Air-air cooling three-phase asynchronous motor fan cover

A three-phase asynchronous motor technology, which is applied to asynchronous induction motors, electric components, cooling/ventilation devices, etc., can solve the problems of poor heat dissipation, complicated disassembly and assembly, and large wind resistance of air-to-air-cooled three-phase asynchronous motors. The effect of solid matching process, enlarged air collection chamber, and smooth flow of air flow path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific drawings and embodiments.

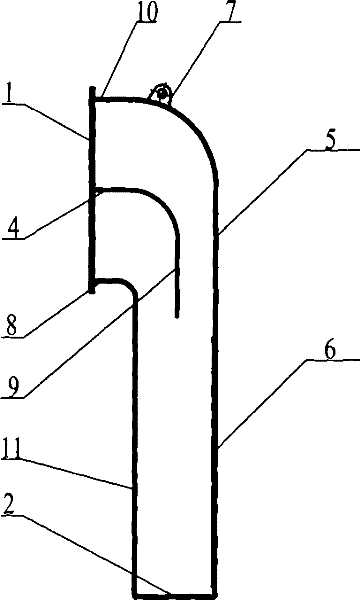

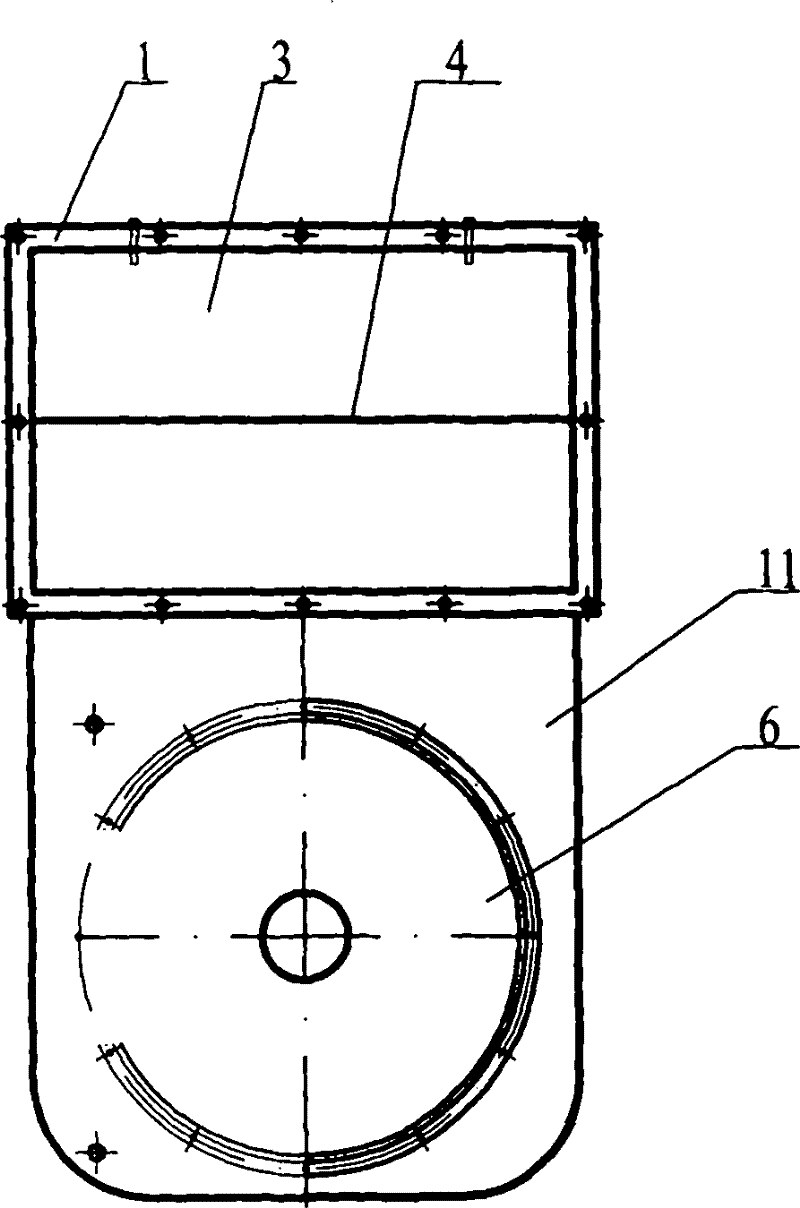

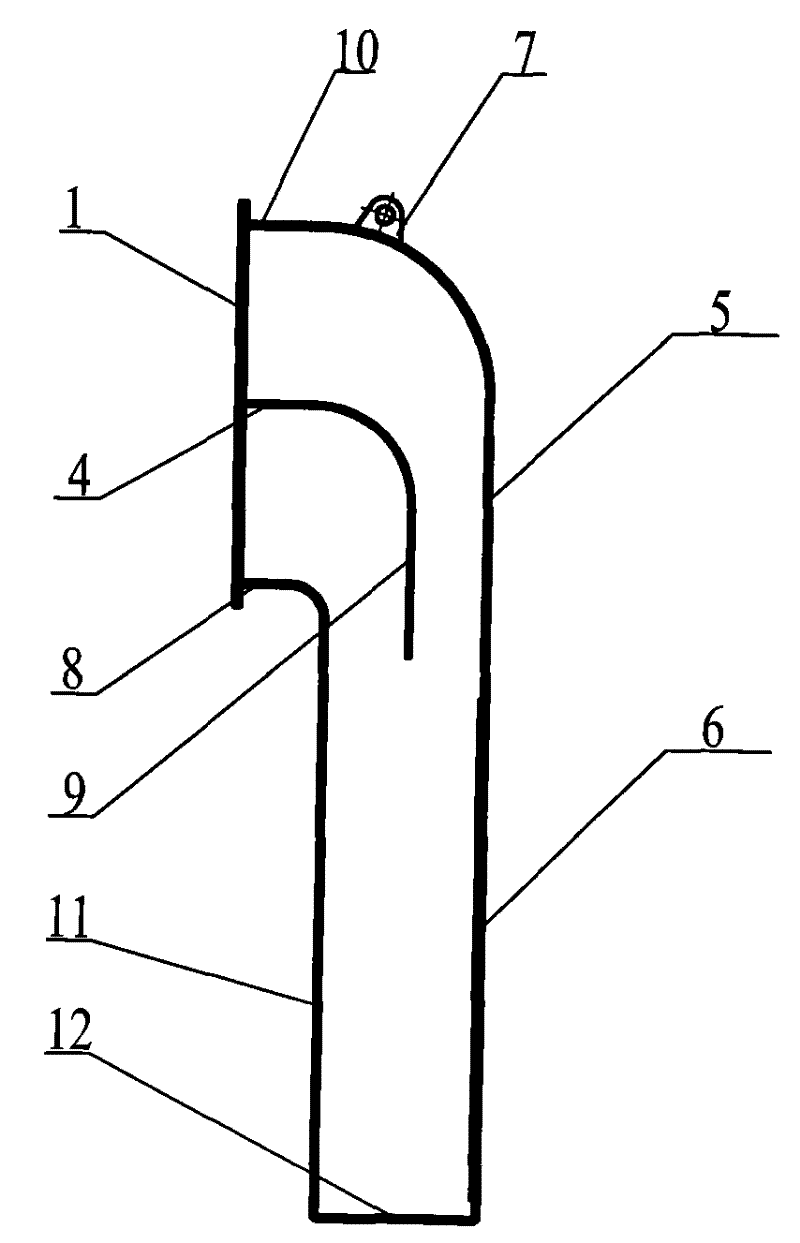

[0010] Such as Figure 1 ~ Figure 2 As shown: the present invention includes a connecting frame 1, a bottom connecting plate 2, an air inlet 3, an intermediate connecting plate 4, a first windshield 5, an air outlet 6, a mounting block 7, a lower connecting plate 8, and a second windshield 9. The upper connecting plate 10 and the third windshield 11 .

[0011] Such as figure 1 and figure 2 As shown: the connecting frame 1 is respectively provided with an upper connecting plate 10, a middle connecting plate 4 and a lower connecting plate 8; the connecting frame 1 includes four interconnected fixing plates, and a frame structure is formed between the four fixing plates; the upper connecting plate 10. The middle connecting plate 4 and the lower connecting plate 8 are respectively located at the upper part, the middle part and the lower part of the connecting f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com