Chlorinated fatty acid tartaric ester flotation agent and preparation method thereof

A chlorinated fatty acid, tartrate technology, applied in the preparation of carboxylic acid halide, flotation, solid separation and other directions, can solve the problems of increased beneficiation cost, poor collection performance, unsatisfactory effect, etc., and achieves good flotation effect, Improved surface activity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

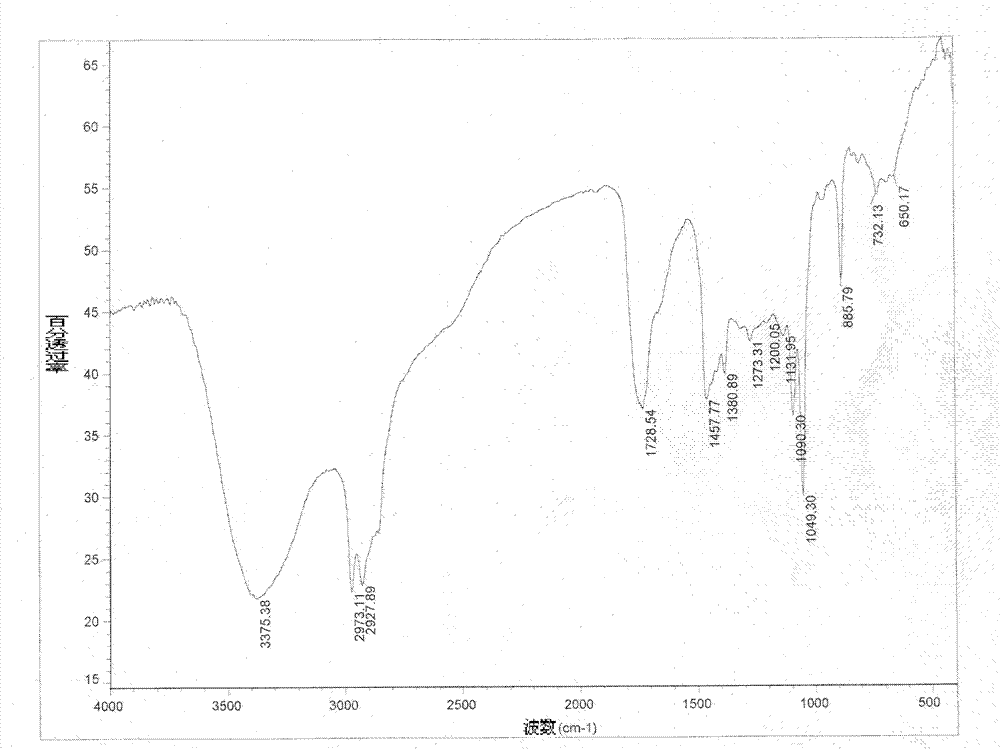

Image

Examples

Embodiment 1

[0022] The preparation method of chlorinated fatty acid tartrate flotation agent, it comprises the steps:

[0023] Add 0.3 mol of soybean oil to a 1L beaker, mechanically stir and heat, add 200mL (15mol / L) of NaOH solution at 80°C, and keep warm at 90°C until no oily flowers appear in a small amount of product in cold water (that is, complete saponification, the time is about 3h), add 100mL of 80°C water and 30mL of NaOH solution (15mol / L) and continue the heat preservation reaction for half an hour to obtain a saponified product; add 0.4mol NaCl to the saponified product and let it stand for salting out for 5 hours, then take the saponified product in the upper layer and wash it with water (The amount of water should not be so much as to produce jelly), and the saponification product was obtained by suction filtration; the concentrated sulfuric acid was diluted with distilled water into a sulfuric acid solution with a concentration of 12mol / L, and 125mL (12mol / L) of sulfuric a...

Embodiment 2

[0034] The preparation method of chlorinated fatty acid tartrate flotation agent, it comprises the steps:

[0035] Add 0.6 mol of soybean oil to a 2L beaker, mechanically stir and heat, add 400mL (12mol / L) of NaOH solution at 90°C, and keep warm at 100°C until a small amount of product is put in cold water without oily flowers to obtain saponified product (i.e. completely saponified , the time is about 3h), add 80 ℃ water 200mL and NaOH solution 100mL (12mol / L) and continue to keep warm for half an hour to obtain saponified product; add 0.8mol NaCl to the saponified product and let it stand for salting out for 5 hours, take the upper saponified product and wash it with water (the amount of water should not be so much as to produce jelly) to obtain saponification product by suction filtration; the concentrated sulfuric acid is diluted with distilled water into a sulfuric acid solution with a concentration of 8mol / L, and the saponification product obtained is added to 400mL (8mol...

Embodiment 3

[0039] The preparation method of chlorinated fatty acid tartrate flotation agent, it comprises the steps:

[0040] Add 0.6 mol of soybean oil into a 2L beaker, mechanically stir and heat, add 400mL (12mol / L) of KOH solution at 80°C, and keep warm at 80°C until no oily flowers appear in a small amount of product in cold water (that is, the saponification is complete, the time is about 4h), add 200mL of 80°C water and 100mL of KOH solution (12mol / L) and continue the heat preservation reaction for half an hour to obtain a saponified product; add 0.8molNaCl to the saponified product and let it stand for salting out for 5 hours, then take the upper saponified product and wash it with water (the amount of water should not exceed As much as to produce jelly) to obtain saponified product by suction filtration; the concentrated sulfuric acid is diluted with distilled water into a sulfuric acid solution with a concentration of 8mol / L, and the saponified product is added with 400ml (8mol / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com