Cutting line on glass sheet providing apparatus

A glass plate and cutting line technology, applied in glass cutting devices, fine work devices, glass manufacturing equipment, etc., can solve problems such as cracking of glass plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, typical embodiments of the present invention will be described with reference to the drawings.

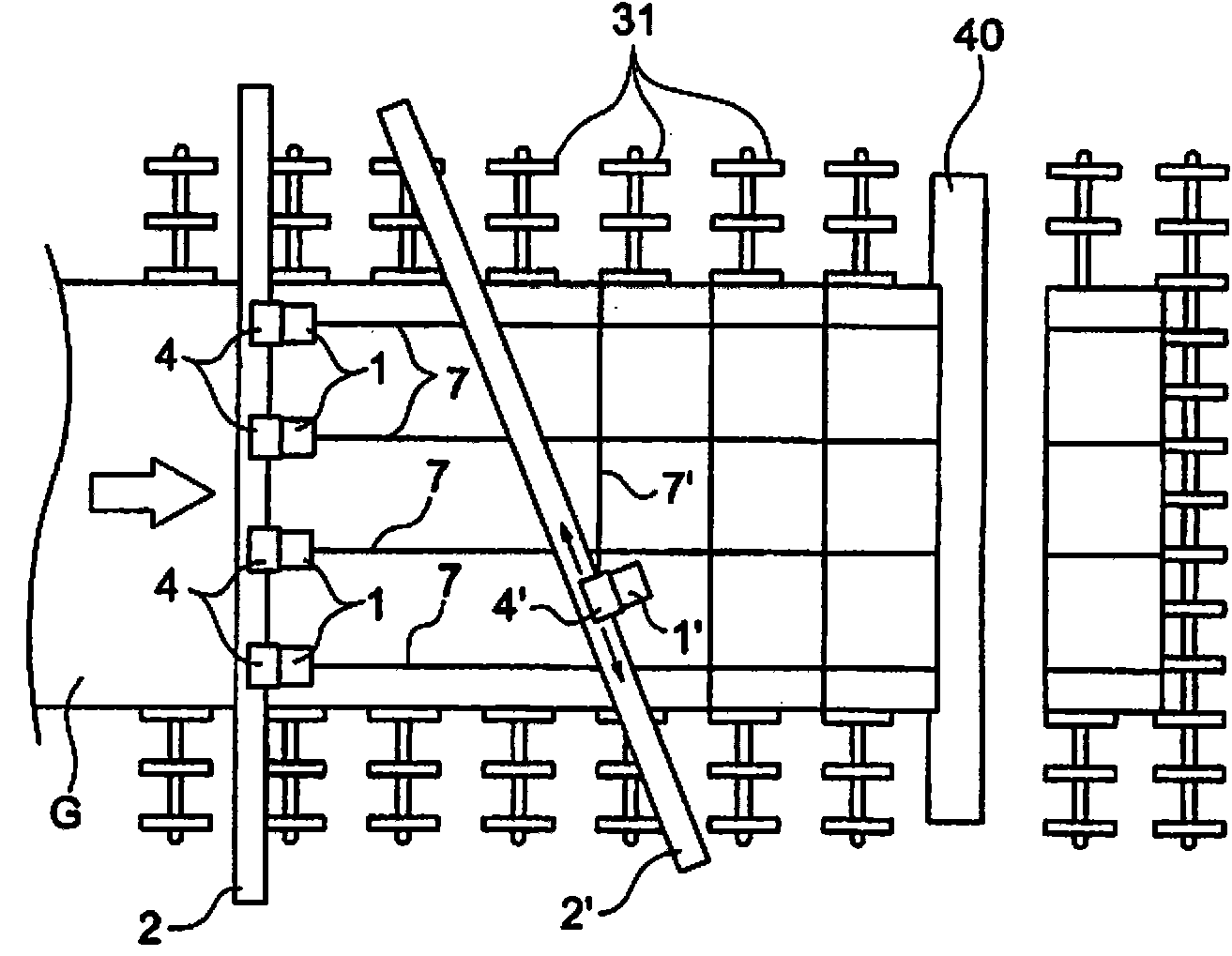

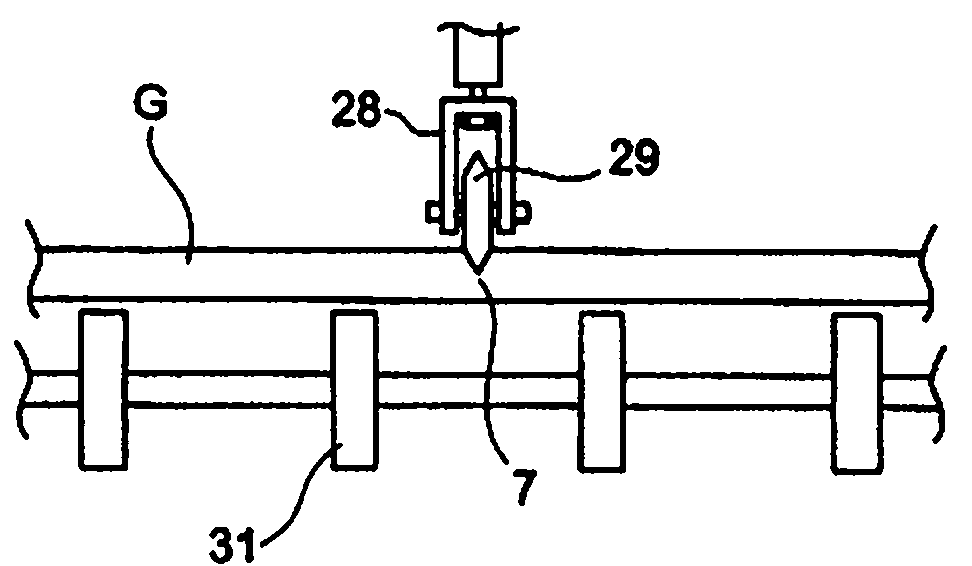

[0028] like figure 2 As shown, in order to cut off the glass plate G conveyed in a wide band shape with a predetermined size, by pressing the wheel-shaped cutter head 29 of the cutter against the surface of the glass plate, the upper side surface of the glass plate is preliminarily cut. The conveying direction (longitudinal line 7) and the width direction (cross line 7') of the glass plate are given groove-shaped line 7 (refer to image 3 ). Thus, the glass sheet is separated by breaking along the widthwise scribe line 7 ′ by the break roller 40 provided on the downstream side, and is separated along the longitudinal scribe line 7 in a subsequent process not shown. break to separate. As a result, a glass plate of the target size can be obtained.

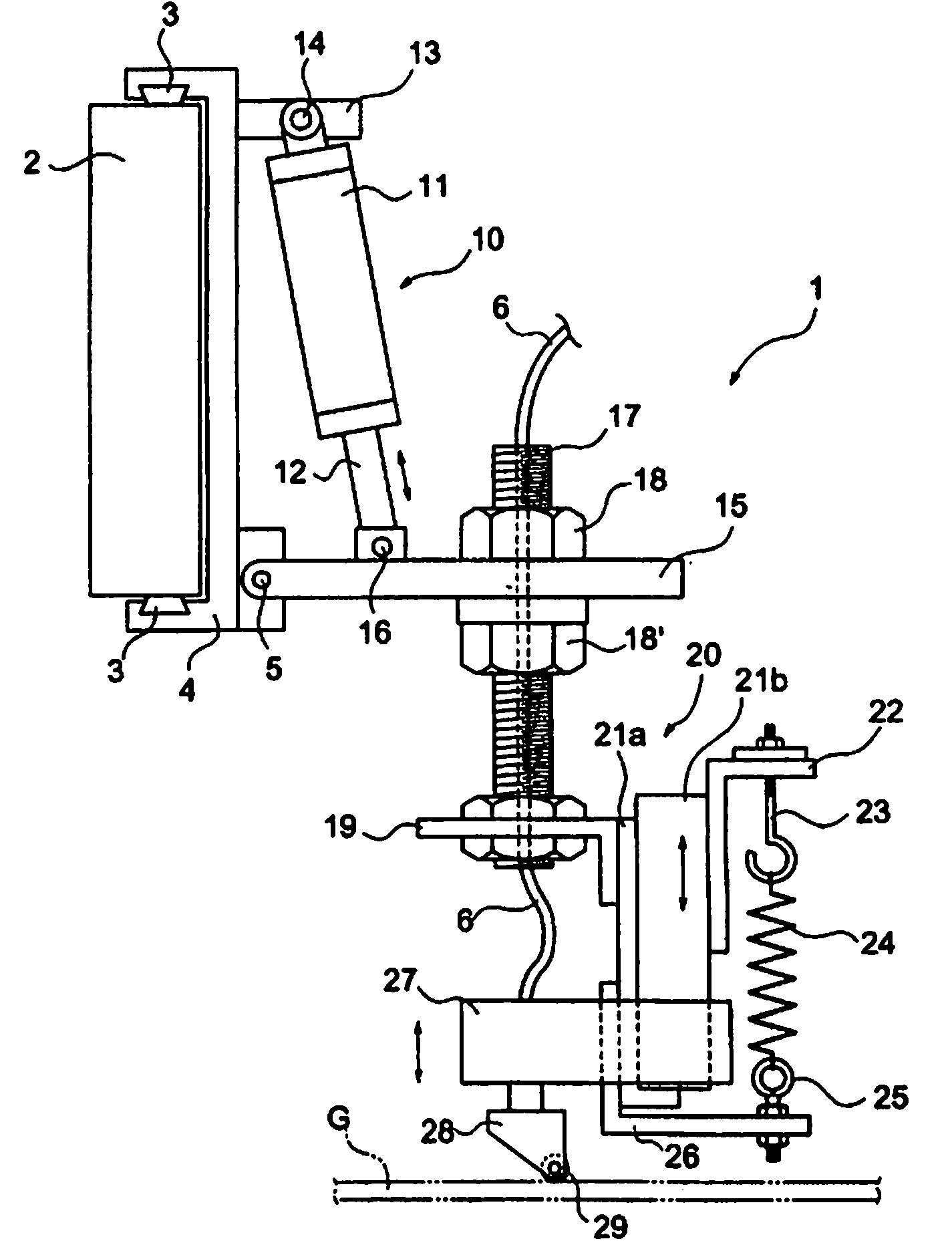

[0029] like figure 1 As shown, in a typical embodiment of the present invention, such as figure 2 As shown, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com