Control method capable of improving COP value of direct current variable-frequency compressor

A variable frequency compressor, DC frequency conversion technology, applied in the direction of pump control, liquid variable capacity machinery, mechanical equipment, etc., can solve the problems of inaccurate electrical angle delay of the compressor motor, and the COP value of the compressor cannot reach the maximum value, etc. Achieve the effects of easy implementation, reduced torque ripple, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The body of the DC variable frequency compressor motor is a brushless DC motor (BLDCM). In order to make the technical solution of this application easier to understand, the following is a brief description of the DC variable frequency control technology and the "back EMF zero crossing point" detection technology:

[0034] Simply put, the DC frequency conversion technology is to rectify the 50 / 60Hz AC voltage into a DC voltage. The brush and the rotor adopt permanent magnets, which rotate with the stator magnetic field, and the speed and torque can be adjusted by adjusting the energization frequency and voltage amplitude.

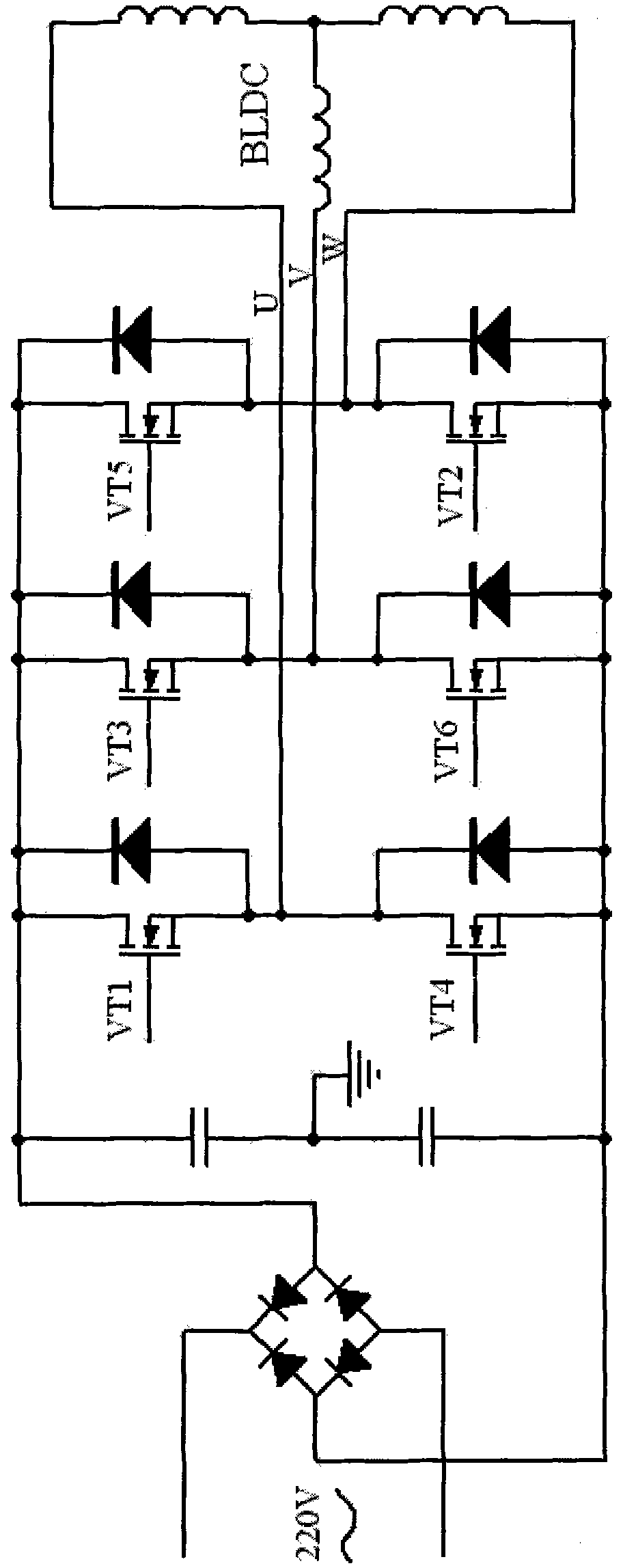

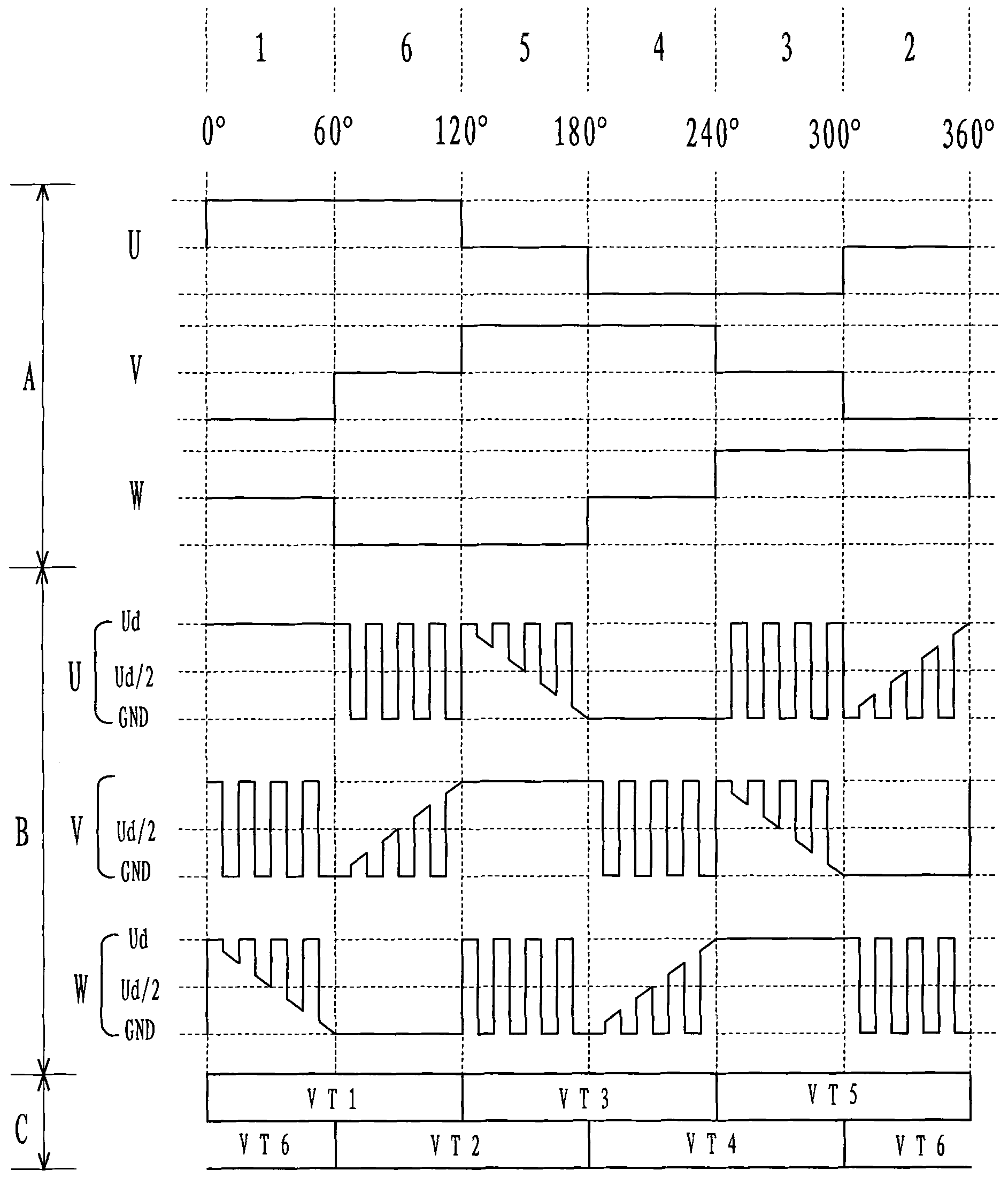

[0035] The driving circuit of the compressor motor discussed in the present invention is shown in figure 1 , the stator adopts Y-shaped windings, the three phases are U, V, W, and the drive circuit uses 6 IGBTs. Only two phases are turned on each time, and the other phase is turned off. Only one of the upper and lower bridge arms is turned on at the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap