Concentric flame-retardant cable

A flame retardant cable, flame retardant filling technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of failing to meet the requirements of flame retardant grade, large size, poor flame retardant performance, etc., to achieve stable cable structure, cable The effect of size reduction, increased shielding function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

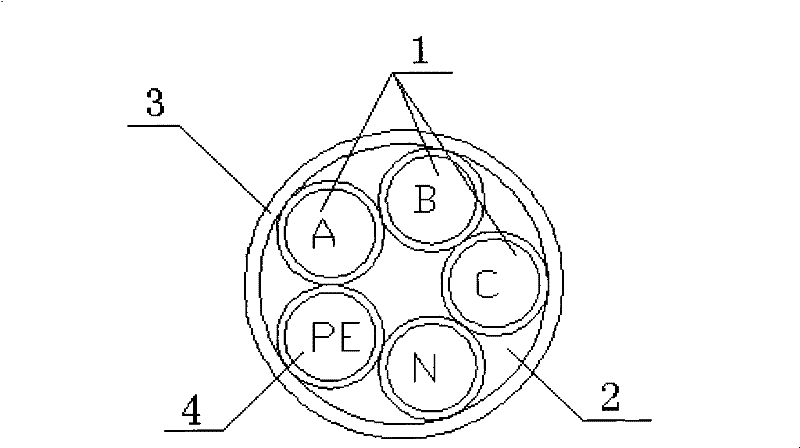

[0013] like figure 1 As shown, the prior art flame retardant cable structure schematic diagram, it includes core, flame retardant filler 2 and cable sheath 3; core includes insulated core 1 and grounding core 4; flame retardant filler 2 is filled in the insulated wire Between core 1, ground core 4 and cable sheath 3. On the one hand, the structure of the flame-retardant cable of the prior art structure is unstable, and the flame-retardant performance is also poor.

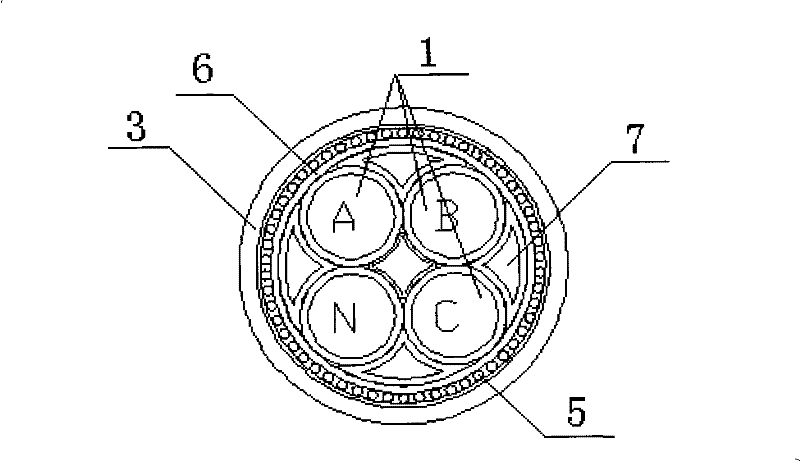

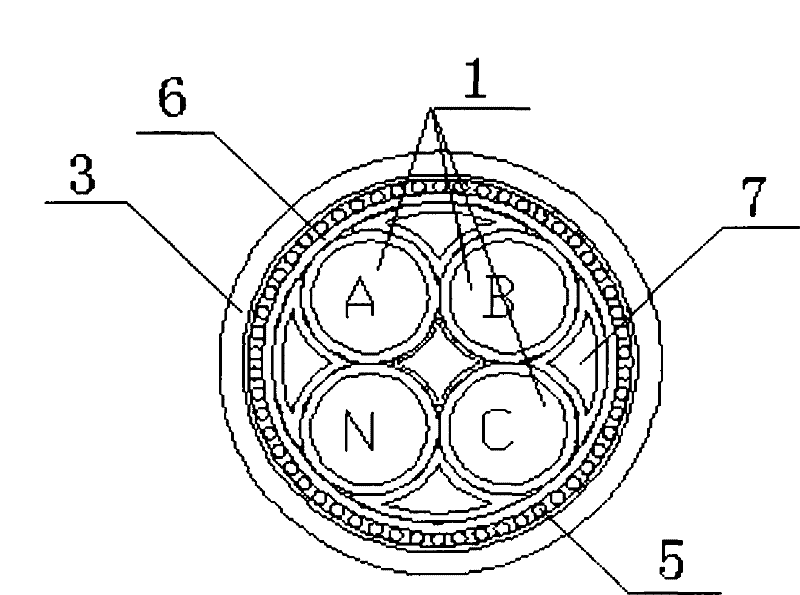

[0014] like figure 2 As shown, the structure diagram of the concentric flame-retardant cable of the present invention includes an insulating core 1, a wrapping layer 6, and a cable jacket 3; a grounding layer 5 is arranged outside the wrapping layer 6, and the cable jacket 3 is wrapped outside the grounding layer 5 ; The grounding layer 5 is a linear structure, which can be copper wire, and is wound out...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap