Wheel speed-limitation structure for mine running-resisting car

A technology for preventing sports cars and wheels, applied in railway car body parts, automatic brakes, transportation and packaging, etc., can solve the problems of many fault points, high impact energy, fast vehicle speed, etc., and achieve the effect of reducing disaster prevention costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

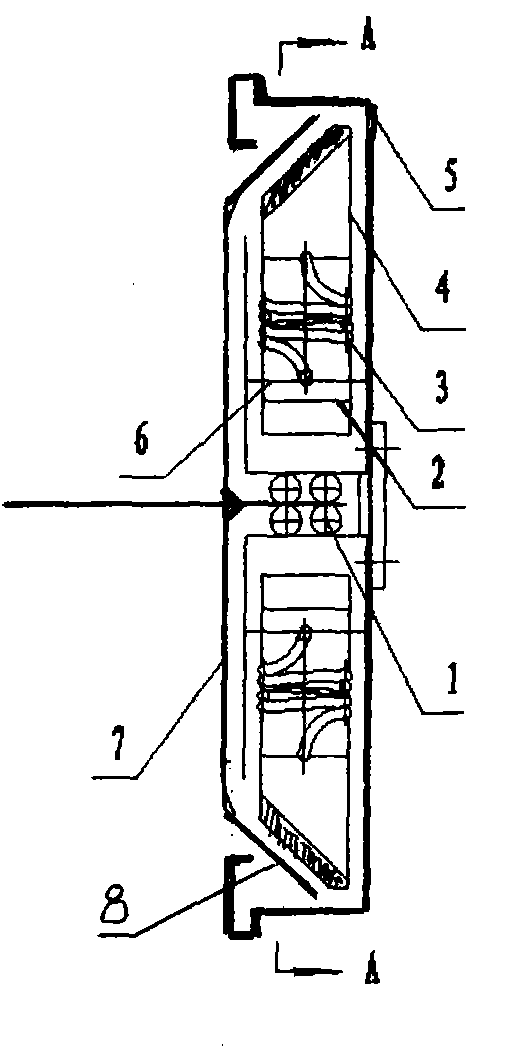

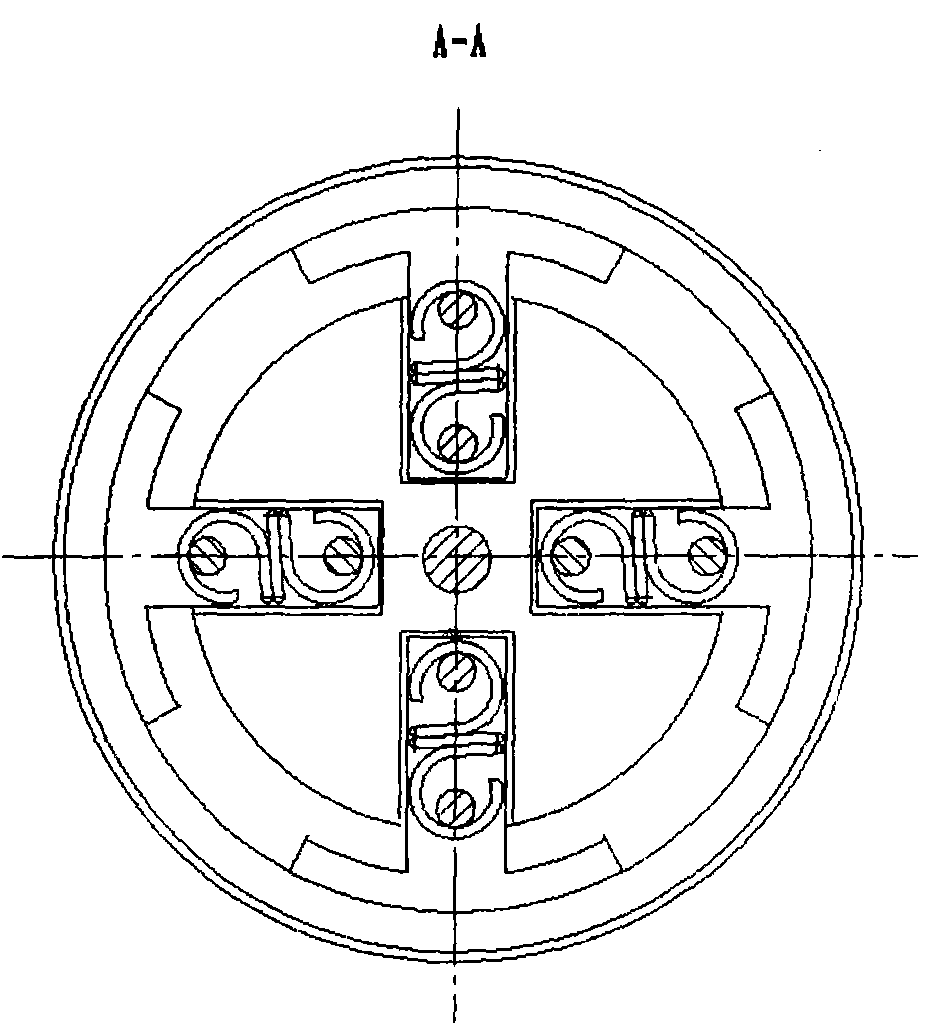

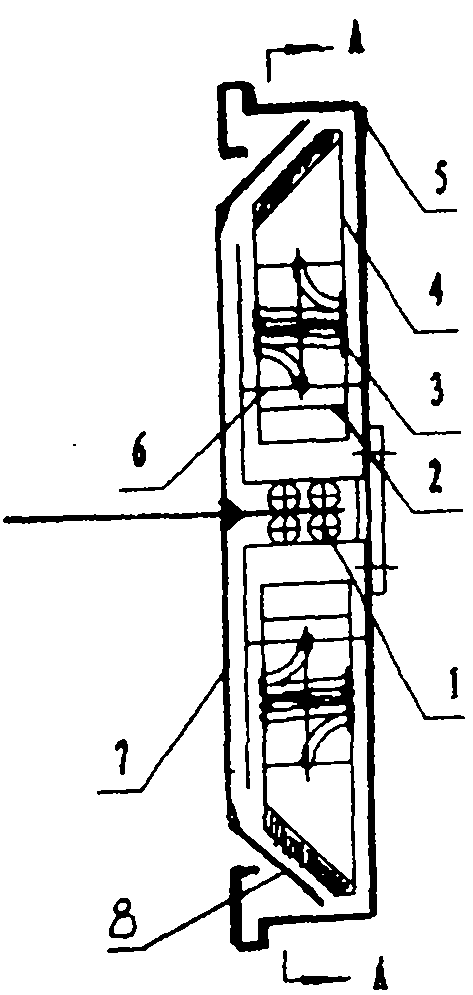

[0012] refer to figure 1 The embodiments of the present invention are further described. From figure 1 It can be seen that the structure of the present invention is: on the wheel hub 5 of the mining wheel, 4 force transmission grooves 2 are evenly distributed radially, and each force transmission groove 2 is equipped with an inertial friction block 4 reset by a return spring 3, each There is a limit pin 6 on the inertial friction block 4; in addition, a brake disc 7 is fixedly connected to the axle 1, and the brake disc 7 is provided with a circle of friction surfaces matched with the inertial friction block.

[0013] In order to increase the friction resistance torque, the friction surface between the brake disc 7 and the inertial friction block 4 is designed as an inclined plane to increase the friction area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com