Backlight module, display and manufacturing method of reflecting cover of backlight module

A technology of a backlight module and a reflector, which is applied in the field of surface light source devices, can solve the problems of increasing the number of light-emitting diodes used and the production cost of the backlight module 100, and achieve the effects of improving display quality, improving uniformity, and increasing light mixing distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

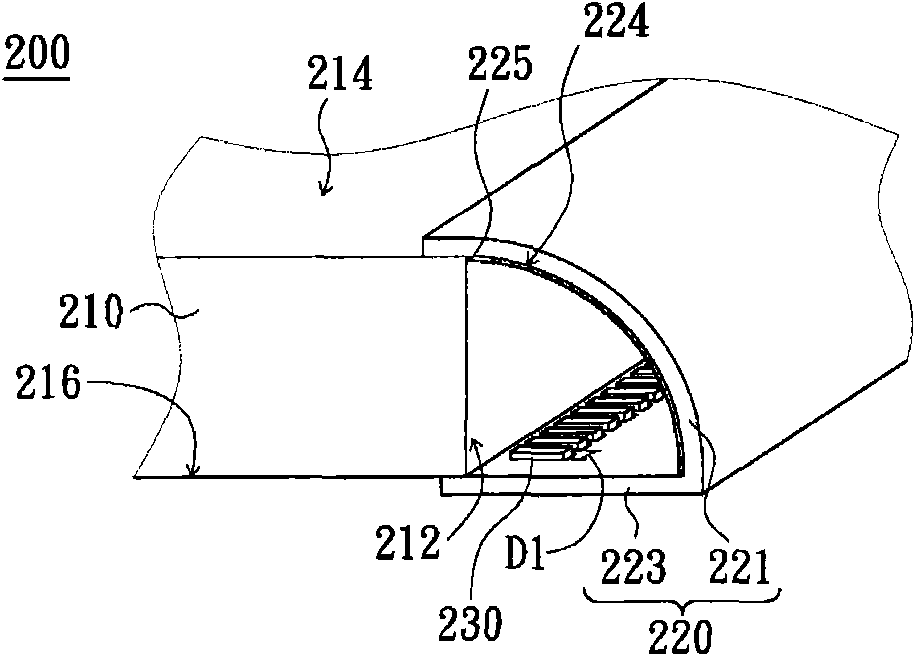

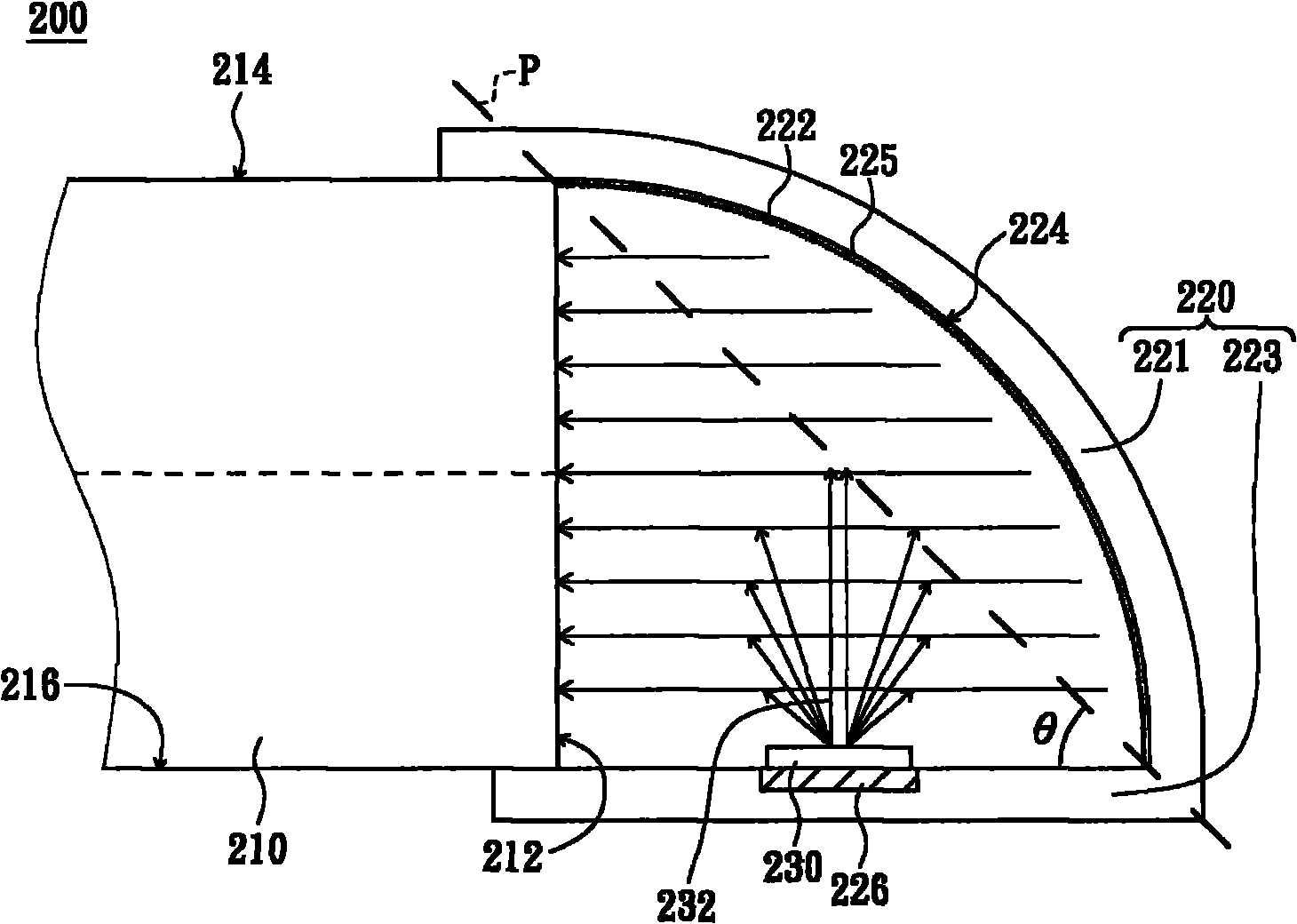

[0050] figure 2 is a three-dimensional schematic diagram of a backlight module according to an embodiment of the present invention, and image 3 yes figure 2 sectional schematic diagram. Please refer to figure 2 and image 3 , the backlight module 200 of this embodiment includes a light guide plate 210 , a reflector 220 and a plurality of point light sources 230 . The light guide plate 210 has a light incident surface 212 , and the reflector 220 is disposed beside the light incident surface 212 . The reflection cover 220 includes a reflection portion 221 , and the reflection portion 221 is provided with a plurality of microstructures 222 . The point light source 230 is used to respectively provide light 232 to the reflective part 221 , and the reflective part 221 is used to reflect the light 232 to the light incident surface 212 .

[0051]The above-mentioned light guide plate 210 also has opposite light-emitting surface 214 and bottom surface 216 , wherein the light-i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com