Method for producing embossed grain yarns by using bundling method

A weaving yarn and bundling technology, which is applied in the spinning field of new-style fancy yarn-long weaving yarn, can solve the problems such as the inability to meet the needs of the society and the rigidity of the cloth surface, and achieve strong uniformity and irregularity. , unique style, fine texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

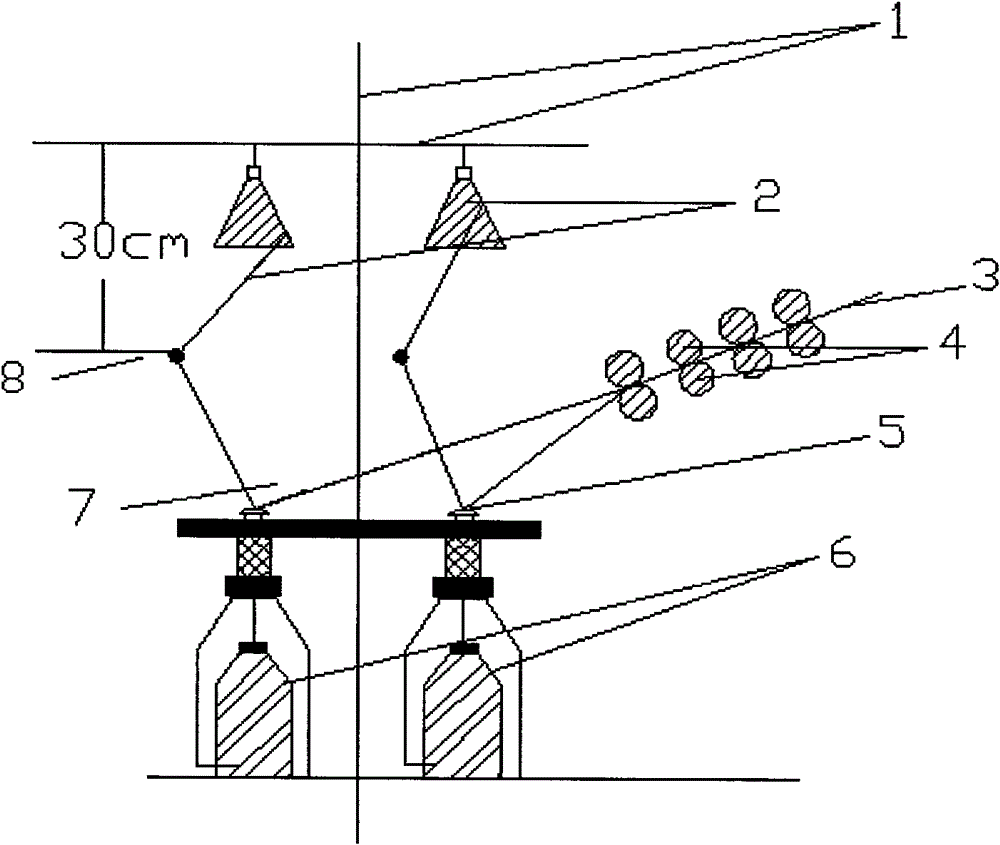

[0033] One or several kinds of cotton fibers with corresponding colors are made into 39.0g / 10m blue (dark blue) without drawing after picking, blending, opening, coiling, carding and drawing. 3. Then draw the blue end drawing frame 3 through the drafting of the roving frame roller 4 to form a roving 7, and then feed it into the roving frame inlet together with the 7.4tex yellow auxiliary yarn 2 (bright yellow, strength 15.8cN / dtex) 5 Carry out roving forming, make bundle type raised yarn roving 6, then make raised yarn on spinning machine. In order to highlight the style, this new style of raised yarn is woven into a fabric, and the specific display style is Figure 4 .

Embodiment 2

[0035] The off-white cotton fiber is made into 39.0 g / 10m white powder drawing frame 3 after catching, blending, opening, coiling, carding and drawing respectively, and then the white powder drawing frame 3 is passed through the roving The drafting of the machine roller 4 forms the roving 7, and then feeds the roving frame inlet 5 together with the 29.5tex black auxiliary yarn (BC02 all black) with a content of 35% of the recycled cotton (BC02 full black recycled cotton) to form the roving. Bundle-type raised yarn roving 6, then make raised yarn on spinning frame. In order to highlight the style, this new style of raised yarn is woven into a fabric, and the specific display style is Figure 5 .

Embodiment 3

[0037]The off-white cotton fiber is made into 39.0 g / 10m white powder drawing frame 3 after catching, blending, opening, coiling, carding and drawing respectively, and then the white powder drawing frame 3 is passed through the roving The drafting of the machine roller 4 forms the roving 7, and then feeds the roving frame inlet 5 together with the blue auxiliary yarn (twist coefficient 245) of 14.8tex to form the roving, and makes the bundled raised yarn roving 6, and then passes it on the spinning frame Make a ridged yarn. In order to highlight the style, this new style of raised yarn is woven into a fabric, and the specific display style is Figure 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com