Automatic solar agriculture greenhouse

A solar energy and greenhouse technology, applied in the agricultural field, can solve the problems of heat waste, inconvenient use, increase production cost, etc., and achieve the effects of clean energy, environmental protection, and convenient irrigation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

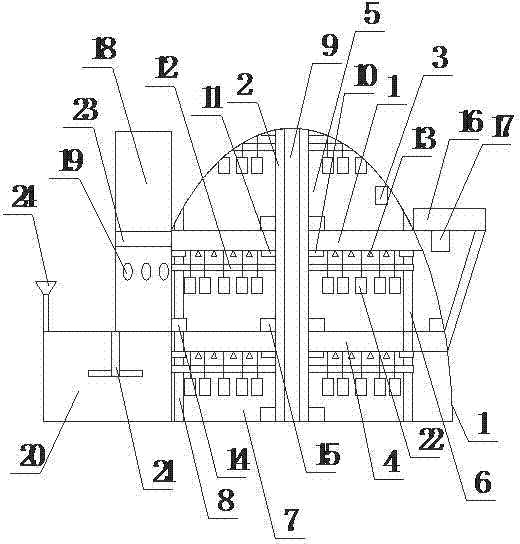

[0017] like figure 1 As shown, a solar automatic agricultural greenhouse includes a hemispherical greenhouse body 1, a column 2 is provided in the middle of the greenhouse body 1, a controller 3 is provided on the inner wall of the greenhouse body 1, and the inside of the greenhouse body 1 is from top to bottom. The bottom is divided into the first planting layer 5, the second planting layer 6 and the third planting layer 7 by the reinforcing board 4, and the four corners of the bottom of the greenhouse body 1 are provided with the third planting layer 7, the second The support column 8 of the planting layer 6 and the first planting layer 5, the greenhouse body 1 is provided with a staircase 9 connecting the first planting layer 5, the second planting layer 6 and the third planting layer 7 around the column 2, the first planting layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com