Bidirectional trash compactor

A garbage compressor and compressor technology, applied in the field of sanitation machinery, can solve the problems of low feeding efficiency and low garbage density of a single vertical garbage compressor, and achieve the goal of overcoming low garbage density, high garbage density, and strong feeding capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

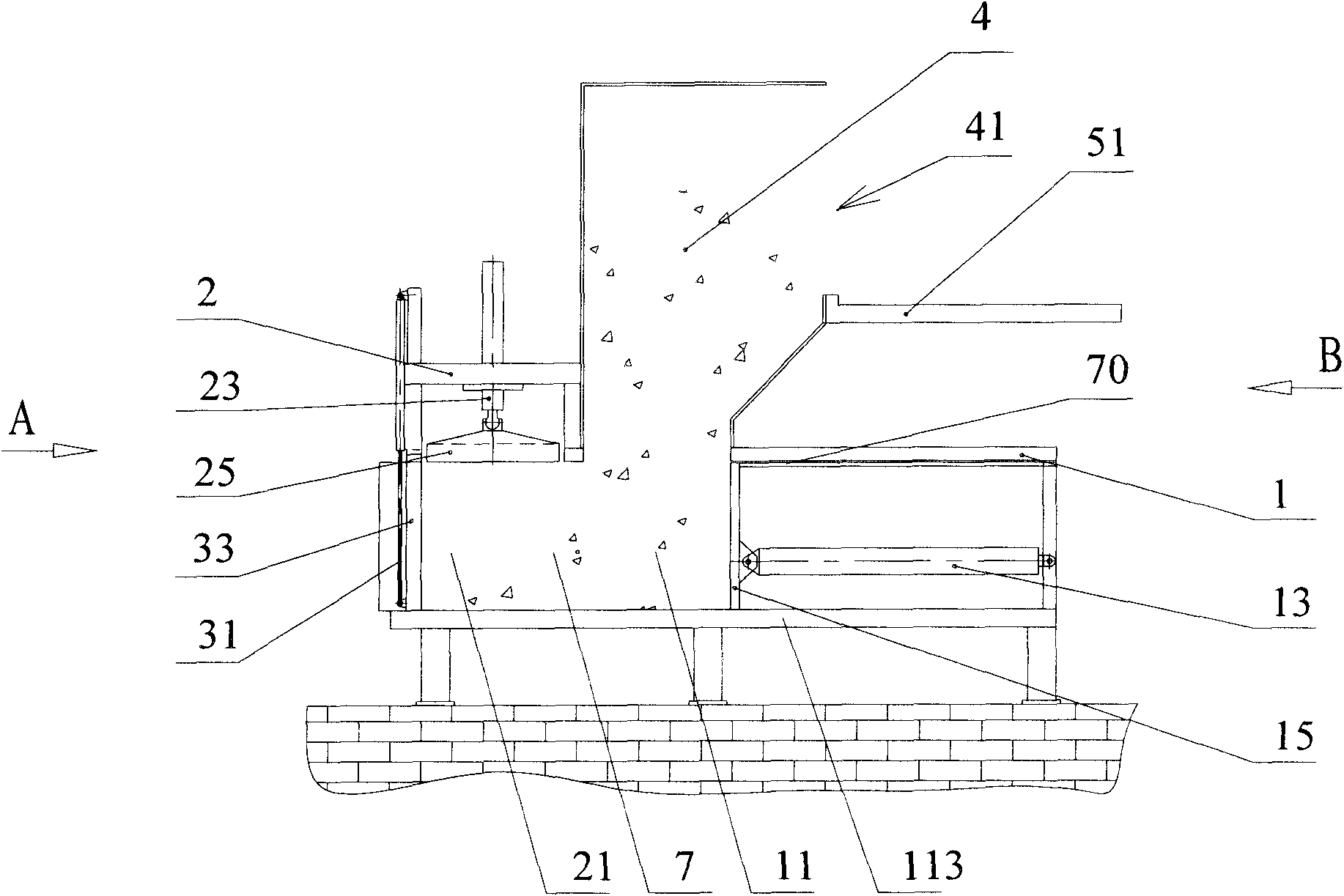

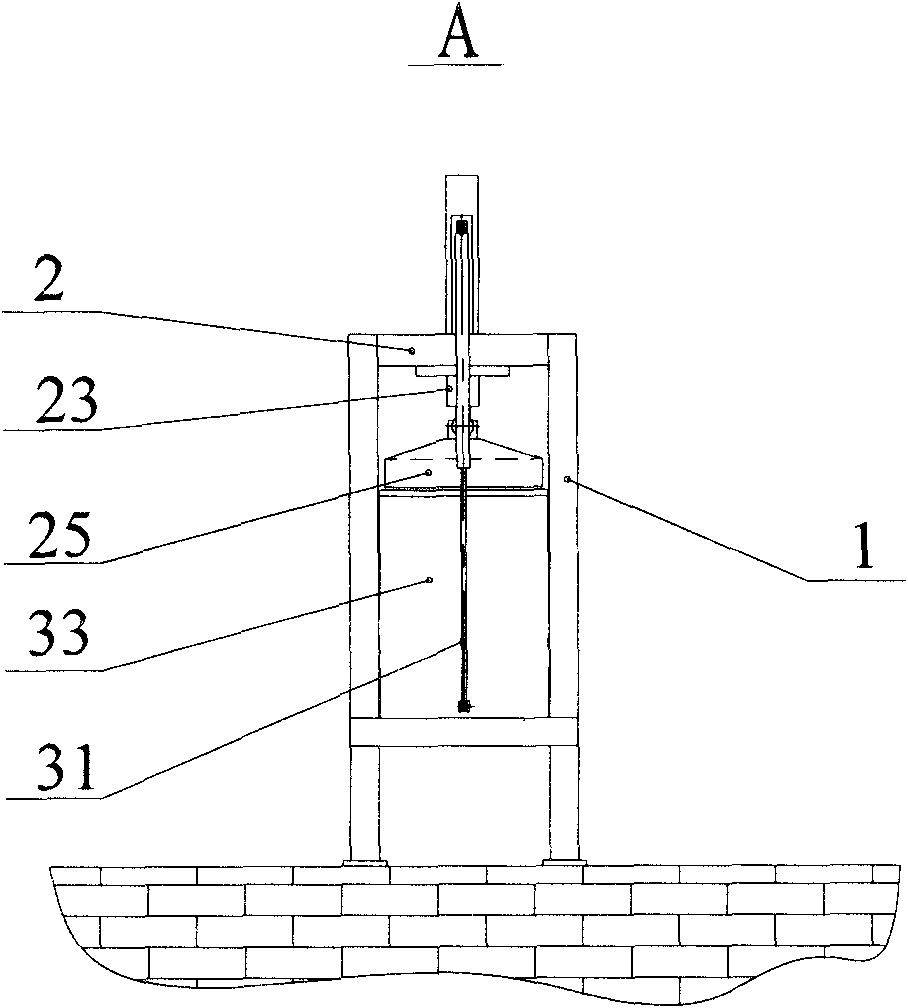

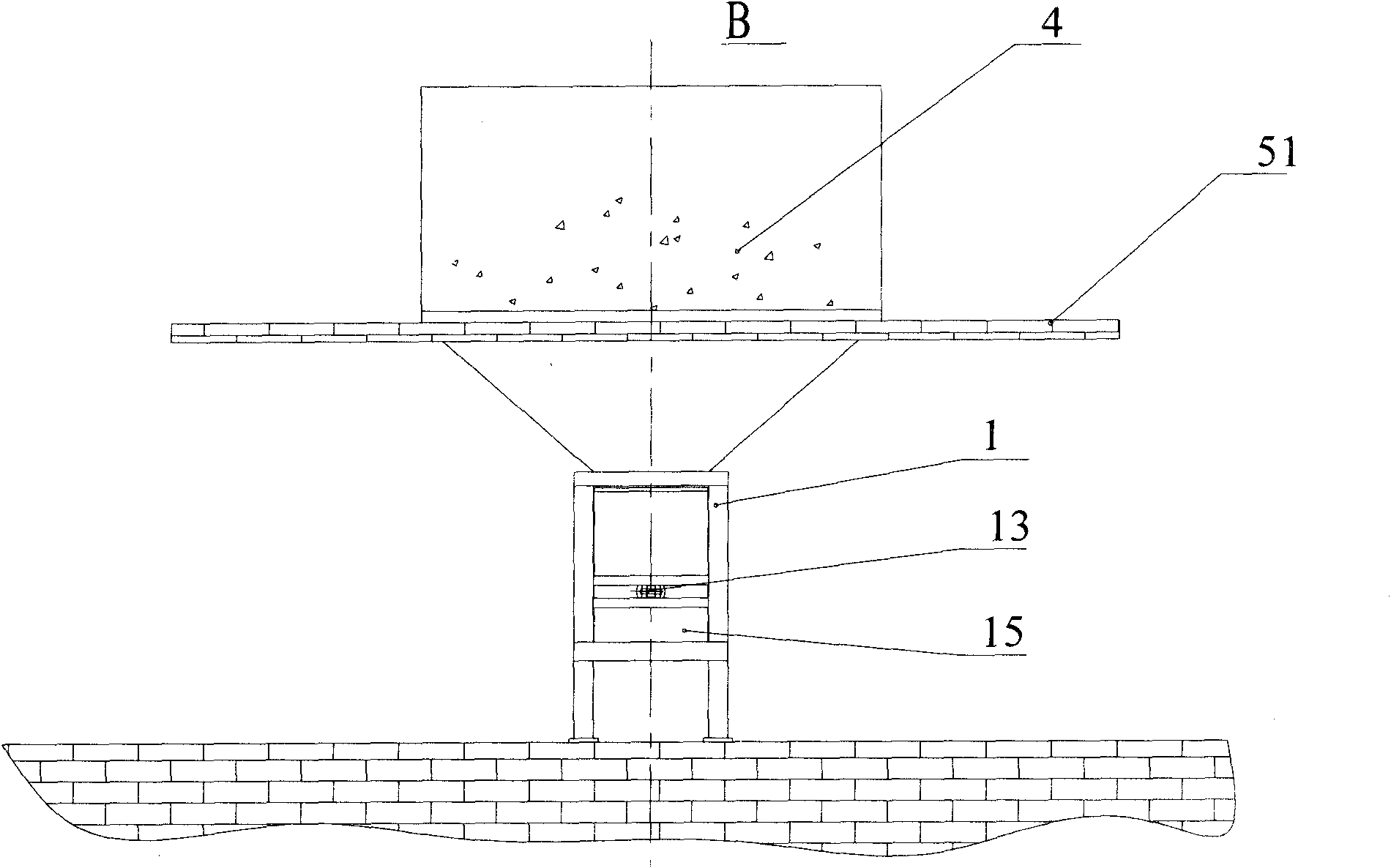

[0032] Such as figure 1 As shown, a two-way garbage compressor according to an embodiment of the present invention includes: a compression chamber, and the compression chamber is provided with a first-direction compression mechanism and a second-direction compression mechanism.

[0033] The compression mechanism in the first direction is, for example, a horizontal compression mechanism, which includes: a horizontal compressor frame 1, a driving device arranged on the horizontal compressor frame 1, such as a hydraulically driven horizontal compression oil cylinder 13, and the horizontal compression oil cylinder 13 can be a single One-stage or multi-stage oil cylinders can also be combined by a plurality of oil cylinders. Its function is to complete the horizontal compression of garbage and reload garbage (i.e. unloading). The horizontal compression ram 15 (the setting here not only includes the up and down position on the horizontal compression chamber, but also includes other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com