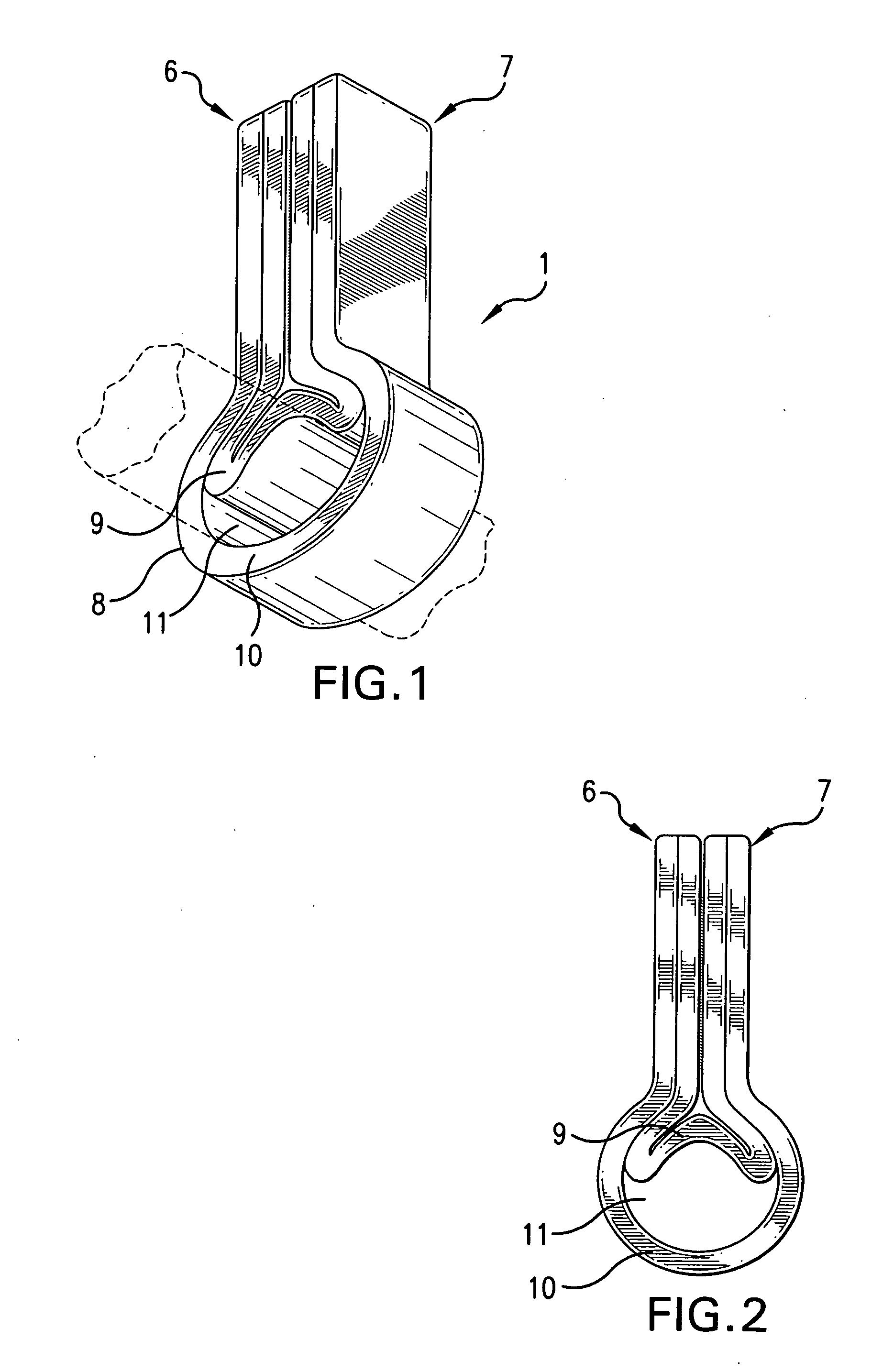

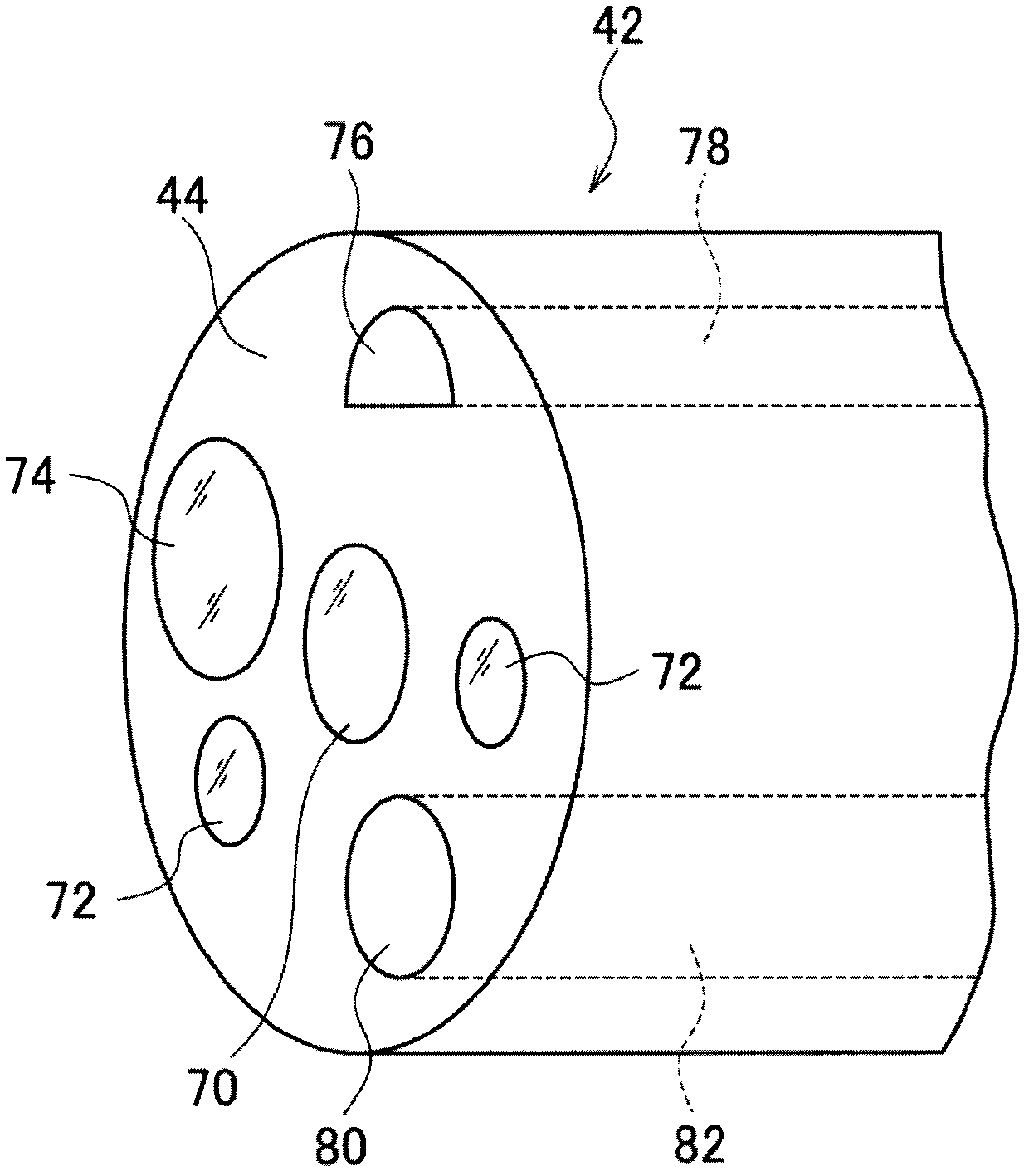

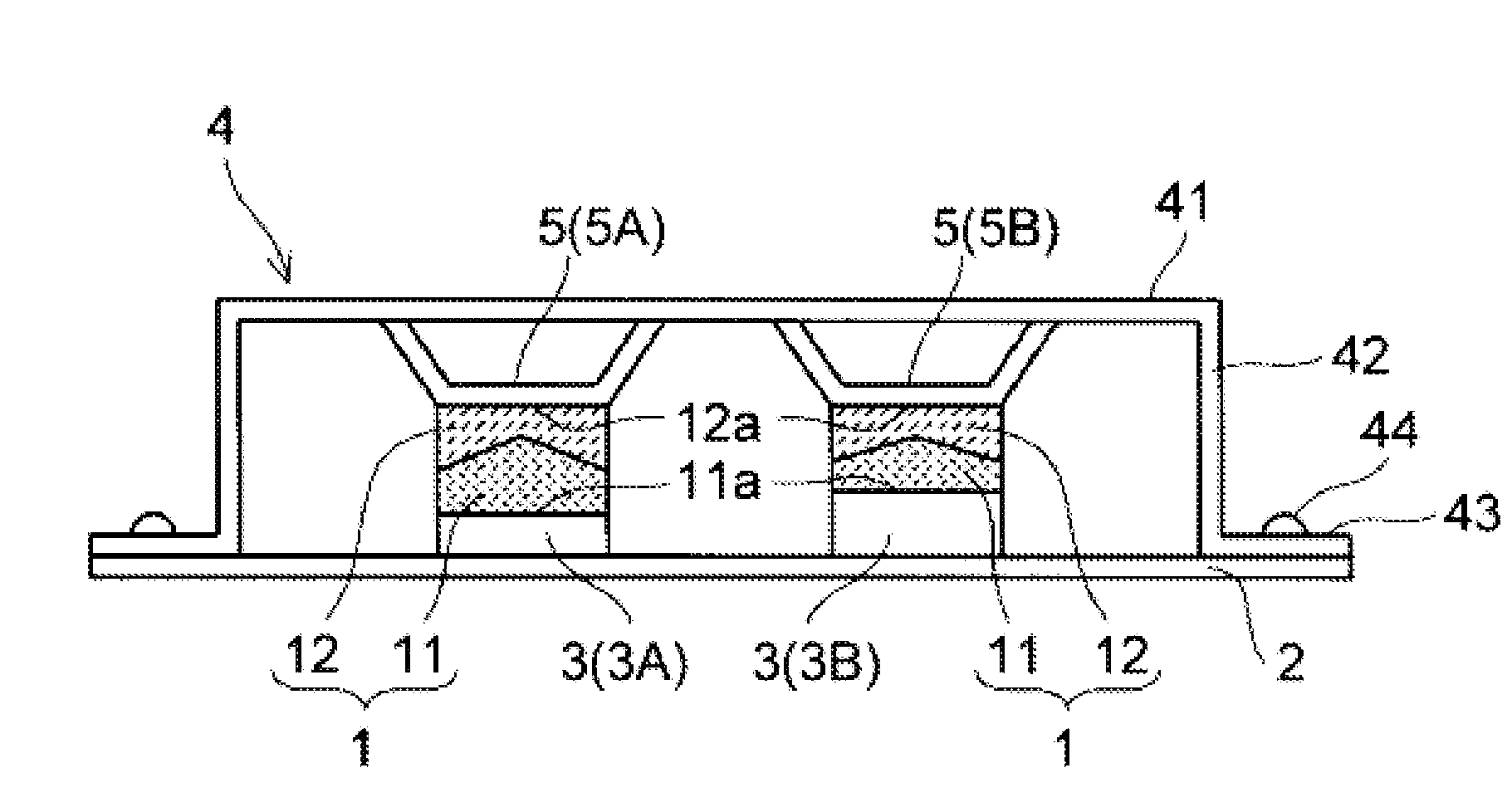

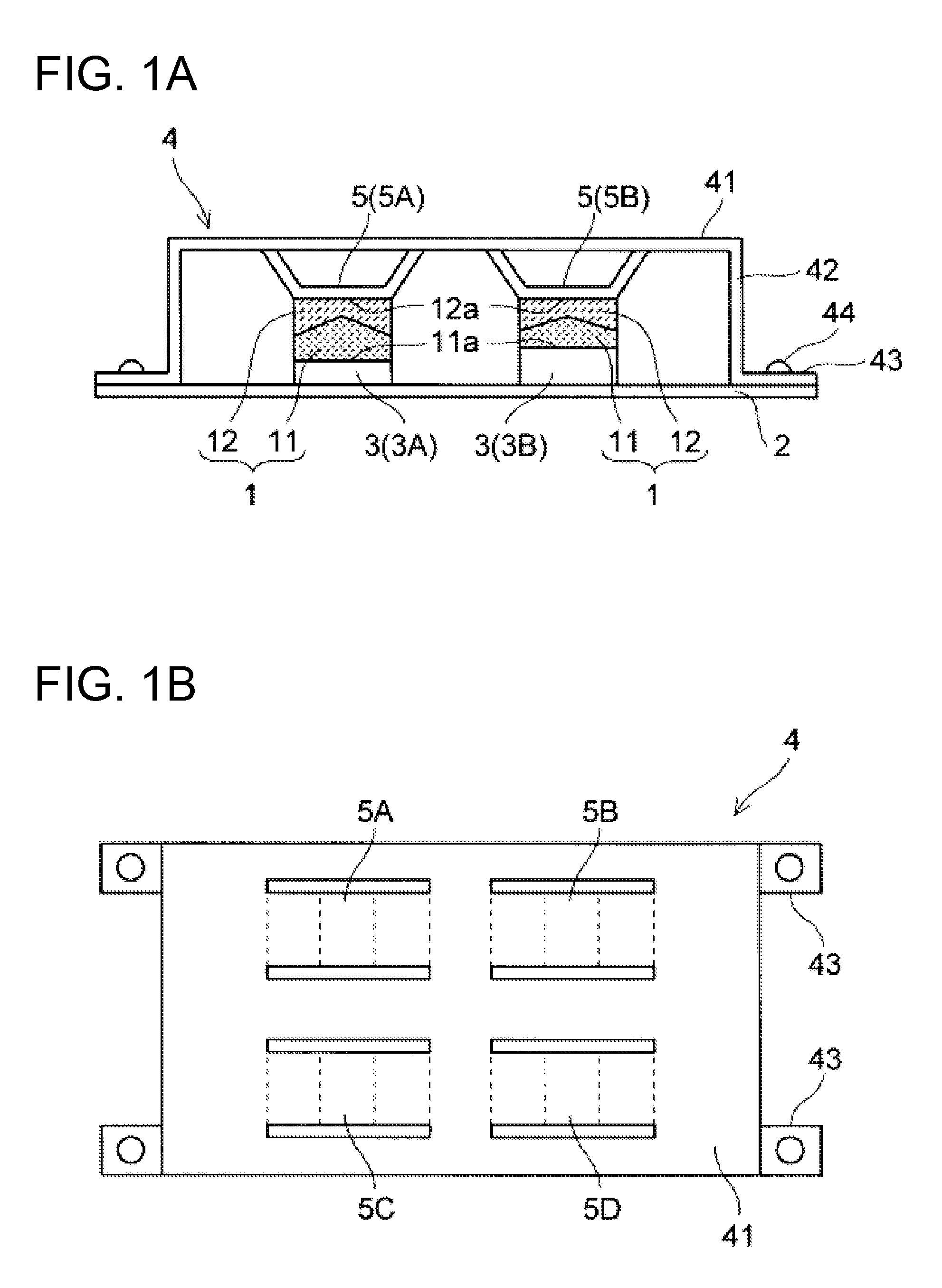

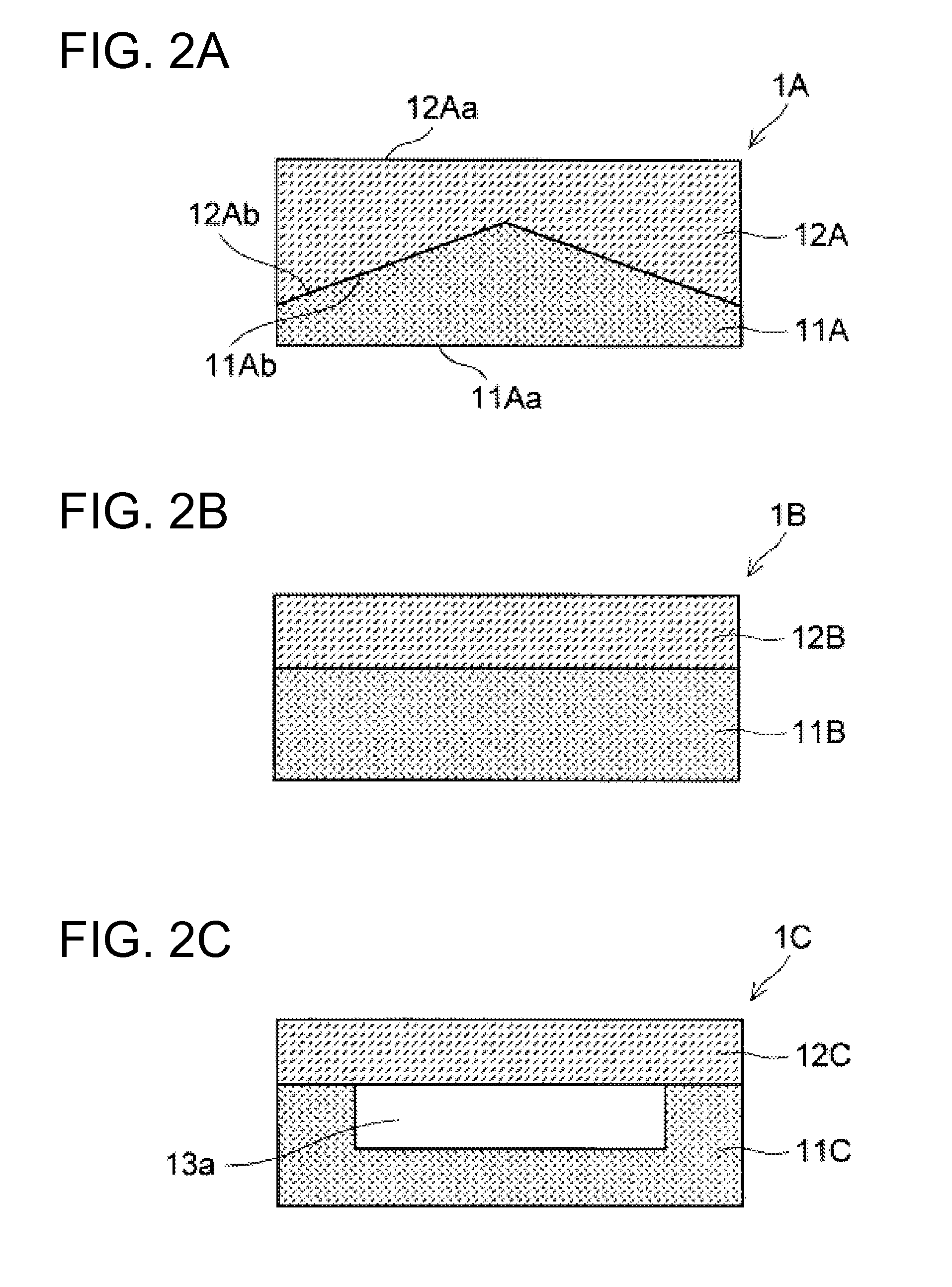

Clip and backlight assembly

InactiveUS20100008066A1Improve workabilityThin structureSnap fastenersSheet joiningEngineeringLight-emitting diode

A clip provided by the present invention includes an insert portion that is inserted into an insertion hole formed in a flat-shaped chassis and that engages with the chassis, and a collar portion that is formed in a flat shape around the circumference of the insert portion. When the insert portion is inserted into the insertion hole, the collar portion and the chassis clamp at least one light emitting board that is positioned in contact with the chassis, and the thickness of the collar portion is set to be equal to or less than an amount of protrusion of a light emitting portion formed protrudingly from the light emitting board.

Owner:SONY CORP

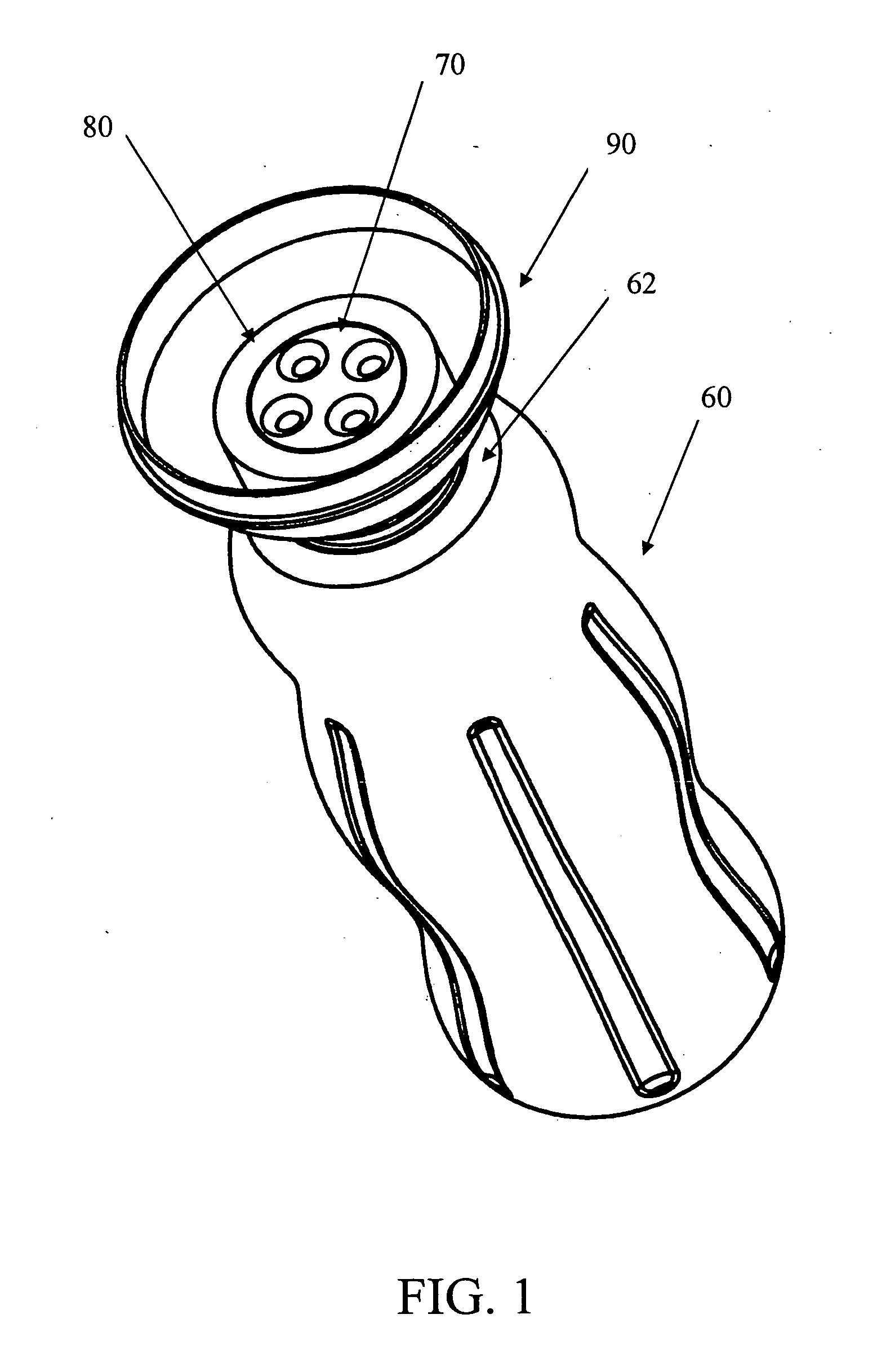

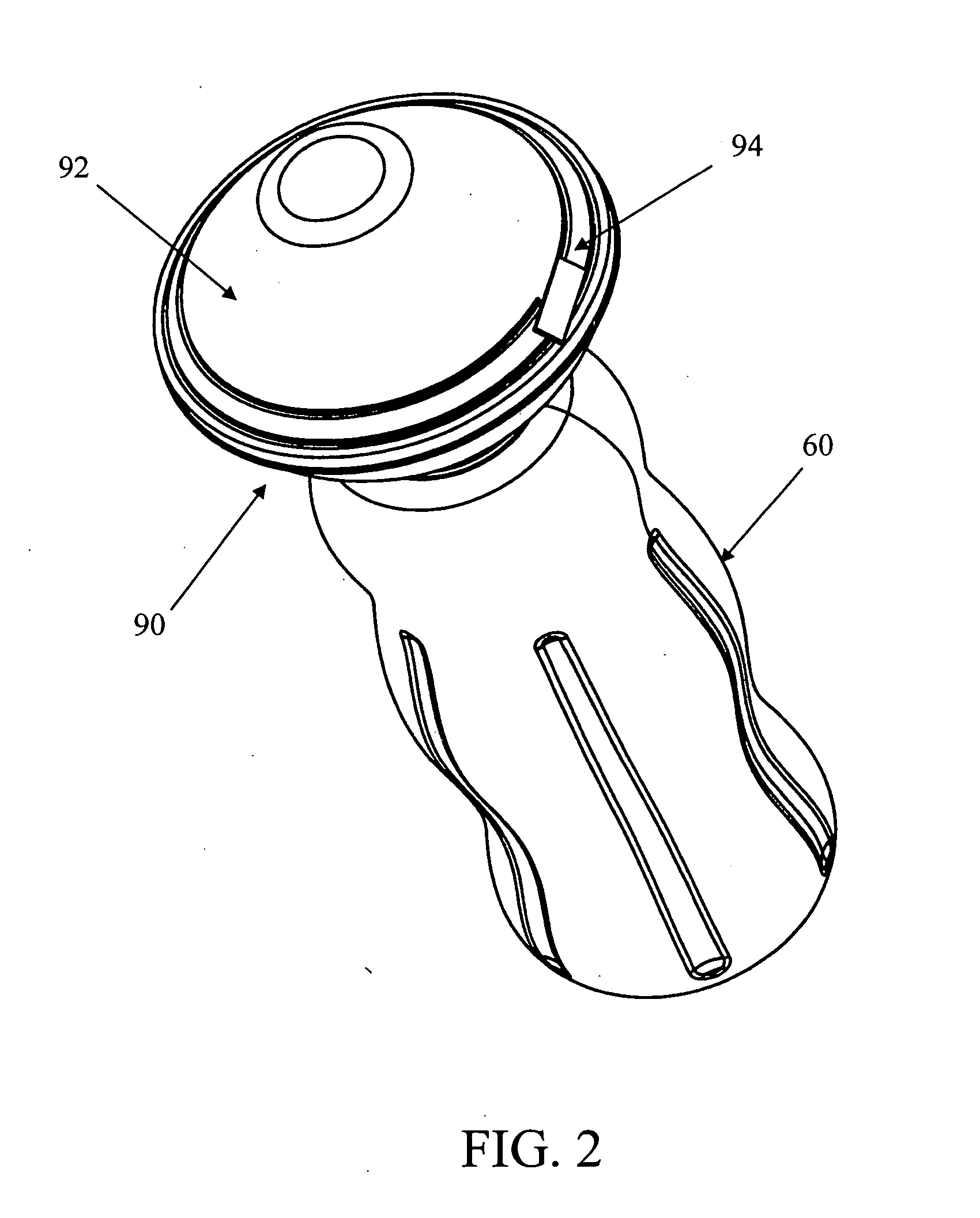

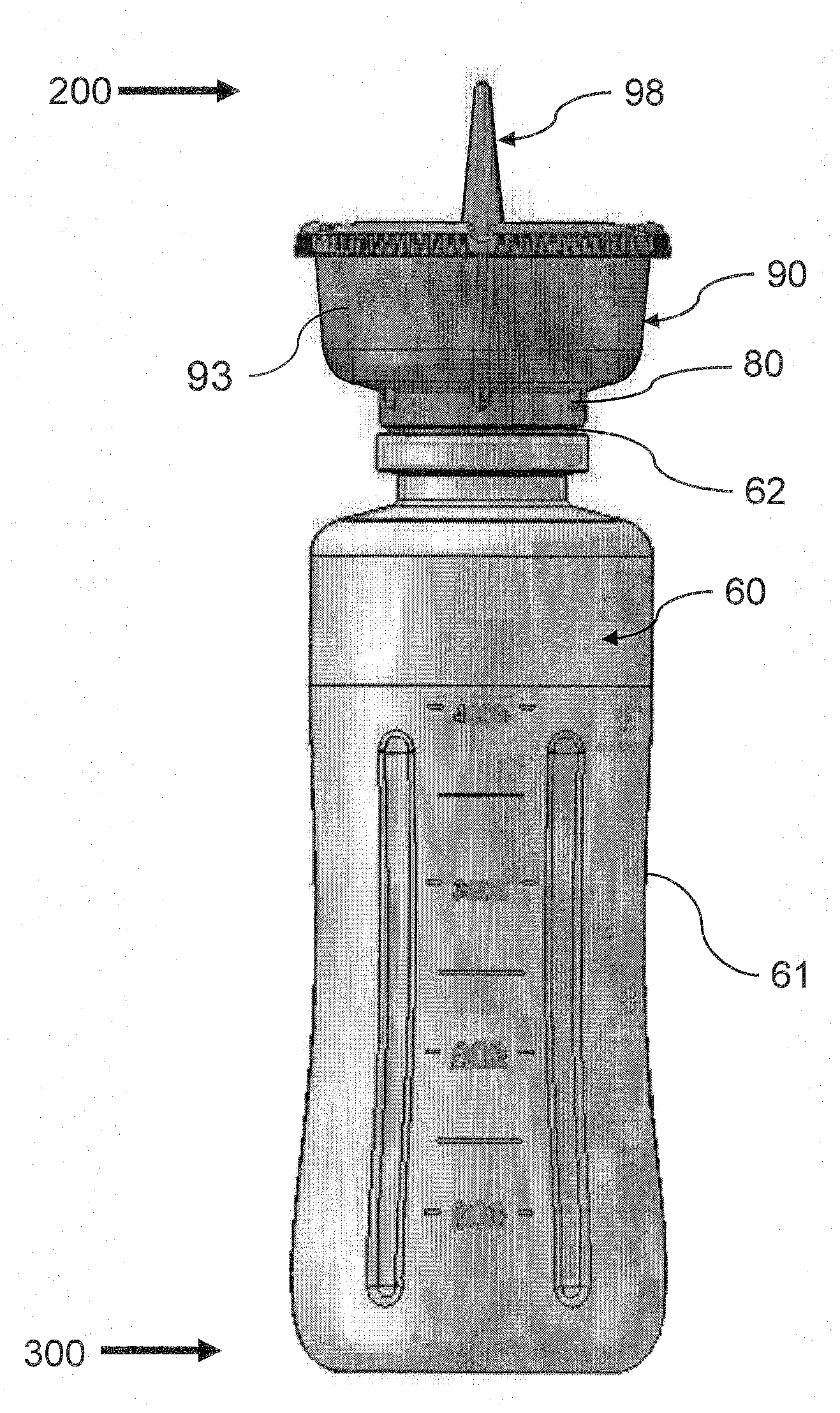

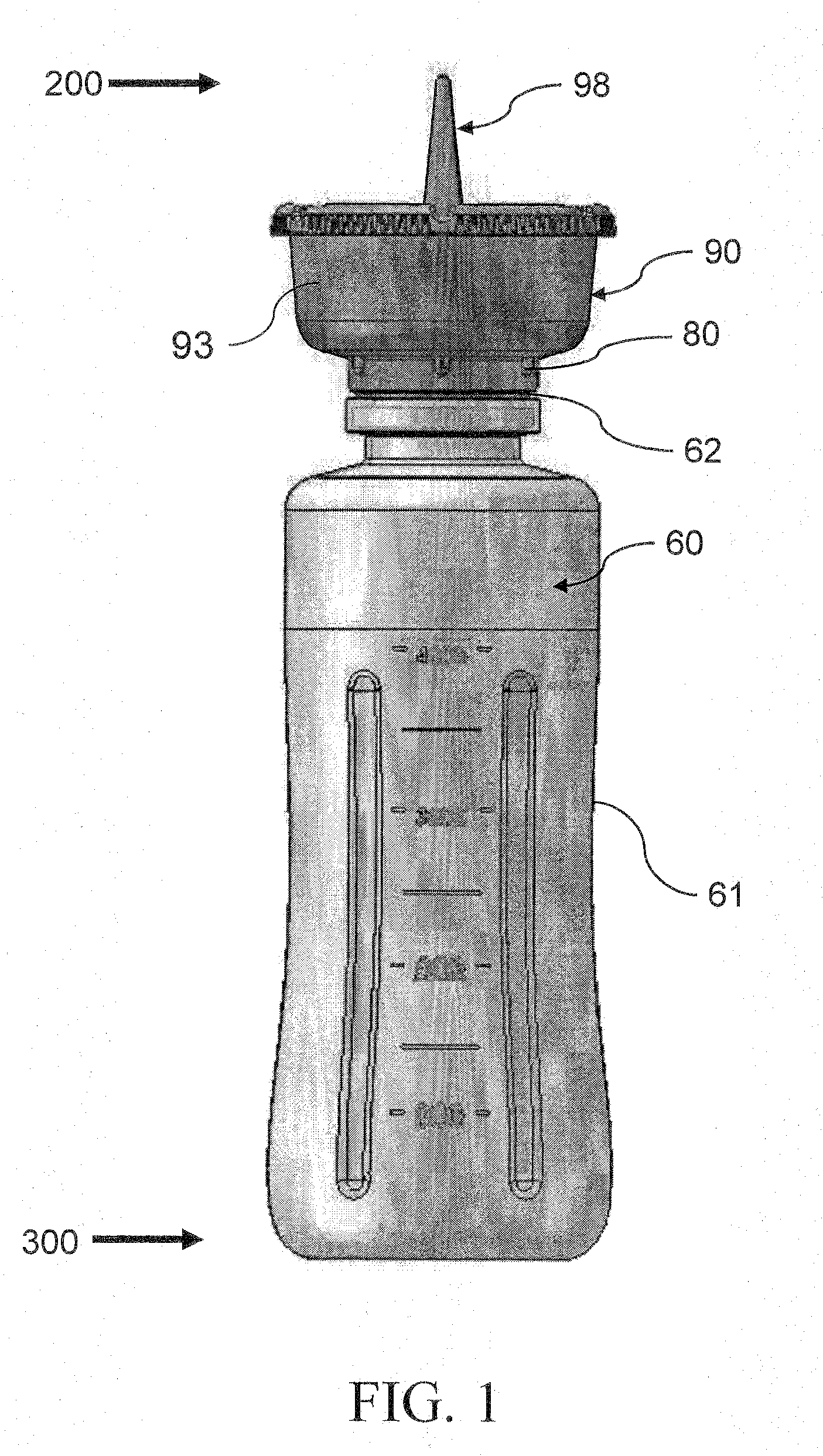

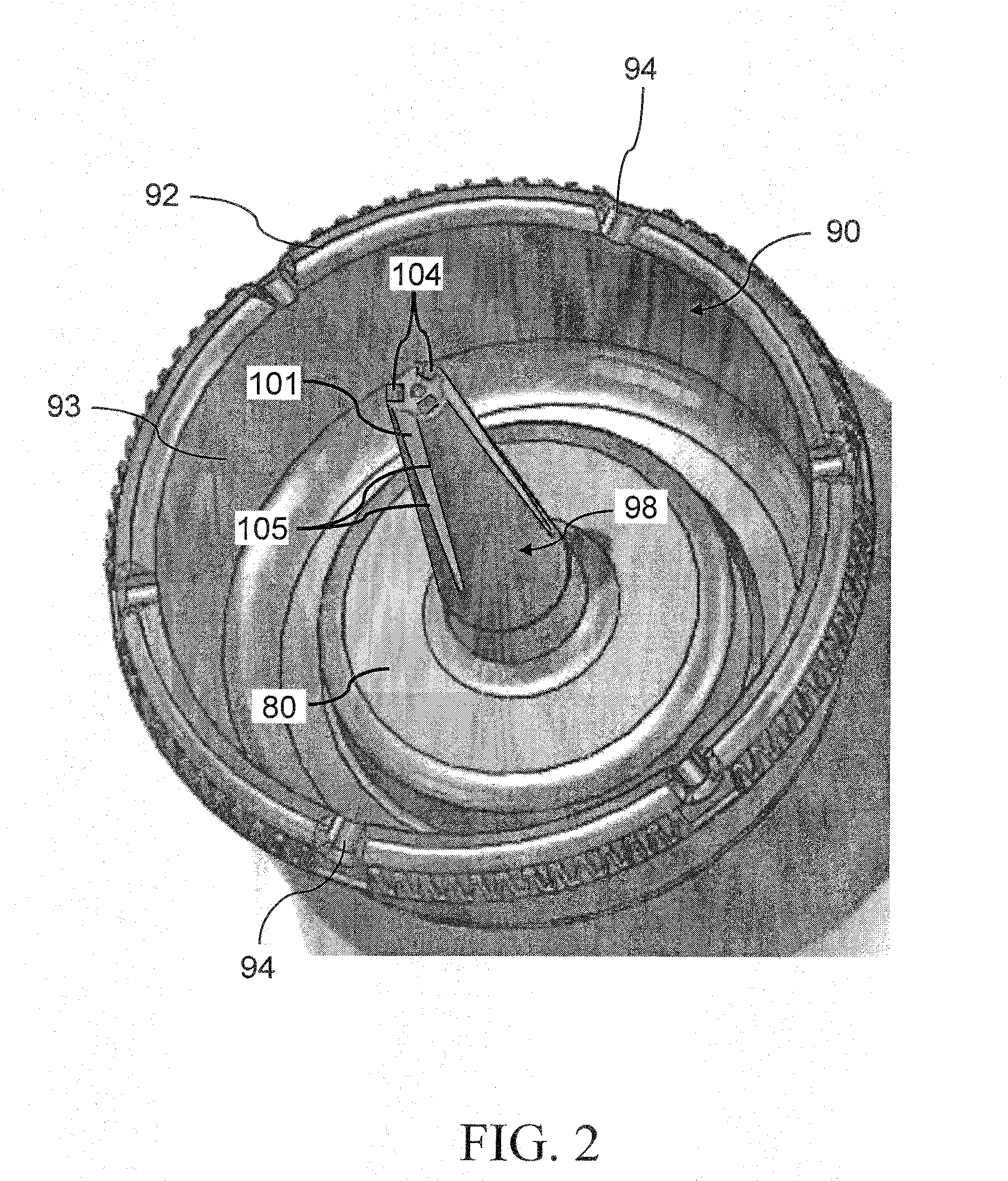

Novel wound irrigation device and method

InactiveUS20050113794A1Novel inexpensive highly effectiveEasy to irrigateCannulasEnemata/irrigatorsEngineeringWound irrigation

The subject invention provides novel, inexpensive, and highly effective methods and devices for convenient and effective wound irrigation. In one embodiment the subject invention provides a discharge means for a reservoir housing containing irrigation solution wherein the discharge means has one or more specifically designed nozzles through which a sufficient volume of the irrigation solution can pass at an appropriate pressure.

Owner:INNOVATION TECH INC

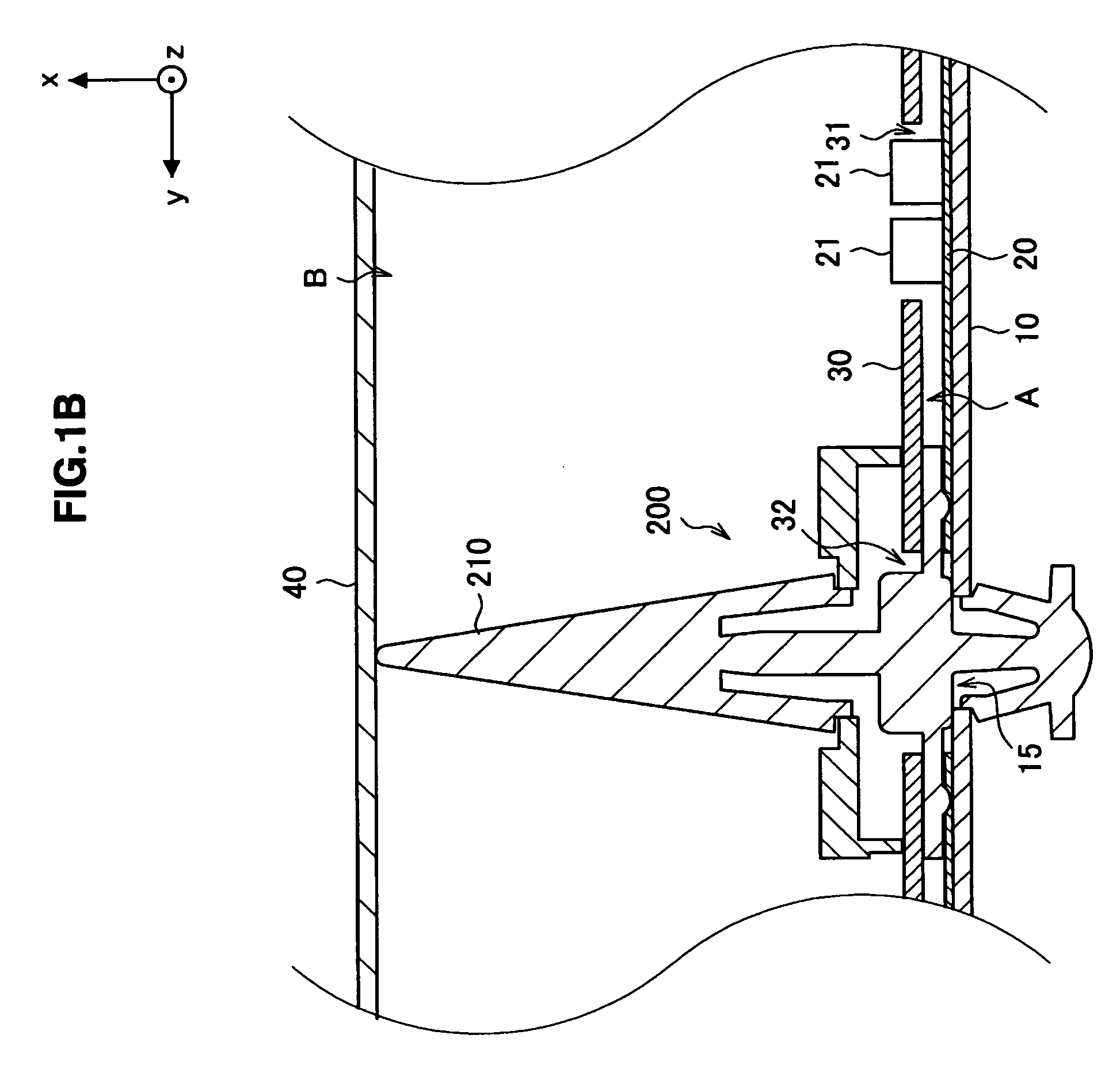

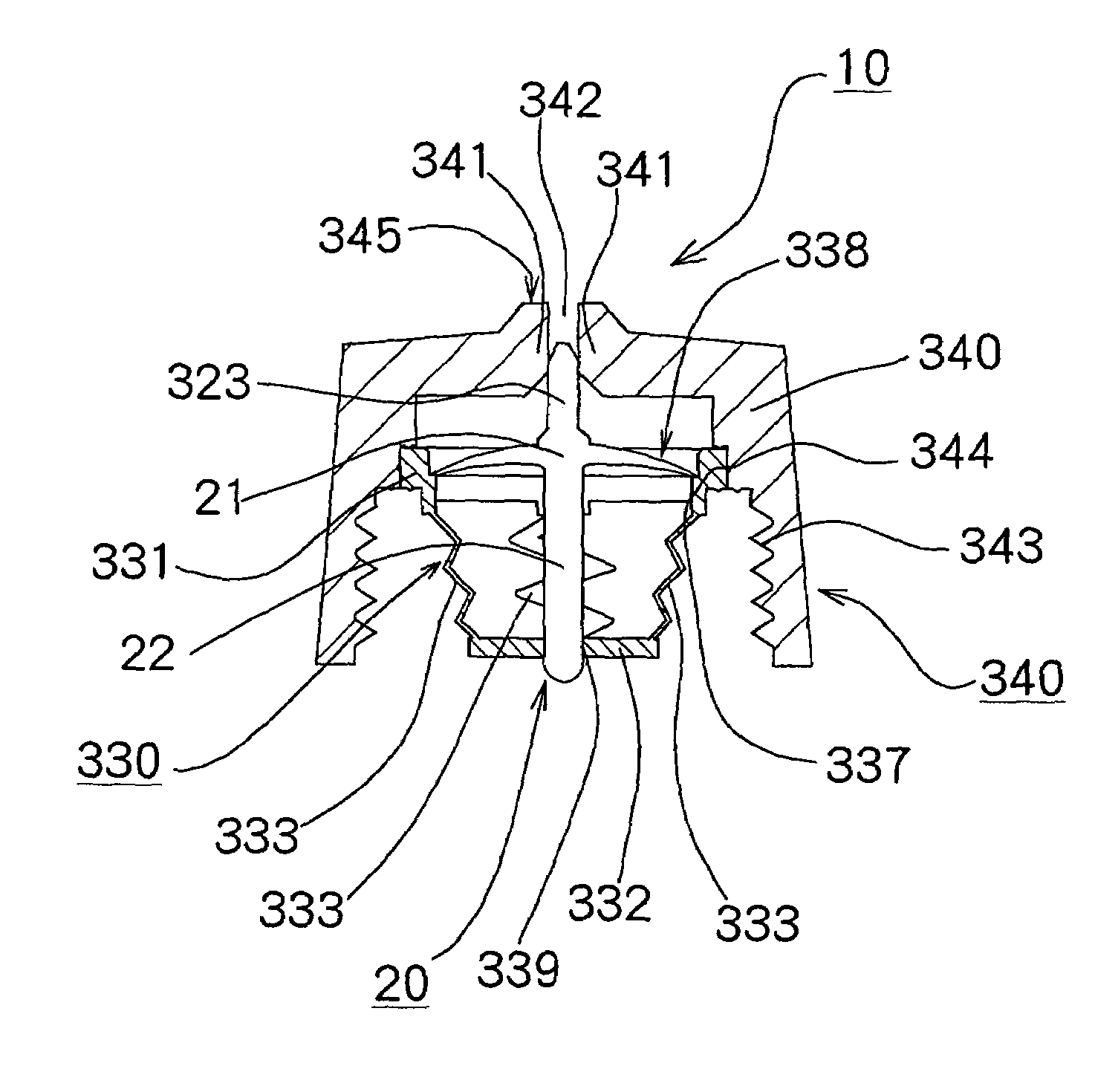

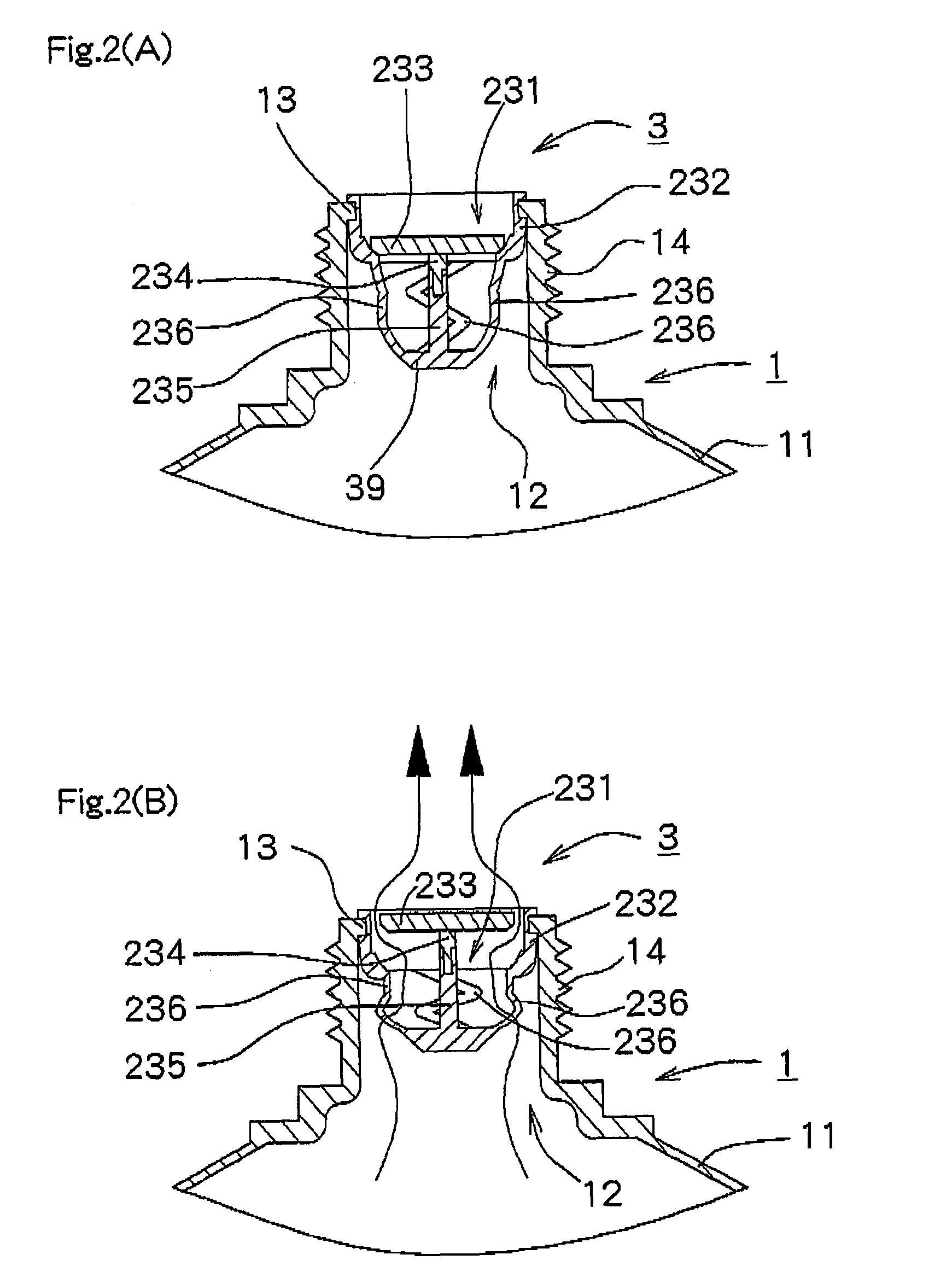

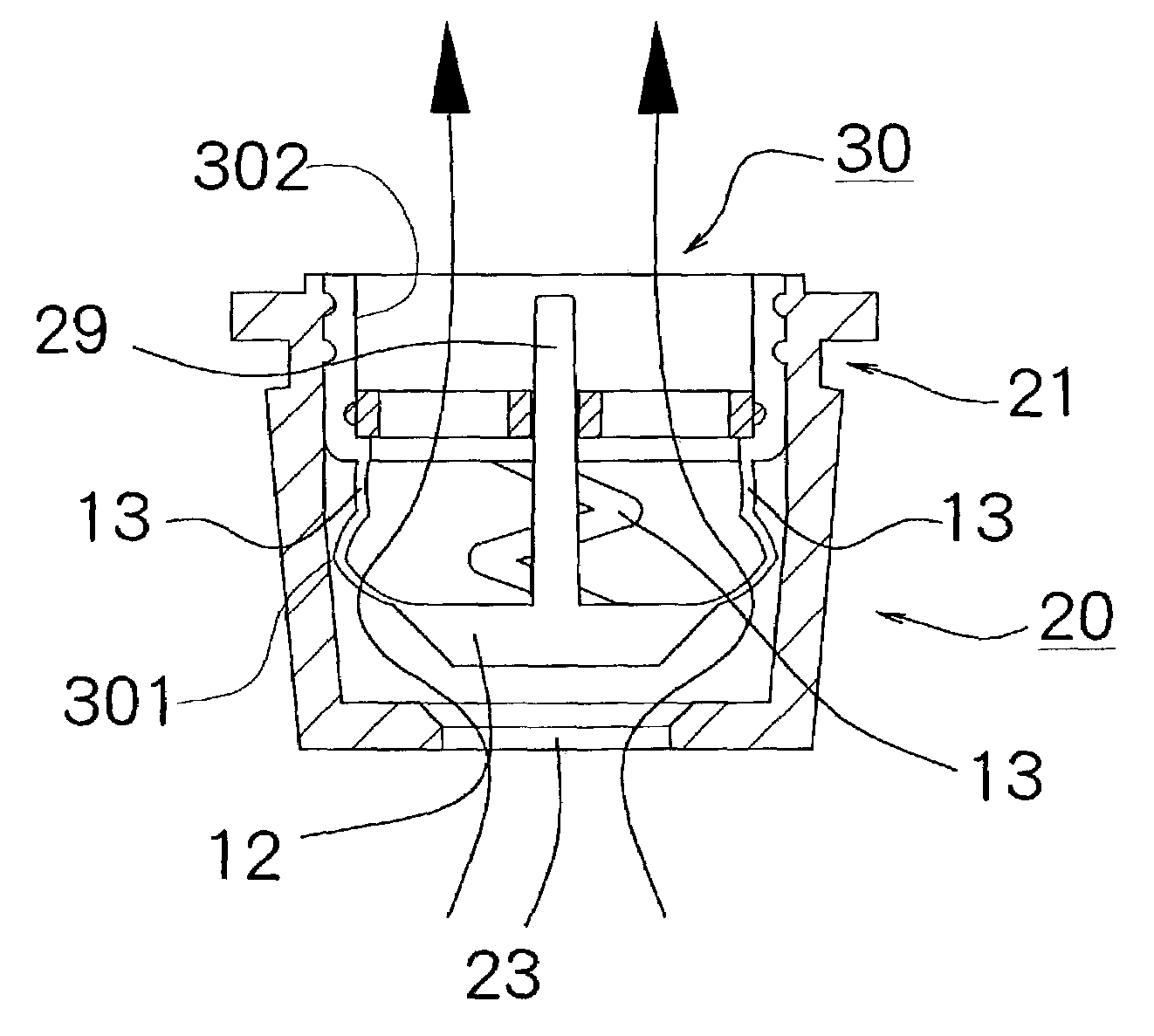

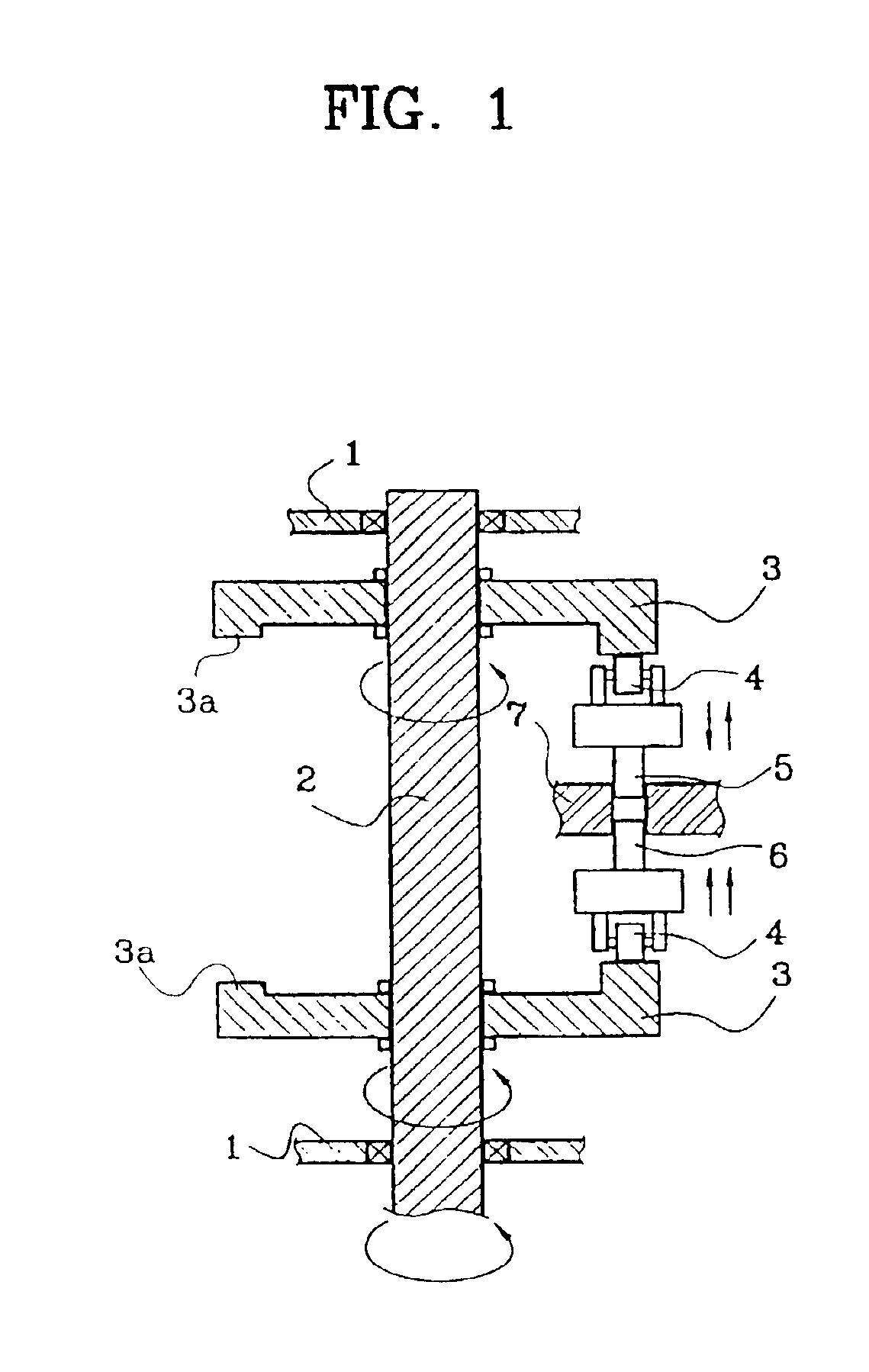

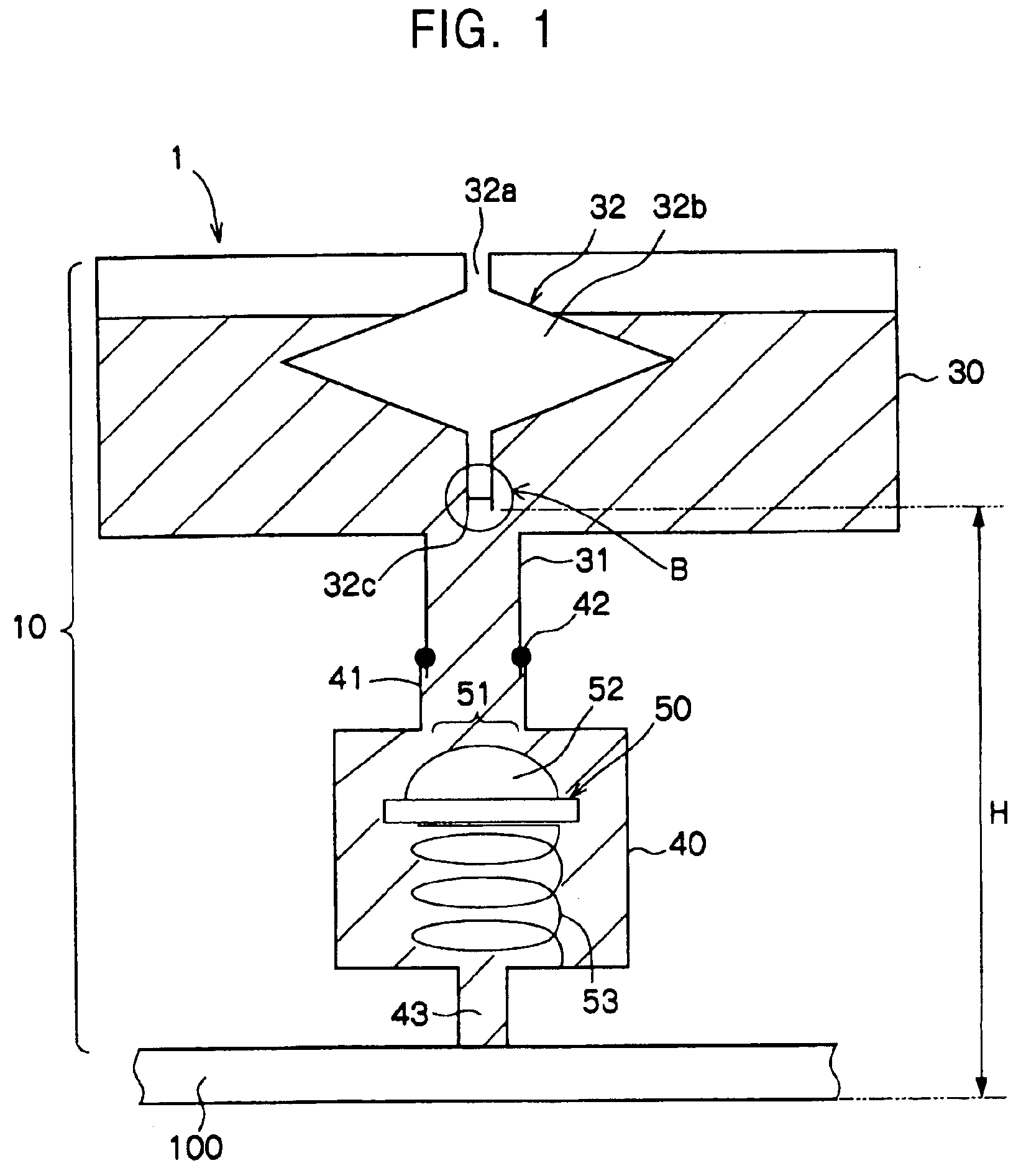

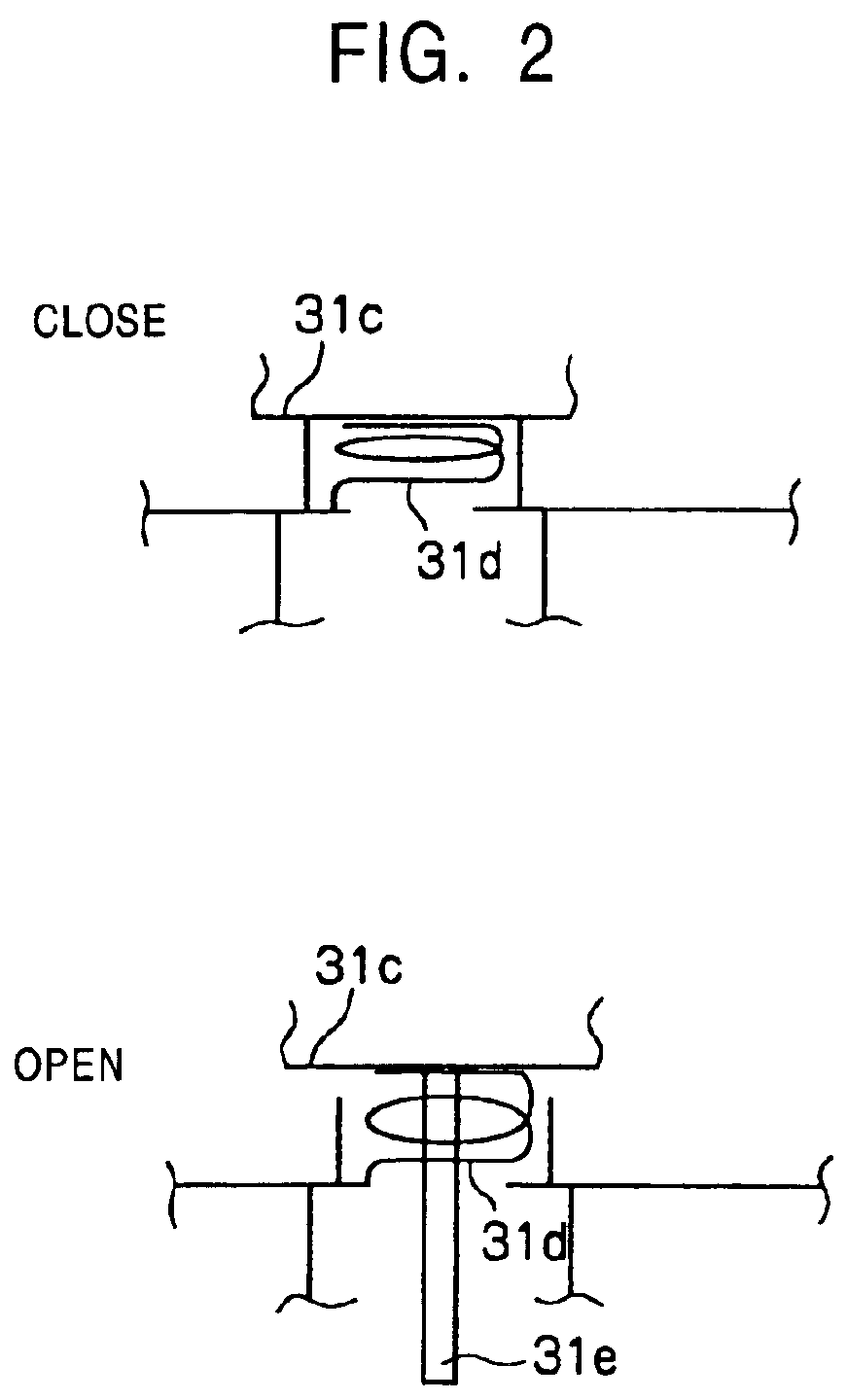

Valve mechanism for tube-type fluid container

InactiveUS7249694B2Close reliableSimple configurationClosuresDischarging meansEngineeringTubing types

A valve mechanism adapted for a fluid-discharging port of a tube-type fluid container, comprising: a valve seat portion 40 having an opening 41 through which a fluid flows; a valve portion 20 comprising a valve body 21 having a shape corresponding to the opening 41, and a shaft 22 connected to the valve body 21 and extending downward from the valve body 22; and a valve support portion 30 comprising: (i) a bottom plate 39 to which a tip of the shaft 22 is connected; (ii) an annular support 35 fixedly connected to the valve seat portion 40; and (iii) multiple connectors 32 connecting the bottom plate 39 and the annular support 31, the connectors 32 elastically urging the bottom plate 39 downward to close the opening 41 with the valve body 21 and being bendable as the bottom plate 39 moves upward and pushes the valve portion 20 to open the opening 41.

Owner:MASUDA MASATOSHI

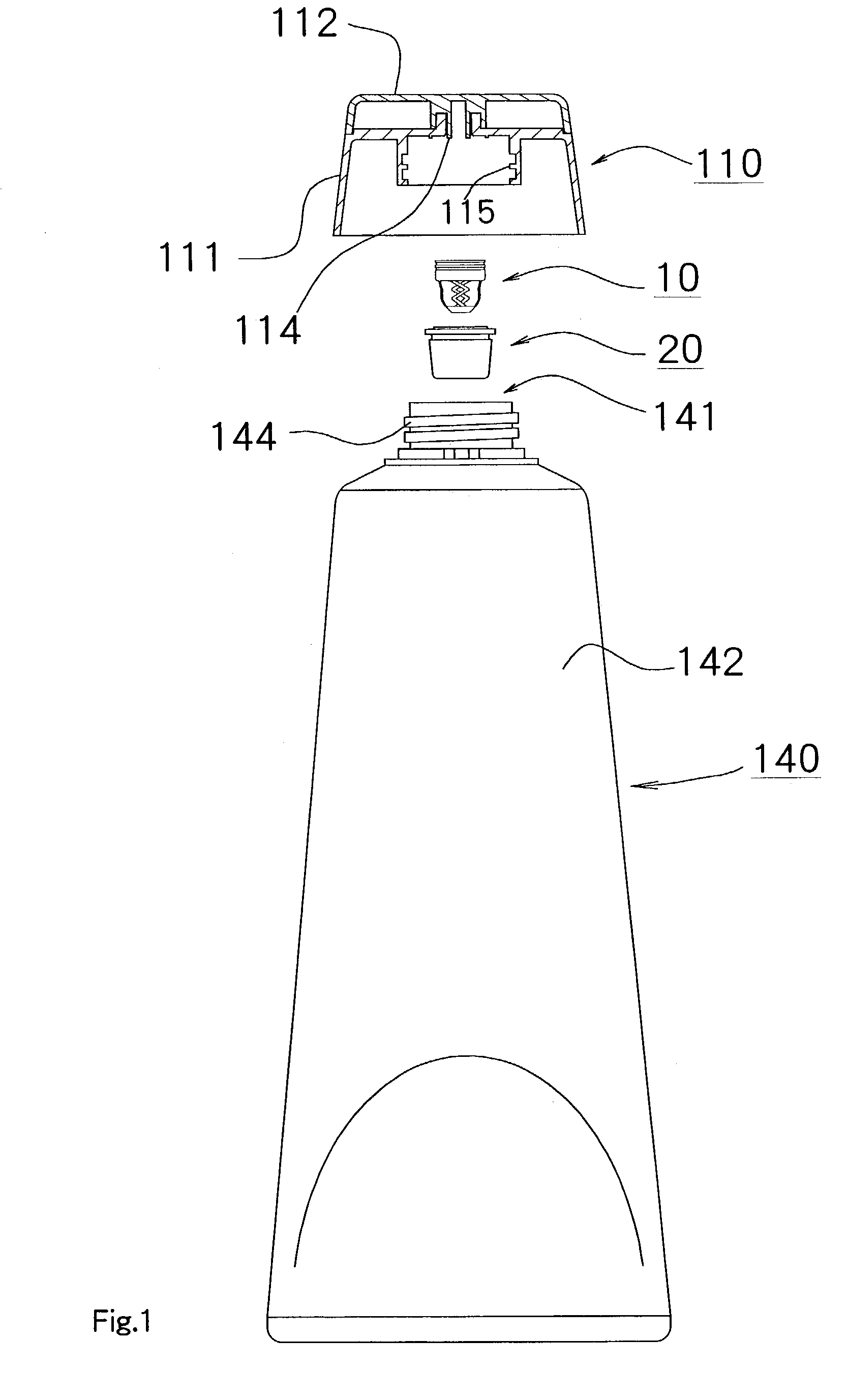

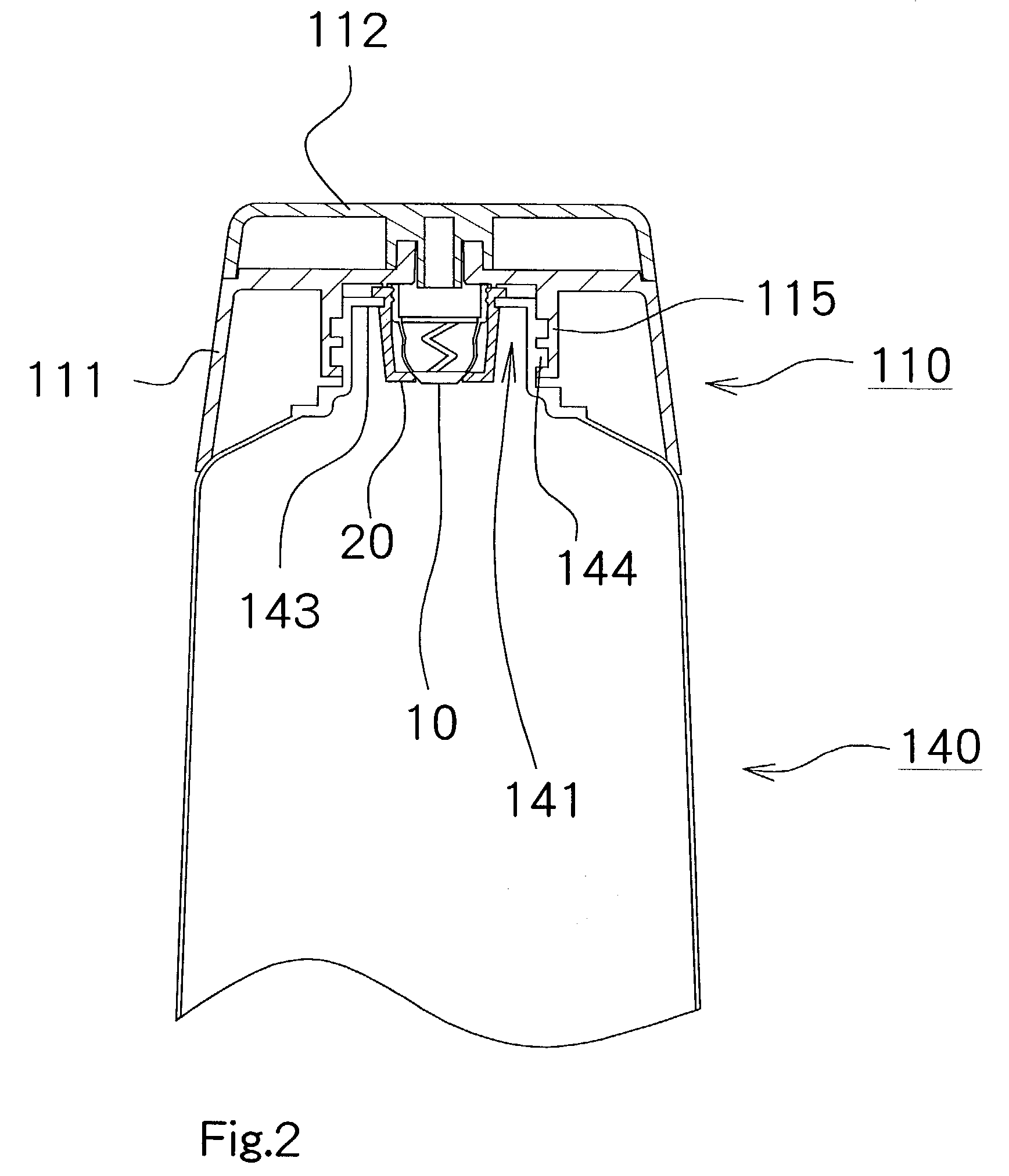

Valve mechanism for tube-type fluid container

InactiveUS7059501B2Close reliableSimple configurationClosuresDispensing apparatusCouplingTubing types

A valve seat portion 20 has a nearly tubular shape, at the bottom of which a circular opening portion 23 which functions as a valve seat is formed. A valve portion 10 has a ring-shaped supporting portion 11 which is disposed inside the valve seat portion 20. A valve body 12 has a shape corresponding to the circular opening portion 23, and multiple coupling portions couple the supporting portion 11 and the valve body 12. In the valve portion 10, the valve body can move between a closed position in which the valve body closes the opening portion 23 in the valve seat portion 20 and an open position in which the valve body opens the opening portion 23 by the flexibility of the four coupling portions 13.

Owner:MASUDA MASATOSHI

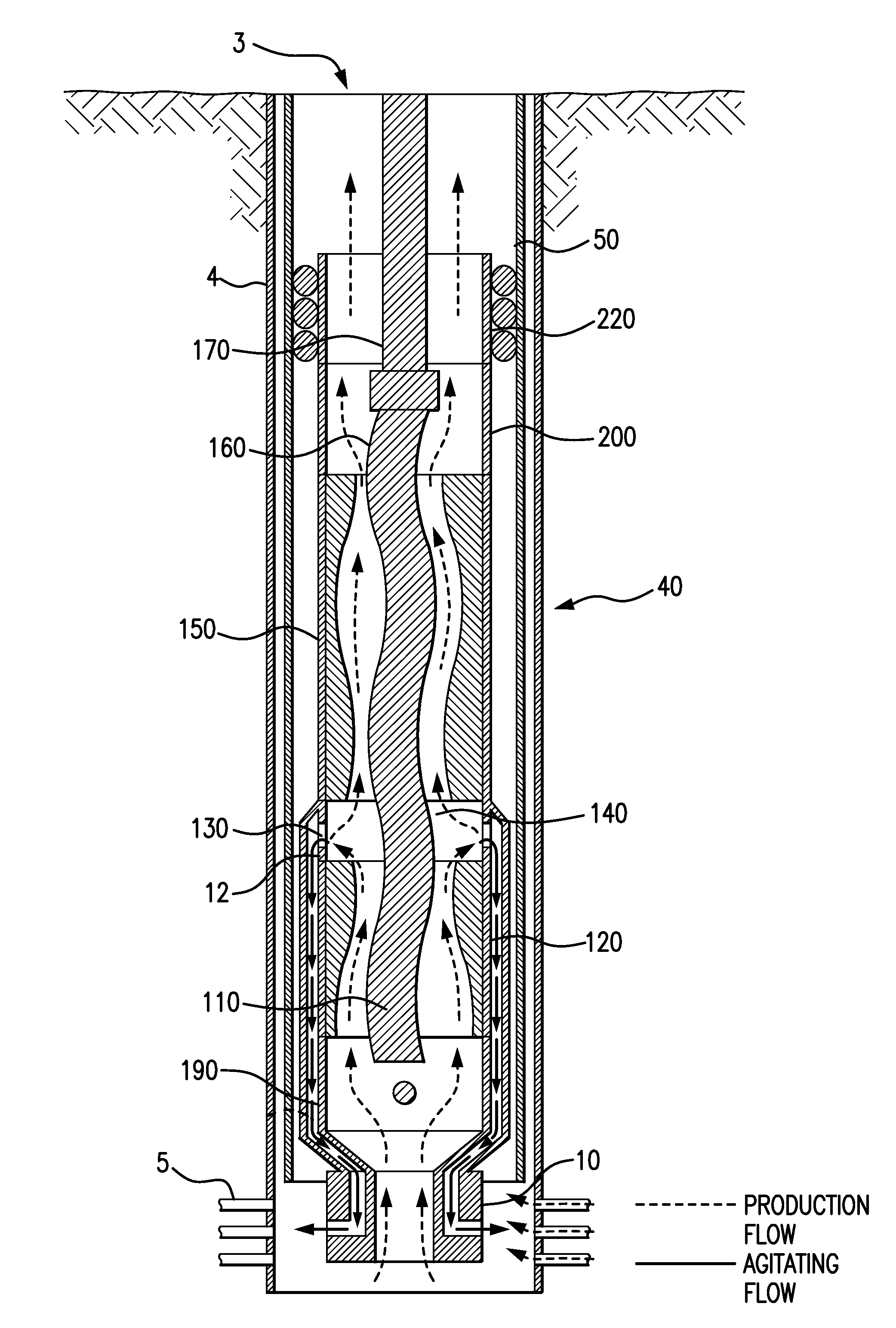

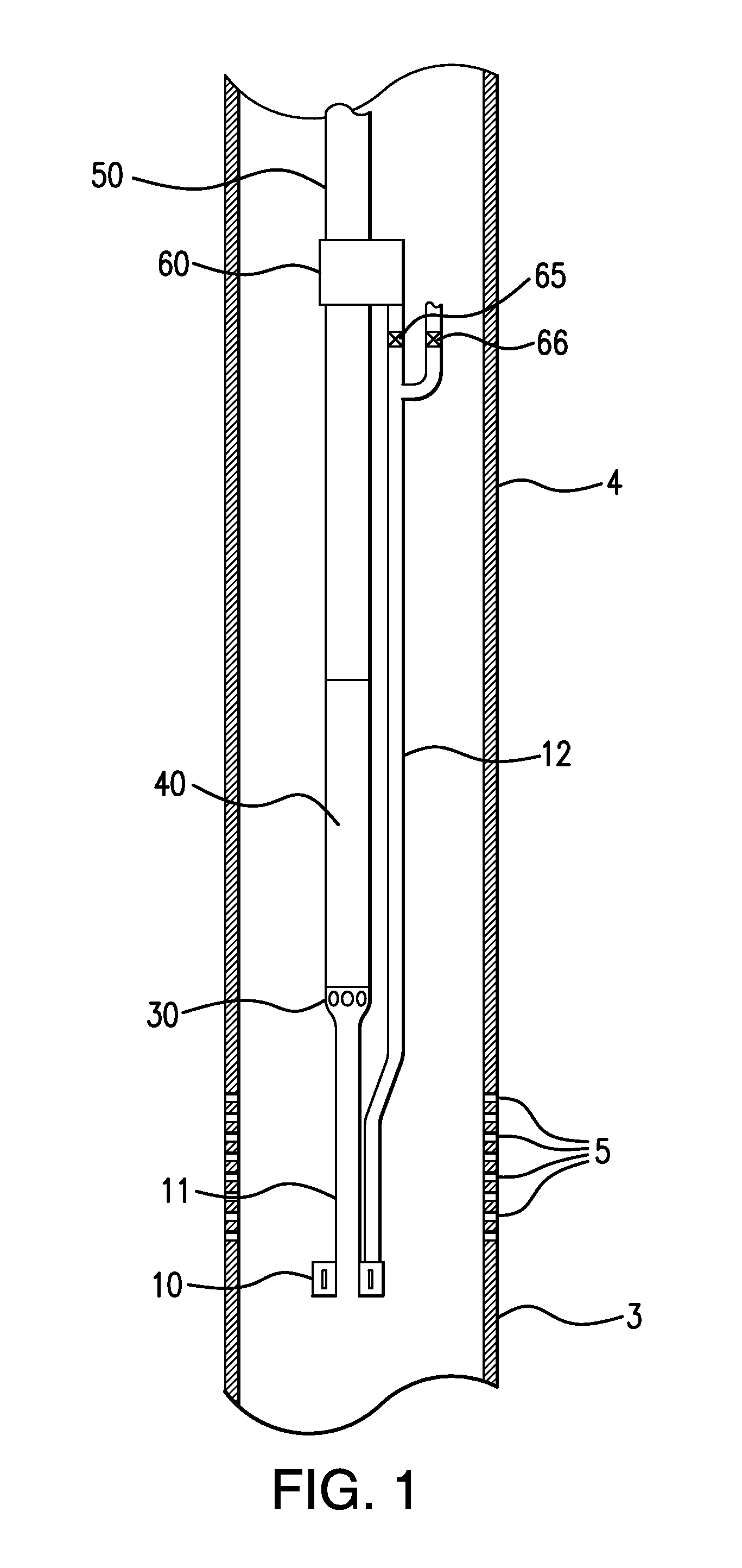

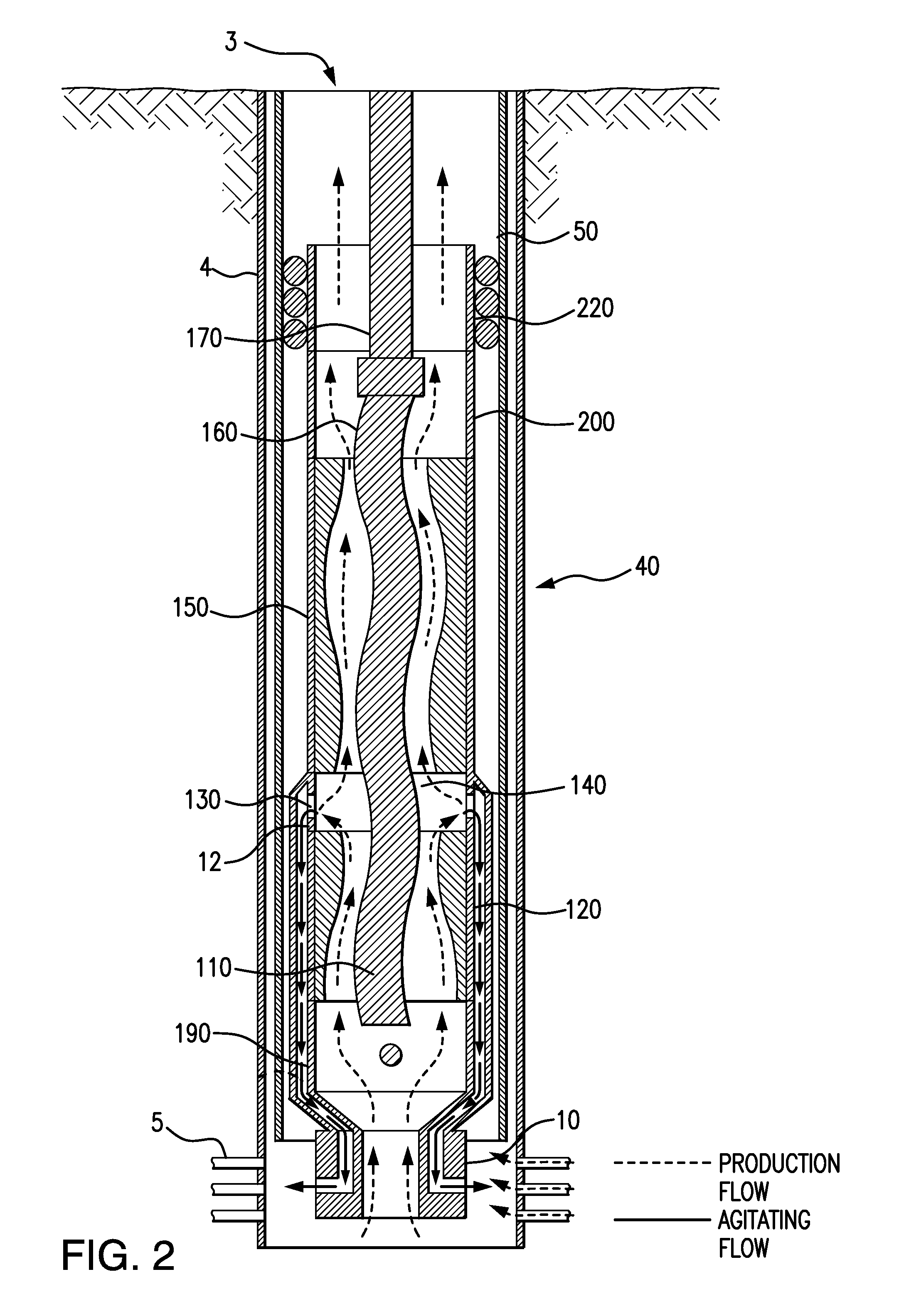

Wellbore desanding system

InactiveUS20150226046A1Reduce pressureAppropriate pressureCleaning apparatusFluid removalPressure balanceProduction tubing

The invention relates to system and method for desanding an oil well that includes a fluidizing device (TORE), connected to a downhole pump that connects to a production tubing such that a supply duct is connected to the discharge of the pump and a discharge duct is connected to the suction of the pump. Embodiments include a pressure balance transition device between the TORE and the pump and / or a flow splitting device in the production tubing after the discharge of the pump. Other embodiments relate to a system and method for desanding an oil well in which a fluidizing unit is connected to a pump such that the supply duct is connected to an opening in the pump body or pump rotor and a discharge duct is connected to the suction of the pump. If connected to the rotor, the supply duct is integral to the pump rotor.

Owner:NAT OILWELL VARCO LP

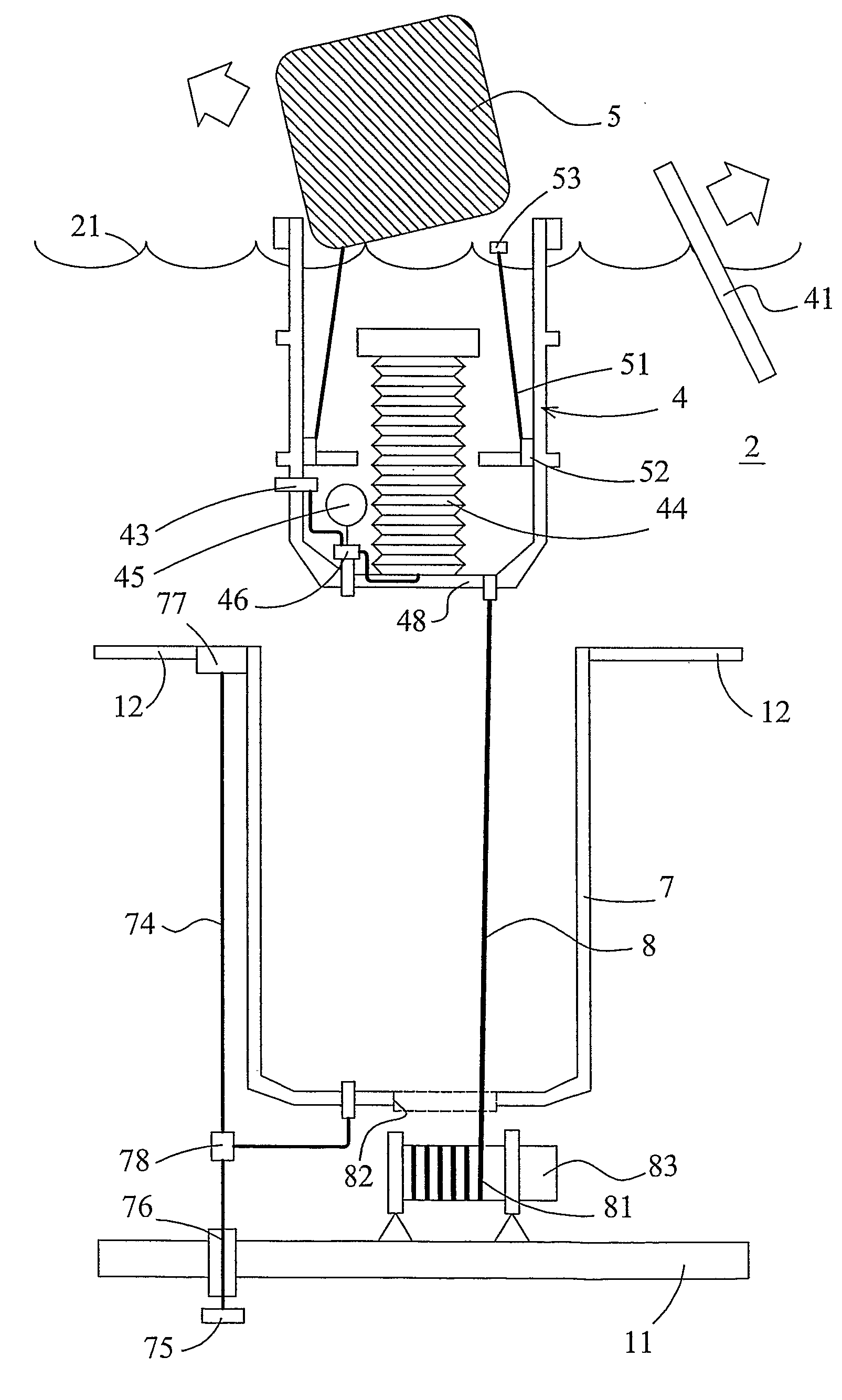

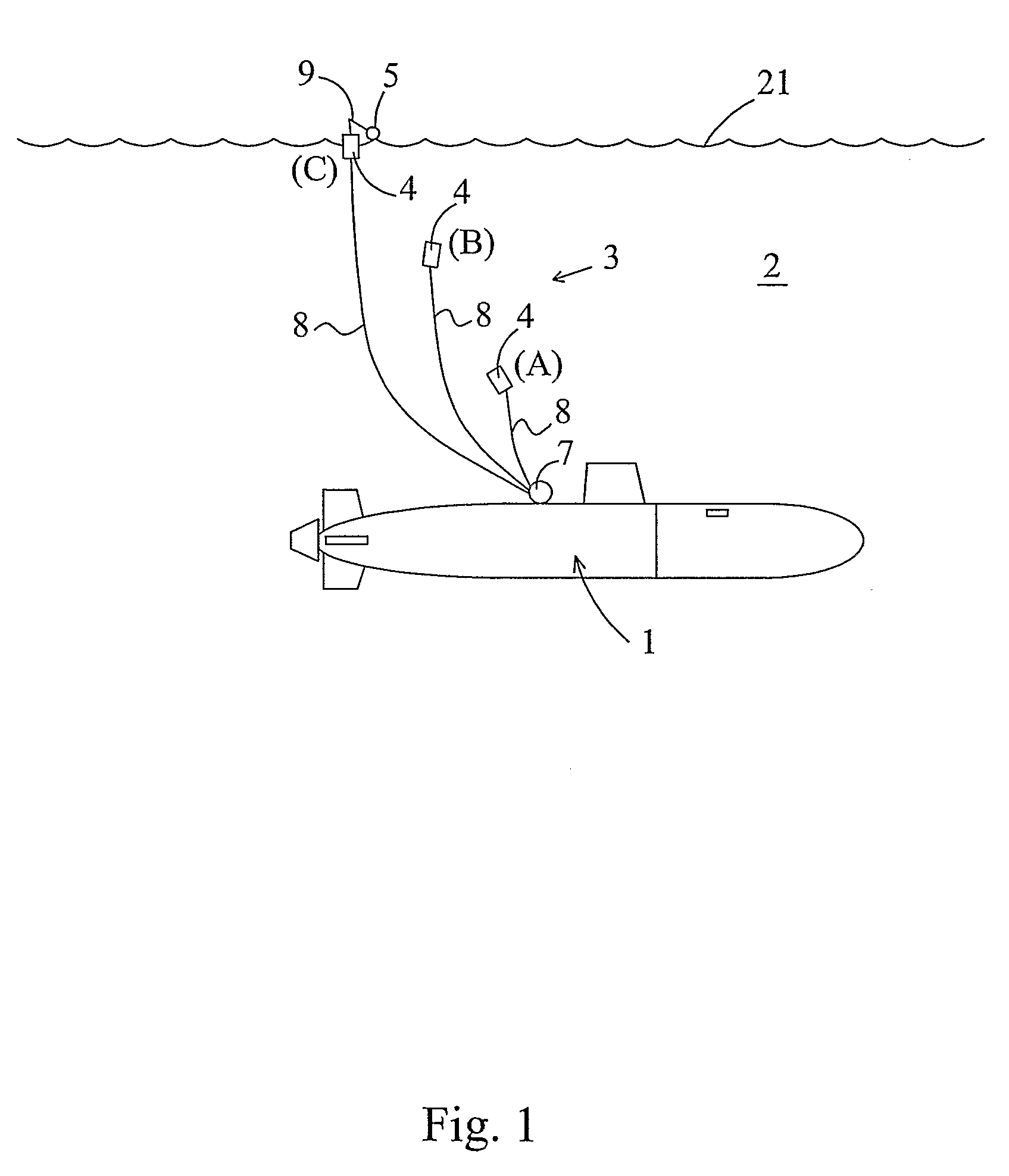

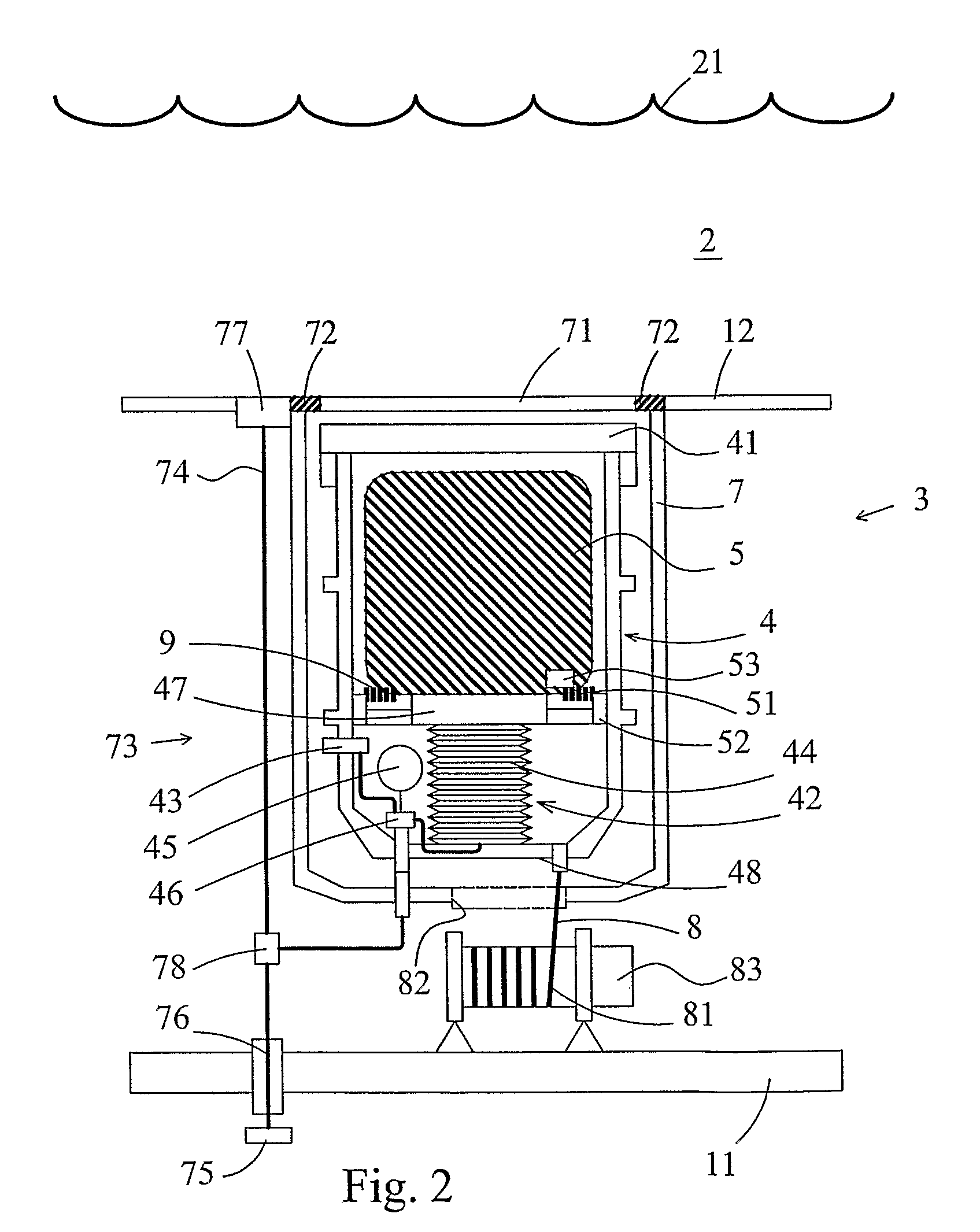

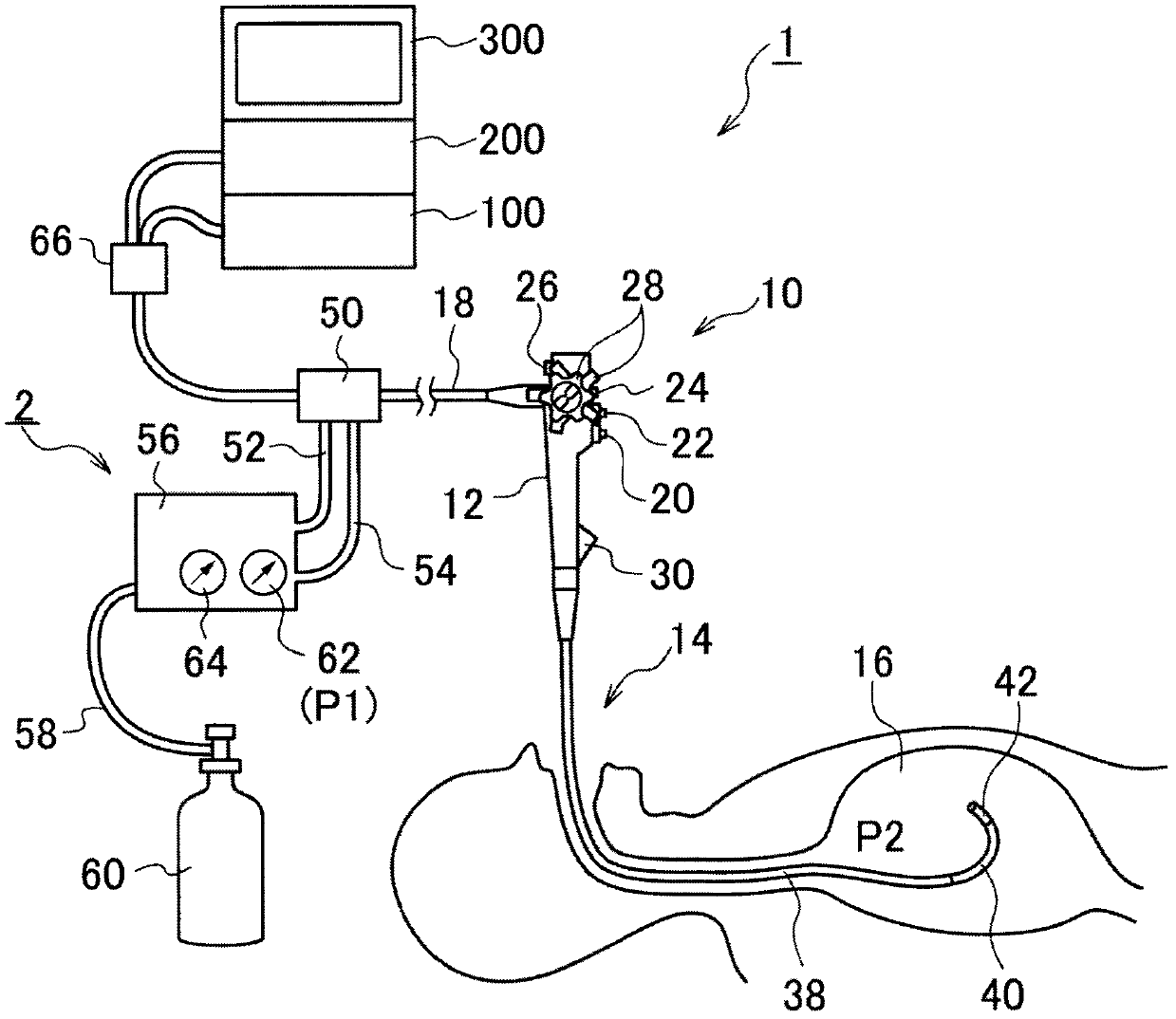

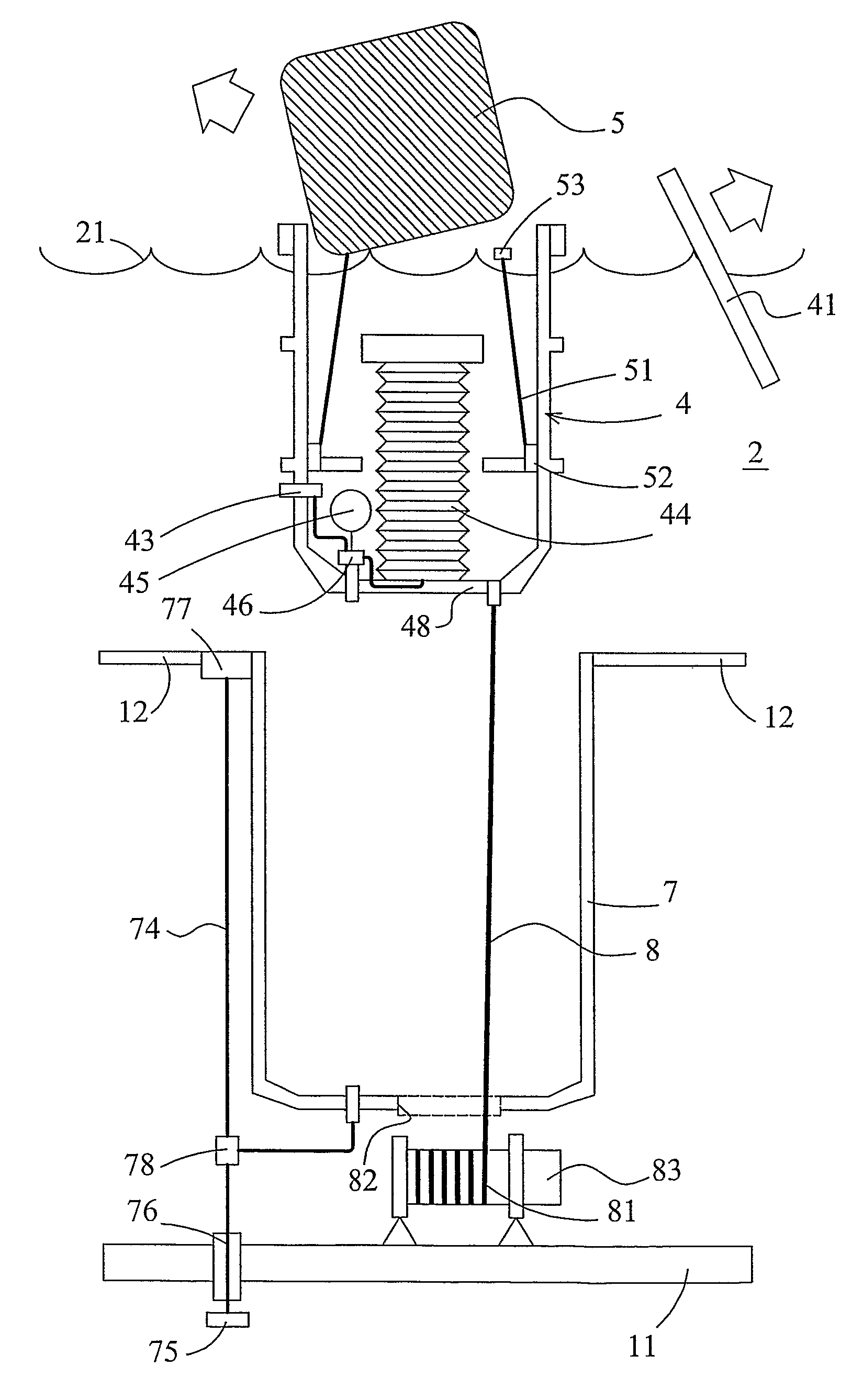

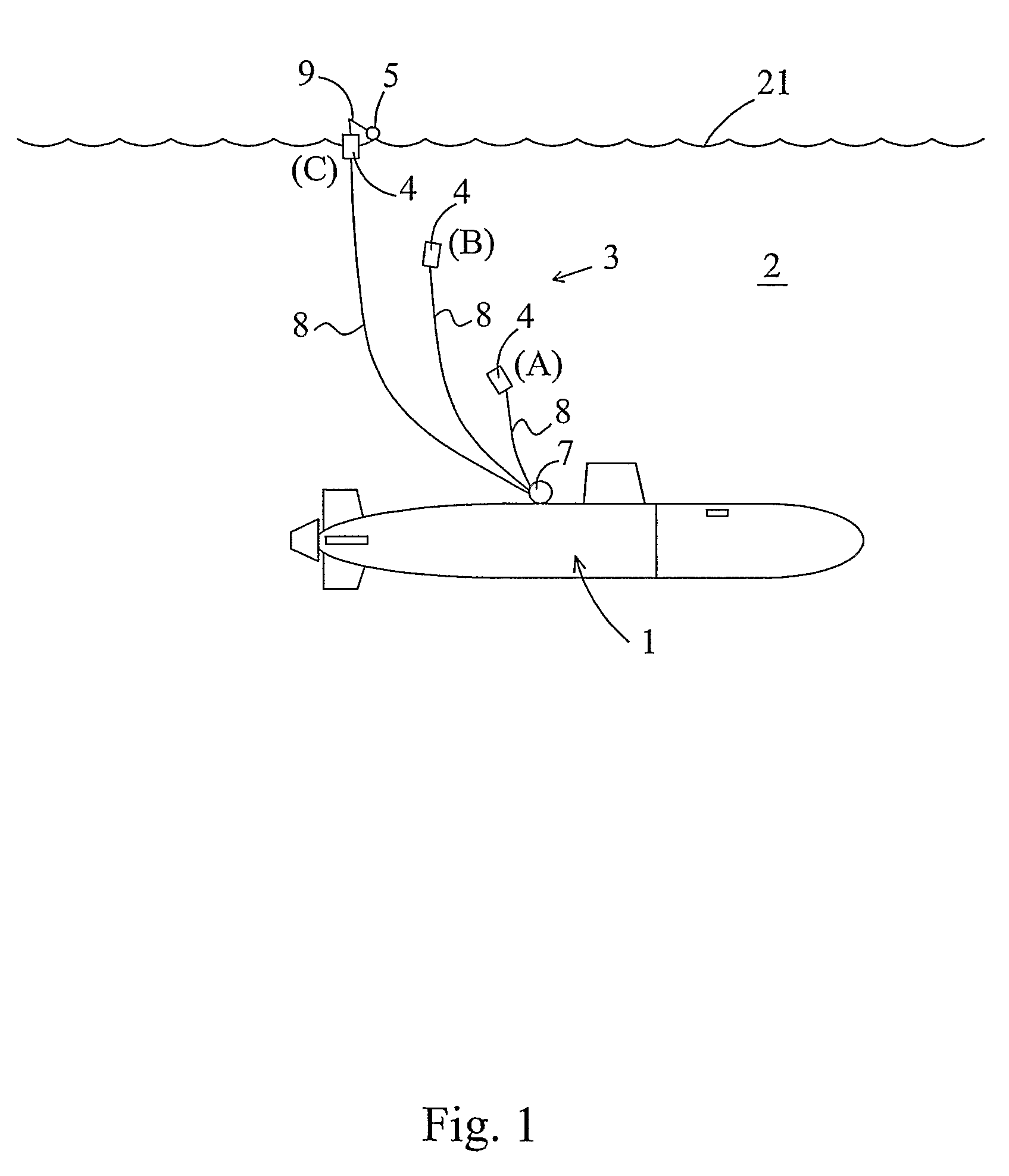

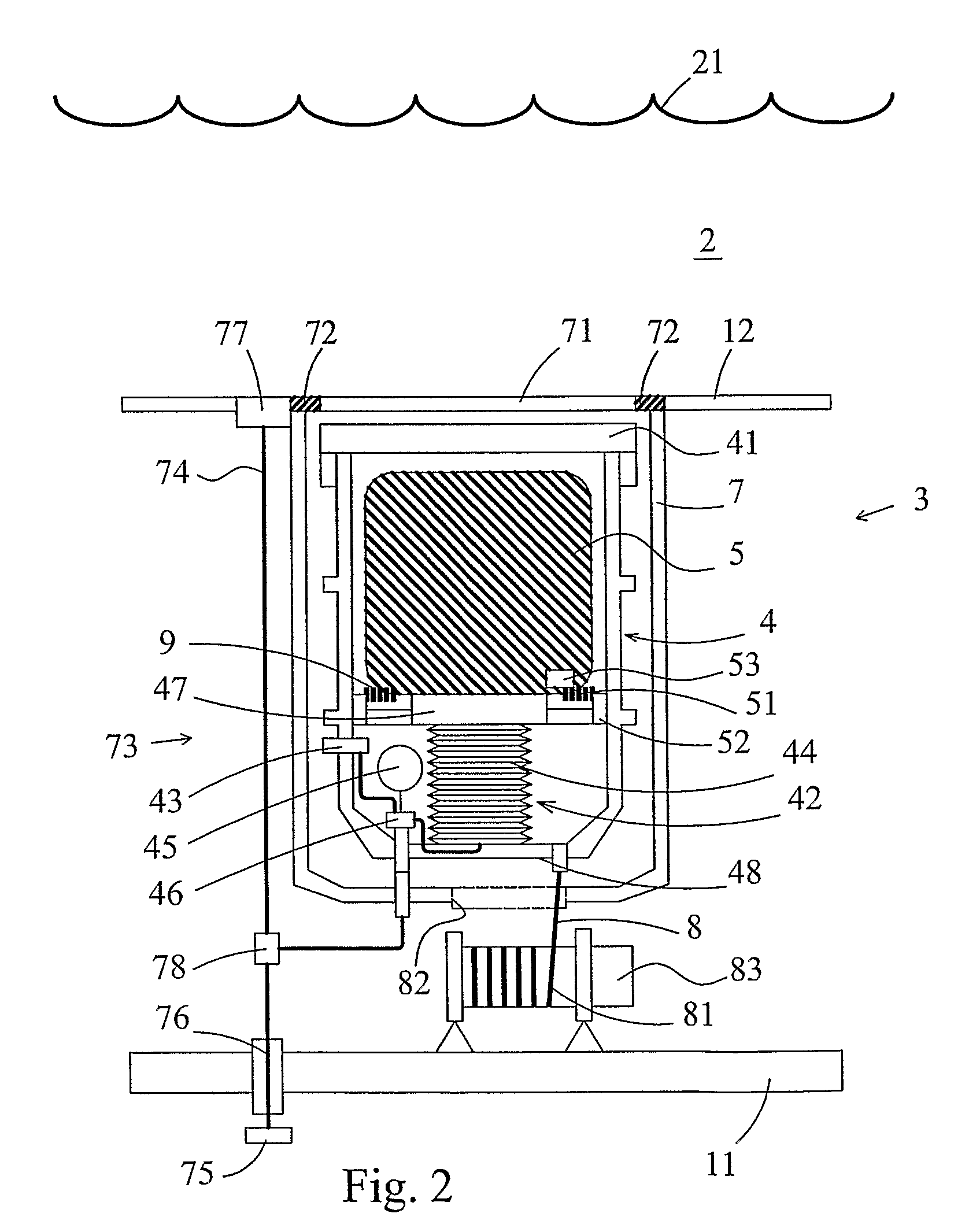

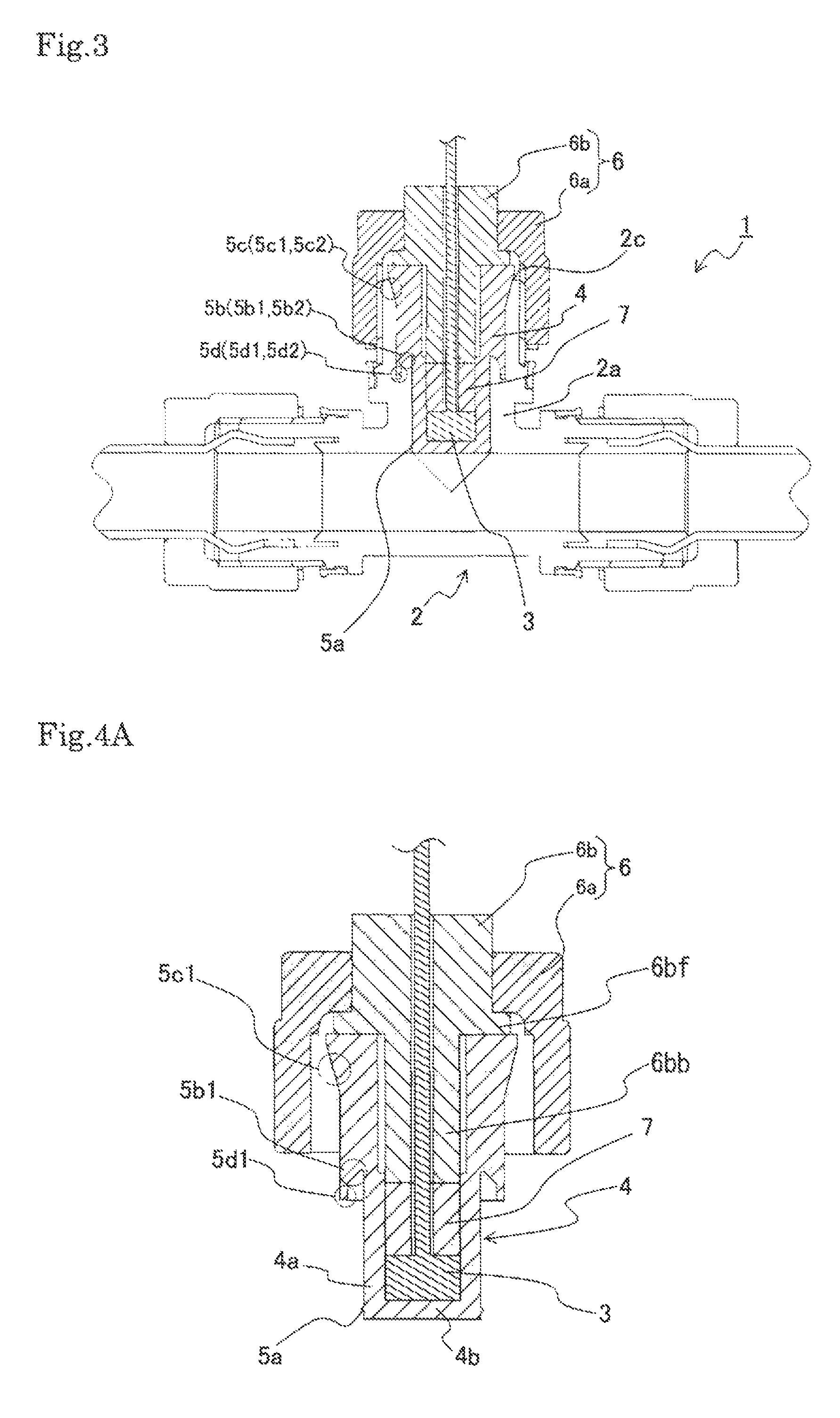

Assembly for Deploying a Payload from a Submarine

A submarine (1) has an assembly (3) for deploying a life raft (5), the assembly (3) being located in a well (7) formed outside the submarine's pressure hull (11). The assembly includes a pressure vessel (4) for storing the life raft (5) in a pressurized state. To deploy underwater, a lid (71) covering an opening to the well (7) is released to permit the assembly (3), which is buoyant, to ascend towards the water surface. A sensor (43) determines proximity to the water surface, whereby a pneumatic ram (42) in the pressure vessel is activated to eject the life raft (5) from the pressure vessel (4).

Owner:BABCOCK IP MANAGEMENT NUMBER ONE LTD

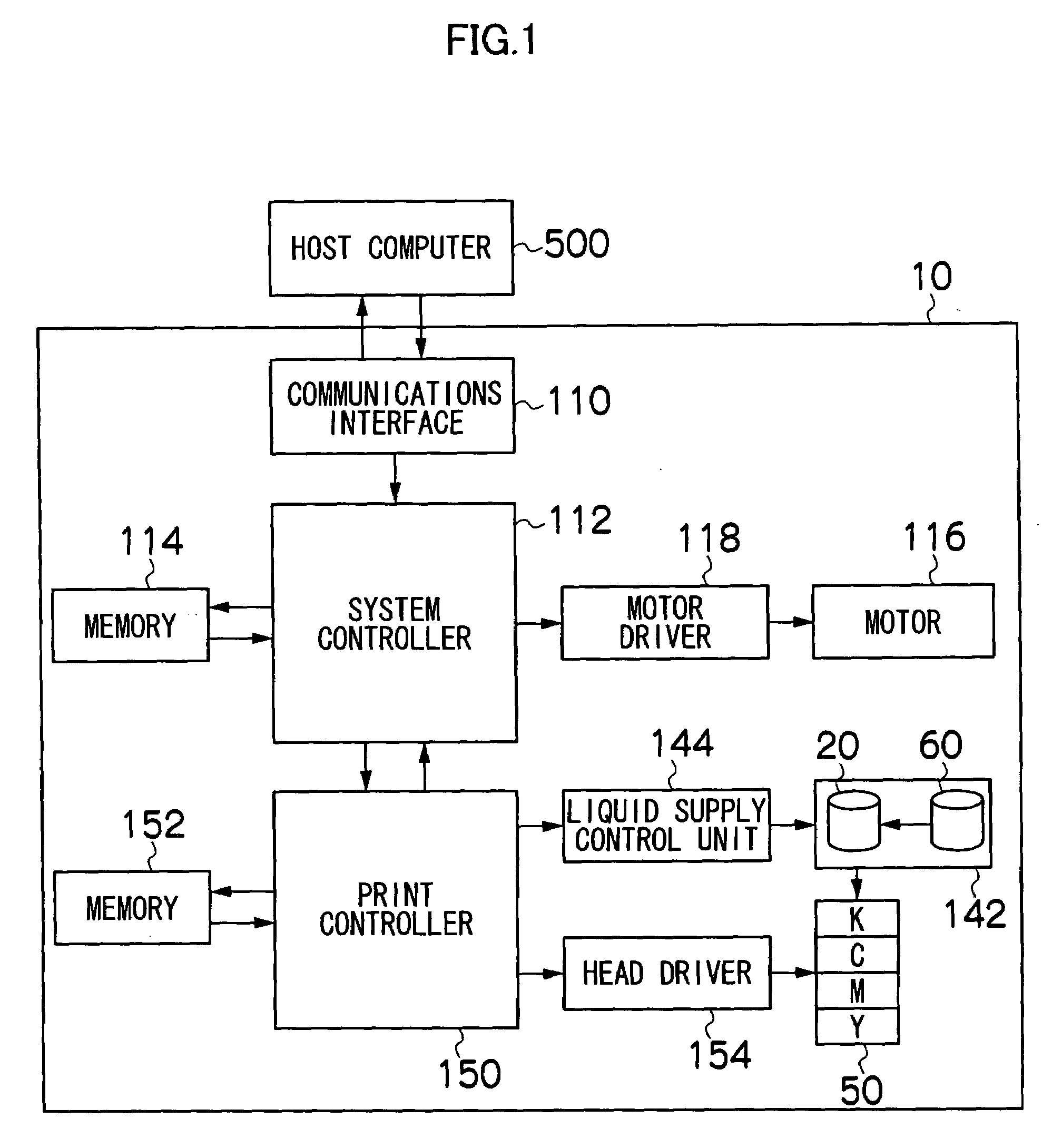

Liquid storage apparatus and image forming apparatus

InactiveUS20070280722A1Avoid it happening againAvoid print quality degradationTemperatue controlFlexible member pumpsHermetic sealImage formation

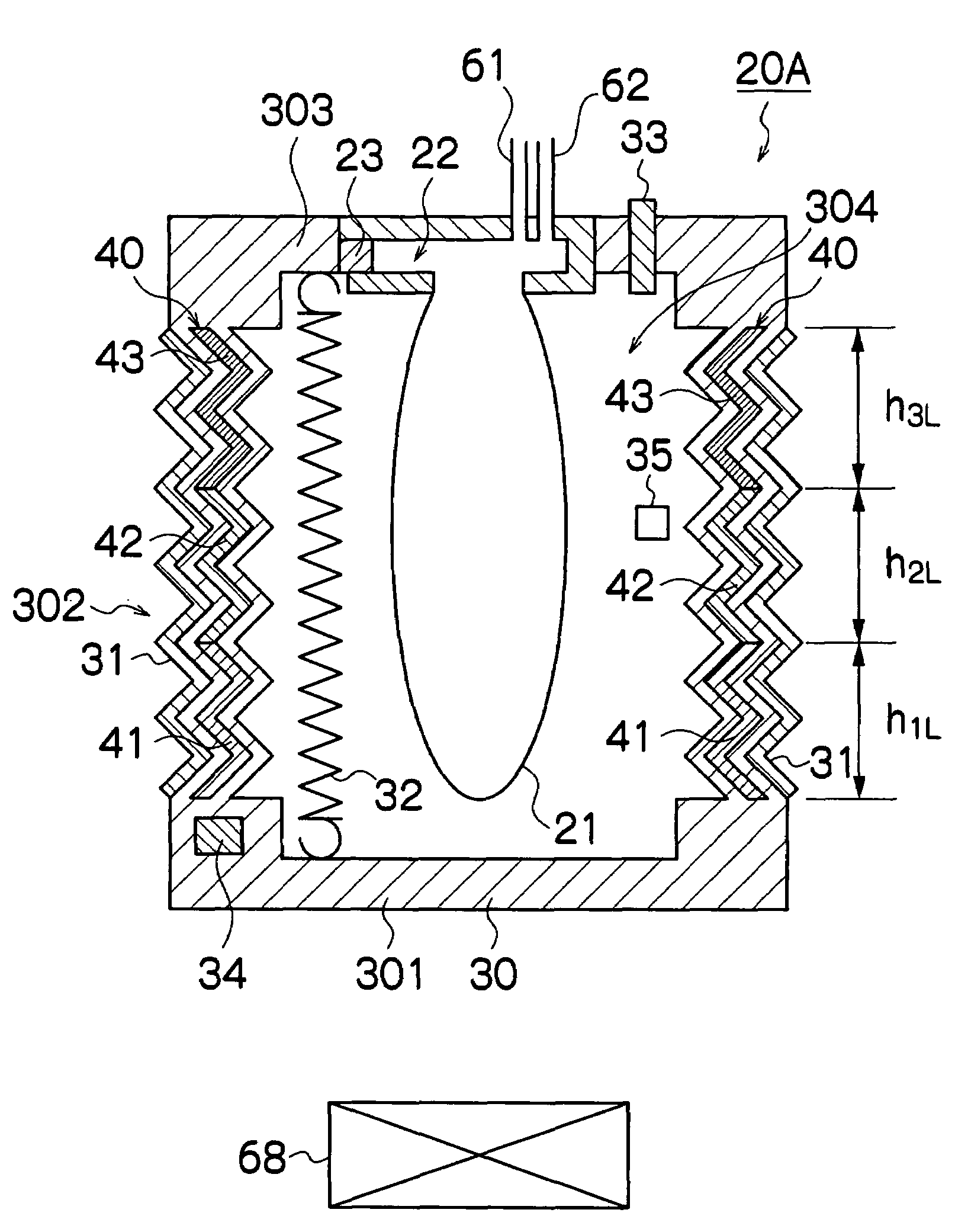

The liquid storage apparatus includes: a liquid storage chamber which is constituted by a flexible bag member and stores liquid; an exterior container which has walls constituted by a shape memory member and has a hermetically sealed space in which the liquid storage chamber is disposed, the shape memory member extending and contracting freely at temperatures not greater than a transformation temperature and recovering a memorized shape at temperatures not less than a shape recovery temperature; a forcing member which applies a contraction force to the walls of the exterior container in a direction in which the walls contract; and a temperature adjuster which adjusts a temperature of the shape memory member directly or indirectly so as to control a ratio of a portion of the shape memory member having temperatures not greater than the transformation temperature and deformed to a contracted shape by the contraction force of the forcing member and a ratio of a portion of the shape memory member having temperatures not less than the shape recovery temperature and recovering the memorized shape more extended than the contracted shape, so that a pressure in the liquid storage chamber is changed depending on a volume change of the exterior container due to deformation of the shape memory member.

Owner:FUJIFILM CORP

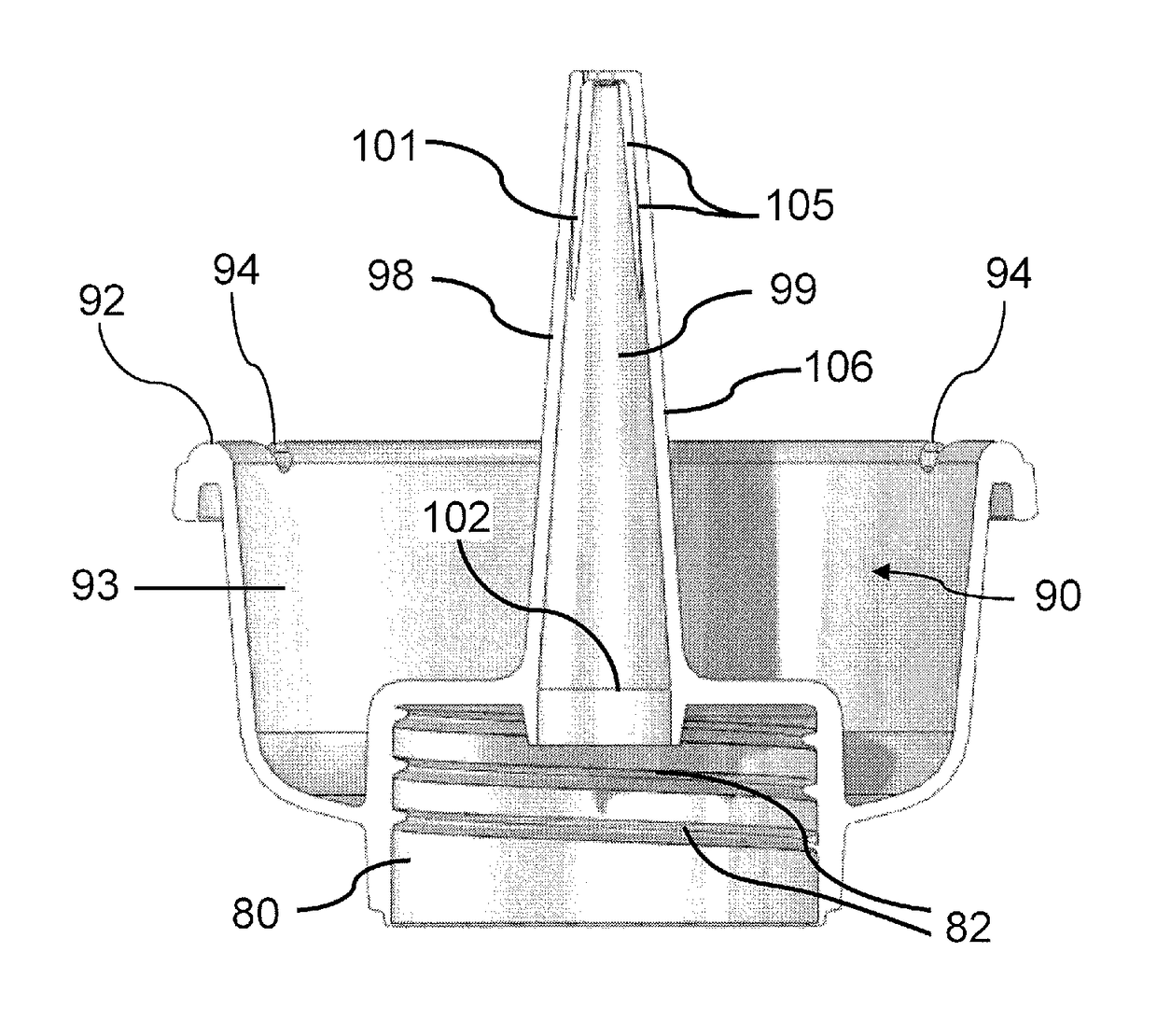

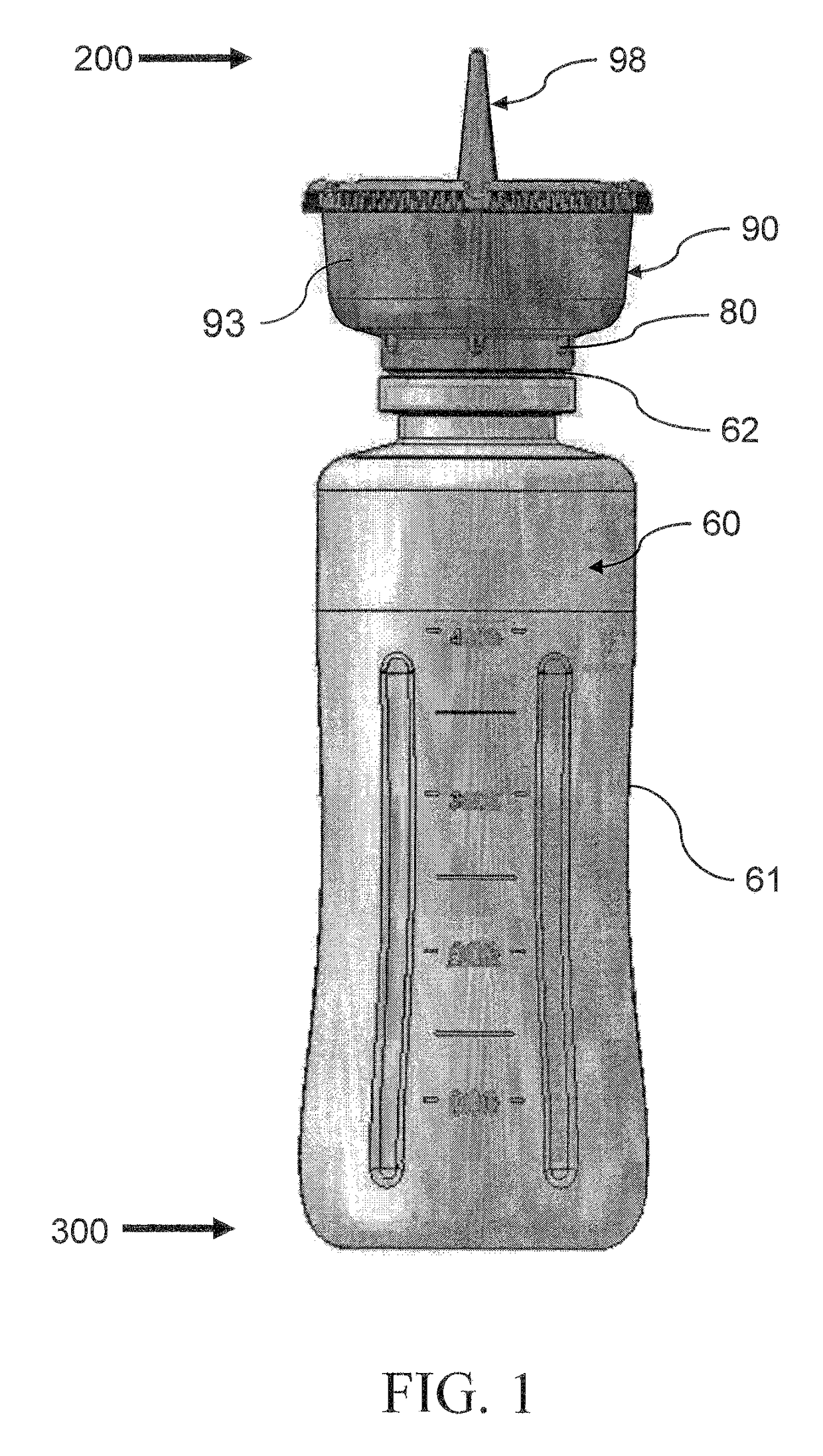

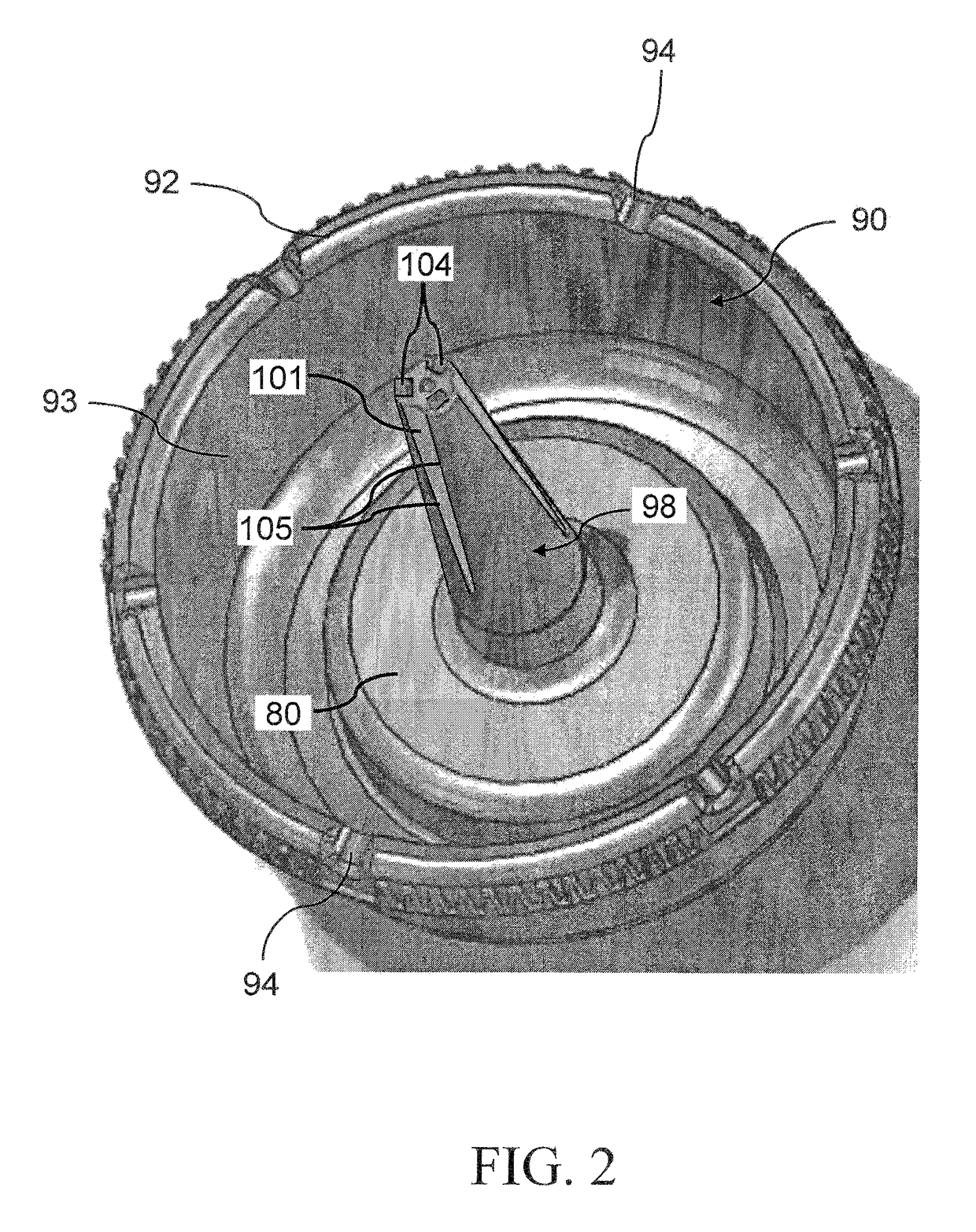

Device and Method for Abscess Irrigation

ActiveUS20120035559A1Inexpensive methodNovel, inexpensive, and highly effective methods and devicesCannulasEnemata/irrigatorsIRRIGATING SOLUTIONSPuncture Wound

The subject invention provides novel, inexpensive, and highly effective methods and devices for convenient and effective irrigation of abscesses, puncture wounds, and similar types of deep tissue wounds. In one embodiment the subject invention provides a discharge apparatus for a reservoir housing containing irrigation solution, wherein the discharge apparatus has a specifically designed nozzle for insertion into a wound opening and through which a sufficient volume of the irrigation solution can pass at an appropriate pressure.

Owner:INNOVATION TECH INC

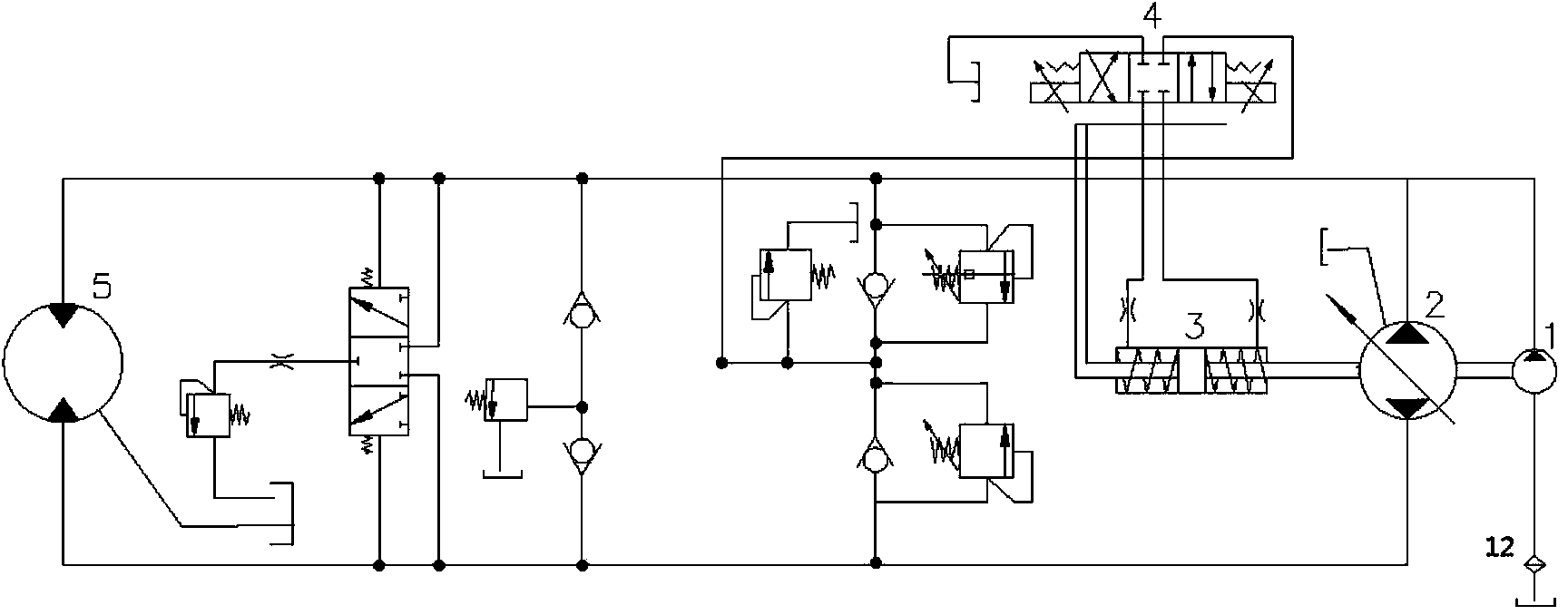

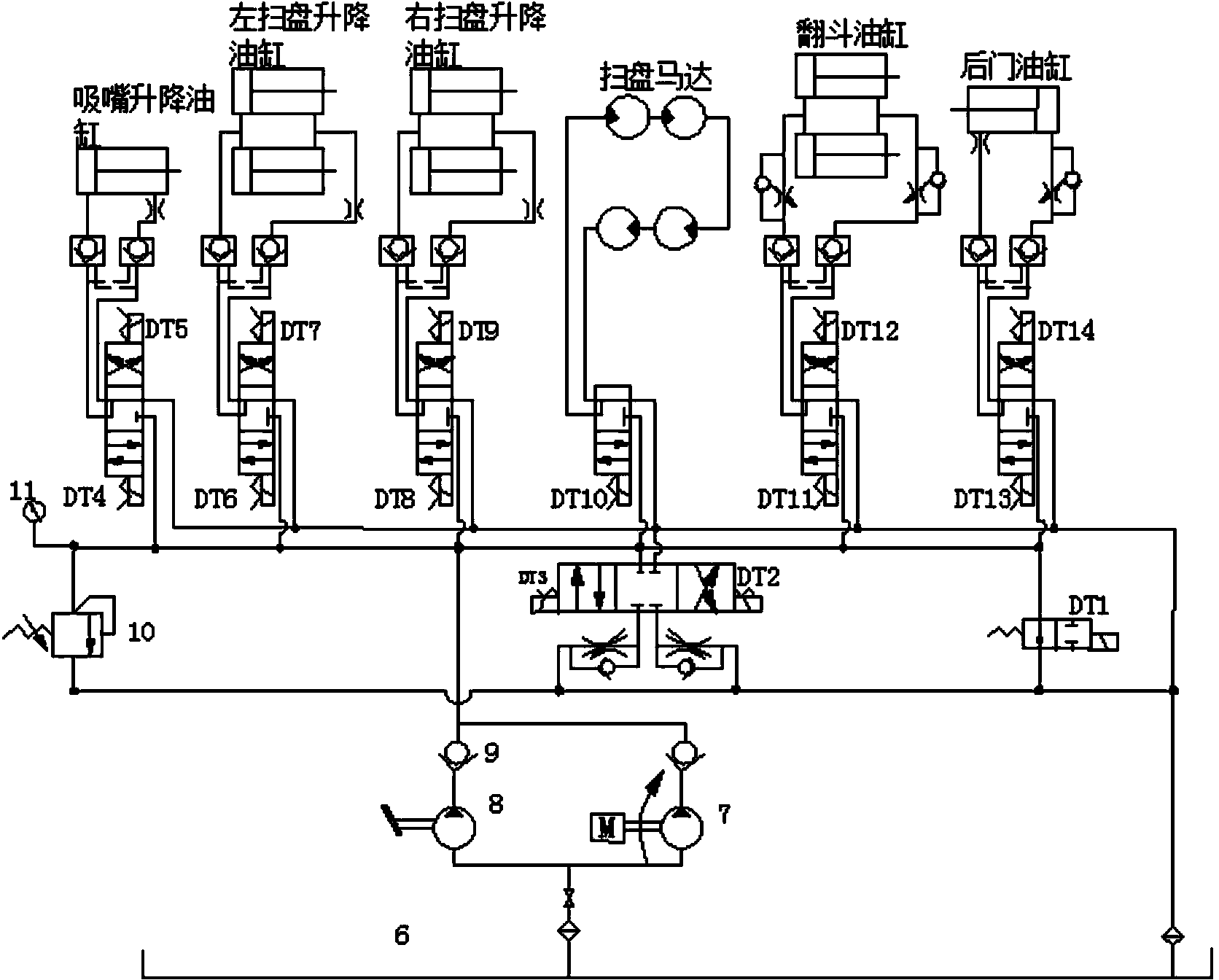

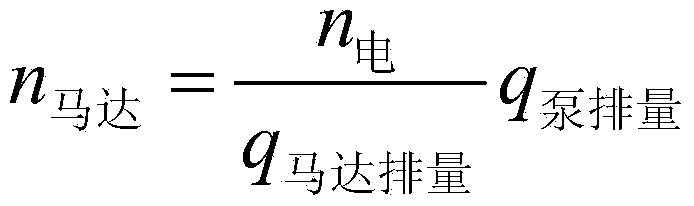

Hydraulic control system based on single-engine road sweeper

InactiveCN104033433ASolve the problem of being in a non-optimal economic zone for a long timePerformance is not affectedServomotorsRoad cleaningTransfer caseFour-way valve

A hydraulic control system based on a single-engine road sweeper comprises a walking hydraulic control system and a sweeping hydraulic control system. The walking hydraulic control system comprises a three-position four-way valve with the control end connected with an accelerator pedal, the output end of the three-position four-way valve is connected with a bidirectional variable pump through an electromagnetic floating valve, and the bidirectional variable pump is respectively connected with an oil inlet and an oil outlet of a bidirectional constant displacement motor to form a circulating loop. The sweeping hydraulic control system comprises an oil tank and transfer cases arranged in parallel, the transfer cases are controlled by two electromagnetic reversing valves with the opposite control actions, the oil tank is connected with the transfer cases through pipelines, and hydraulic pumps are arranged on the connecting pipelines. A disc sweeping motor is controlled by an independent motor electromagnetic reversing valve, and two electromagnetic reversing valves used for flow division are arranged between the electromagnetic reversing valve and the oil tank in parallel. An overflow valve and an unloading electromagnetic reversing valve are respectively connected between the oil tank and the transfer cases. An auxiliary engine is eliminated, the habit of a drive for driving a vehicle is not changed, and a large amount of fuel is saved.

Owner:CHANGAN UNIV

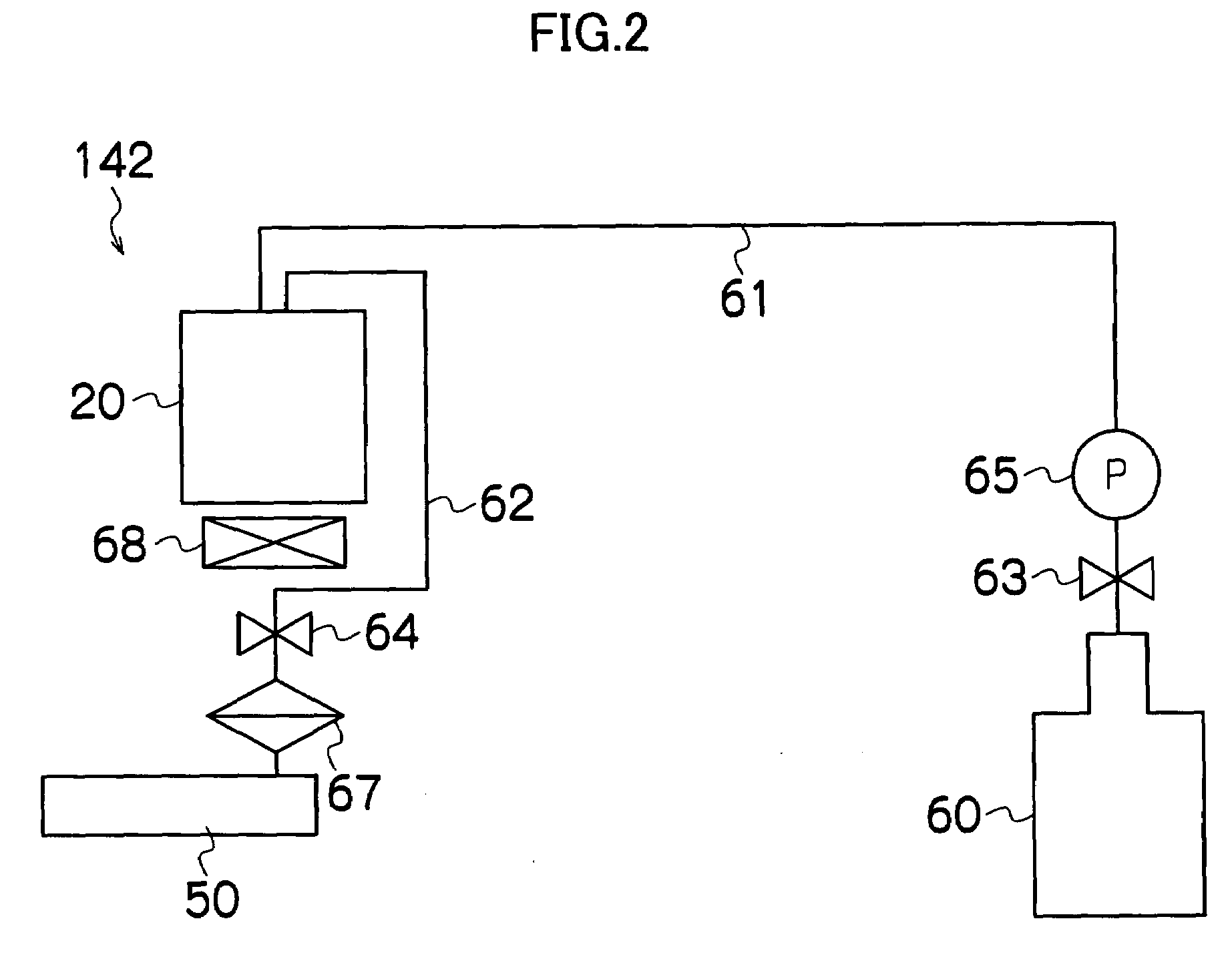

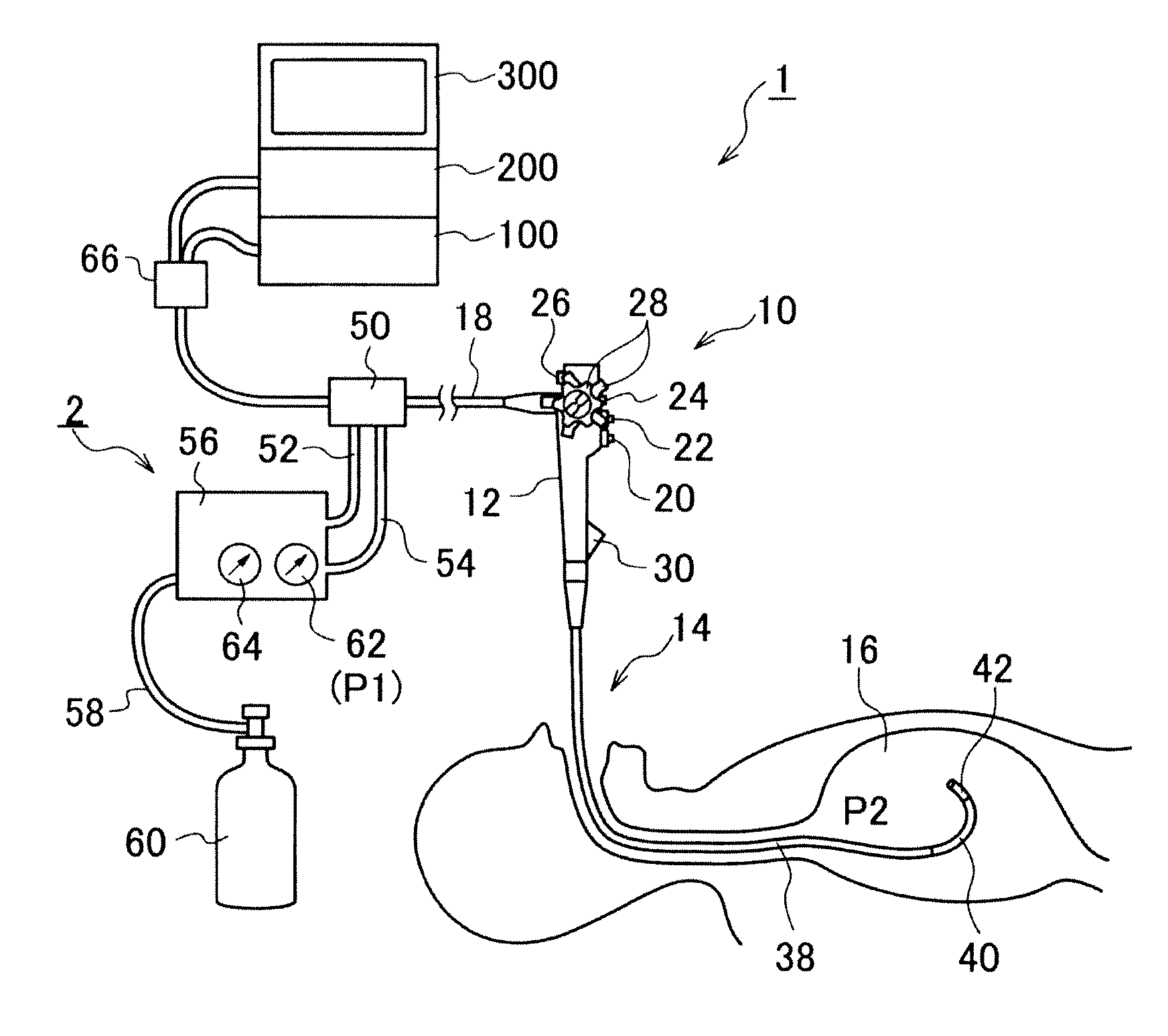

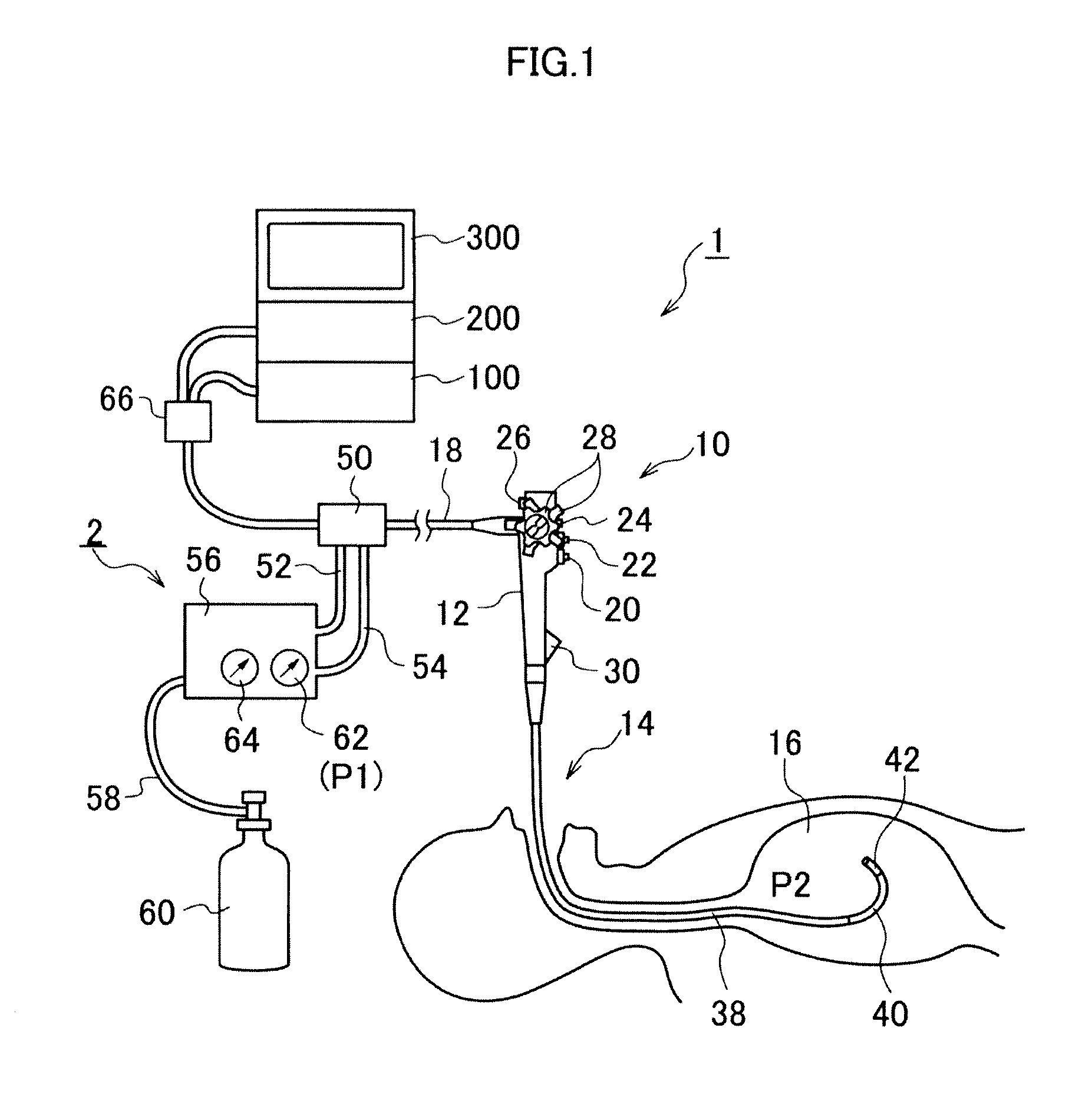

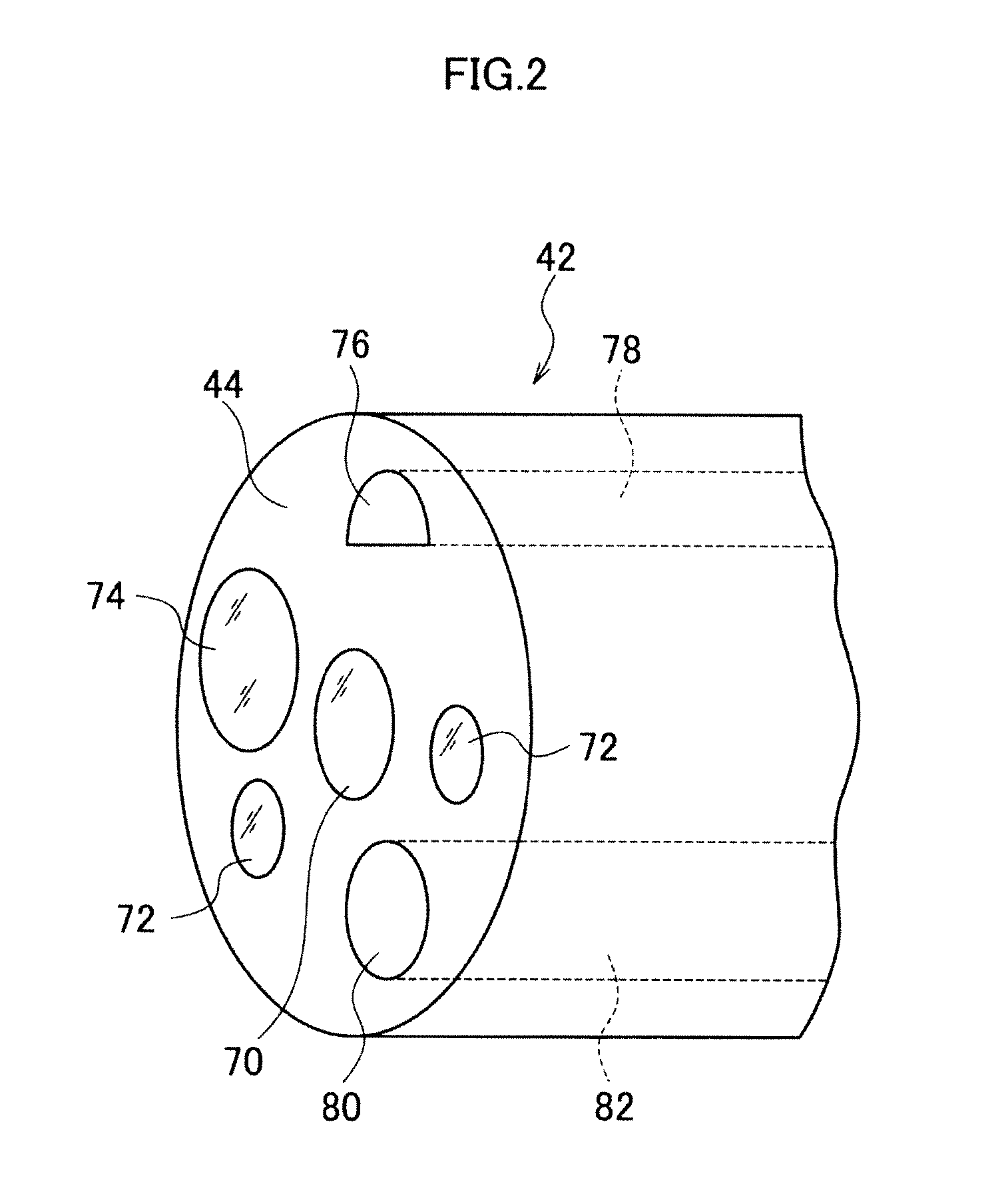

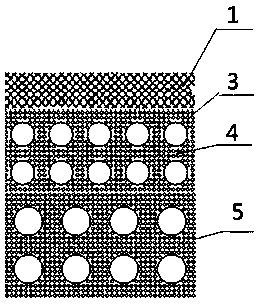

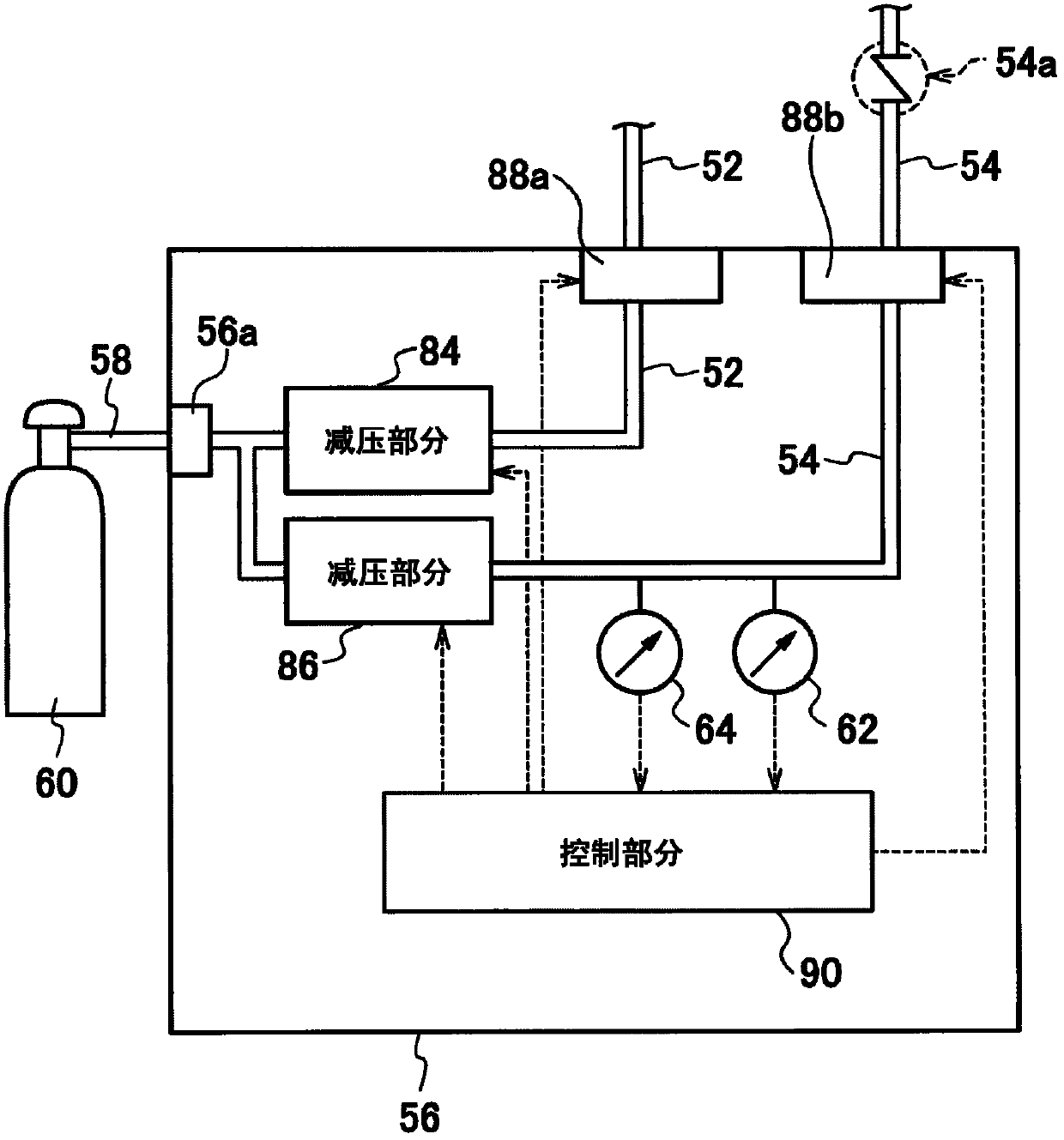

Endoscope air-supply system

InactiveUS20120253124A1Accurate measurementAppropriate pressureSurgeryEndoscopesMeasurement deviceEndoscope

An endoscope air-supply system comprising: a gas supply device which supplies predetermined gas to a lumen of a subject through an air-supply duct; a pressure measurement device which measures pressure in the lumen and which is connected through a duct for pressure measurement communicating with the lumen; a flushing device which supplies gas for flushing to the duct for pressure measurement; and an instruction device which instructs the pressure measurement device to perform pressure measurement and which instructs the flushing device to supply the gas for flushing in synchronism with the pressure measurement by the pressure measurement device.

Owner:FUJIFILM CORP +1

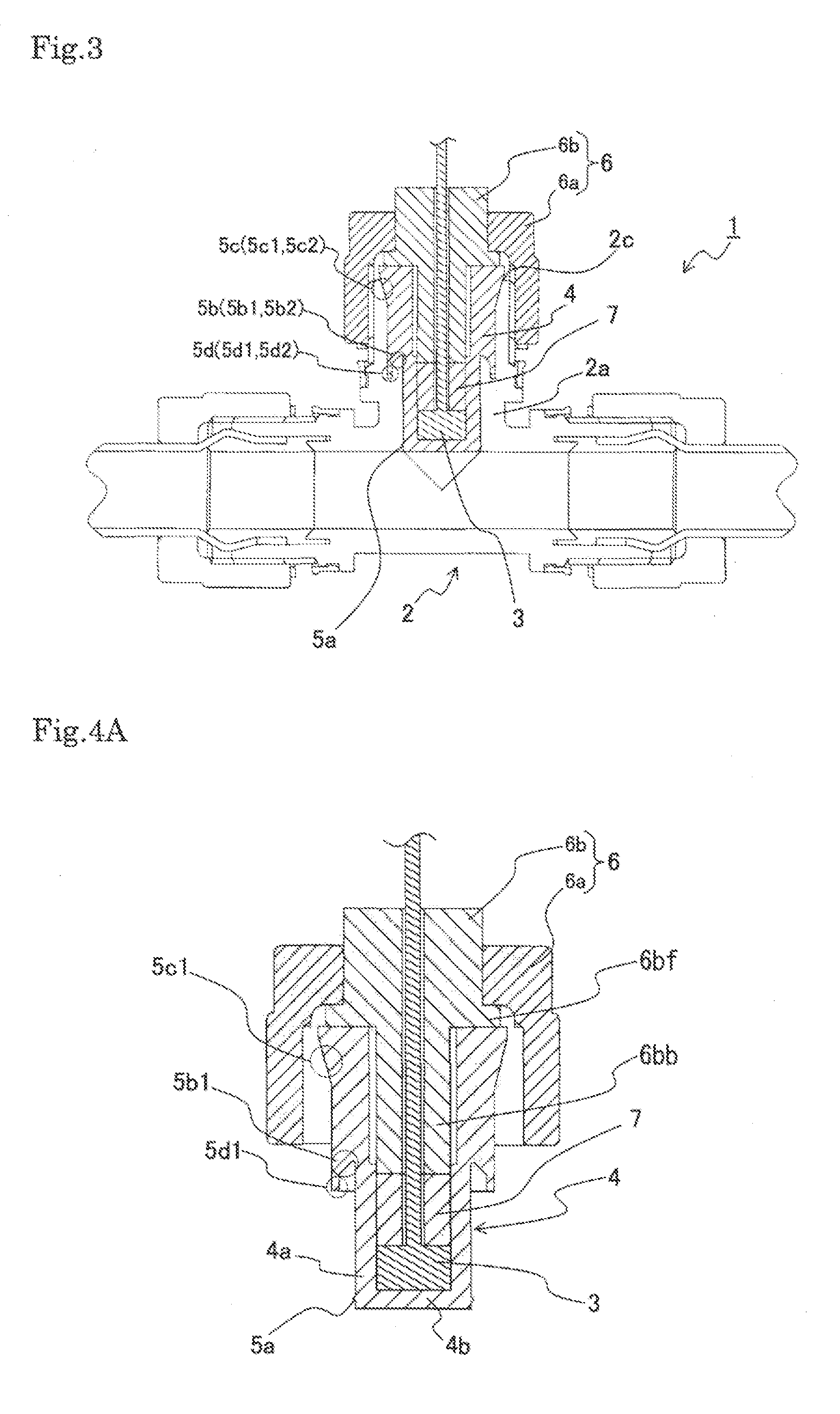

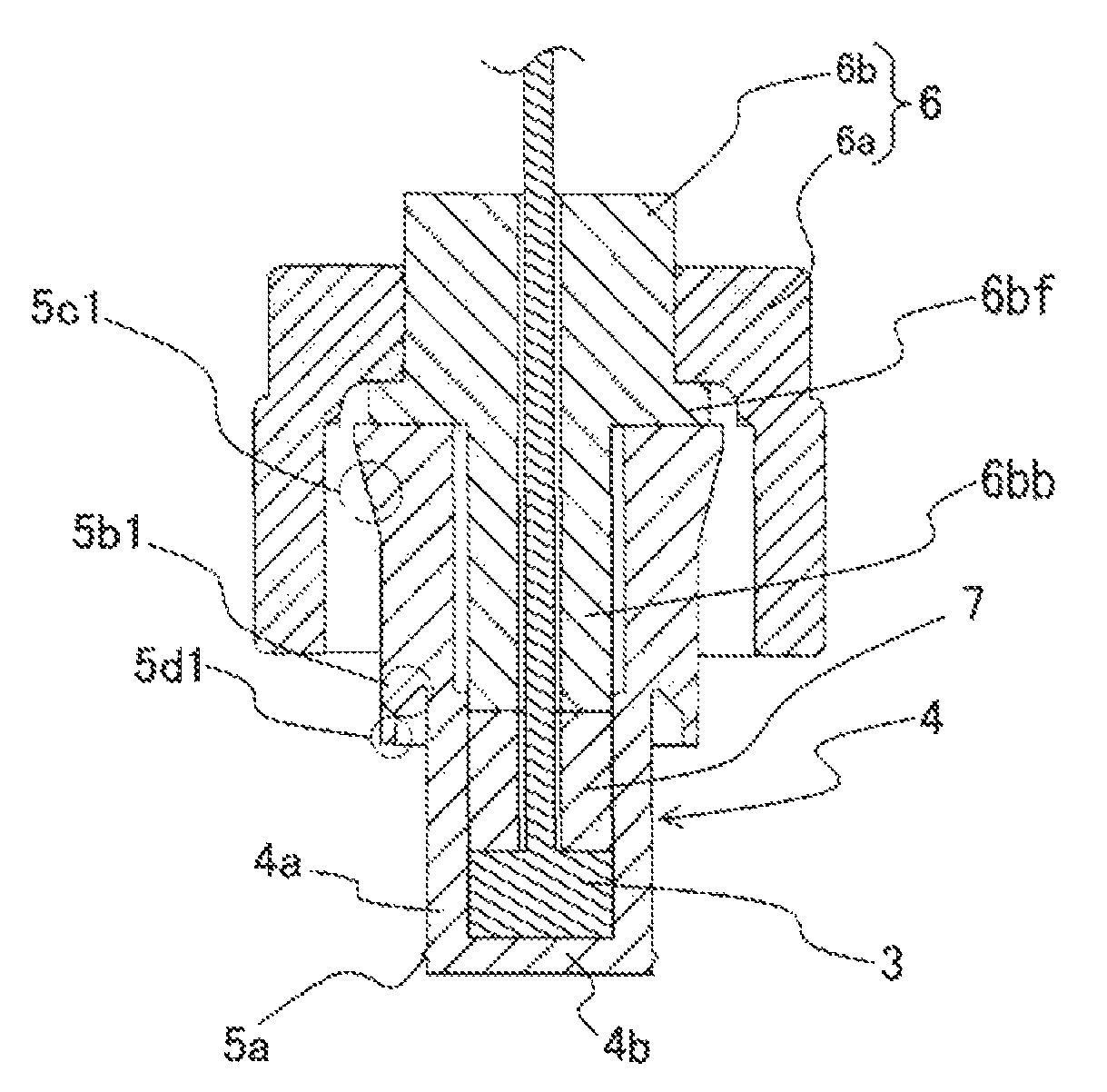

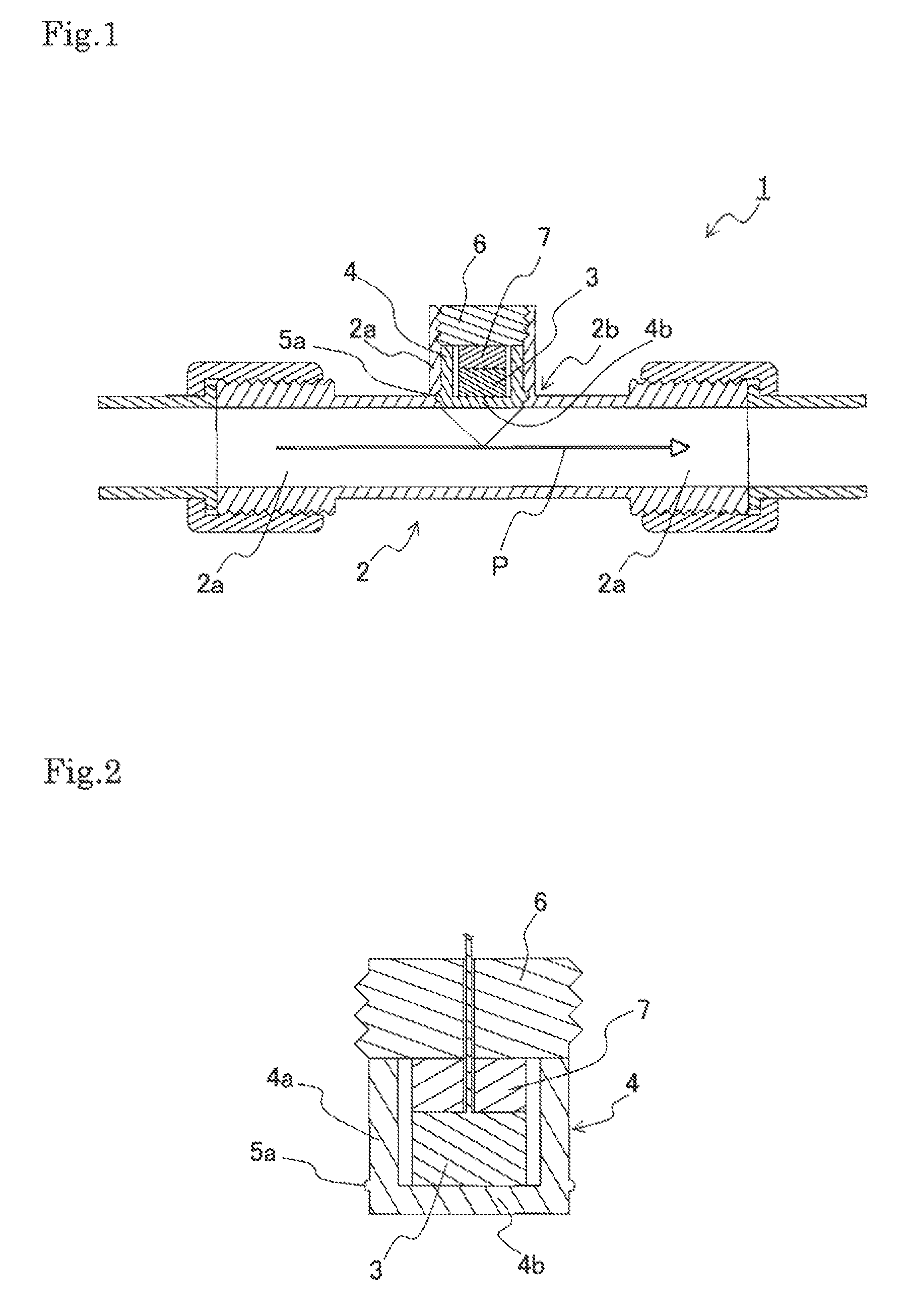

Fluid measurement sensor attachment structure

ActiveUS20130213130A1Ensure correct executionReduce capacityMeasurement apparatus componentsFluid pressure measurementEngineering

The present invention provides a fluid measurement sensor attachment structure in which a fluid measurement sensor is attached to a branch pipe among three or more branch pipes branched from a pipe, thereby measuring properties of a fluid flowing through a flow path that is formed by remaining branch pipes, comprising a sleeve that can accommodate the fluid measurement sensor, wherein the sleeve is a member in a shape of a tumbler including a circumferential wall that is substantially cylindrical and a protective wall that is disposed at one end of the circumferential wall and that does not disturb a function of the sensor, a seal lip is disposed on the circumferential wall near the protective wall, and the sleeve is inserted into the branch pipe such that the protective wall is positioned near a base end of the branch pipes.

Owner:NIPPON PILLAR PACKING CO LTD

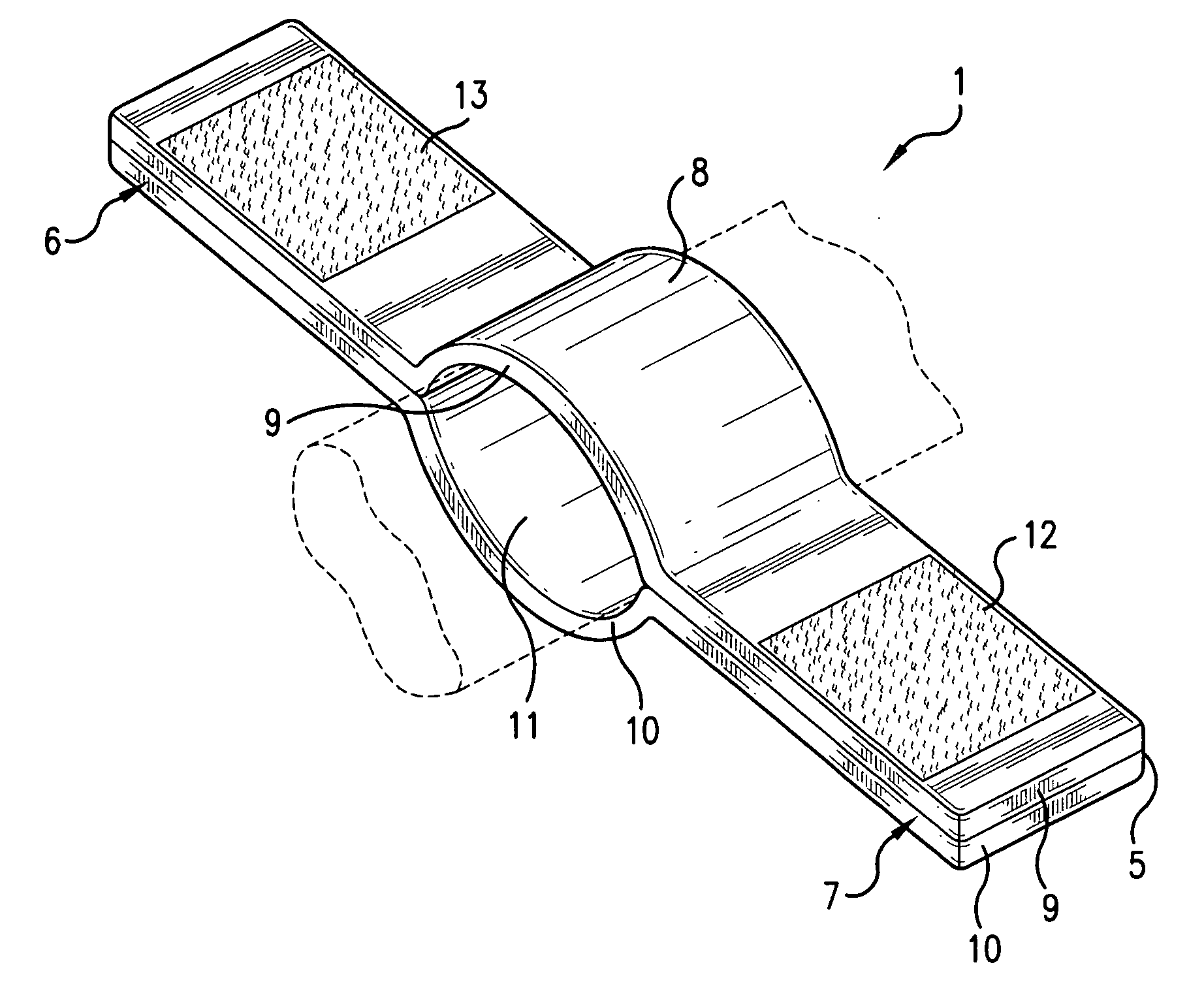

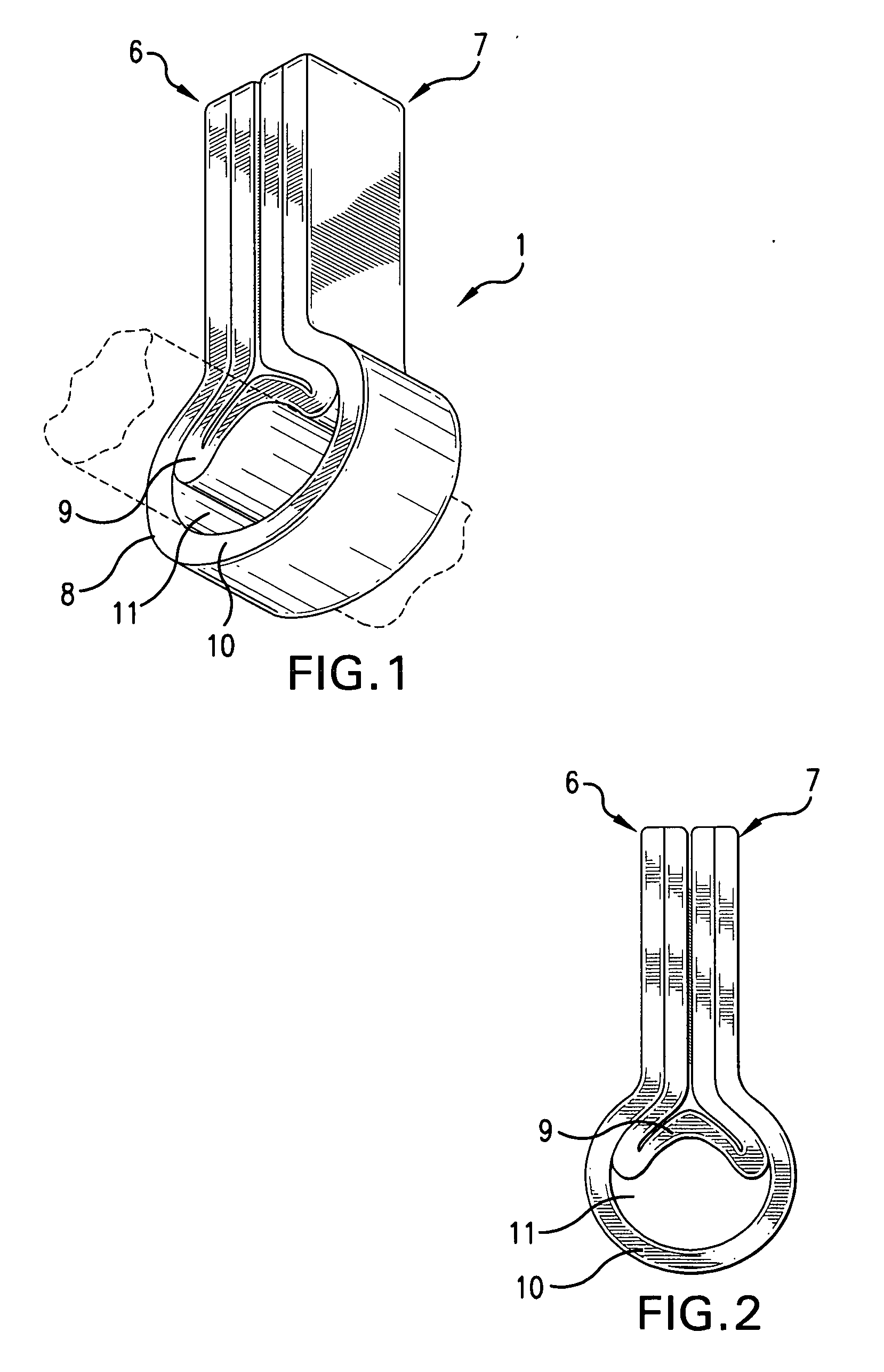

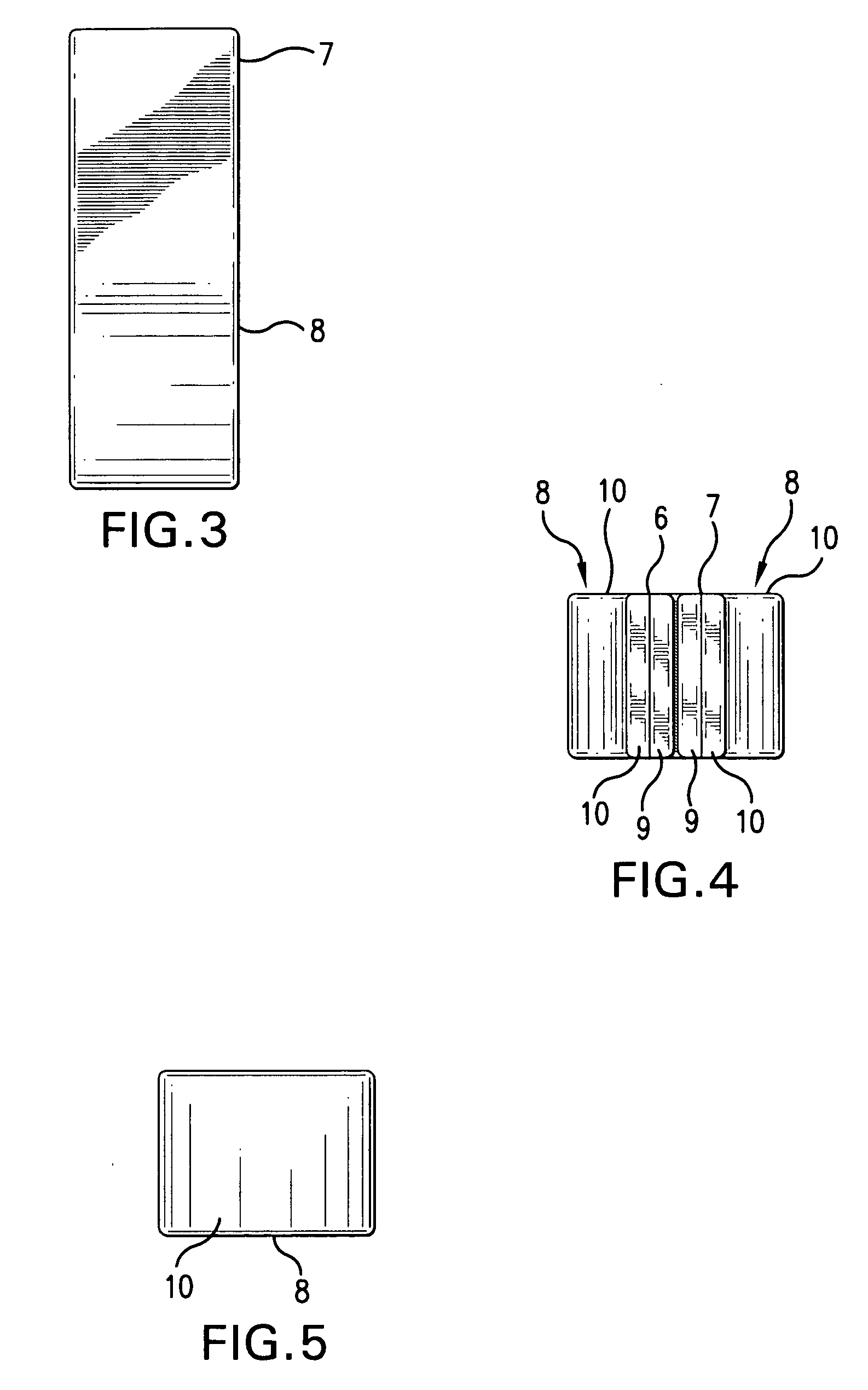

Body or plant part dressing

A dressing having a flexible sleeve shaped to accommodate a substantially cylindrical body or plant portion, the sleeve having a lining which is substantially non-adherent to the body or plant part being bandaged and having a peripheral securement means which attaches two peripheral portions to each other without those portions being circumferentially adhered to the sleeve portion.

Owner:JENNINGS SPRING BARBARA BROOKE

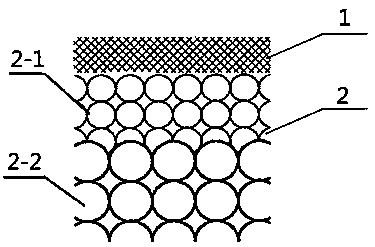

Scaffold for repairing articular subchondral bone

ActiveCN108201635AGood mechanical propertiesHigh strengthTissue regenerationProsthesisMaterial DesignMetallic materials

The invention discloses a scaffold for repairing an articular subchondral bone. The scaffold is composed of a porous salt layer and a porous metal material layer from top to bottom. The porous metal material layer is a gradient porous metal material layer. The scaffold realizes articular subchondral bone bionic simulation. Through the scaffold, the articular subchondral bone can bear complex and large load, has good buffering functions, realizes good force transmission, has the strength higher than that of the porous non-metallic scaffold and solves the problem that the single-pore size high-porosity porous metal material has poor rigidity. The porous salt layer can be fused with the cartilage layer. The scaffold has good transfusion characteristics and a pore size conducive to cell and nutrient solution migration and keeping of appropriate pressure of the liquid in the joint. The pore size and material design of the scaffold are conducive to migration, colonization, differentiation and proliferation and is a real articular subchondral bone repair and regeneration scaffold.

Owner:CHONGQING RUNZE PHARM CO LTD

Endoscope air-supply system

When observation or treatment in a lumen is performed by an endoscope, pressure in the lumen is measured precisely and air supply is performed so as to keep the pressure appropriate. An endoscope air-supply system is provided which includes a gas supply device which supplies predetermined gas to a lumen of a subject through an air-supply duct; a pressure measurement device which measures pressure in the lumen and which is connected through a duct for pressure measurement communicating with the lumen; a flushing device which supplies gas for flushing to the duct for pressure measurement; and an instruction device which instructs the pressure measurement device to perform pressure measurement and which instructs the flushing device to supply the gas for flushing in synchronism with the pressure measurement by the pressure measurement device.

Owner:FUJIFILM CORP +1

Body or plant part dressing

ActiveUS20090317454A1Good hemostasisEasy to disassembleHead bandagesFinger bandagesMedicinePlant Part

A dressing having a flexible sleeve shaped to accommodate a substantially cylindrical body or plant portion, the sleeve having a lining which is substantially non-adherent to the body or plant part being bandaged and having a peripheral securement means which attaches two peripheral portions to each other without those portions being circumferentially adhered to the sleeve portion.

Owner:JENNINGS SPRING BARBARA BROOKE

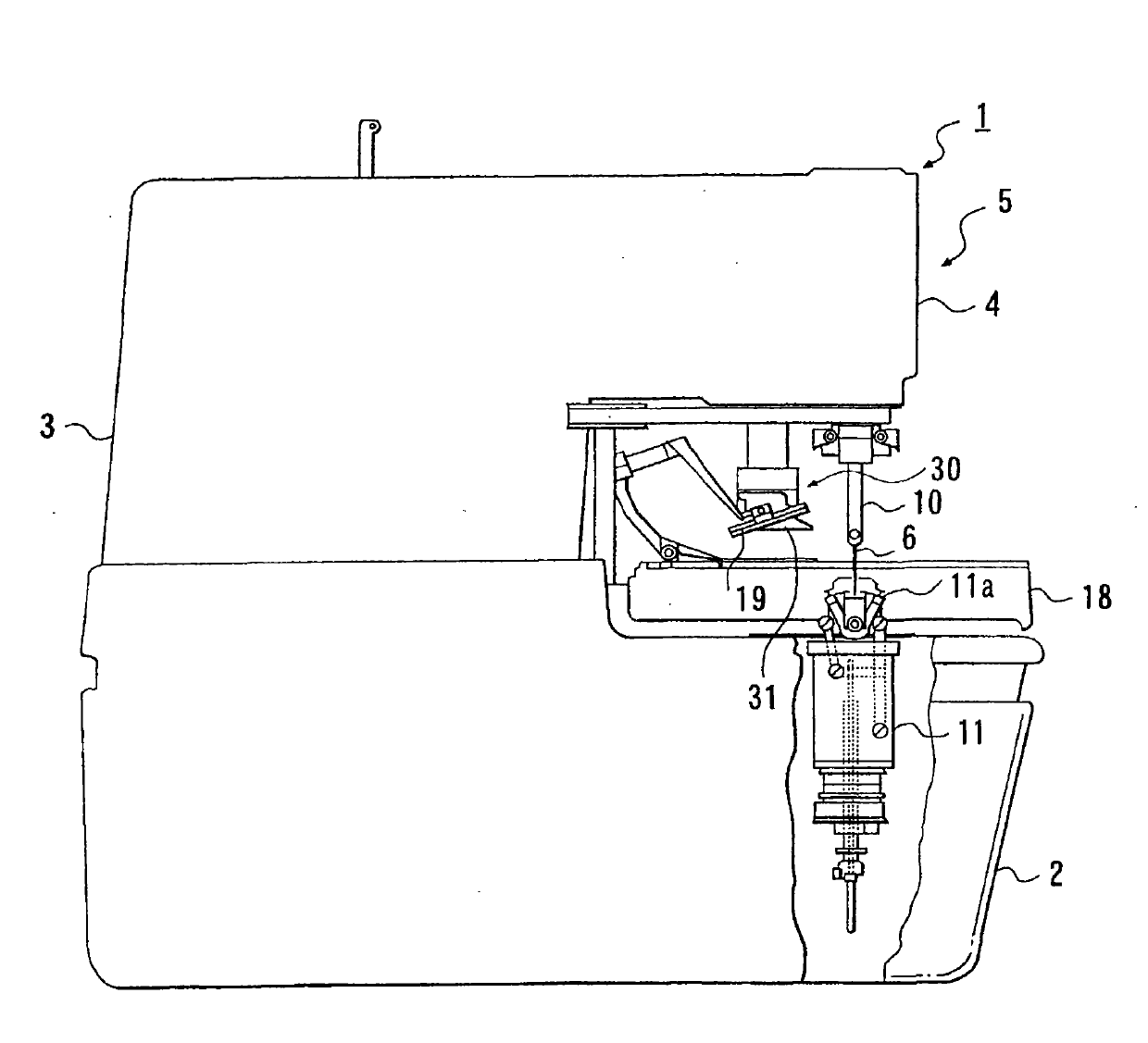

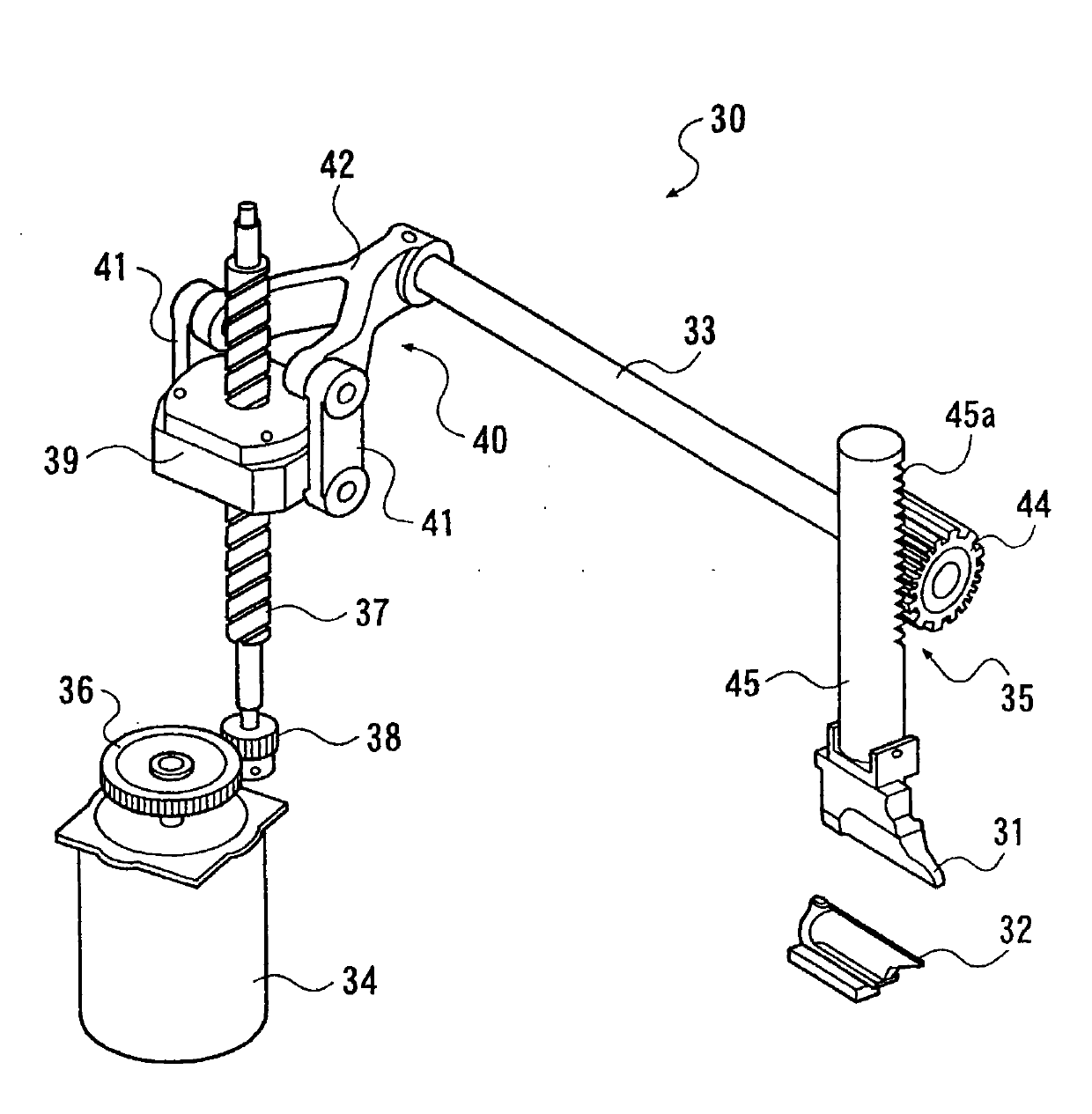

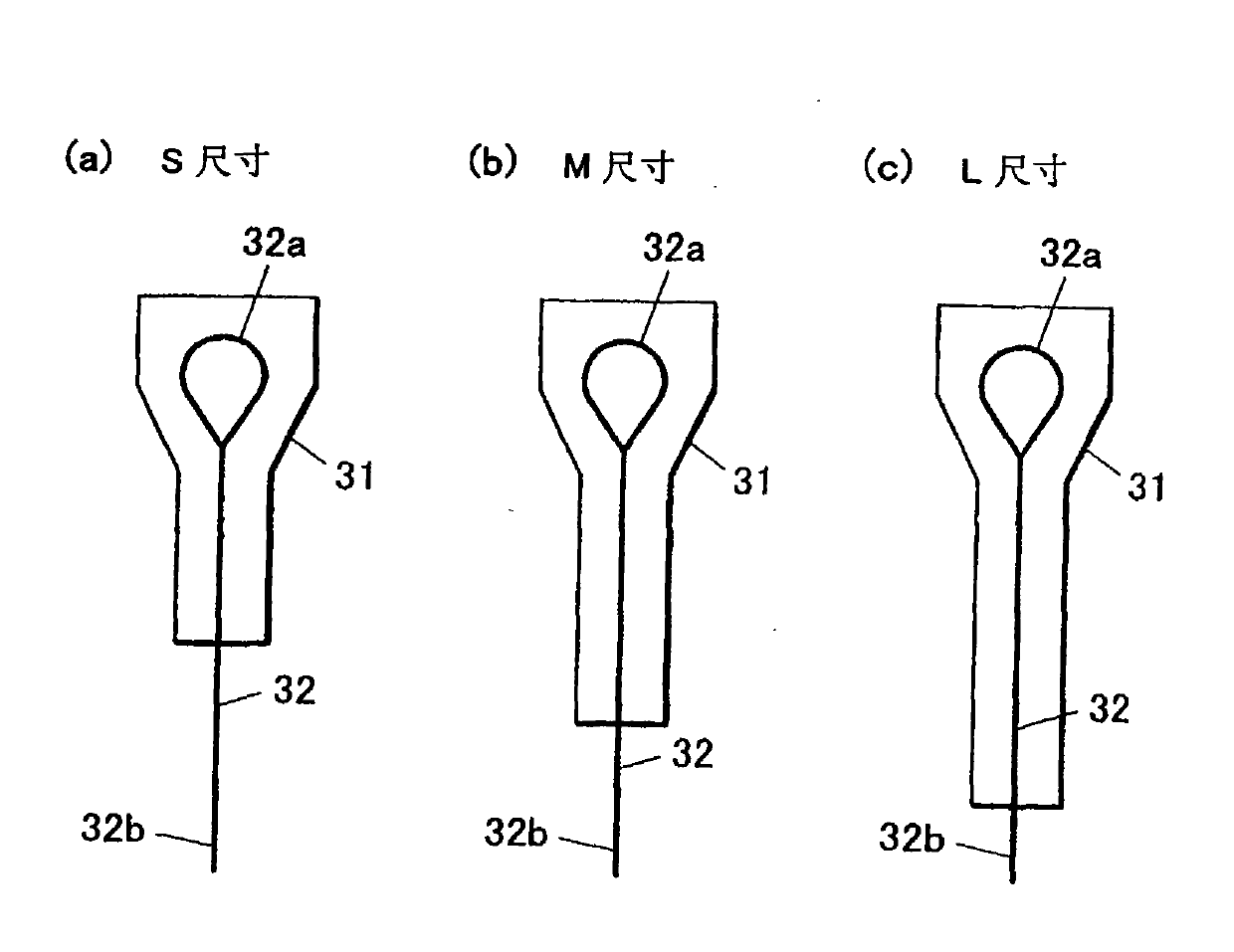

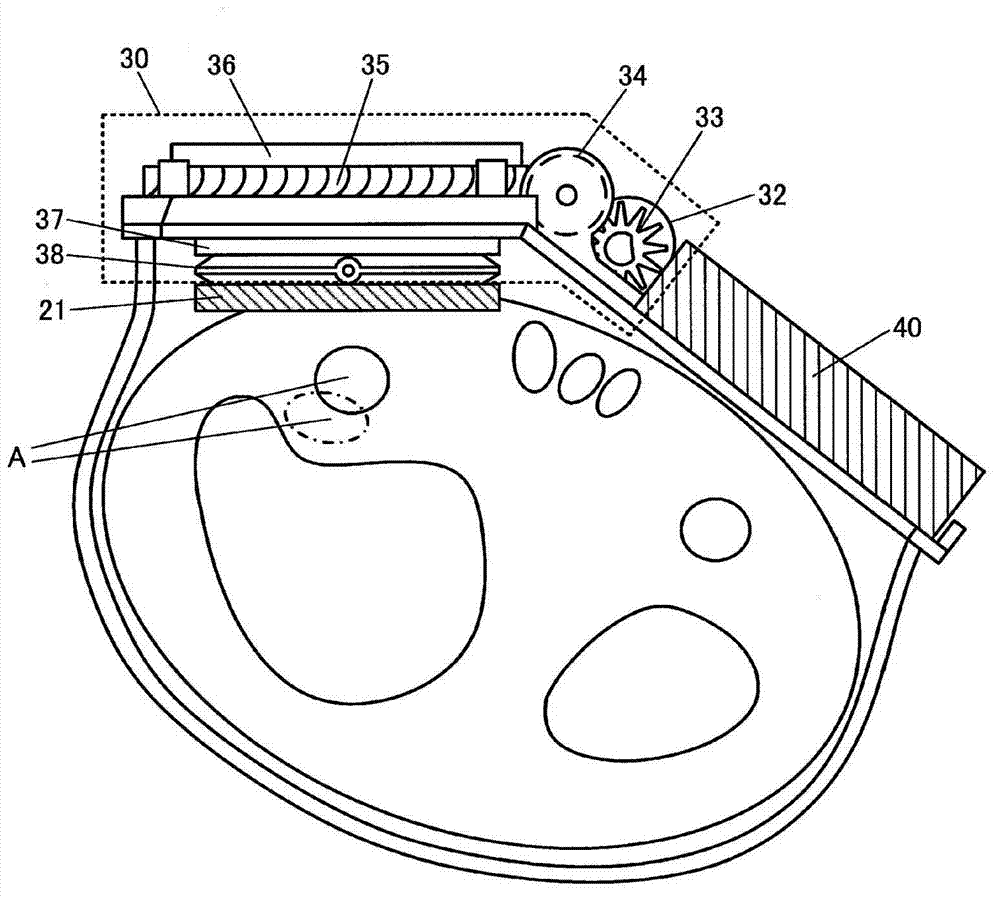

Cloth cutting device of hole stitching machine

ActiveCN102021765ARelaxed contact pressurePrevent each other from damagingProgramme-controlled sewing machinesWorkpiece carriersEngineeringLow speed

The invention relates to a cloth cutting device of hole stitching machines, wherein period time is not lost and right pressing force is easily to be set.The cloth cutting device (30) comprises a knife (32), a knife receiver (31), a moving mechanism (35) which moves the knife (32) or the knife receiver (31), a pulse motor (34) which serves as a drive source of the movement of the knife or the knife receiver, a rotation amount detector (55) which detects a rotation amount of the pulse motor, and a controller (50) which controls the pulse motor.; The controller executes a control to switch the movement of the knife or the knife receiver to be low speed on its way, and includes a cutting control means (50c) which controls the pulse motor to stop driving if a deviation determining means determines that the deviation of the pulse motor reaches the set value, and a current control means (50c) which limits, during the low-speed movement, a current value applied to the pulse motor to be lower than that during a high-speed movement.

Owner:JUKI CORP

Scaffold for repairing joints

ActiveCN108201634AImprove mechanical propertiesImprove seepage characteristicsTissue regenerationProsthesisSubchondral boneMolecular materials

The invention discloses a scaffold for repairing joints. The scaffold is composed of a porous polymer material layer, a porous salt layer and a porous metal material layer from top to bottom. Throughthe biomimetic means and reasonable design of the porous polymer material layer, porous salt layer and porous metal material structures, the subchondral bone and articular cartilage are simulated, good force transmission is realized, excellent mechanical properties and good percolation characteristics are obtained, colonization, differentiation and proliferation of chondrocytes are promoted and the scaffold is an excellent scaffold for cartilage-subchondral bone repair.

Owner:CHONGQING RUNZE PHARM CO LTD

Assembly for deploying a payload from a submarine

A submarine (1) has an assembly (3) for deploying a life raft (5), the assembly (3) being located in a well (7) formed outside the submarine's pressure hull (11). The assembly includes a pressure vessel (4) for storing the life raft (5) in a pressurized state. To deploy underwater, a lid (71) covering an opening to the well (7) is released to permit the assembly (3), which is buoyant, to ascend towards the water surface. A sensor (43) determines proximity to the water surface, whereby a pneumatic ram (42) in the pressure vessel is activated to eject the life raft (5) from the pressure vessel (4).

Owner:BABCOCK IP MANAGEMENT NUMBER ONE LTD

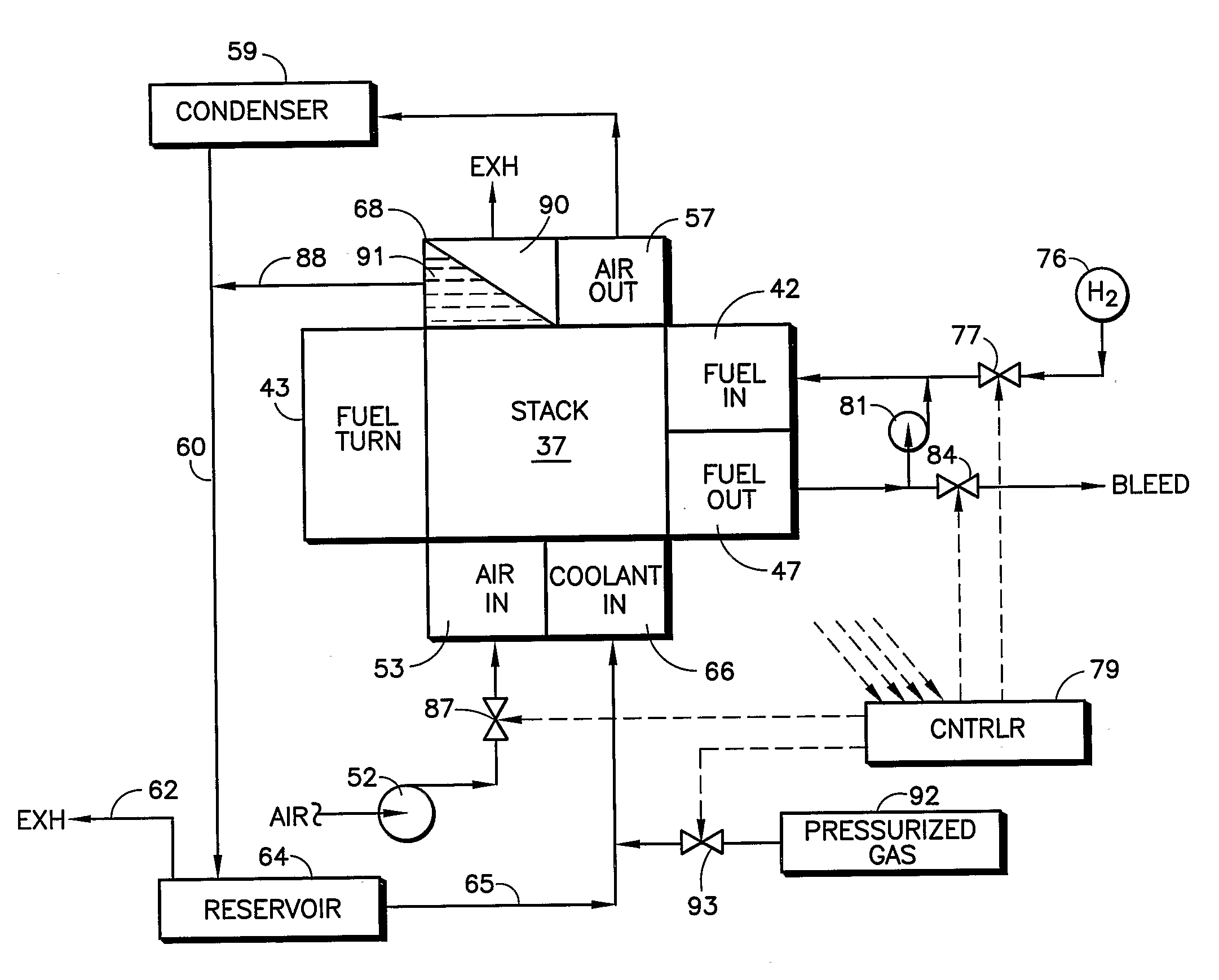

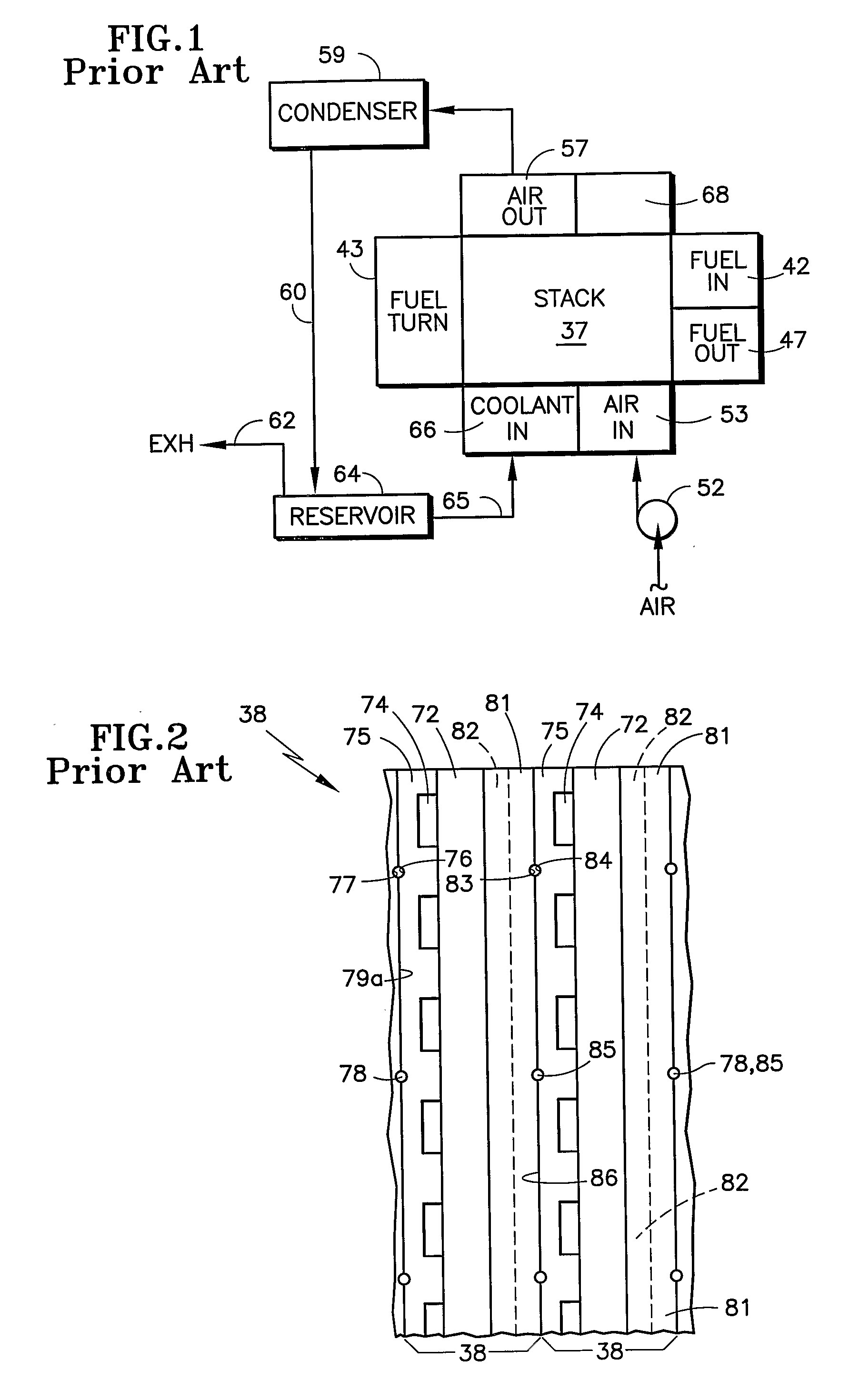

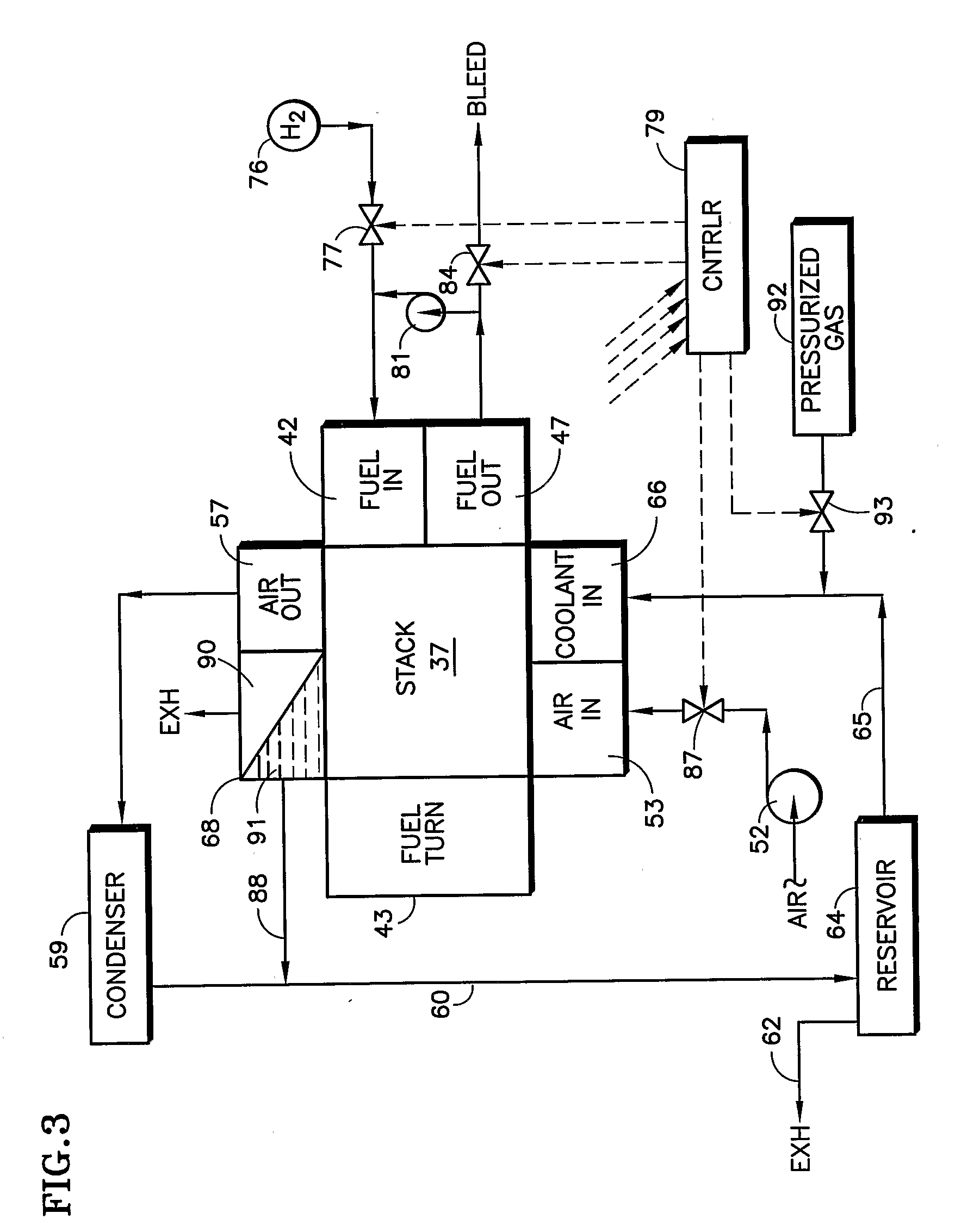

Circulation of Gas-Entrained Fuel Cell Coolant

ActiveUS20090011288A1Excessive ingestionIncrease moistureFuel cell heat exchangeWater management in fuel cellsHydrogenFuel cells

Coolant velocity greater than zero everywhere within the coolant channels (78, 85) of fuel cells (38) in a fuel cell stack (37) is assured by providing a flow of gas in the coolant channels, the flow being created by gas pressure from a source (92) of pressurized gas, an oxidant reactant air pump (52), a source (75) of hydrogen-containing fuel, or the fuel outlet (47), or the outflow of a condenser (59). Positive pressure may be applied to the coolant inlet (66) or negative pressure from an eductor (97) may be applied to a gas outlet (90) of the coolant channels, or both. Using gas to induce flow within the coolant channels eliminates the need for a bubble-clearing liquid pump and reduces liquid inventory and other plumbing; this makes the fuel cell power plant more freeze tolerant. Biphase flow from the condenser, which may be a vehicle radiator (120), renders the coolant return flow more freeze tolerant. Separate cooler plates (122) may be used with a coolant management system (125).

Owner:AUDI AG

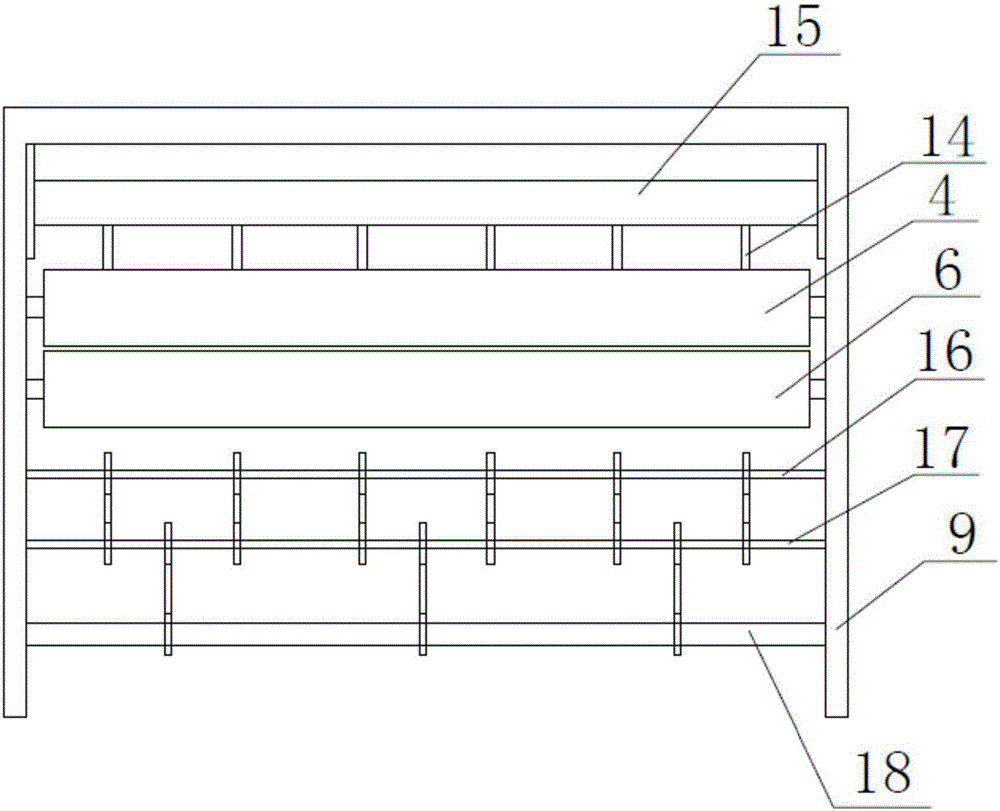

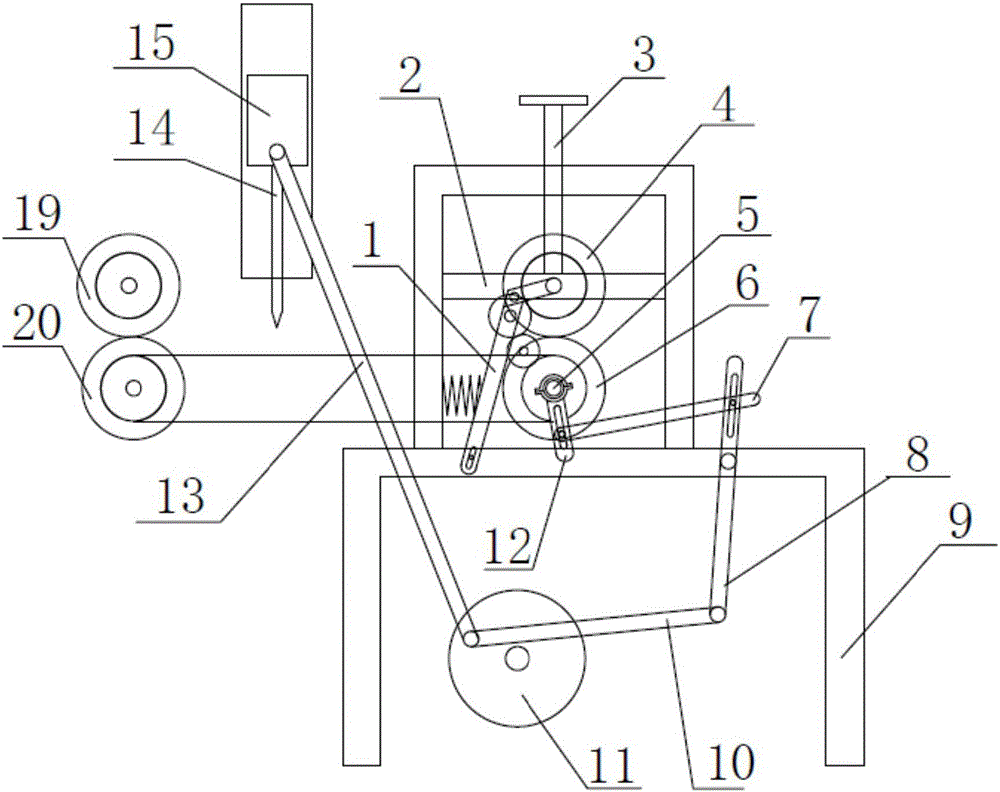

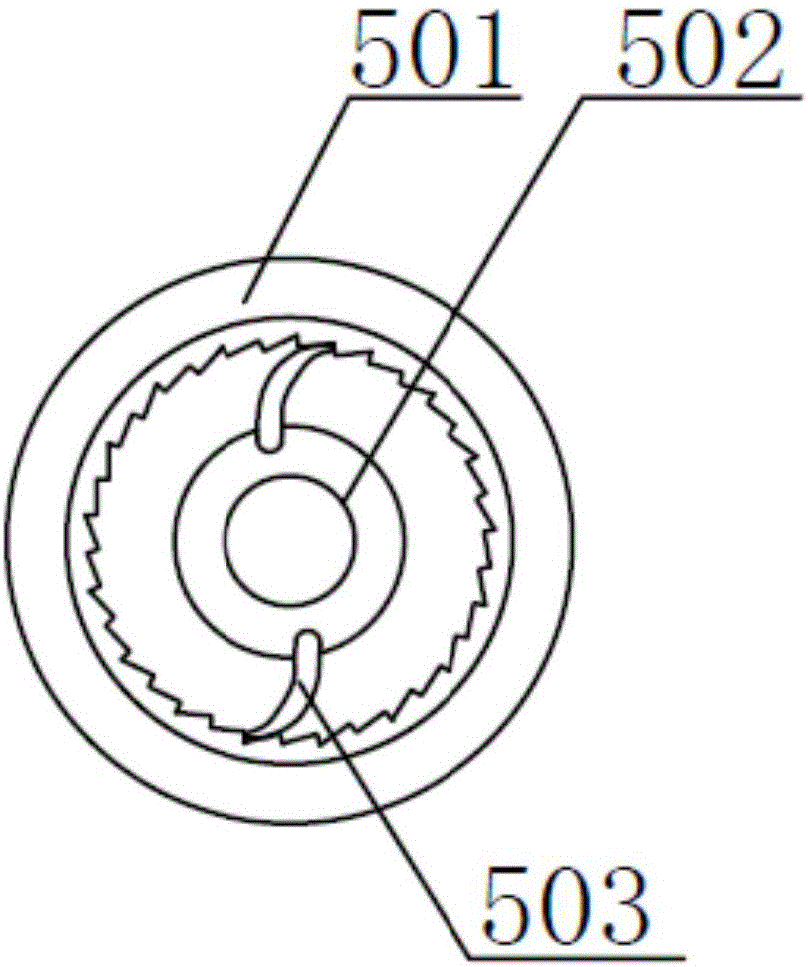

Quilting machine

InactiveCN106835511AEven stitchesSimple structureWork-feeding meansSewing-machine control devicesDrive wheelDrive shaft

The invention provides a quilting machine, which includes a frame, a feeding device, a sewing needle device and a feeding roller adjustment device, and the feeding device includes a driving wheel, a first feeding roller, a second feeding roller, a first connecting rod, a second The two connecting rods, the first swing rod and the second swing rod drive the first feeding roller to rotate through the first connecting rod, the second connecting rod, the first swing rod and the second swing rod, and the ratchet is connected to the first feeding roller, The second feeding roller is arranged above the first feeding roller, and the sewing needle device includes a driving shaft, an intermediate shaft, a shuttle shaft, a third connecting rod, a beam and a needle, and the driving shaft, the intermediate shaft and the shuttle shaft all rotate Installed on the frame, the drive shaft is connected to the intermediate shaft through a sprocket, the intermediate shaft is connected to the shuttle shaft through a sprocket, a hook is provided on the shuttle shaft, and a beam is provided directly above the shuttle shaft. The third connecting rod drives the crossbeam to move in the vertical track. The quilting machine of the invention has the advantages of simple structure, reliable operation and convenient maintenance.

Owner:天津市善文玻璃纤维制品有限公司

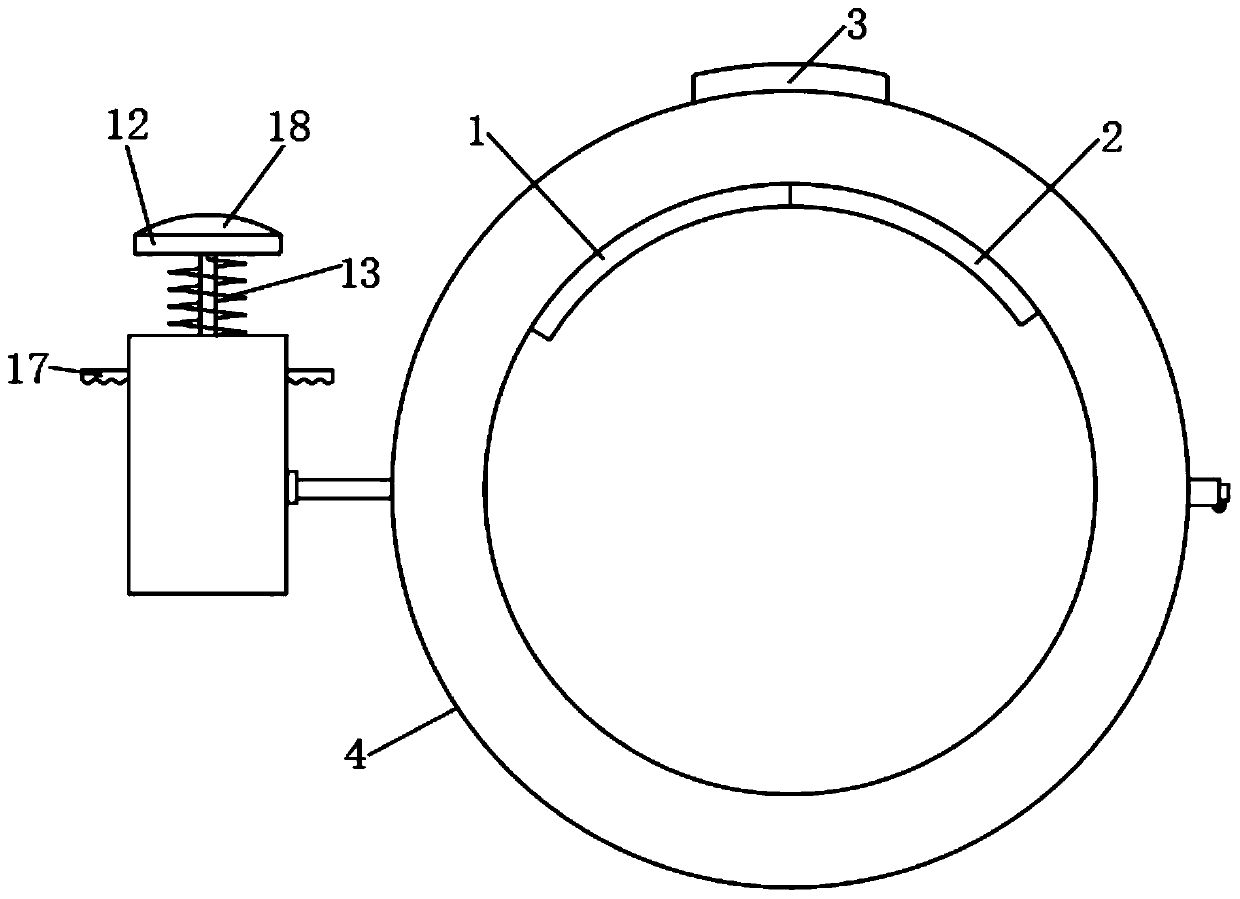

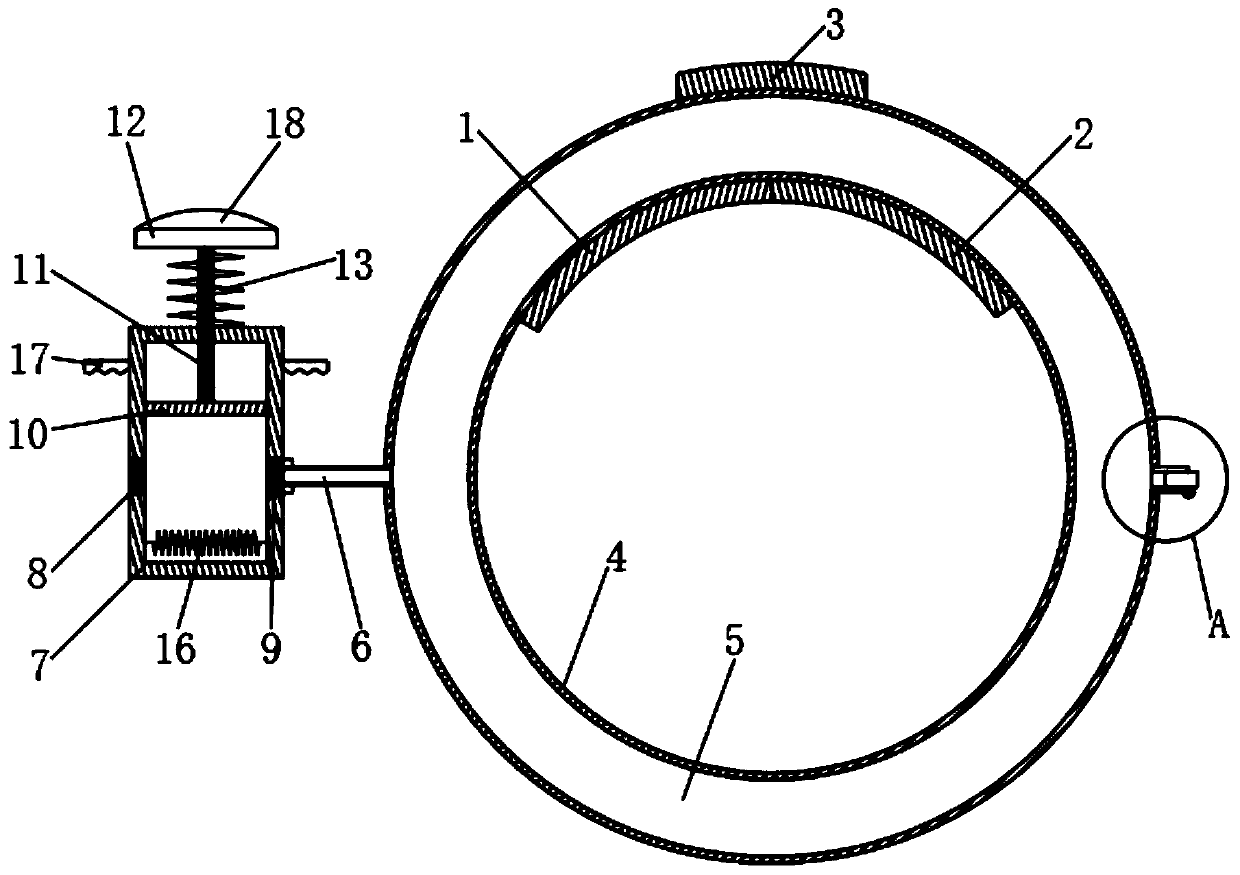

Postoperative puncture site pressing device for cerebrovascular intervention

InactiveCN110101428AQuick pressPlay a pressing effectTourniquetsEngineeringUltimate tensile strength

The invention discloses a postoperative puncture site pressing device for cerebrovascular intervention. The postoperative puncture site pressing device for the cerebrovascular intervention comprises asensing module, a monitoring module and an alarm module, wherein the opposite surfaces of the sensing module, the monitoring module and the alarm module are fixedly connected with a pressing device,the pressing device comprises an annular air bag and an air inlet shell, the inner ring surface of the annular air bag is fixedly connected to the surface of the sensing module and the monitoring module, and the outer ring surface of the annular air bag is fixedly connected to the surface of the alarm module, a through hole is formed in a left side of the annular air bag, and through the through hole, a connecting tube is in fixed sealed connection with the annular air bag. The postoperative puncture site pressing device for the cerebrovascular intervention, through the cooperative use of theabove structures, solves the problem that due to the fact that the adjustment of the pressing strength of a traditional presser is not convenient in the actual use process and it is necessary to pullout an adhesive tape several times and then perform re-bonding in order to achieve a suitable pressing strength, secondary damage to a puncture site is caused, the work efficiency is lowered, and inconvenience is brought to the use.

Owner:周林国

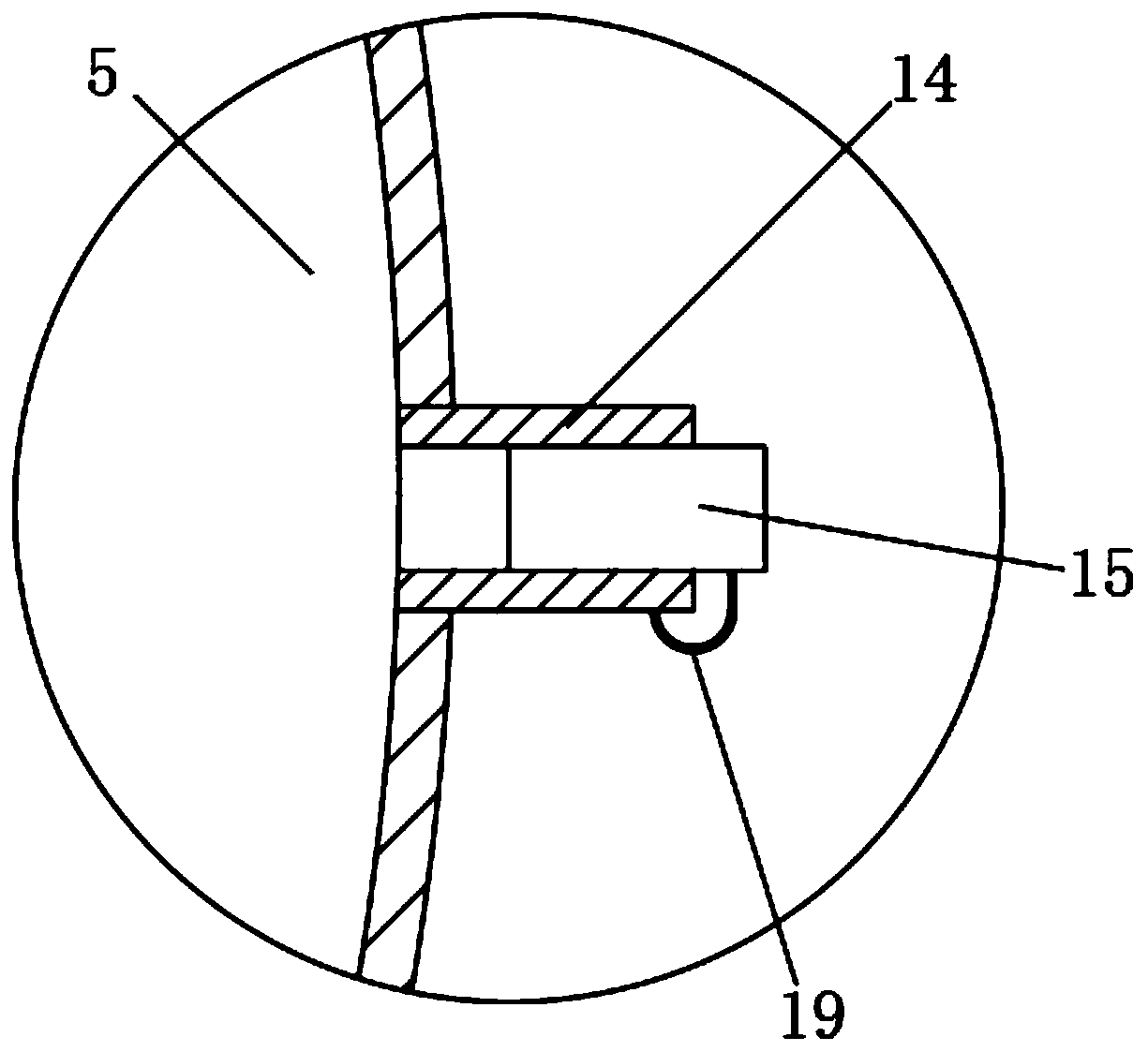

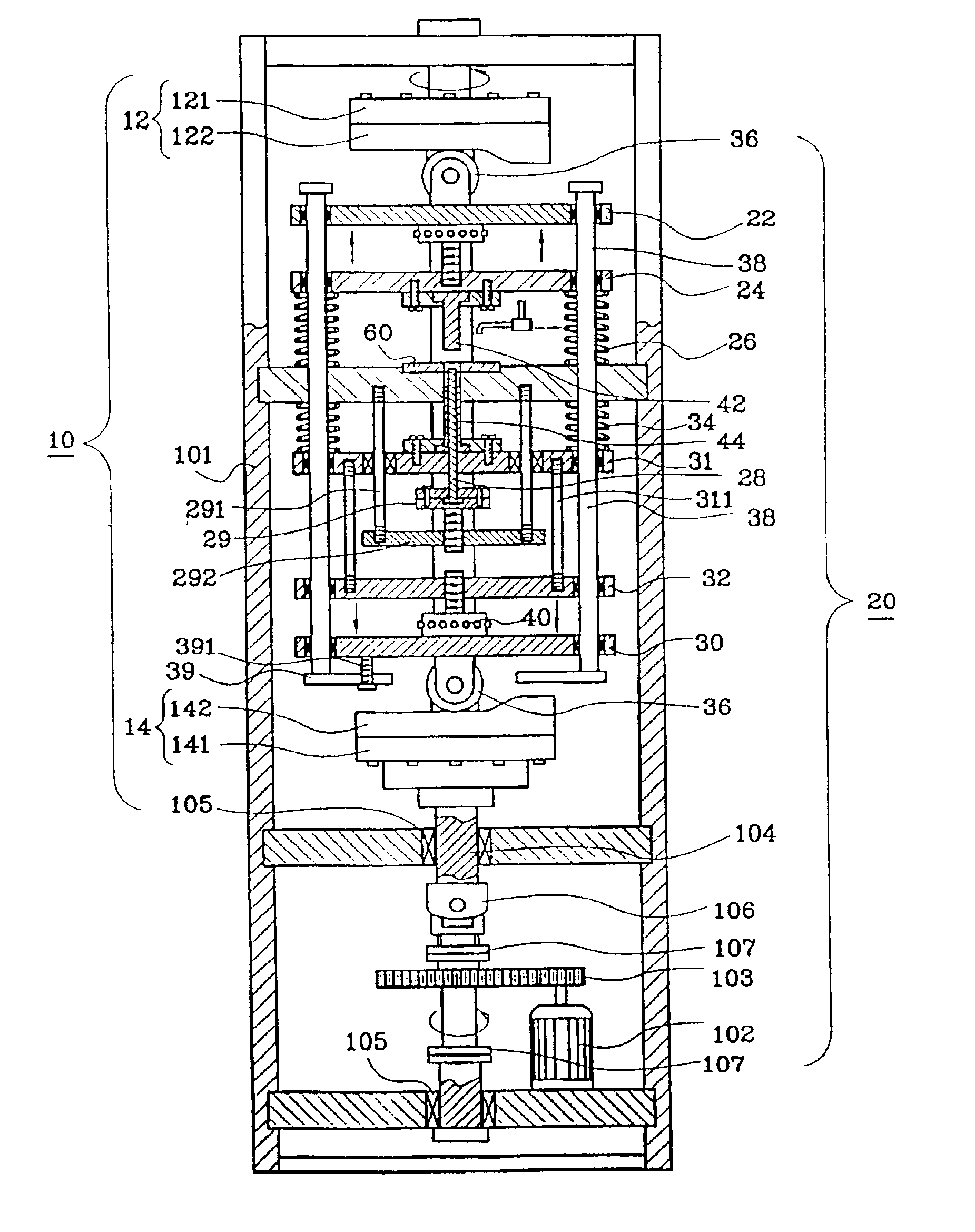

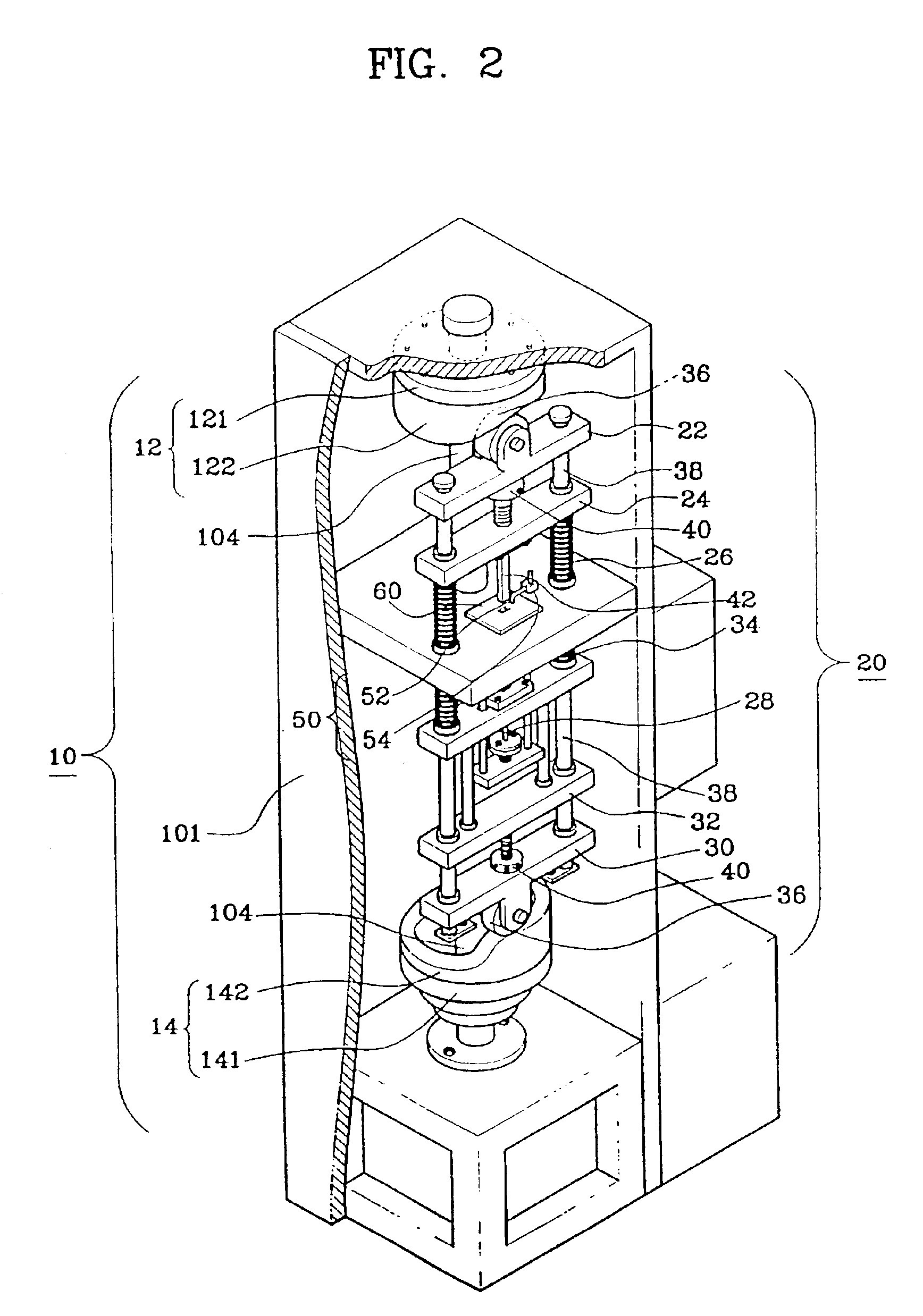

Biaxial press molding system

InactiveUS6890168B2Easy pressure controlSimple designConfectionerySweetmeatsReciprocating motionEngineering

A biaxial press molding system includes a cam apparatus having cams facing each other, and a biaxial press apparatus, disposed between the cams and installed to be capable of sliding contacting the cams, for forming a biaxial pressure to a molding object by converting rotational motion of the cams to linear reciprocating motion. Thus, a repulsive force generated during pressing concentrates only on the rotation shaft, so that an optimal design of the frame and a light system are possible. The upper and lower pressure continuously applied to a pressed object can be changed and the maximum pressure can be freely maintained, increased and decreased by forming upper and lower portions at the frictional surfaces of the cams facing each other. Also, a fine control of pressure is possible, the pressure can be appropriately distributed according to part of the pressed object, and mass production of accurate molding products is possible by controlling the pressing point of time.

Owner:KIM YOUNG JUNG

Device and method for abscess irrigation

ActiveUS9629953B2Novel and inexpensive and highly effectiveEasy to irrigateCannulasEnemata/irrigatorsPuncture WoundMedicine

The subject invention provides novel, inexpensive, and highly effective methods and devices for convenient and effective irrigation of abscesses, puncture wounds, and similar types of deep tissue wounds. In one embodiment the subject invention provides a discharge apparatus for a reservoir housing containing irrigation solution, wherein the discharge apparatus has a specifically designed nozzle for insertion into a wound opening and through which a sufficient volume of the irrigation solution can pass at an appropriate pressure.

Owner:INNOVATION TECH INC

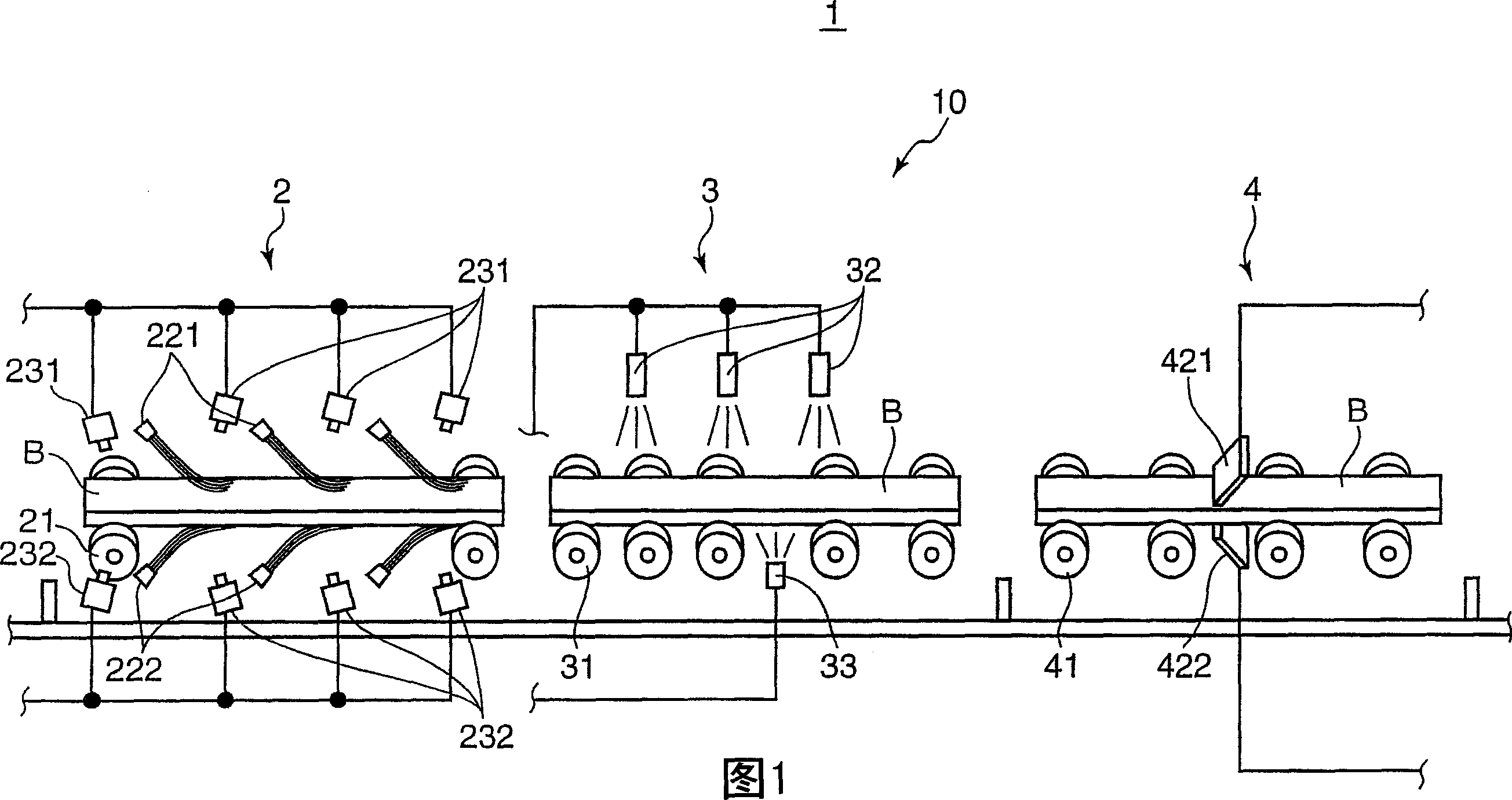

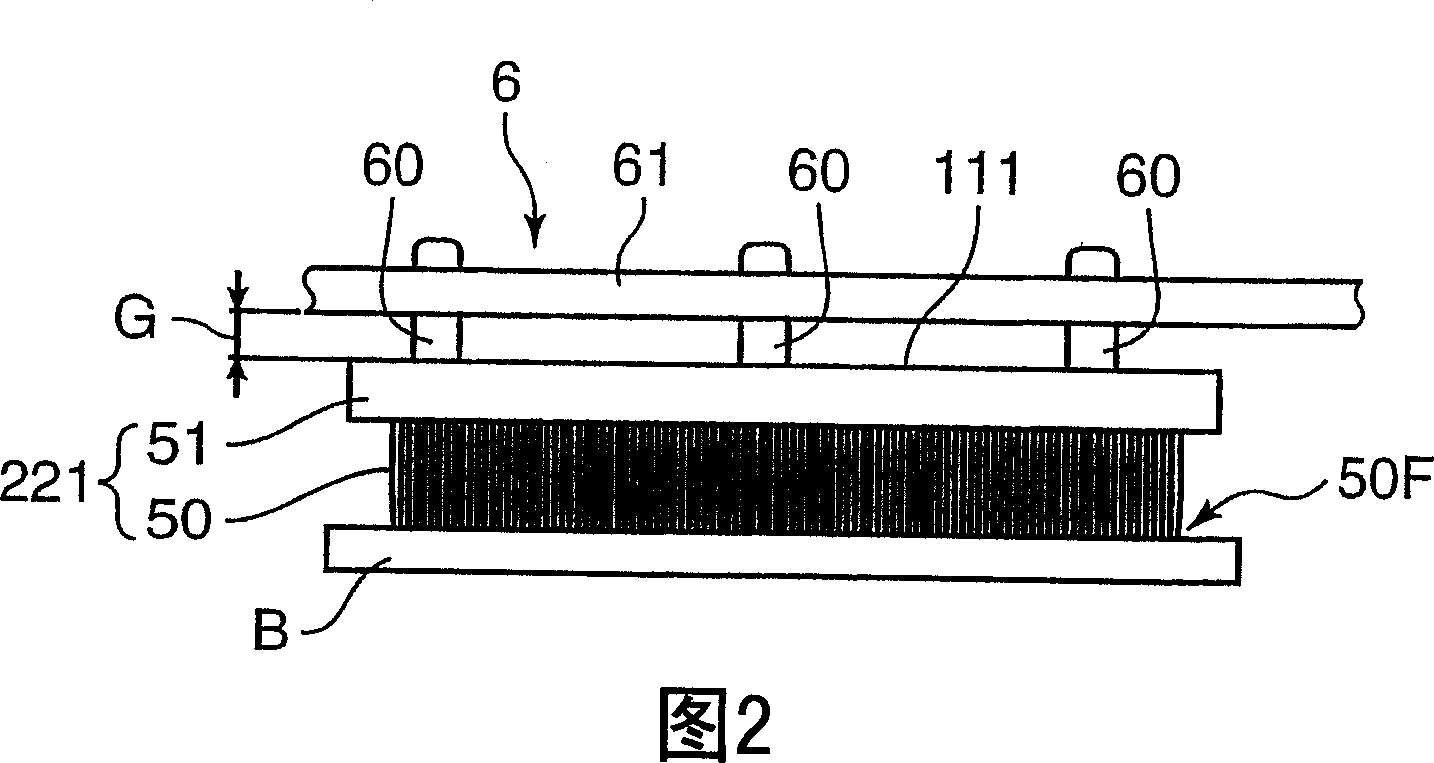

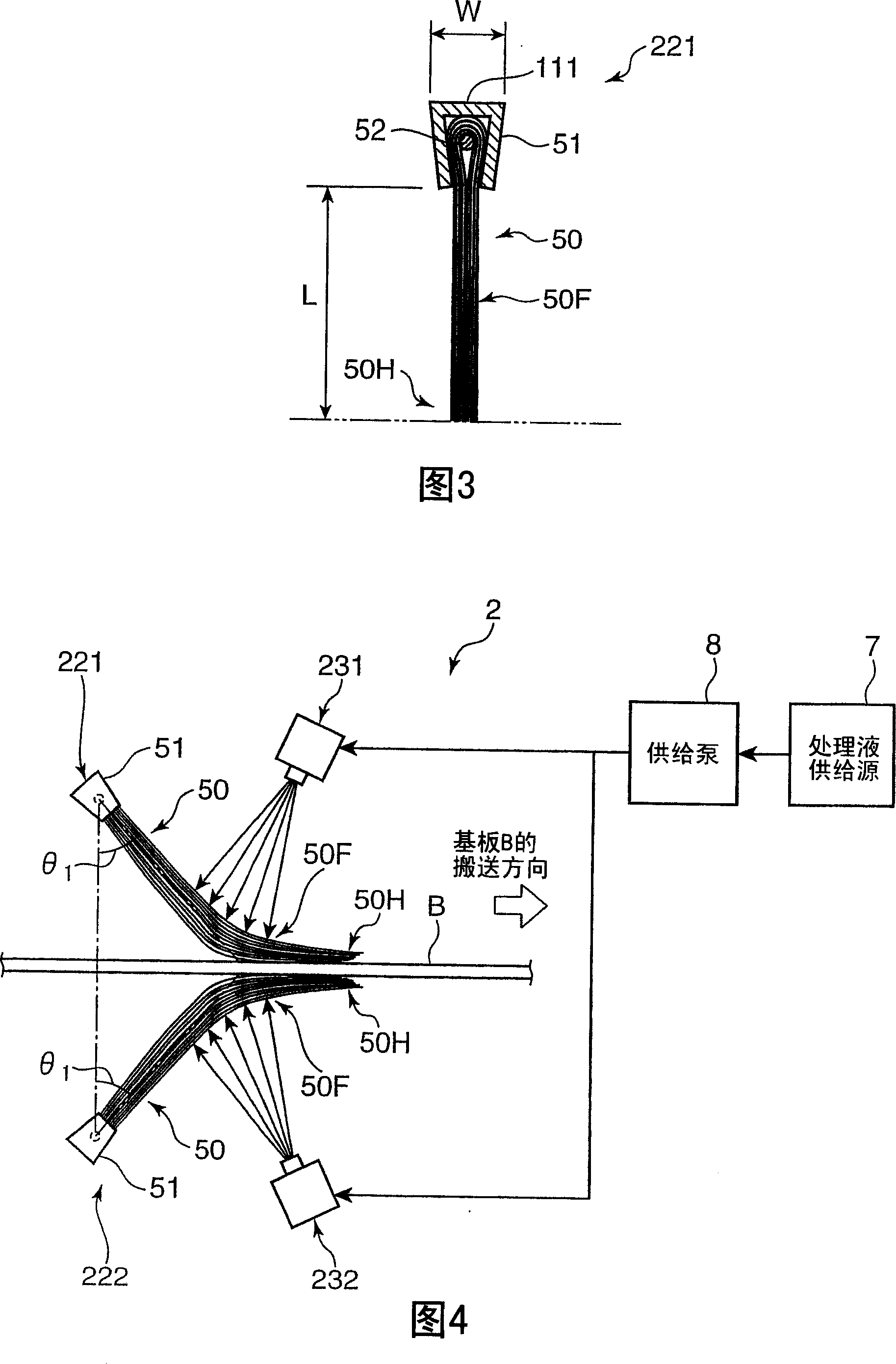

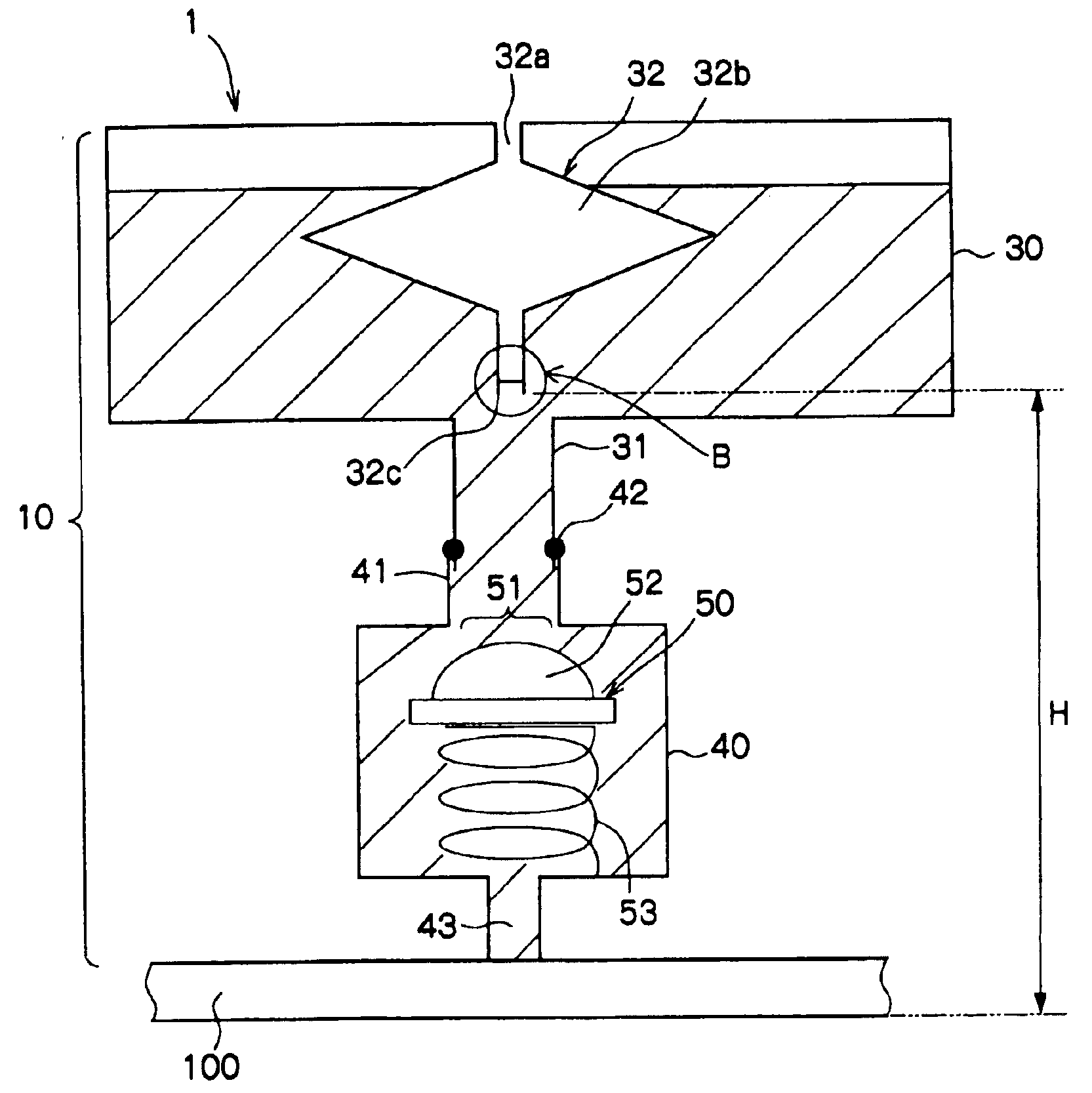

Substrate processing method and substrate processing apparatus

InactiveCN1983516AFloat evenlyAvoid damageSemiconductor/solid-state device manufacturingCleaning using toolsEngineeringNozzle

The present invention provides a substrate processing method and substrate processing apparatus, which can lighten the damage for the surface of the substrate during cleaning, and can insure sufficient cleaning function. The device comprises: a long shape cleaning brush (221) having a hair bundle composed of many hairs; a removing roller for removing the substrate (B) relative to cleaning brush (221) in the direction crossing with the extending direction of the cleaning brush (221); a support mechanism for supporting the cleaning brush (221) by making the front end (50H) of the cleaning brush hair bundle (50) of the cleaning brush (221) toward the downstream of the moving direction of the substrate (B) of the moving roller and making the flank part (50F) of the cleaning brush hair bundle (50) of the cleaning brush (221) contact with the top surface of the substrate; a processing liquid supply nozzle (231) for supplying processing liquid to the cleaning brush hair bundle (50) of the cleaning brush (221) supported by the support mechanism.

Owner:DAINIPPON SCREEN MTG CO LTD

Liquid-feeding device and liquid ejection apparatus

InactiveUS6926398B2Large liquid-capacitySimple structureLiquid surface applicatorsLiquid flow controllersFresh airEngineering

There is provided a liquid-feeding device with large liquid-capacity and a simplified structure and capable of stably holding liquid without leakage. An ink-feeding device includes an ink reservoir; an ink chamber; a valve displaced so that a closing member opens an open region by reduction in pressure due to reduction in the ink amount in the ink chamber; a fresh-air communicating hole for communicating with fresh air; and an air inlet tube capable of bringing air, when an amount of ink in the ink chamber is reduced, from the fresh-air communicating hole by the amount of air corresponding to the amount of the reduced ink, wherein a bore diameter of the lower end of the air inlet tube and a water head are determined so that the ink meniscus holding power P at the lower end of the air inlet tube and the water head pressure H corresponding to the height from the bottom surface of an ink ejection unit (nozzle surface) to the lower end of the air inlet tube satisfy the relationship P>H.

Owner:SONY CORP

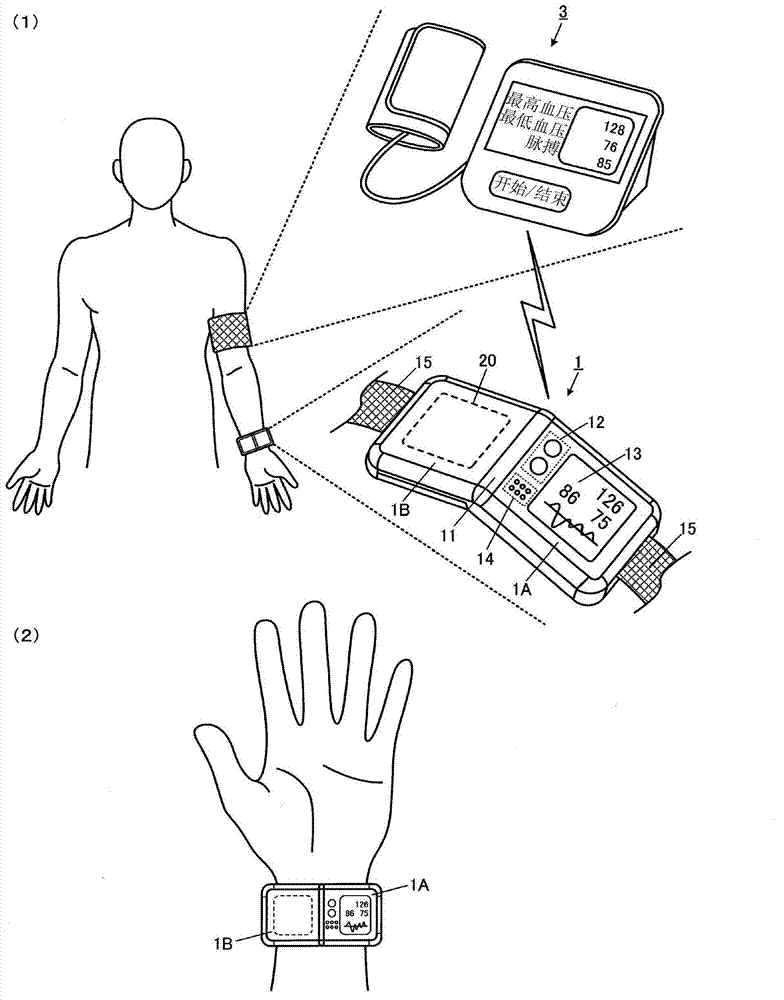

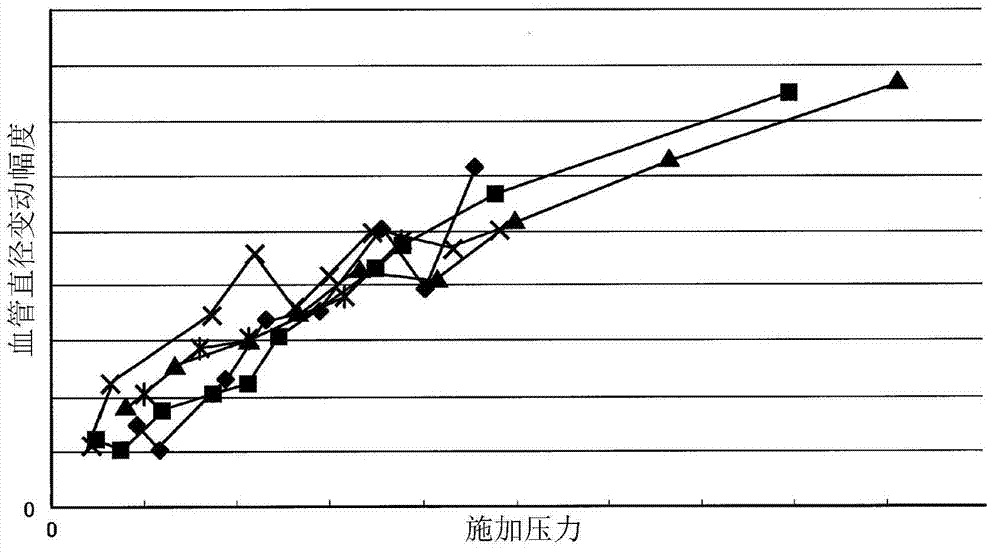

Blood pressure measurement apparatus and blood pressure measurement method

ActiveCN103156588AImprove calculation accuracyAppropriate pressureHealth-index calculationEvaluation of blood vesselsBlood pressure monitorsDiameter measurement

In an ultrasound blood pressure monitor (1), a blood pressure diameter measurement section (110) measures blood pressure diameter of a radial artery which is a measurement target based on reception results of ultrasound from an ultrasound sensor (21). In addition, a pressurizing section (30) adds a pressure from a body surface so that the radial artery is pressed. Then, a correlation formula (823), which expresses a relationship between blood vessel diameter and blood pressure of the radial artery under pressurization by the pressurizing section (30), is found and stored in a storage section (800). Then, a blood pressure calculation section (160) calculates blood pressure using the blood vessel diameter which is measured under pressurization and storage data in the storage section (800) by controlling the pressurization operation of the pressurizing section (30).

Owner:SEIKO EPSON CORP

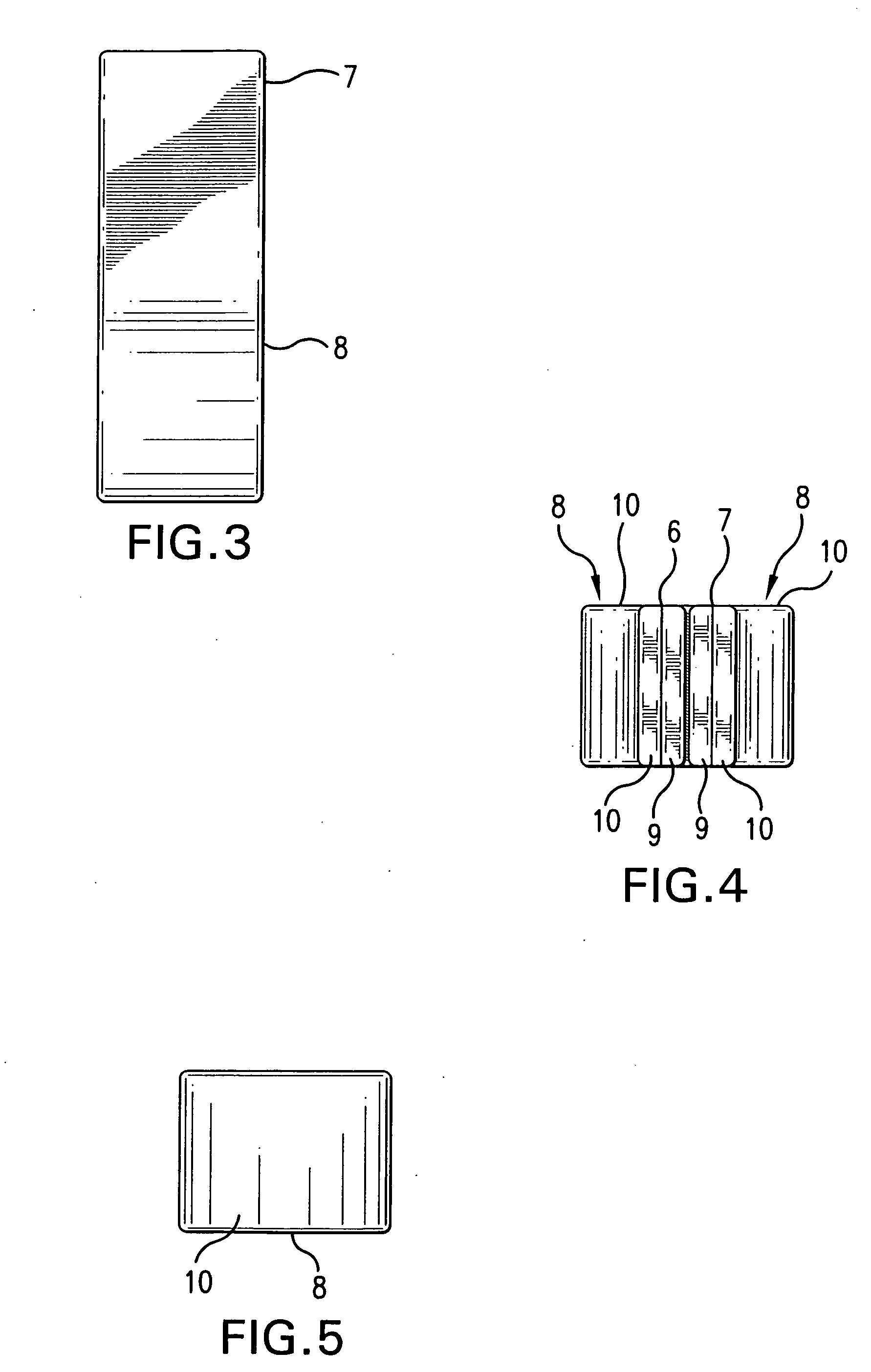

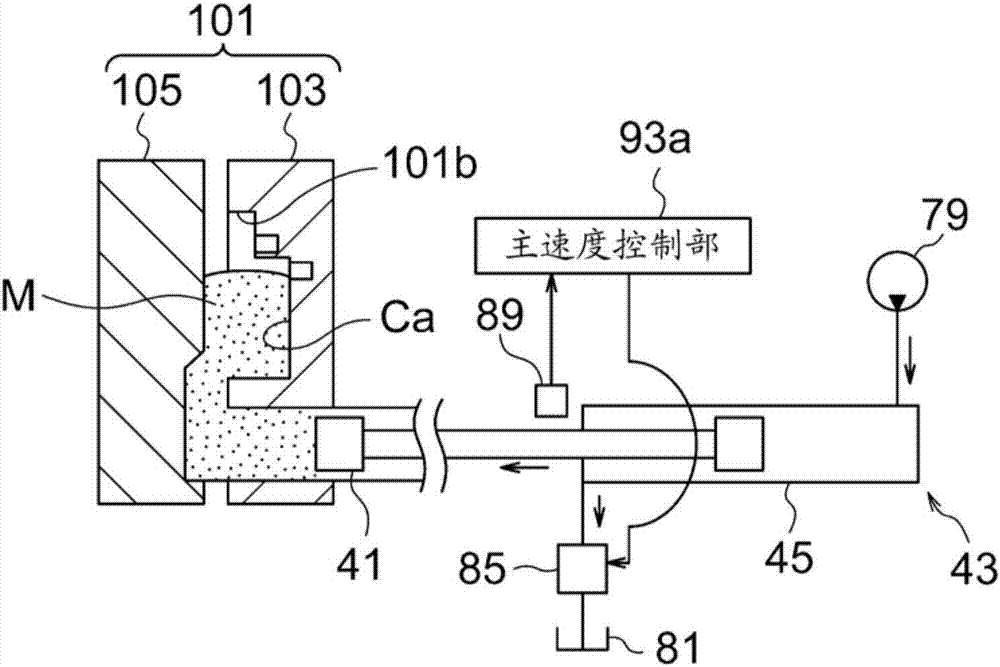

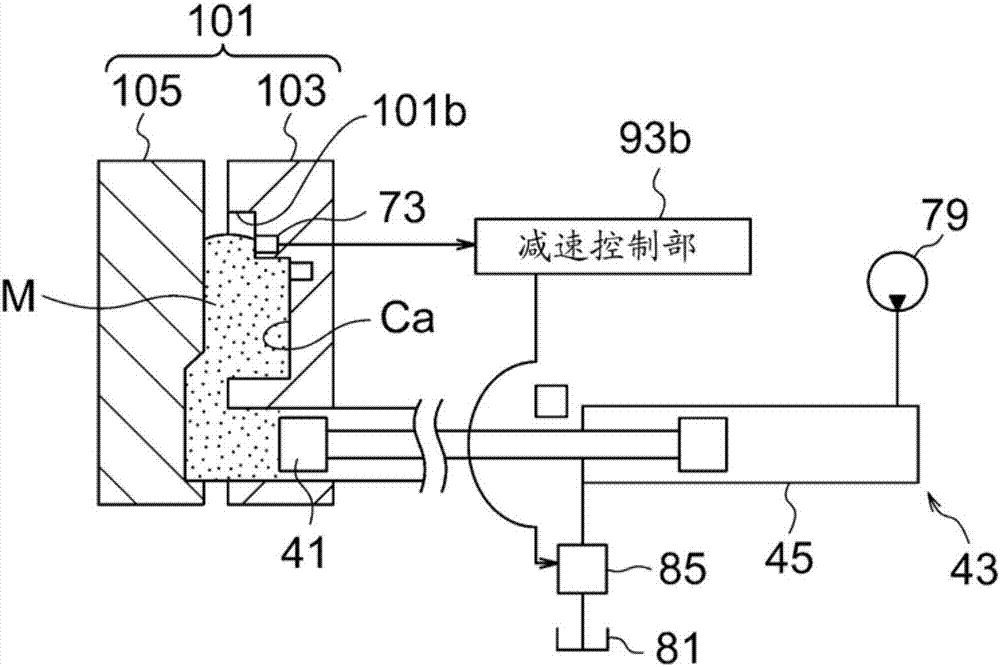

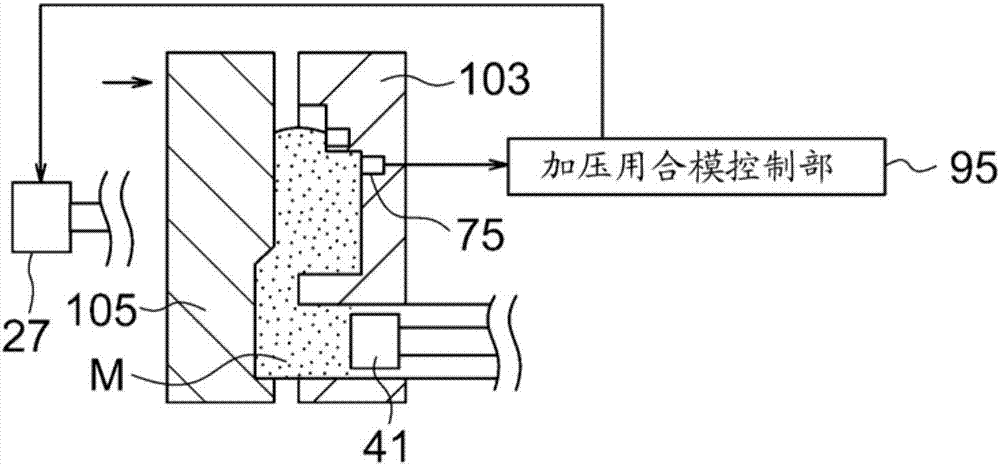

Die casting machine and shaping method of solid-liquid coexisting metal

The invention provdies a die casting machine, which can properly applying pressure to a solid-liquid coexisting metal, and includes a clamping device 7 which opens and closes and clamps a pair of die halves 101, an injection apparatus 9 which performs injection to the pair of die halves by making a plunger 41 move forward in a sleeve 39 communicated with a space between the pair of die halves, and a control device 47 which controls the clamping device 7 and injection apparatus 9. The control device 47 includes an injection control part 93 and press-use clamping control part 95. The injection control part controls the injection apparatus so as to start the injection in a state where the pair of die halves face each other through a gap. The press-use clamping control part controls the clamping device so that the die contact and clamping are carried out after the start of injection. Further, the injection control part performs control for decelerating the plunger before the plunger stops.

Owner:TOSHIBA MASCH CO LTD

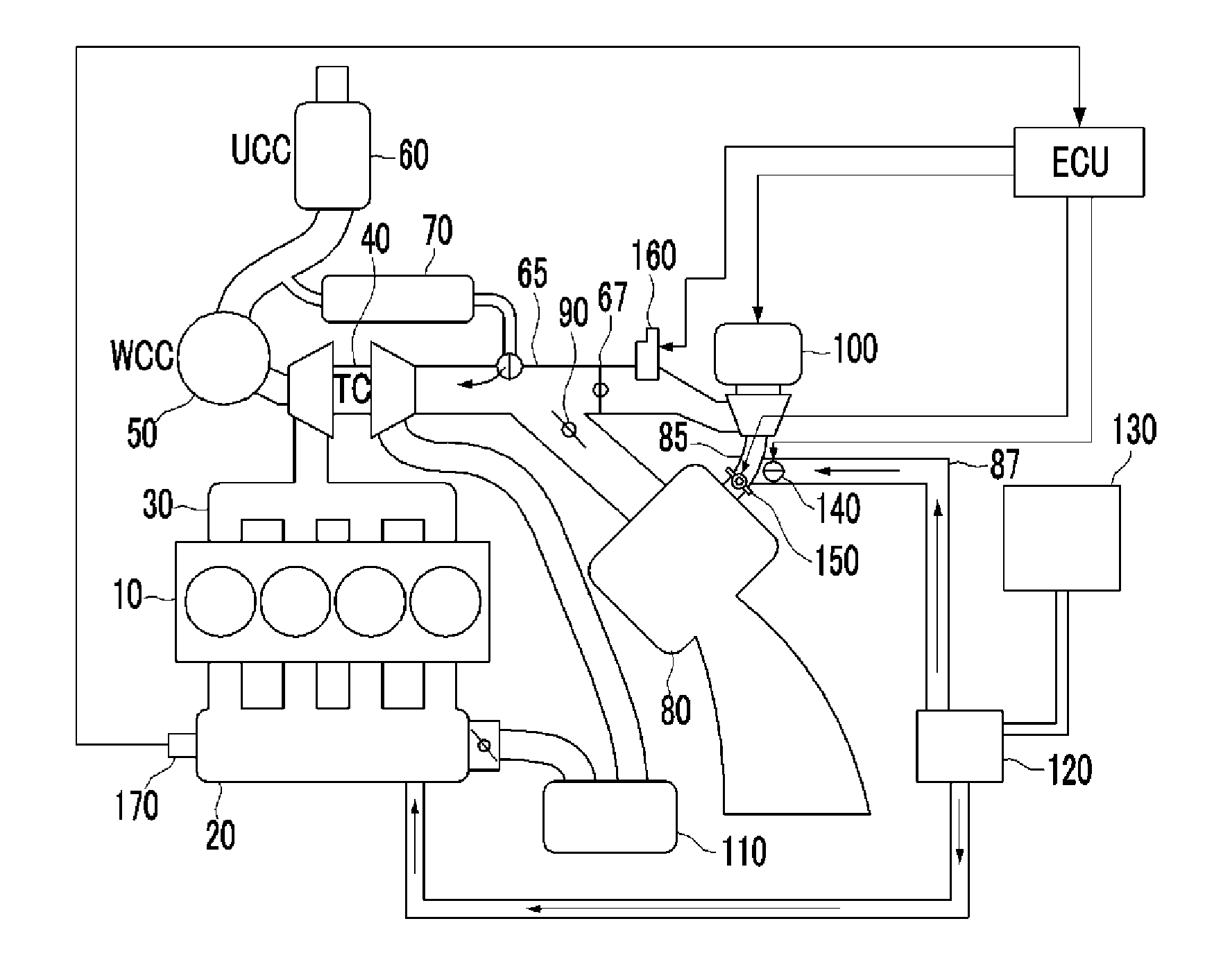

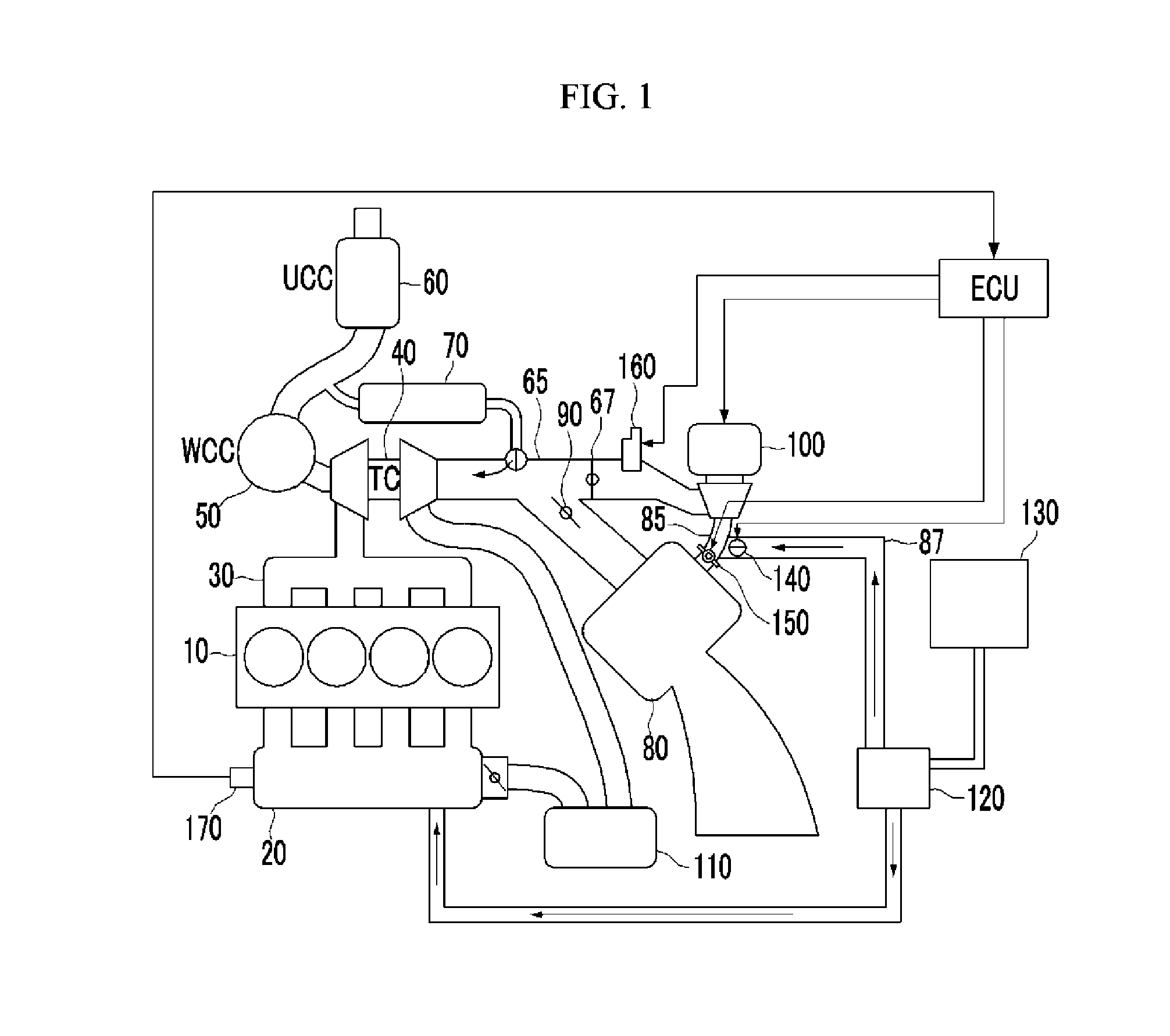

Brake negative pressure generating device for vehicle

ActiveUS20140182565A1Sufficient negative pressureAppropriate pressureInternal combustion piston enginesAir intakes for fuelEngineeringPressure controlled ventilation

A brake negative pressure generating device of a vehicle includes: an electrically-driven supercharger for drawing in, compressing, and supplying outside air; a vacuum chamber connected to an inlet opening of the electrically-driven supercharger and supplying negative pressure for brake force boosting; a negative pressure supply passage for connecting the inlet opening of the electrically-driven supercharger and the vacuum chamber; and a first negative pressure control valve for opening and closing an inlet passage. Accordingly, the electrically-driven supercharger is run to supplement brake negative force if the brake negative force is not sufficient.

Owner:HYUNDAI MOTOR CO LTD

Fluid measurement sensor attachment structure

ActiveUS9267833B2Ensure correct executionReduce capacityMeasurement apparatus componentsFluid pressure measurementEngineering

The present invention provides a fluid measurement sensor attachment structure in which a fluid measurement sensor is attached to a branch pipe among three or more branch pipes branched from a pipe, thereby measuring properties of a fluid flowing through a flow path that is formed by remaining branch pipes, comprising a sleeve that can accommodate the fluid measurement sensor, wherein the sleeve is a member in a shape of a tumbler including a circumferential wall that is substantially cylindrical and a protective wall that is disposed at one end of the circumferential wall and that does not disturb a function of the sensor, a seal lip is disposed on the circumferential wall near the protective wall, and the sleeve is inserted into the branch pipe such that the protective wall is positioned near a base end of the branch pipes.

Owner:NIPPON PILLAR PACKING CO LTD

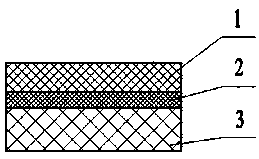

Heat dissipating structure of electronic apparatus

InactiveUS20130063899A1Improve reliabilityAdequate heat dissipationSemiconductor/solid-state device detailsSolid-state devicesHardnessHeat sink

Disclosed is a heat dissipation structure of an electronic device that has an IC chip that is a heat generating element mounted on a substrate and a heat dissipation sheet disposed between the IC chip and a cover member so as to dissipate heat. In such a heat dissipation structure, even if variation in a gap between the IC chip and the cover member is generated, the heat dissipation sheet can come in contact with the IC chip and with the cover member with appropriate pressure. This way, heat is sufficiently dissipated, and therefore, reliability of the electronic device can be improved. A heat dissipation sheet (1) has a double-layered structure in which a first heat dissipation sheet (11) and a second heat dissipation sheet (12) are laminated in a thickness direction. A rubber hardness of the first heat dissipation sheet is set different from that of the second heat dissipating sheet, and a softer heat dissipation sheet and a harder heat dissipation sheet are laminated in a direction of the gap between an IC chip (3) and a cover member (4).

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com