Air-exhaust decompression-preventing diaphragm type booster pump for spraying

A booster pump and diaphragm type technology, applied in the field of spraying diaphragm booster pumps, can solve the problems of the non-return rubber pad 80 and the drainage seat 71 being unable to be completely sealed, insufficient structural strength, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

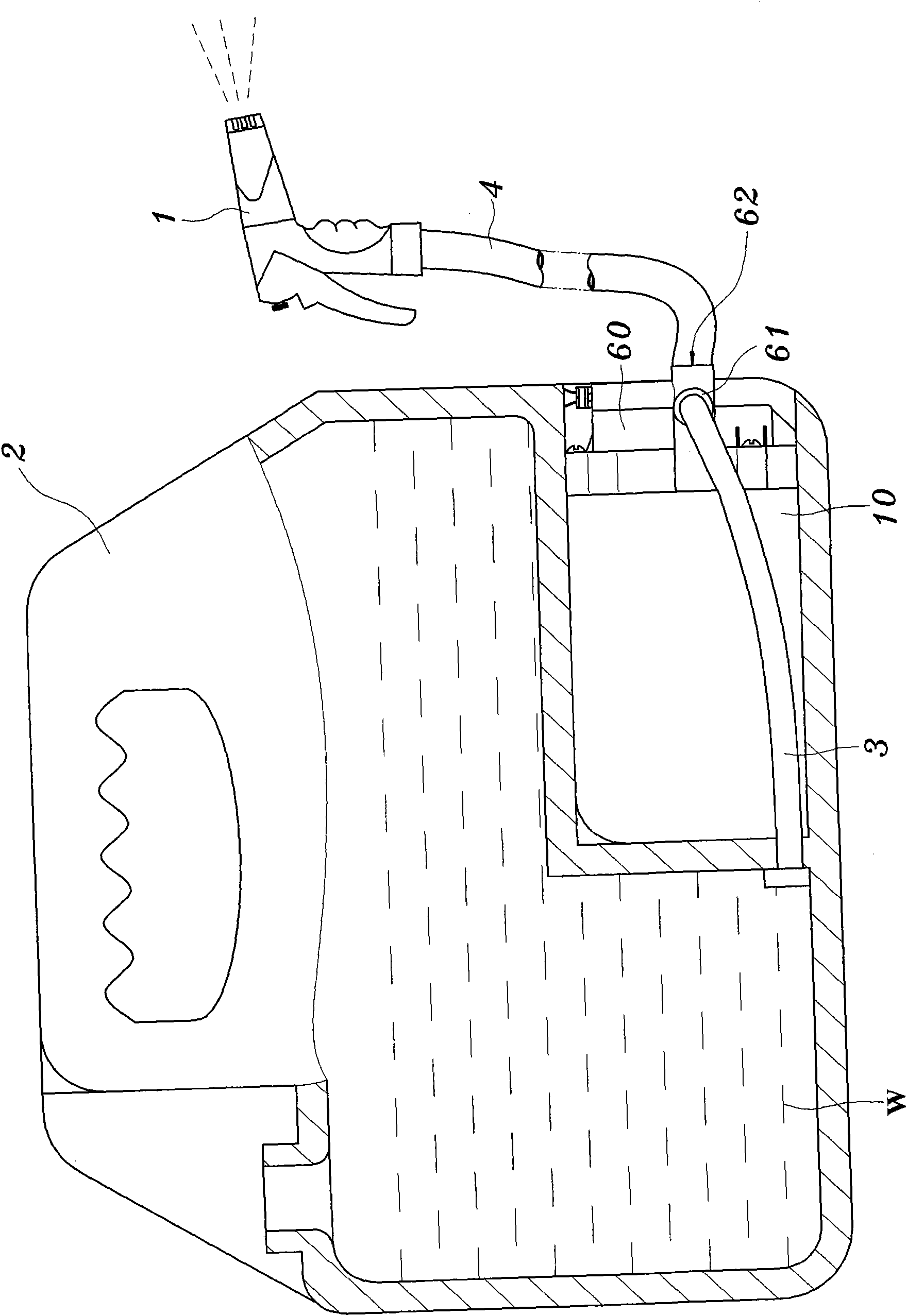

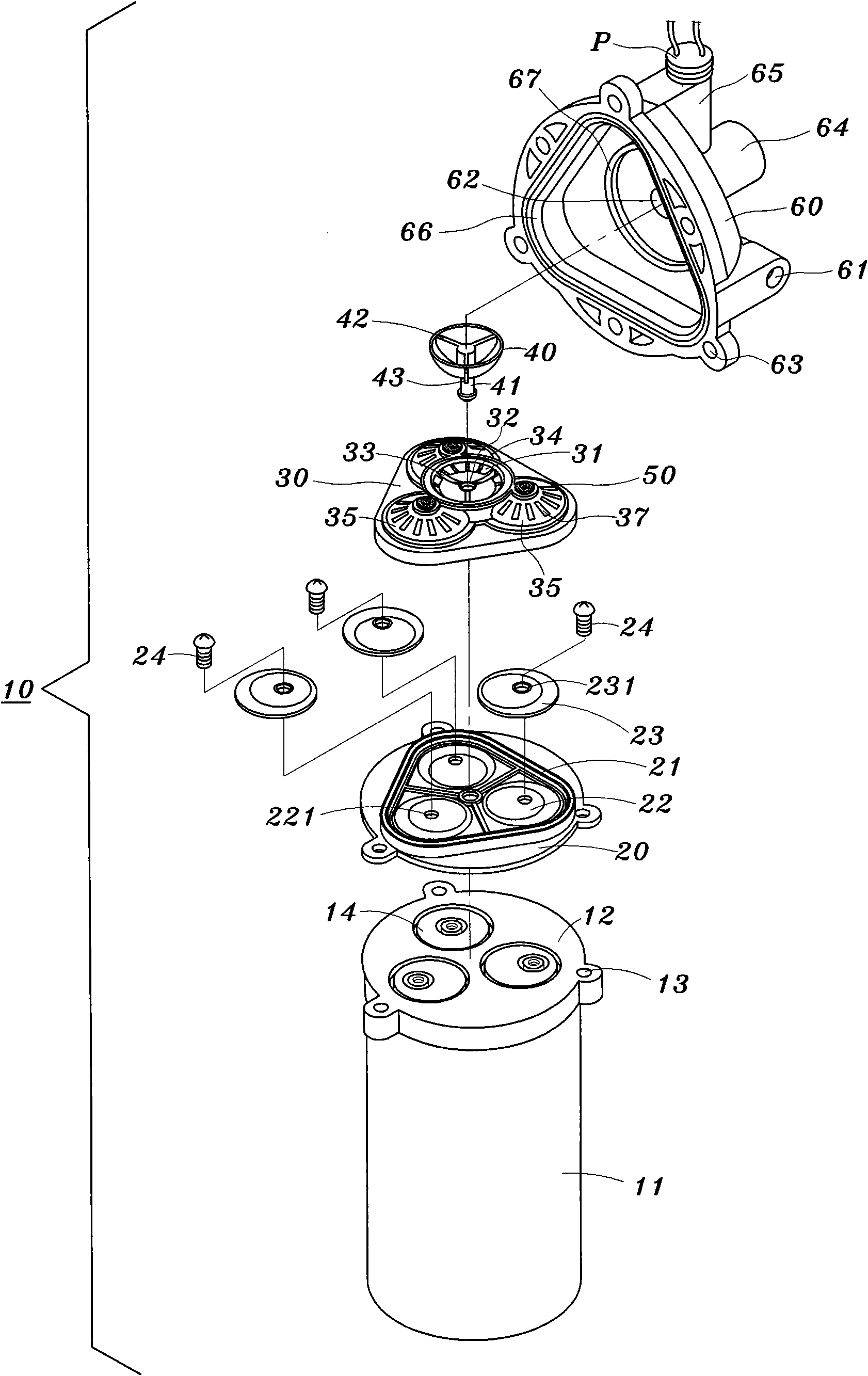

[0079] Such as Figure 13 and Figure 14 Shown is the first embodiment of a diaphragm booster pump for spraying that can be exhausted according to the present invention, which includes:

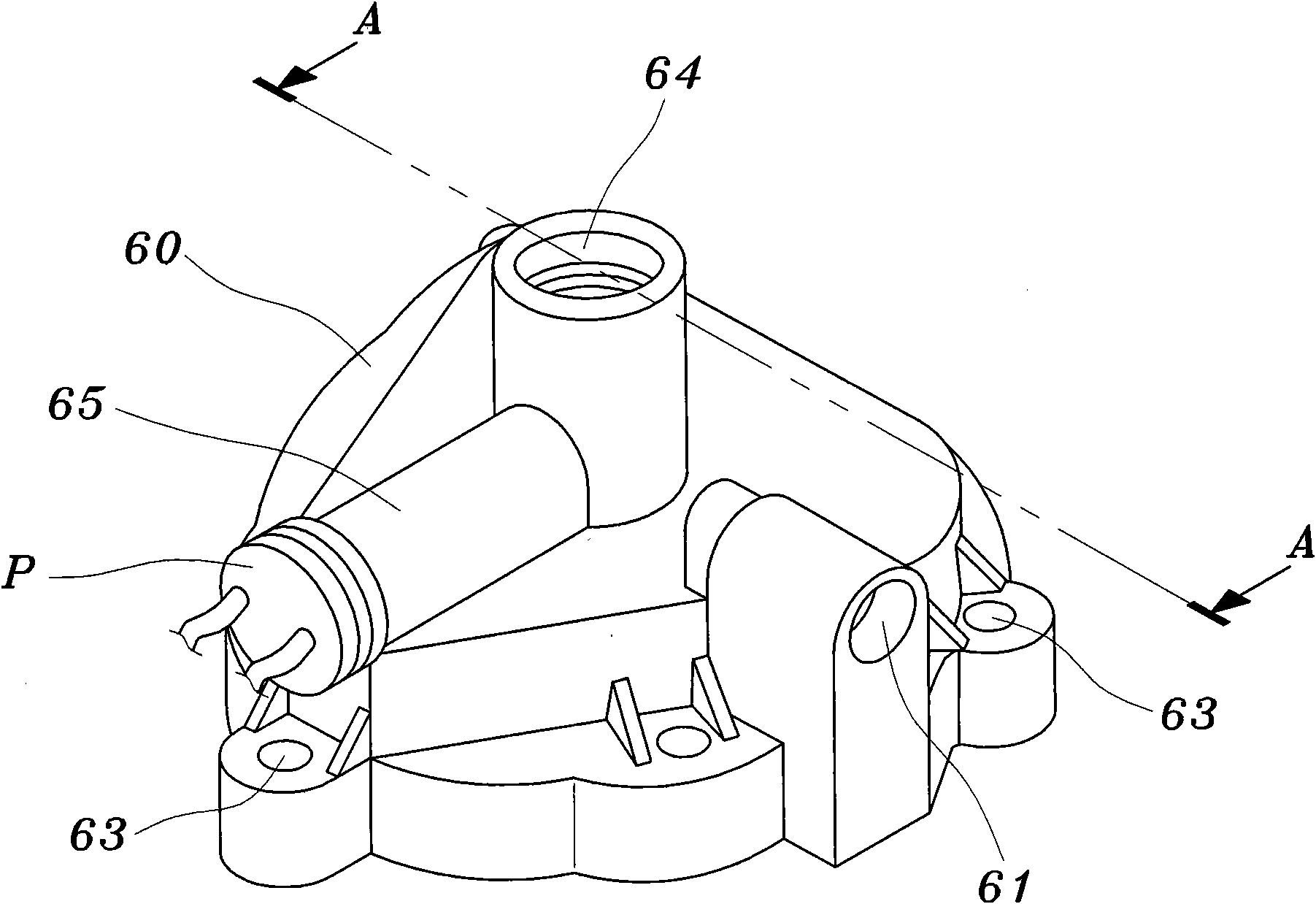

[0080] An exhaust seat 100 is a hollow cylindrical body and is connected to the side wall surface of the outlet pipe seat 64 of the upper pump head cover 60 of the diaphragm type booster pump 10 for spraying. The lower section and the upper section are respectively provided with a first exhaust chamber. 101 and a second exhaust chamber 102, the diameter of the first exhaust chamber 101 is larger than the second exhaust chamber 102 and communicates with each other, and the first exhaust chamber 101 and the outlet pipe seat of the pump head cover 60 A vent 103 is pierced at the junction of the side walls of 64, and a vent 104 is pierced in the center of the top surface of the exhaust seat 100 toward the second exhaust chamber 102; and

[0081] A pneumatic piston seat 200, the top surface is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com