Scaffold for repairing articular subchondral bone

A technology for articular cartilage and bone repair, applied in the field of prostheses, can solve problems such as collapse, damage, and bionic human joints, and achieve the effects of excellent mechanical properties, good seepage characteristics, and good cushioning functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

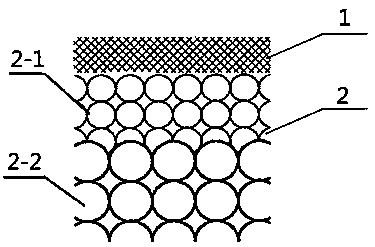

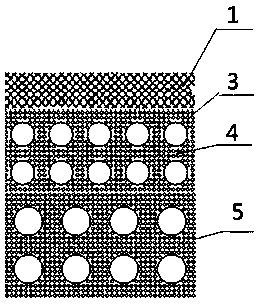

[0024] see figure 1 , the scaffold for articular subchondral bone repair in this embodiment is composed of a porous salt layer 1 and a porous metal material layer 2 from top to bottom. The porous salt layer 1 is a porous inorganic salt layer, prepared by porous hydroxyapatite, with a pore size of 3 μm-6 μm, a porosity of 43%, and a thickness of 0.5 mm; the porous metal material layer 1 is a porous titanium alloy, the material is TC4, Wherein the porous titanium alloy has two layers, see figure 1 , wherein the upper layer 2-1 connected to the porous salt layer has a pore diameter of 3 μm-10 μm, a porosity of 38%, and a thickness of 2 mm; the lower layer 2-2 has a pore diameter of 100 μm-450 μm, a porosity of 82%, and a thickness of 4 mm , the pores in each layer of porous titanium alloy and between layers are interconnected. The preparation method of the material for artificial joint repair is as follows:

[0025] (1) The porous titanium alloy upper layer was prepared by mix...

Embodiment 2

[0030] The scaffold for articular subchondral bone repair in this example is similar to Example 1, except that the porous metal material layer is porous niobium, the pore diameter of the upper layer is 75 μm-100 μm, and the porosity is 43%, and the pore diameter of the lower layer is 400 μm-700 μm , the porosity is 78%, and the pores inside and between the layers of porous niobium are interconnected. The pore diameter of the porous hydroxyapatite is 5 μm-10 μm, and the porosity is 36%. The preparation method is similar to Example 1.

Embodiment 3

[0032] The scaffold for articular subchondral bone repair in this example is similar to Example 1, except that the porous metal material layer is made of nickel-titanium alloy, the pore diameter of the upper layer is 50 μm-80 μm, the porosity is 39%, and the pore diameter of the lower layer is 700 μm -1000μm, the porosity is 72%, the pores inside and between layers of porous nickel-titanium alloy are interconnected, the porous salt layer is made of ammonium hyaluronate as raw material, its pore size is 4μm-8μm, and the porosity is 38 %, the preparation method is similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com