Novel wound irrigation device and method

a wound and irrigation device technology, applied in the field of wound management and treatment, can solve the problems of dirty wounds, contaminated with bacteria, defeating the purpose of the irrigation process, etc., and achieve the effect of convenient and effective wound irrigation, low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

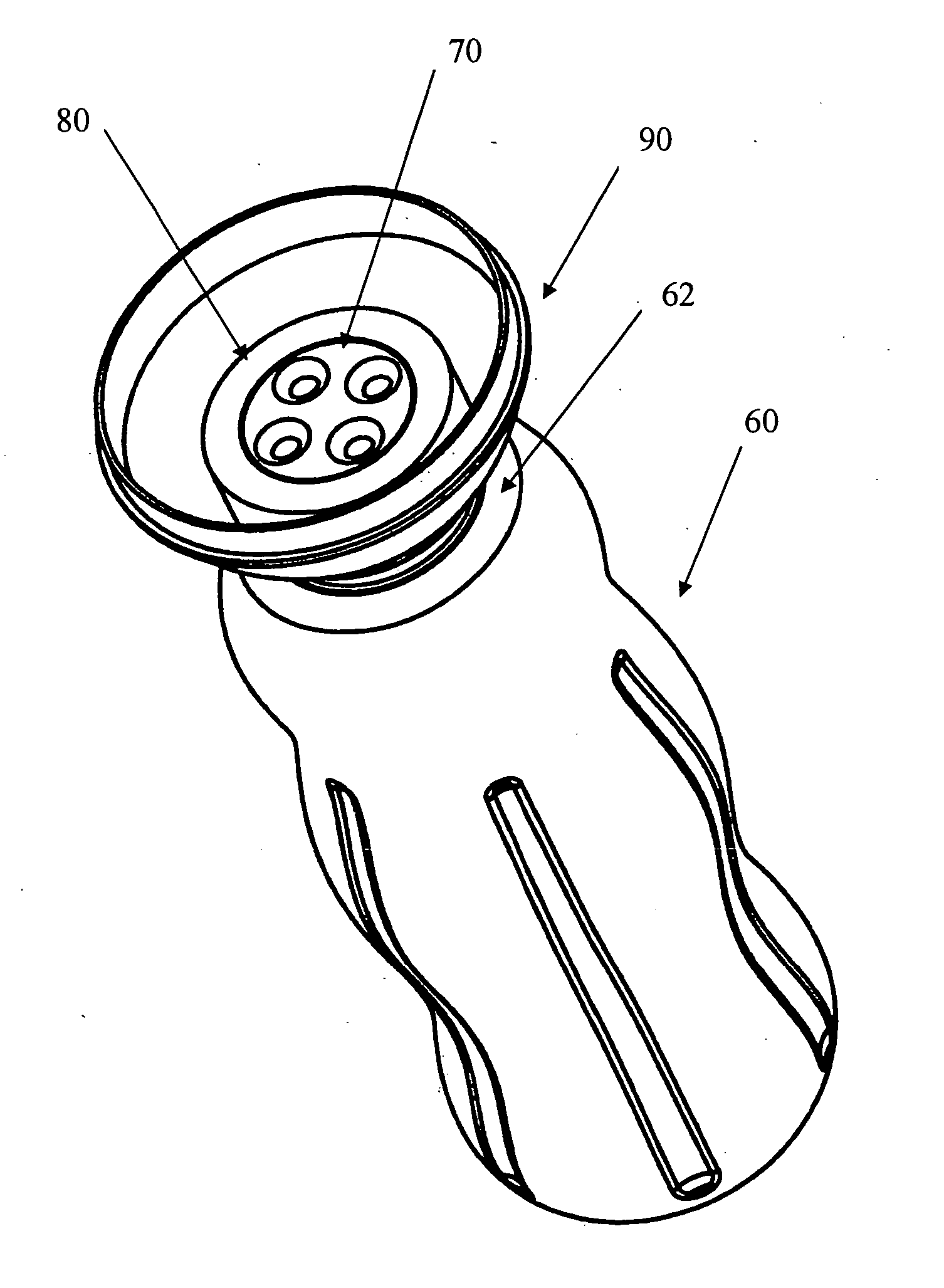

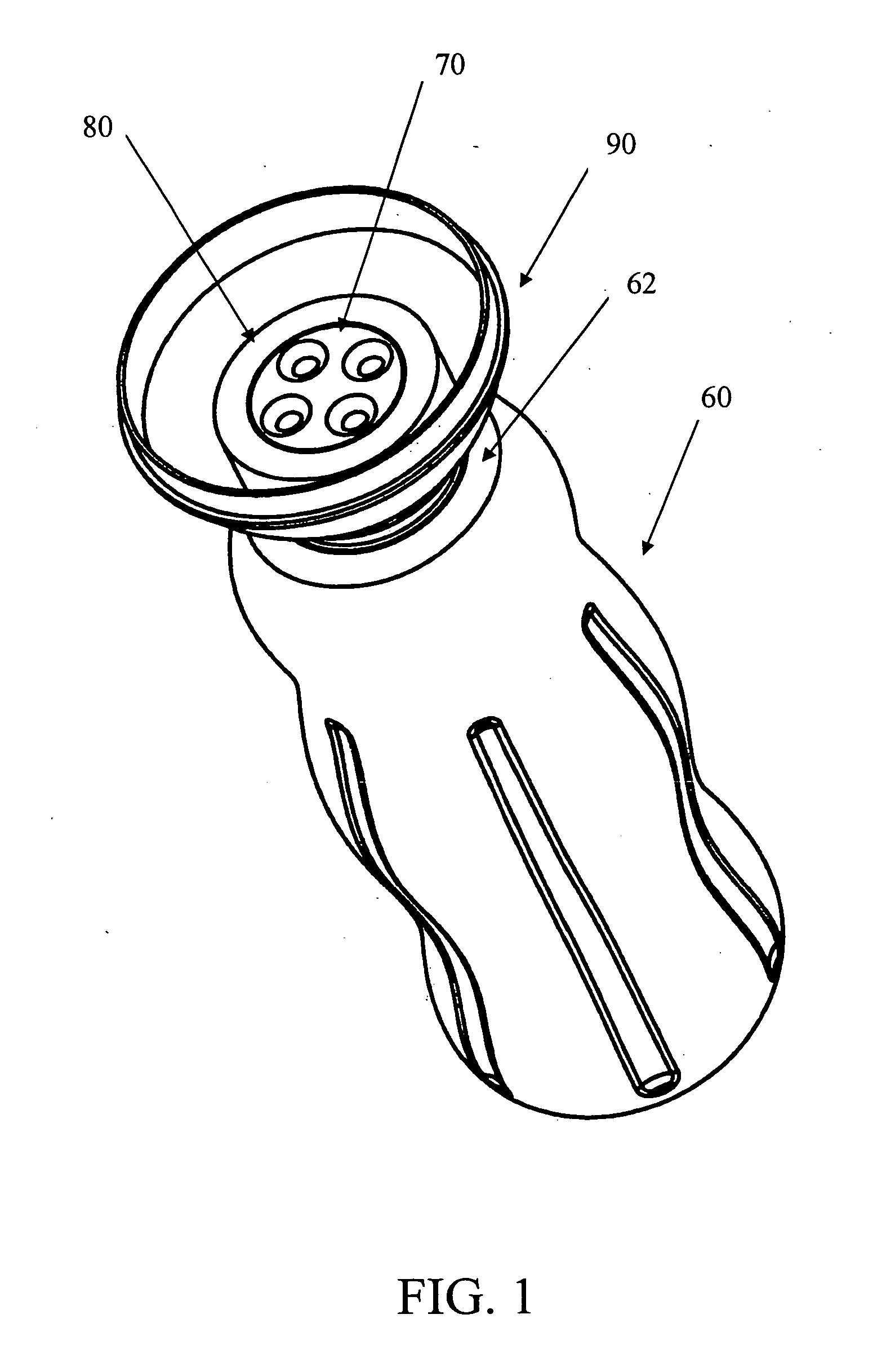

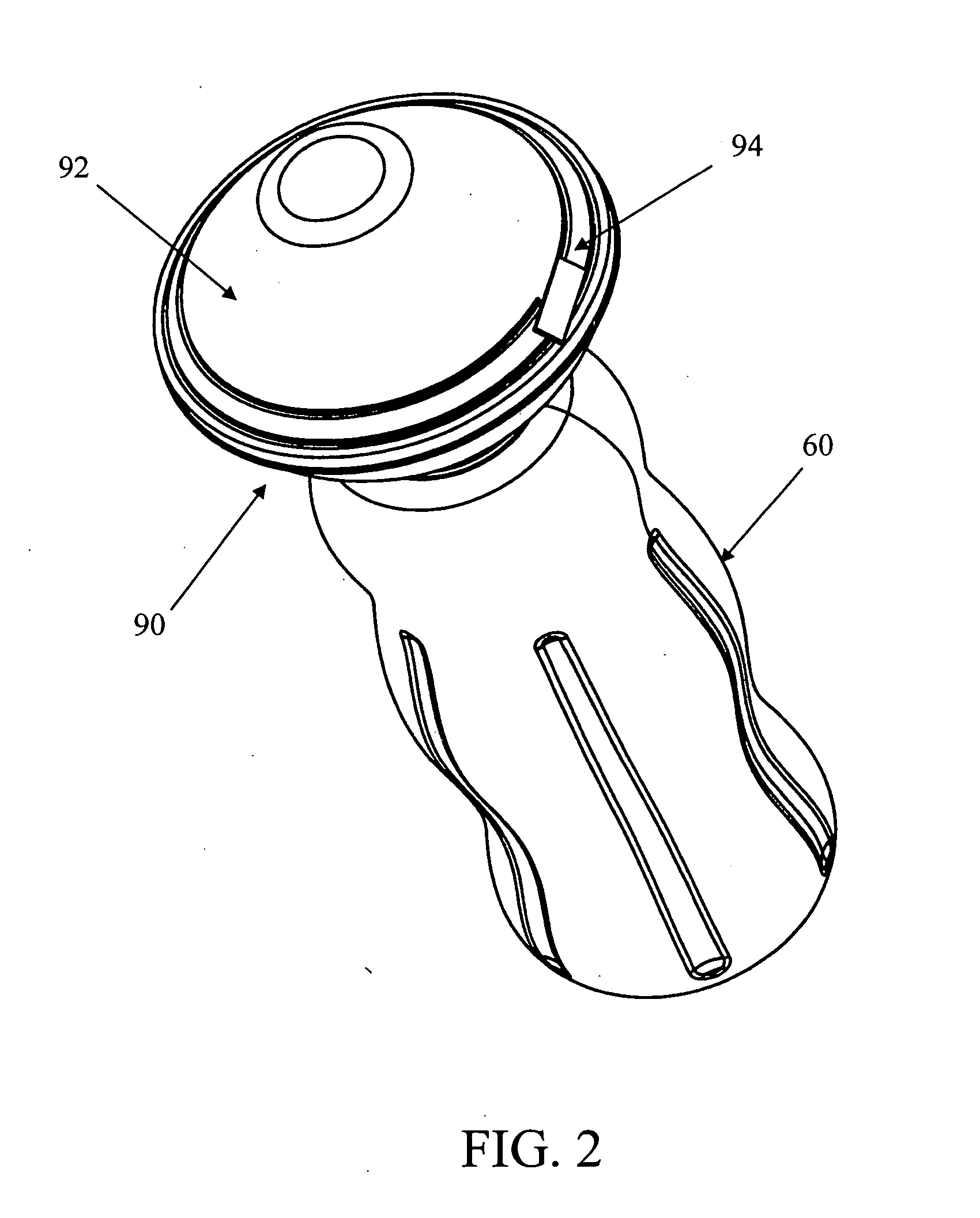

Preferred Nozzle Designs

[0080] Performance of nozzle designs with regard to pressure, flow rate and dynamic pressure, were compared.

[0081] In one test, a squeeze bottle with inlet fitting and pressurized reservoir was set up on its side and filled. A flow meter was placed between the squeeze bottle and the reservoir. A test pressure range of 2-7 psi was applied to each nozzle design and the flow rate was recorded for each test pressure (1 psi increments).

[0082] The shaped nozzle design (defined by a venturi shaped passageway) created greater flow than the sharp edged, non-shaped nozzle at the same fluid pressure.

[0083] For a pressure test, a fulcrum and scale were set-up in front of the horizontally mounted irrigation device. The pressure to the nozzles was varied from 2 to 7 psi and the force was recorded at each 1 psi increment.

[0084] The shaped nozzle produces between 70%-200% more force than the sharp-edged nozzle.

[0085] At 4 psi the calculations show 25.7 and 19.2 grams o...

example 2

Methods of Wound Irrigation

[0087] When a patient presents a wound to a medical or other health care professional skilled in the art, that medical professional assesses the extent of the injury sustained by the patient, including all other life threatening injuries. Appropriate action regarding these life threatening injuries is performed and a history is recorded. All wounds are covered to minimize further contamination until the actual repair process begins.

[0088] For examination of the wound, it is assumed that a medical professional would have performed a detailed evaluation of the extent of tissue injury, including but not limited to: anatomical area considerations, depth of the wound, type of injury, e.g., crash injury, puncture wound, bites, missiles, cuts with sharp objects, or the like. Included in this examination would be a determination of the type(s) of contamination, time elapsed between the occurrence of the injury to presentation, gross contamination of a wound, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com