Sliding door

A sliding door and door leaf technology, applied in the field of vehicles, can solve problems such as difficult opening, wear and tear, and achieve the effect of reduced push-pull force and effective sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

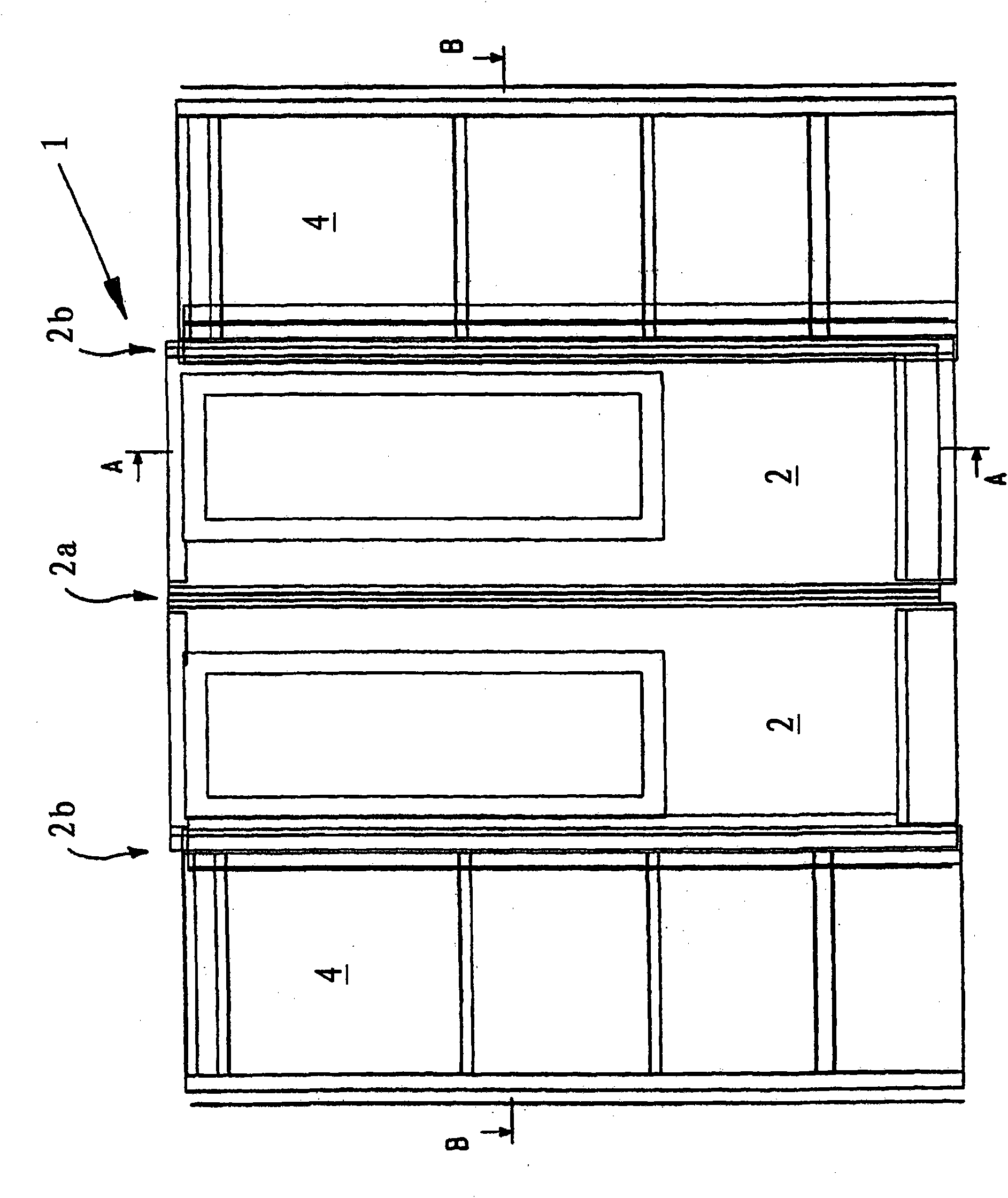

[0016] figure 1 A sliding door 1 is shown with two door leaves 2 which are moved behind an outer door frame lining 4 when the door is opened. exist figure 1 For the sake of simplicity, only the side door frame liner is shown, but there is also a part of the door frame liner above the door ( figure 2 shown in ), which covers the upper area of the door leaf 2. The secondary closing edge (Nebenschlieβkante) 2b and the main closing edge (Hauptschlieβkante) 2a of the door leaf 2 are likewise shown.

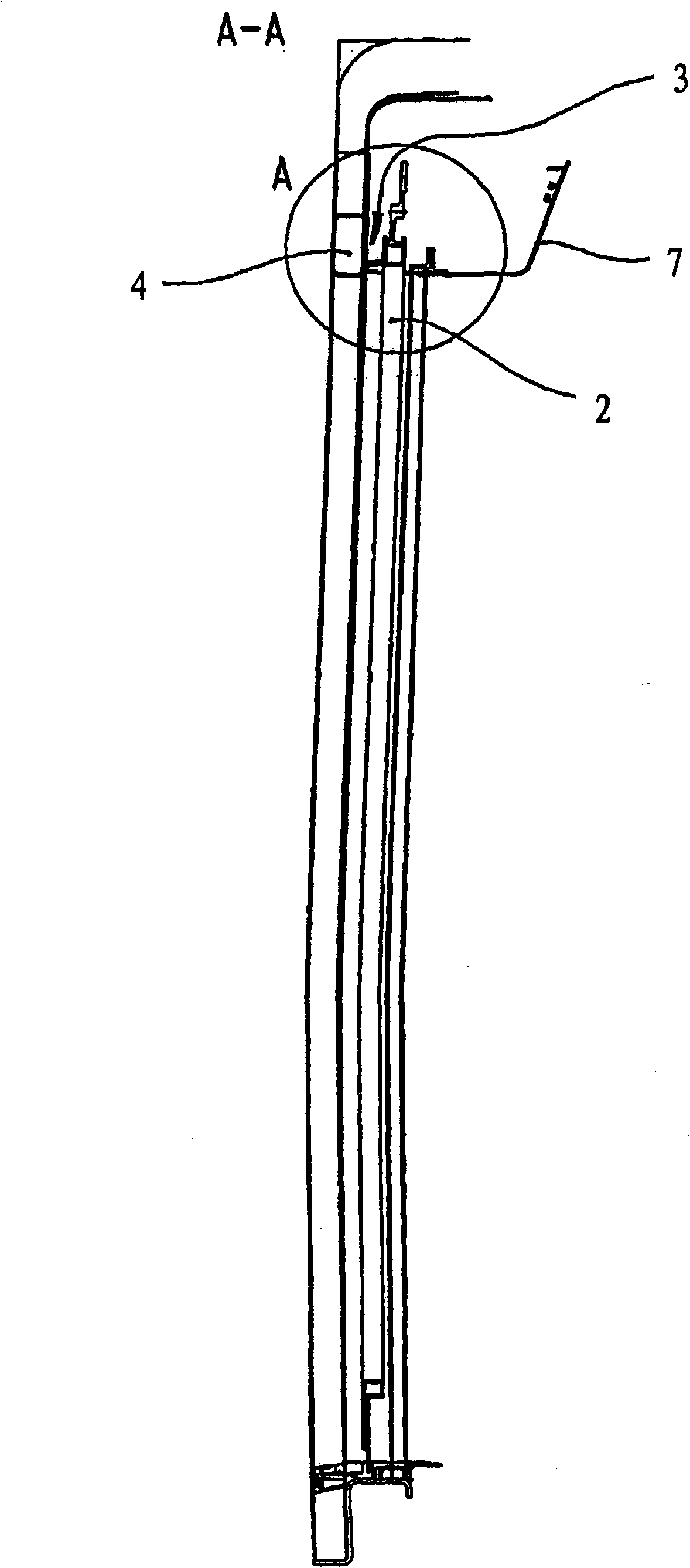

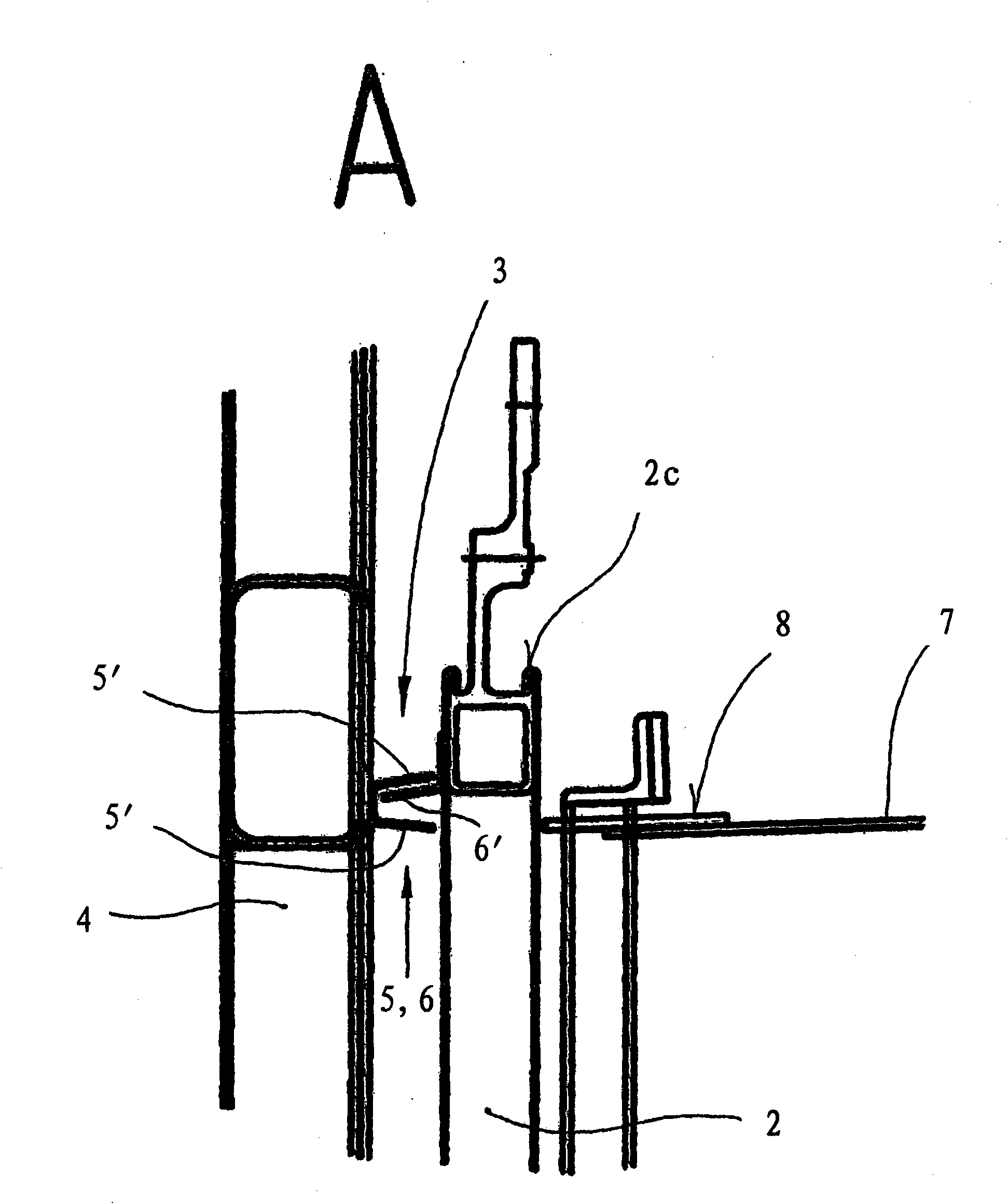

[0017] figure 2 shows that it is perpendicular to figure 1 Vertical section A-A of the door leaf plane. exist figure 2 The gap 3 between the outer door frame lining or skin 4 and the door leaf 2 is described in detail in . The door leaf 2 moves perpendicularly to the plane of the drawing during opening and closing. Adjacent to the inner side of the door leaves 2 is a cover plate 7 for a door operator (not shown) which acts on one or each door leaf 2 during opening and clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com