Mechanism for adjusting printing spray head module of inkjet printer

An inkjet printer and printing nozzle technology, which is applied in printing and other directions, can solve the problems of easy occurrence of streaks in the printed image and affect the quality of inkjet printing, and achieve the effect of improving the quality of inkjet printing and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

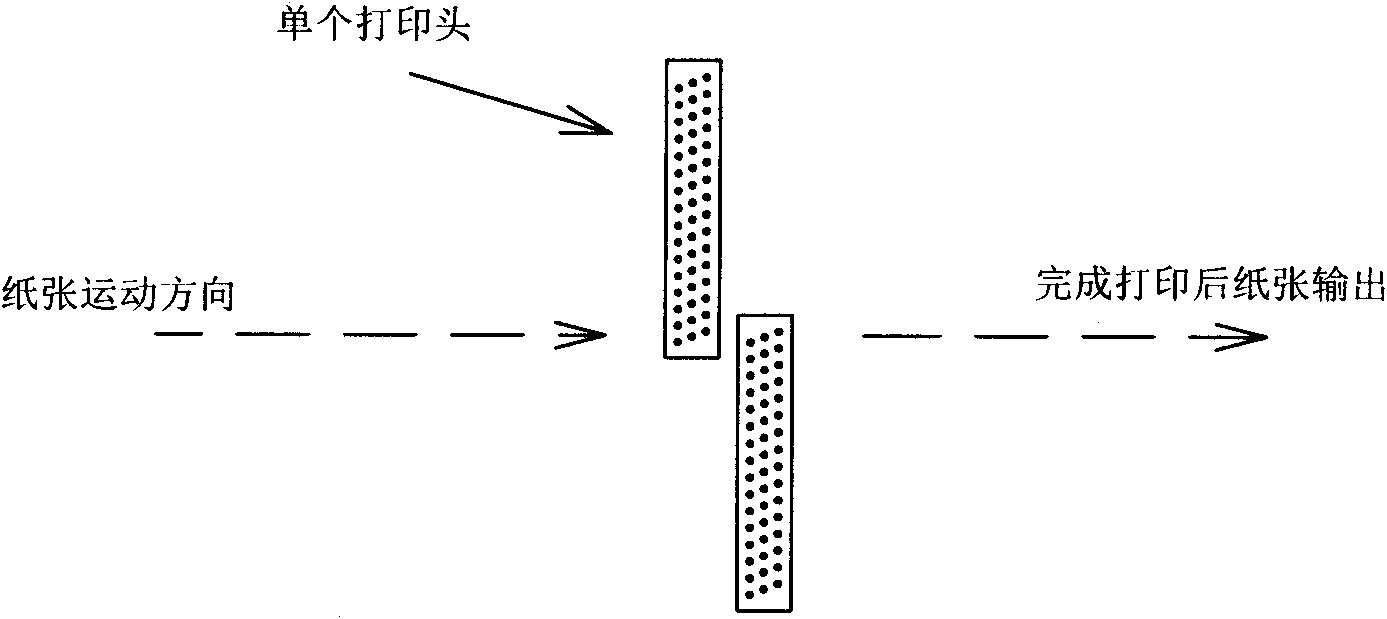

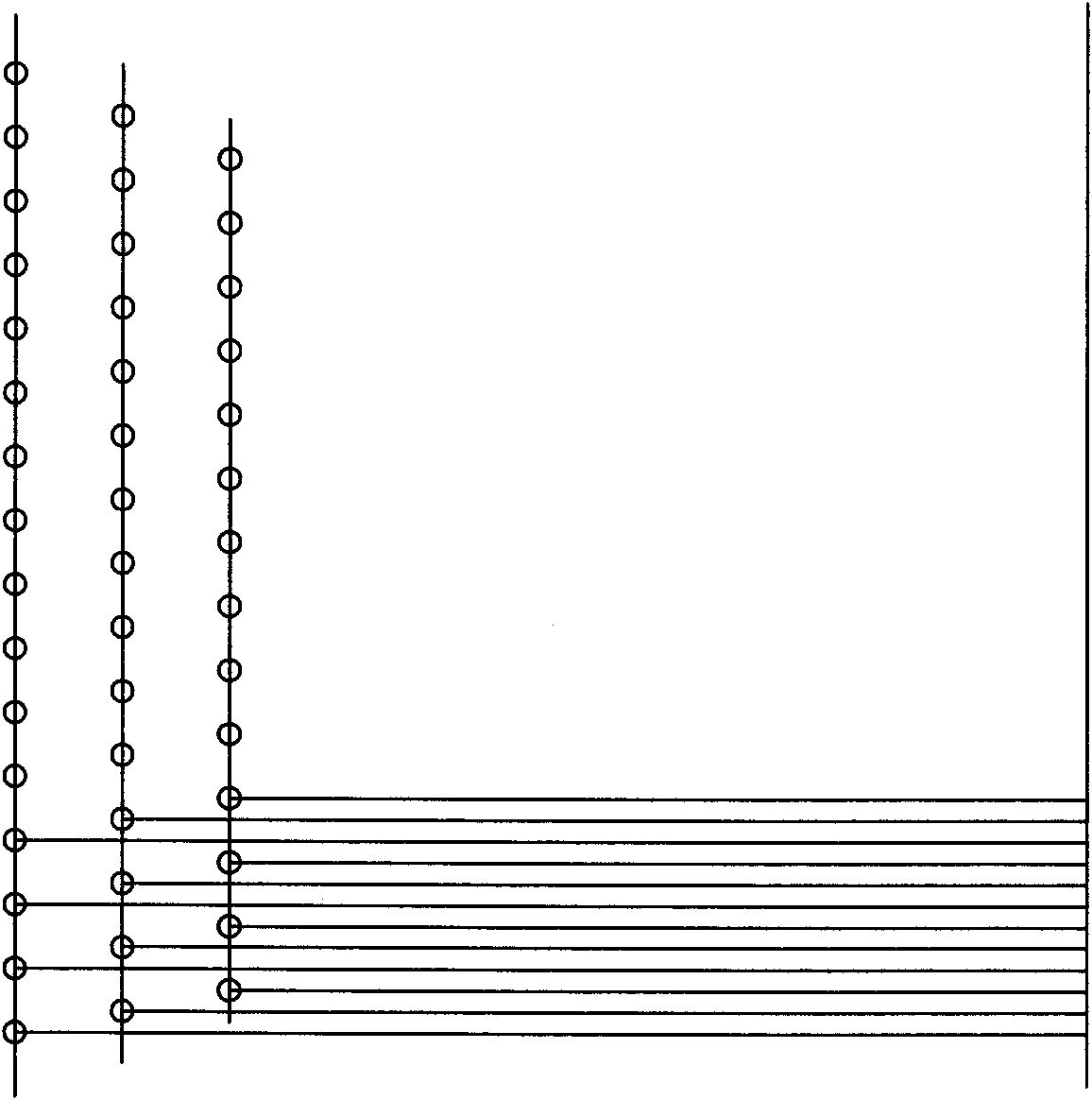

[0030] Such as Figure 4 As shown, the nozzle module adjustment mechanism of the present invention can realize the adjustment of the print nozzle module in five degrees of freedom, that is, move along the X axis and the Z axis, and rotate around the X, Y, and Z axes. During the printing process, the nozzle is completely parallel to the printing medium, and completely parallel to the moving direction of the printing medium, which improves the inkjet printing quality.

[0031] The print head module adjustment mechanism of the inkjet printer of the present invention will be described in detail below in conjunction with the accompanying drawings.

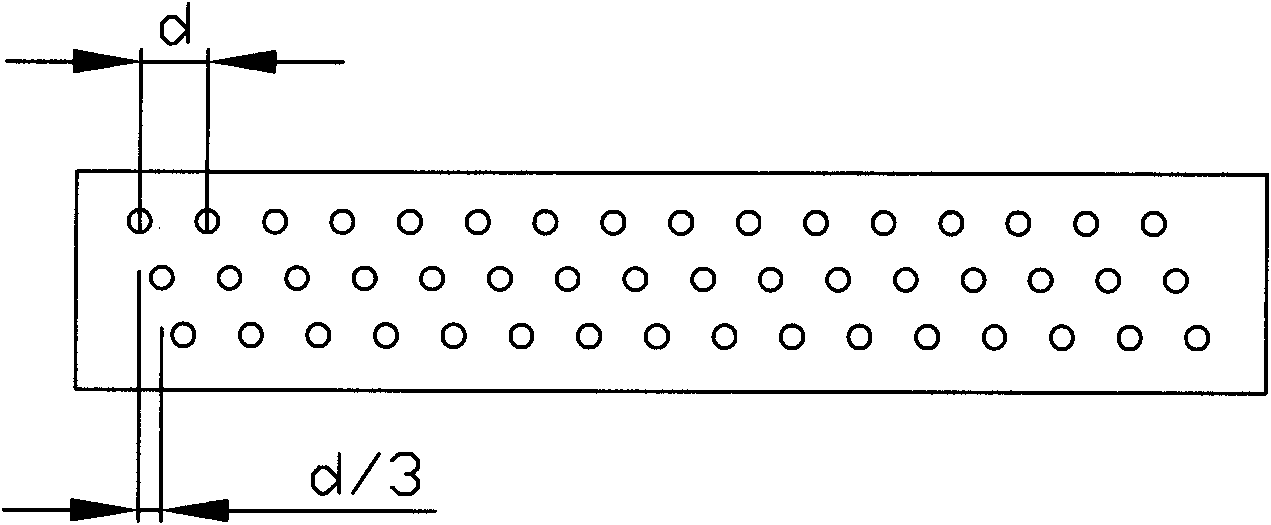

[0032] Such as Figure 5 , 6, 8 and 16, the inkjet printer printing head module adjustment mechanism of the present invention includes a bracket 2, a rear mounting plate 3 and a nozzle module mounting plate 4, two optical axes 21 parallel to each other are set on the support 2, Four sliders 23 and a sliding plate 22 are sleeved on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com