Hydraulic control system based on single-engine road sweeper

A hydraulic control system and single-engine technology, applied in road cleaning, mechanical equipment, cleaning methods, etc., can solve the problems of high noise, increased manufacturing cost of sweeping vehicles, increased fuel consumption, etc., to reduce exhaust emissions and noise, and save fuel Consumption and reduction of sub-engine effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

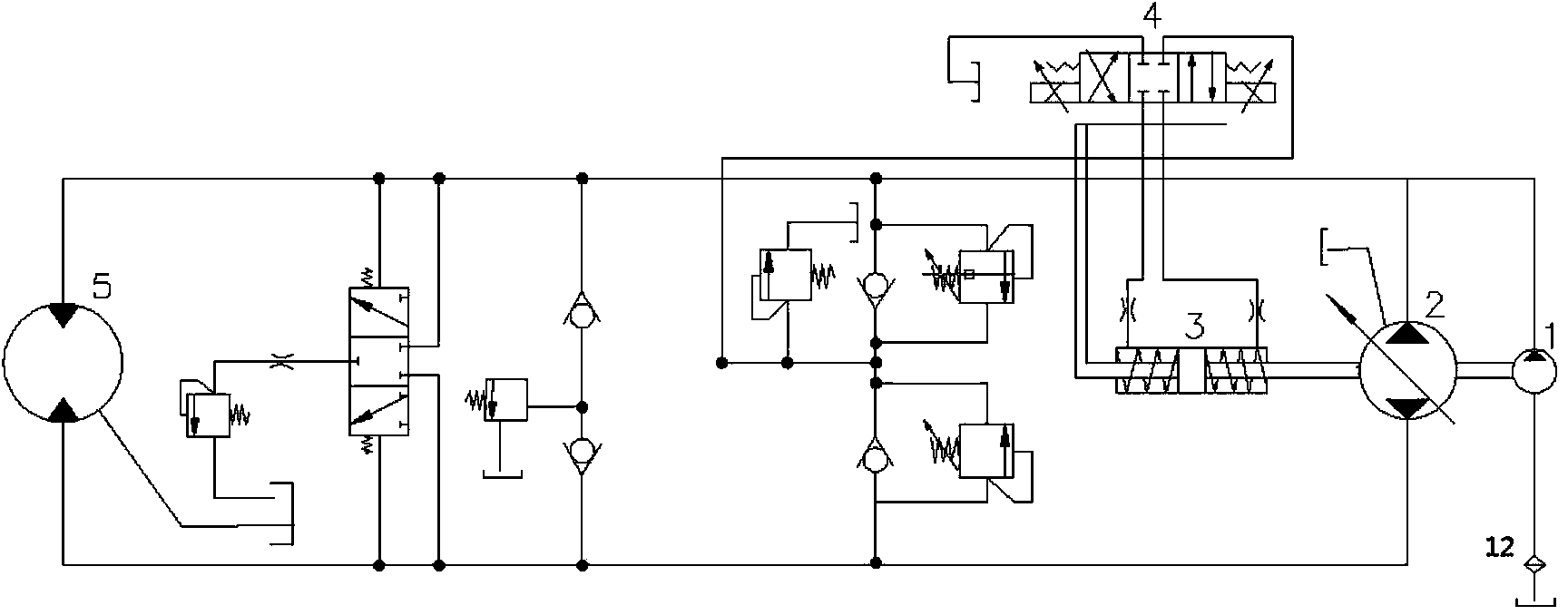

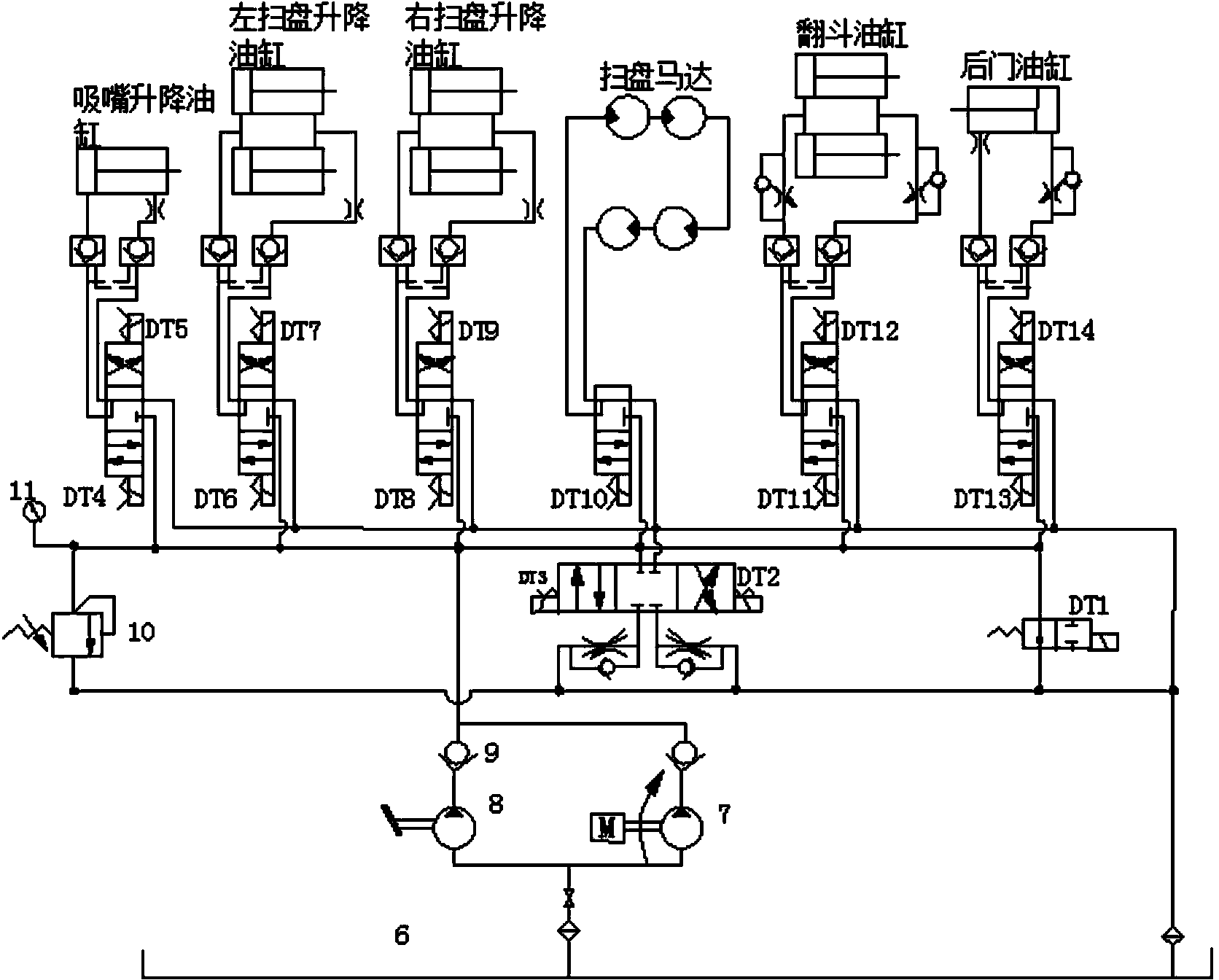

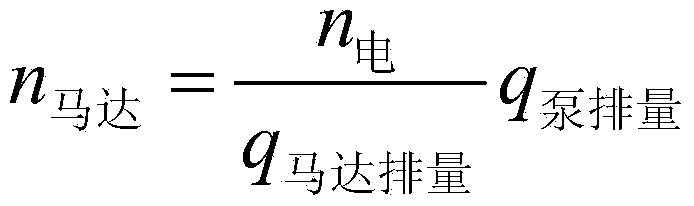

[0018] see figure 1 , 2. The present invention includes a walking hydraulic control system and a cleaning hydraulic control system; the walking hydraulic control system includes a three-position four-way valve 4 whose control end is connected to the accelerator pedal, and the output end of the three-position four-way valve 4 is connected through an electromagnetic floating valve 3 Bidirectional variable variable pump 2, the oil outlet of bidirectional variable variable pump 2 is connected to the oil inlet of bidirectional quantitative motor 5, and the oil inlet of bidirectional variable variable pump 2 is connected to the oil outlet of bidirectional quantitative motor 5 to form a circulation loop; A charge pump 1 for auxiliary work is connected, and a filter 12 is arranged on the inlet pipeline of the charge pump 1; the cleaning hydraulic control system inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com