Oil-water pressure conversion device

A conversion device and pressure technology, which is applied in the field of servo hydraulic stations, can solve the problems of hydraulic oil loss, increased test costs, and emulsified products that cannot be used continuously, and achieve the effect of avoiding waste and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

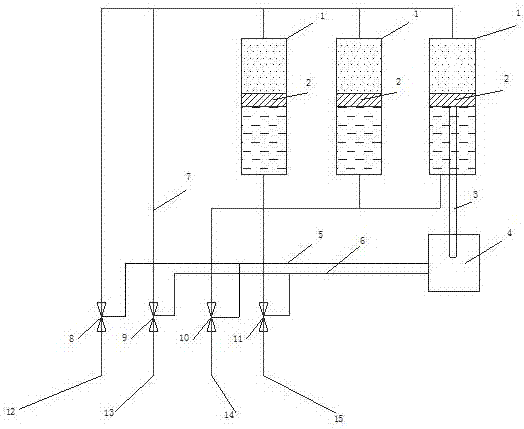

[0011] Such as figure 1 As shown, an oil-water pressure conversion device of the present invention includes a hydraulic cylinder 1, four electromagnetic switches and a displacement electromagnetic switch 4; there are three hydraulic cylinders 1, one of which is of the type with a ejector rod, and two are without ejector rods type, with ejector rod type hydraulic cylinder 1 controls the displacement electromagnetic switch 4 through the ejector rod displacement, opens and closes to realize the circuit on and off, and controls the displacement electromagnetic switch 4 to open and close; here, when the maximum and minimum strokes of the ejector rod displacement are preset, the hydraulic pressure When the displacement of the ejector rod of cylinder 1 reaches the set maximum and minimum strokes, the trigger displacement electromagnetic switch 4 is opened or closed. The displacem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com