Coal mine up-dip working face slant range paste-like filling method

A paste-like technology on the working face, which is applied to filling materials, mining equipment, earth square drilling and mining, etc., can solve the problems of insufficient filling effect, difficult filling and compactness, etc., so as to avoid old empty water damage and increase paste filling Height, the effect of reducing the amount of sinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

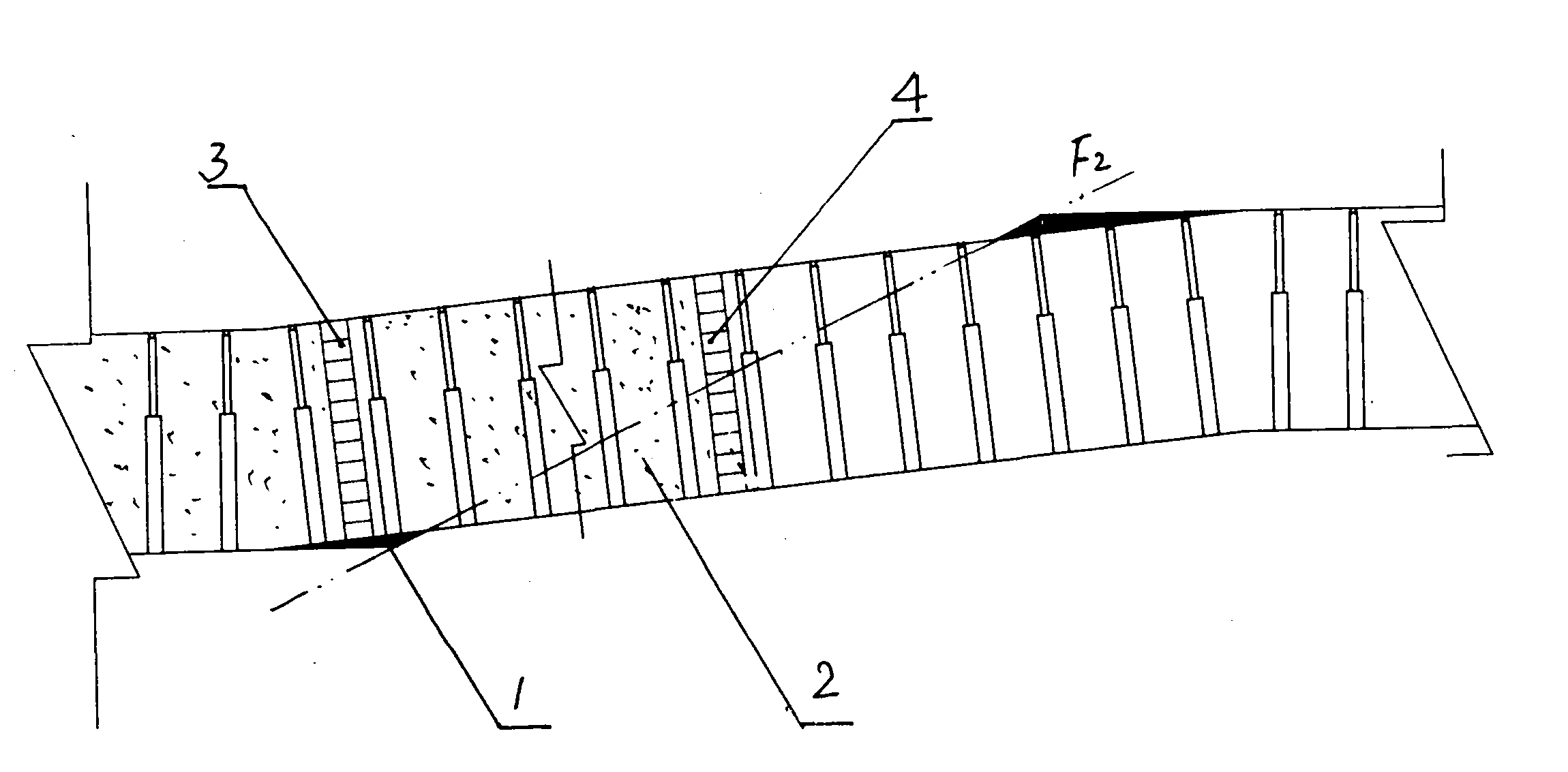

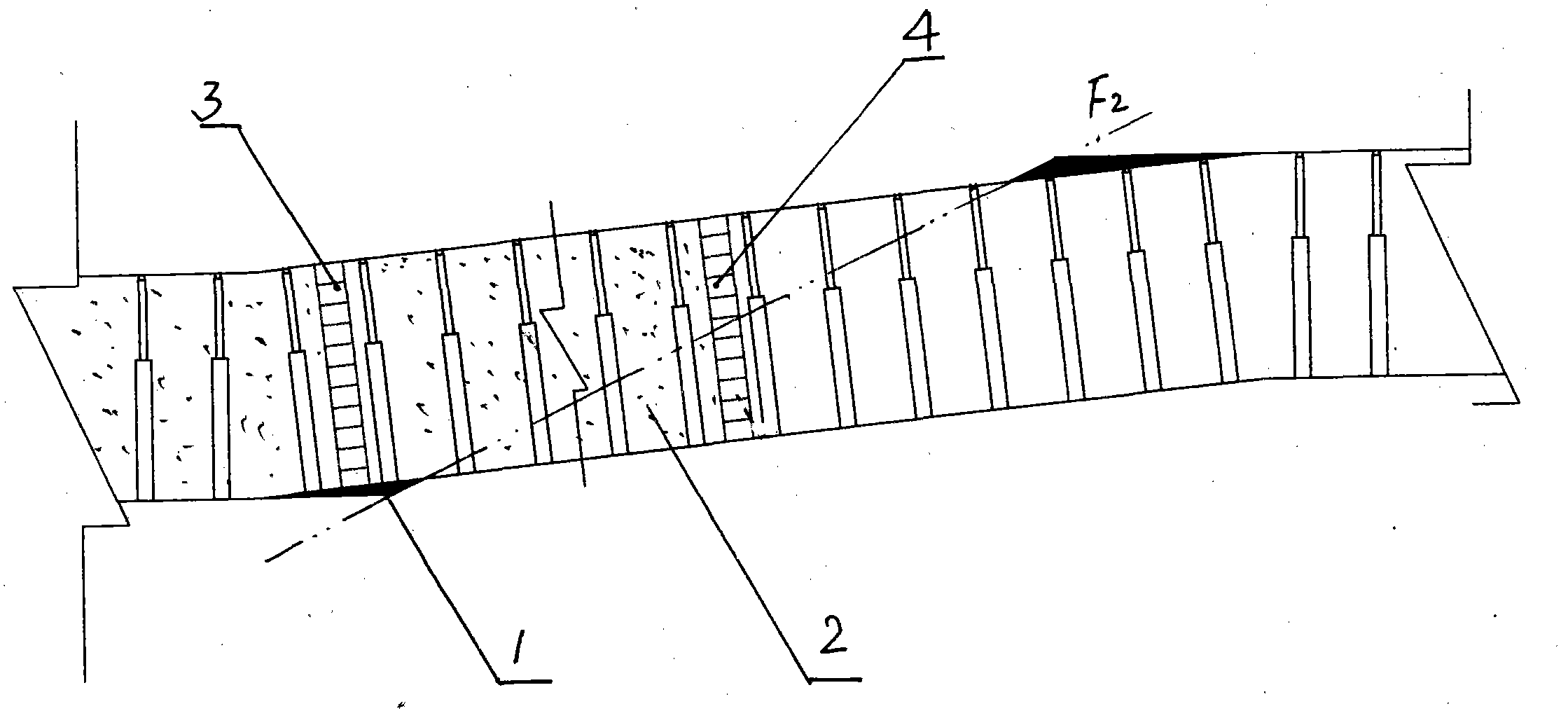

[0012] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] As shown in the figure, in the process of inclined mining of the working face, two sets of retaining walls 3 and 4 are installed at the step 1 where a large drop is encountered. , stacked side by side along the advancing direction of the working face, the height of the retaining wall is 18-22cm from the top plate, and it is stacked forward as the working face is pushed forward; after the working face is pushed forward to reach a filling step, the grout wall will be removed from the working face The filling pipeline extends to the goaf, and fills the paste 2 section by section according to the sections divided by the retaining wall; so that each section reaches the specified filling height.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com