Twist-off picking paw mechanism and picking method thereof

A claw and break-type technology, applied to the picking mechanism and its picking field, can solve the problems of increasing the cost of the mechanism and the complicated structure of the claw, and achieve the effects of accurate and stable grasping, saving manpower, and ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

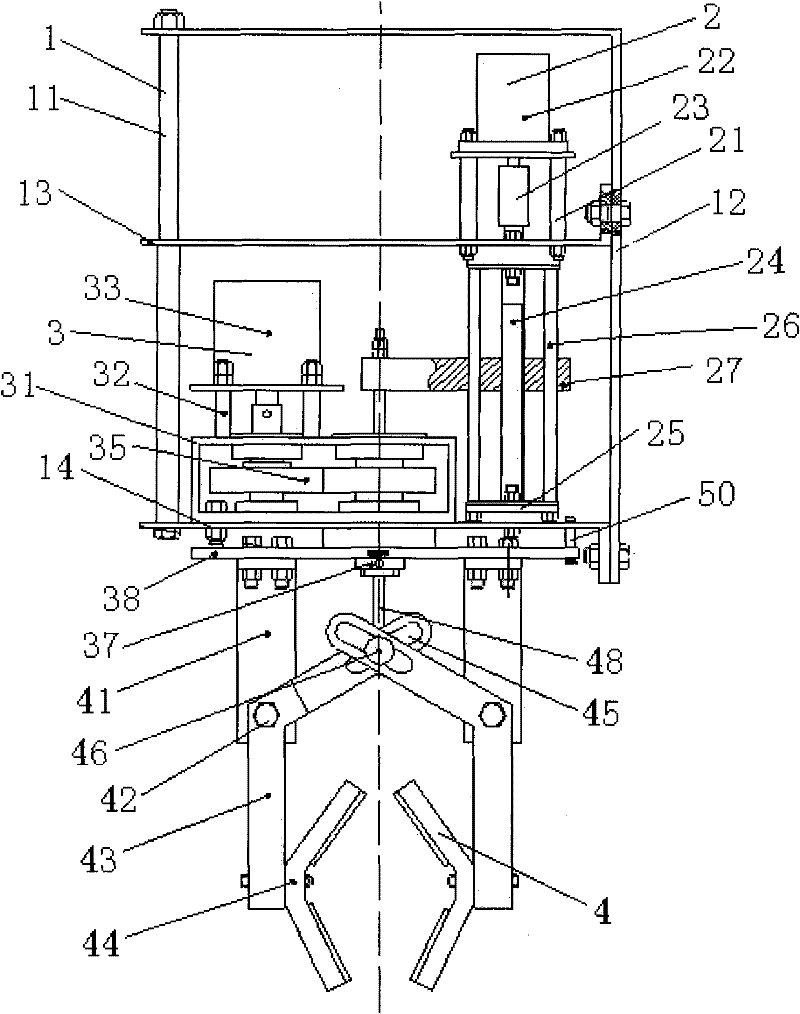

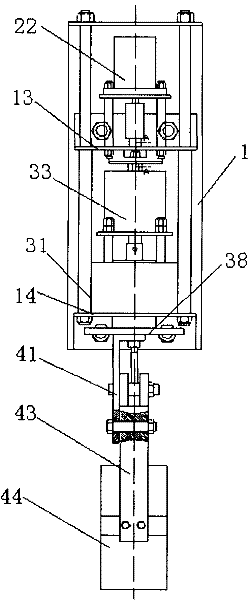

[0018] Such as Figure 1~3 As shown, the present invention includes a screw drive device 2 , a rotating device 3 and a claw device 4 arranged on a bracket 1 .

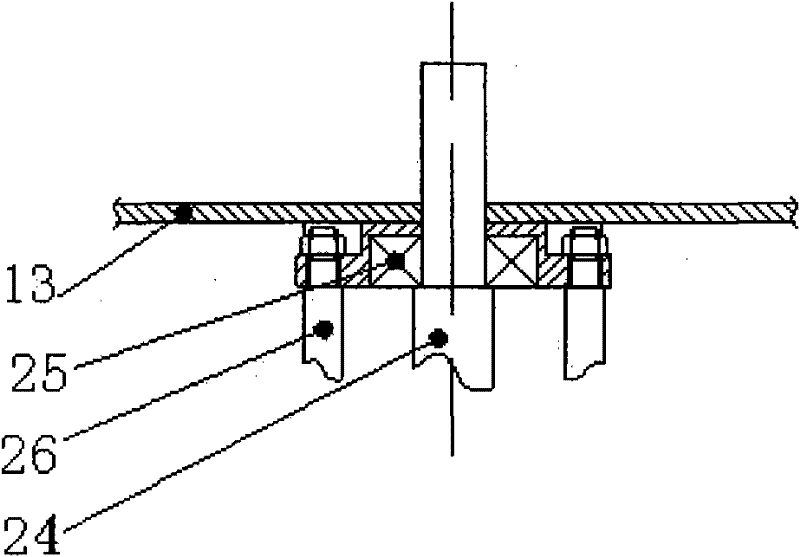

[0019] The bracket 1 of the present invention is made up of two vertical support rods 11 and an L-shaped support plate 12 fixedly connected to its top, the upper middle part of the bracket 1 is fixedly provided with an upper support plate 13 by a nut, and the bottom of the bracket 1 is fixed by a nut A support plate 14 is provided.

[0020] The screw transmission device 2 of the present invention includes four motor struts 21 fixed on the top surface of the upper support plate 13 by nuts, and the upper ends of each motor strut 21 are jointly fixed with a screw motor 22 by a nut, and the output of the screw motor 22 is The end is connected vertically downwards with a lead screw 24 through a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com