Color selector

A color sorter and vibrating feeding technology, which is applied in the field of color sorting machines, can solve problems such as poor feeding consistency, parameter errors, and large material jumps, and achieve the effects of not being easy to jump, ensuring normal feeding, and ensuring color sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

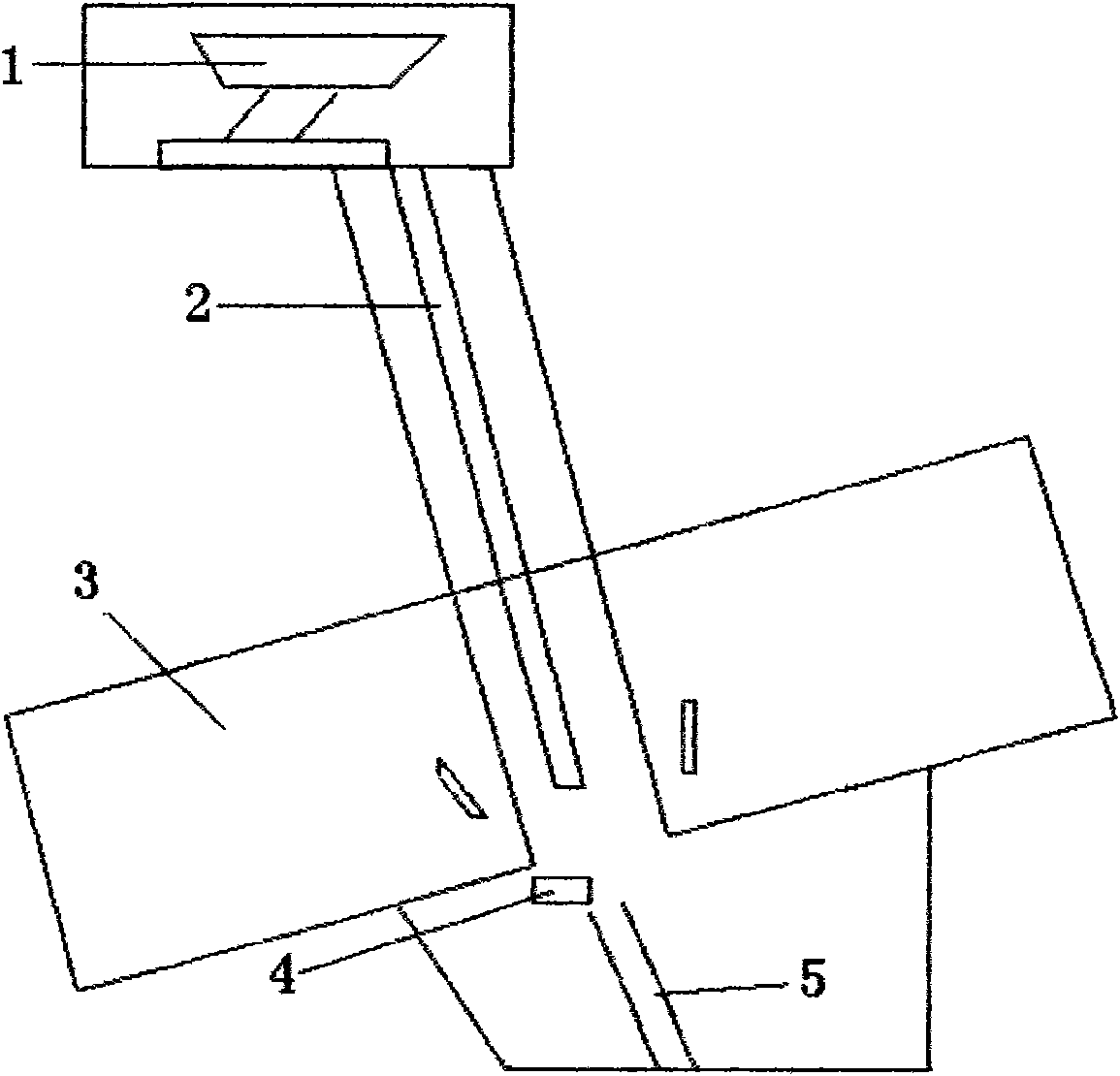

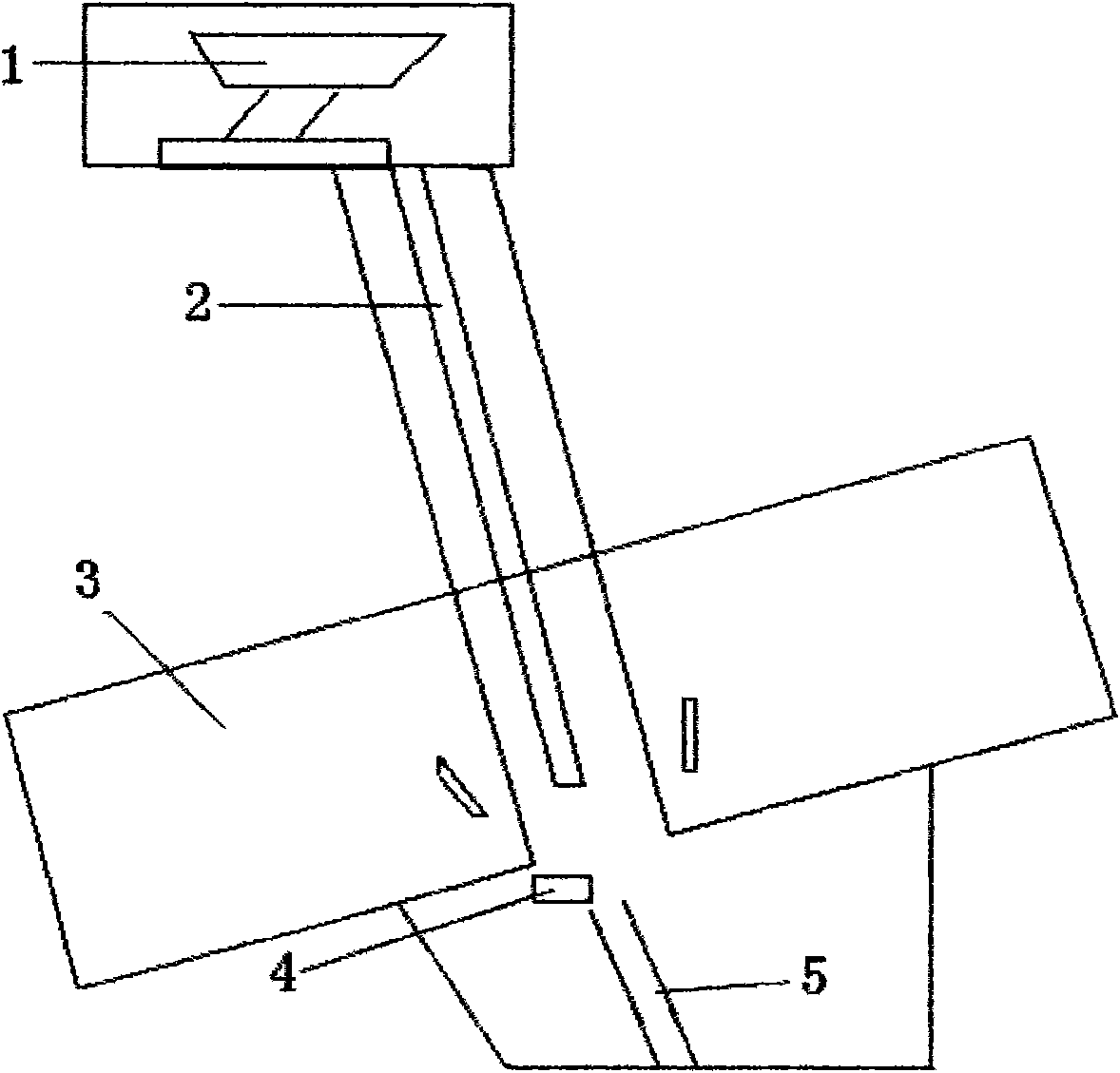

[0009] A color sorter, comprising a vibrating feeder 1, a flat chute 2, an optical resolution chamber 3, an air flow nozzle 4 and a distribution hopper 5, the vibrating feeder 1 is installed on the back and upper side of the flat chute 2, the vibrating feeder 1 The horizontal direction of the funnel is consistent with that of the flat chute 2, and the bottom of the flat chute 2 is provided with an optical resolution chamber 3, the bottom of the optical resolution chamber 3 is provided with an airflow nozzle 4, and the bottom of the airflow nozzle 4 is provided with a distribution hopper 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com