Longitudinal connected comb-tooth-type vertical lifting parking equipment

A technology of vertical lifting and parking equipment, which is applied in the direction of buildings, building types, and buildings where cars are parked. It can solve the problems of increased parking equipment costs, reduced garage capacity, and long access time to reduce parking equipment. The effect of reducing cost, reducing access time, and increasing the number of parking lots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

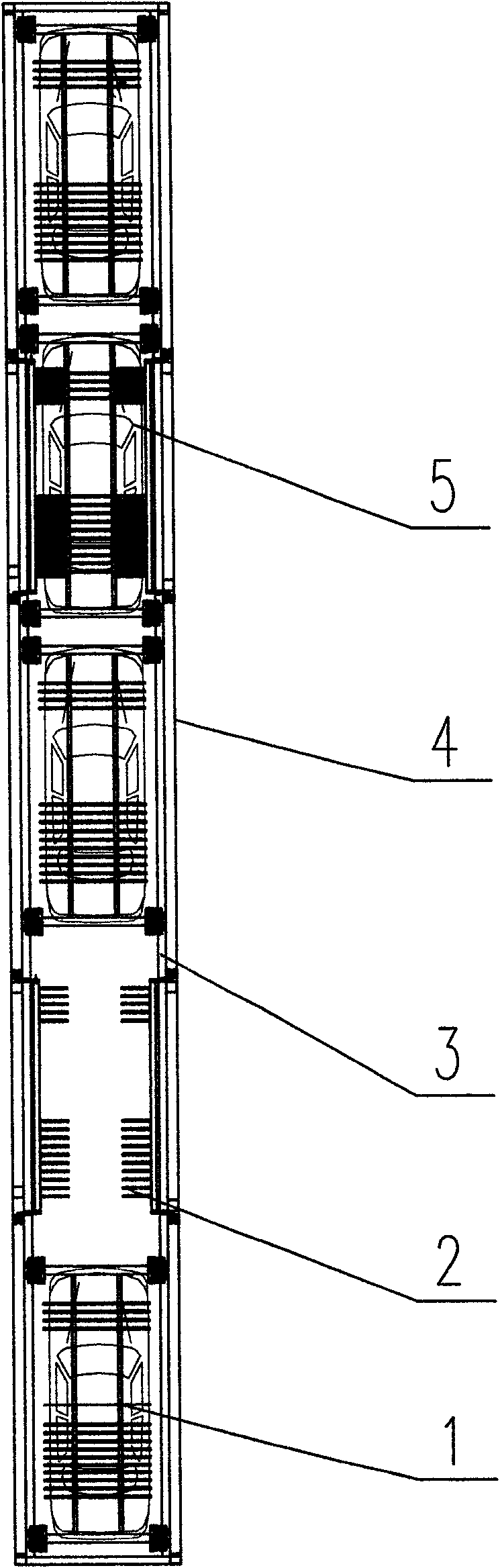

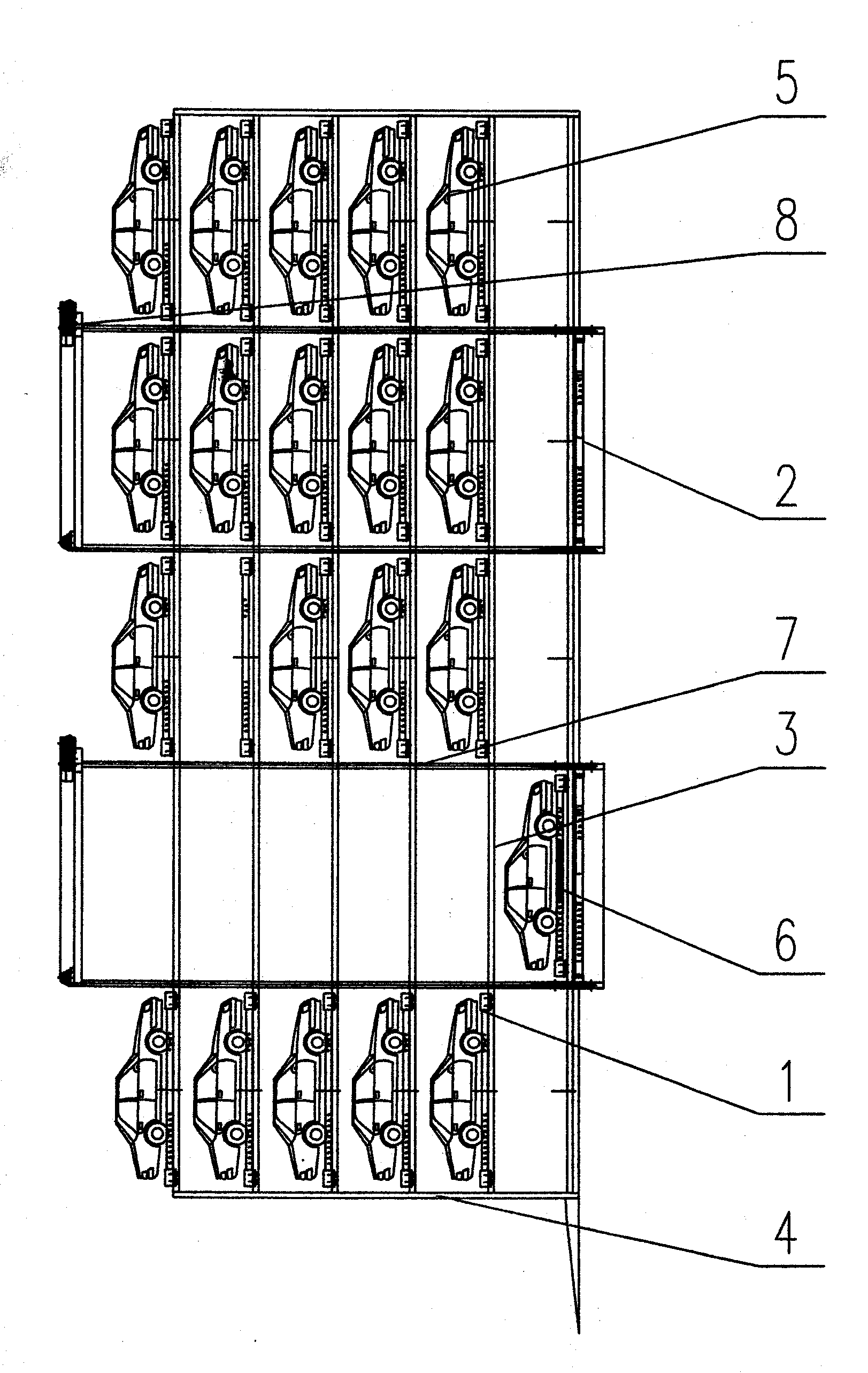

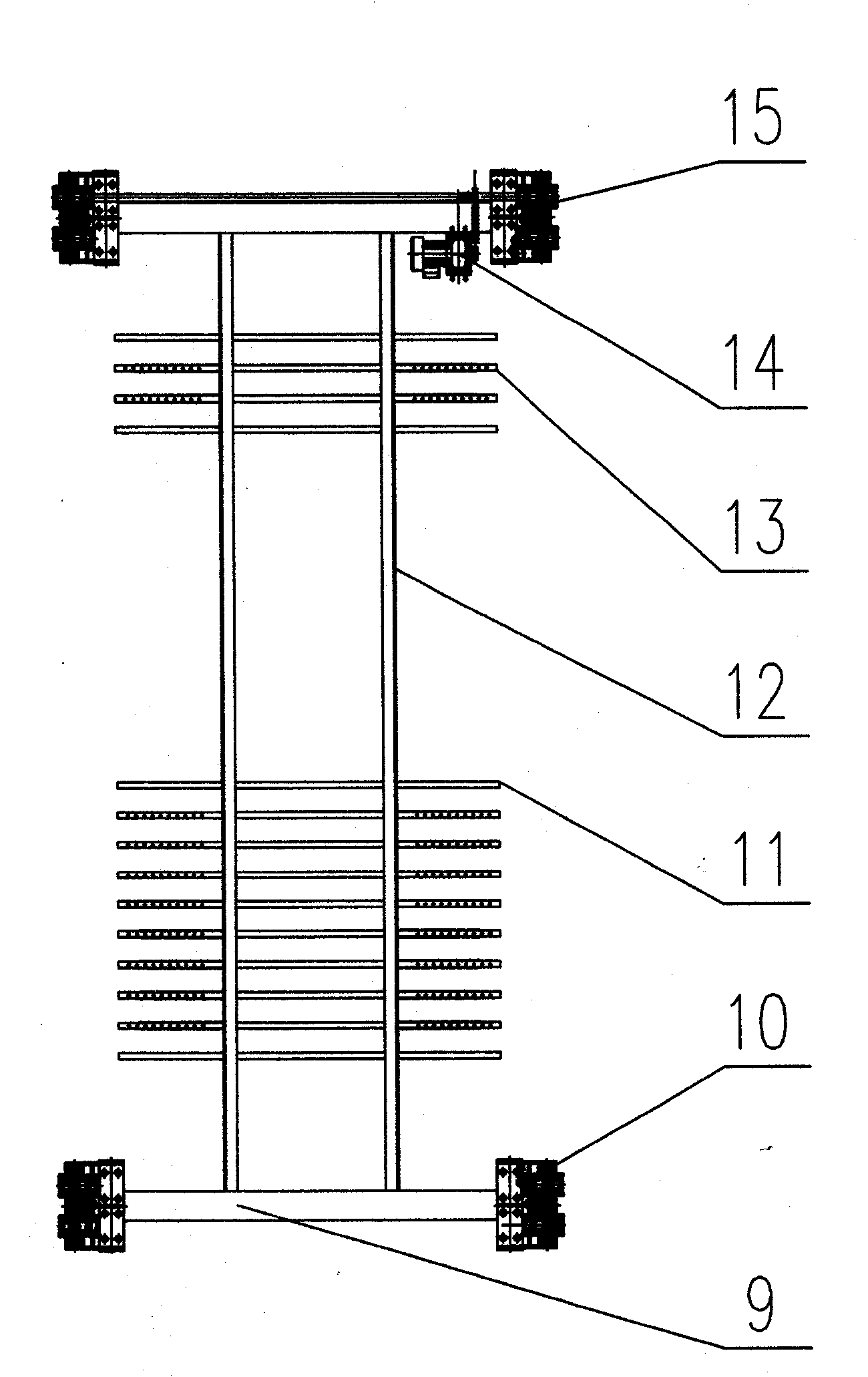

[0021] see Figure 1~5 .

[0022] The tandem comb-tooth type vertical lifting parking equipment of the present invention mainly consists of a steel structure 4, a comb-tooth type vehicle loading plate 1, a lifting carrier 2, an entrance and exit horizontal carrier 6, a lifting drive mechanism 8, and a guide rail 7 for the lifting carrier. Layer horizontal track 3 and so on. The steel structure 4 is composed of columns, beams, longitudinal beams, etc., and is a structural support that bears the mass of the entire parking facility. The comb-toothed vehicle-carrying board has a beam 9 and a longitudinal beam 12 to form a planar main frame, and a front comb rack 13 and a rear comb rack 11 are arranged at the positions corresponding to the front and rear wheels of the automobile, and the wheels of the automobile are directly placed on the front and rear comb teeth. On the bar, there is a running drive mechanism 14 on this, and a geared motor directly drives the transmission shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com