Cooling system of variable frequency generator

A cooling system and generator technology, applied in the direction of machine/engine, mechanical equipment, etc., can solve the problems of reducing the service life of the generator, increasing the overall structure size of the unit, affecting the overall performance of the unit, etc. weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

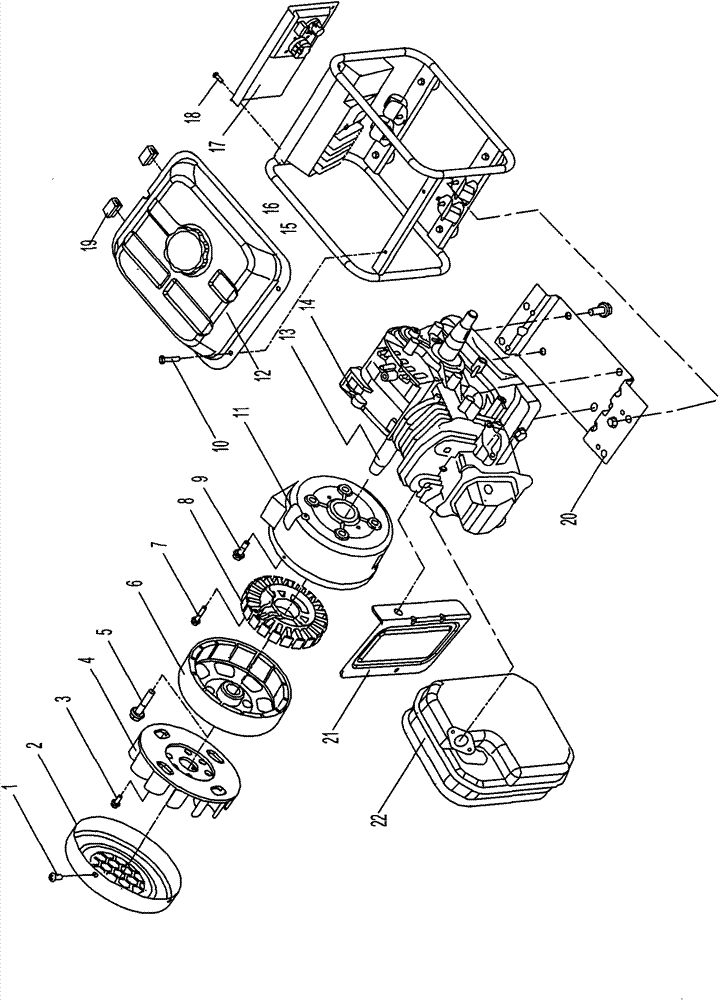

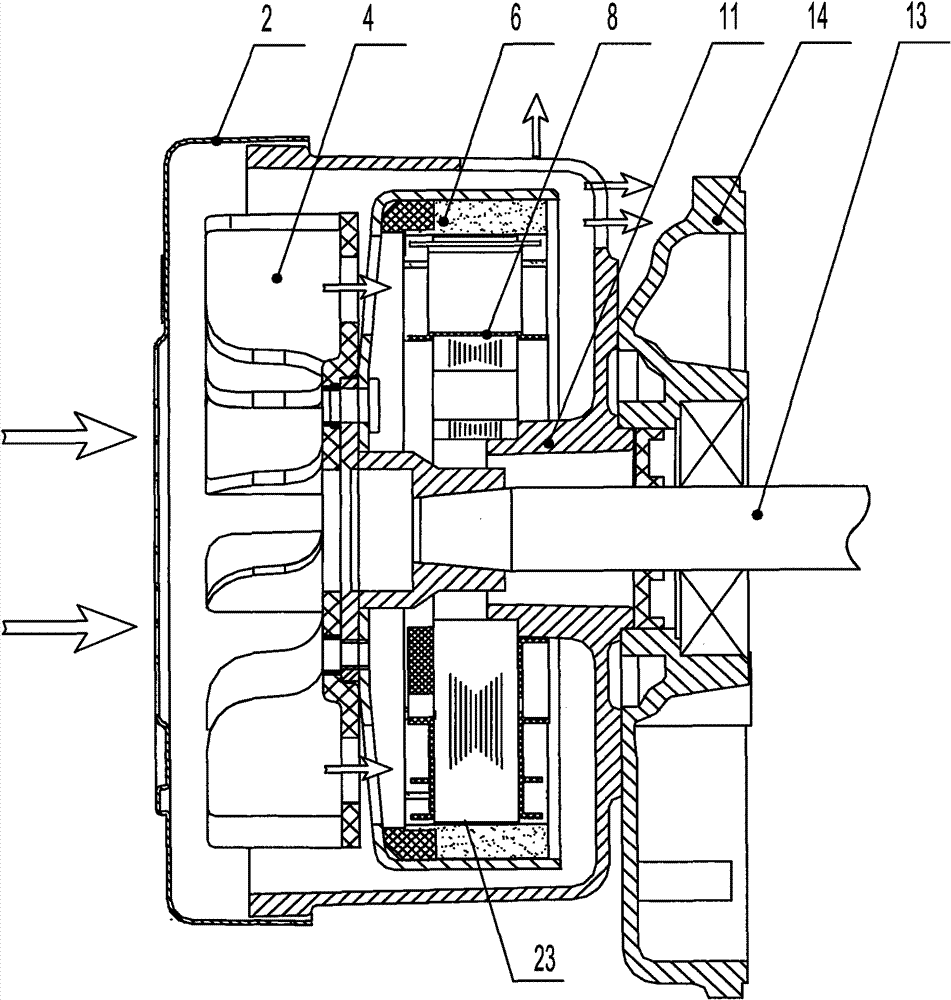

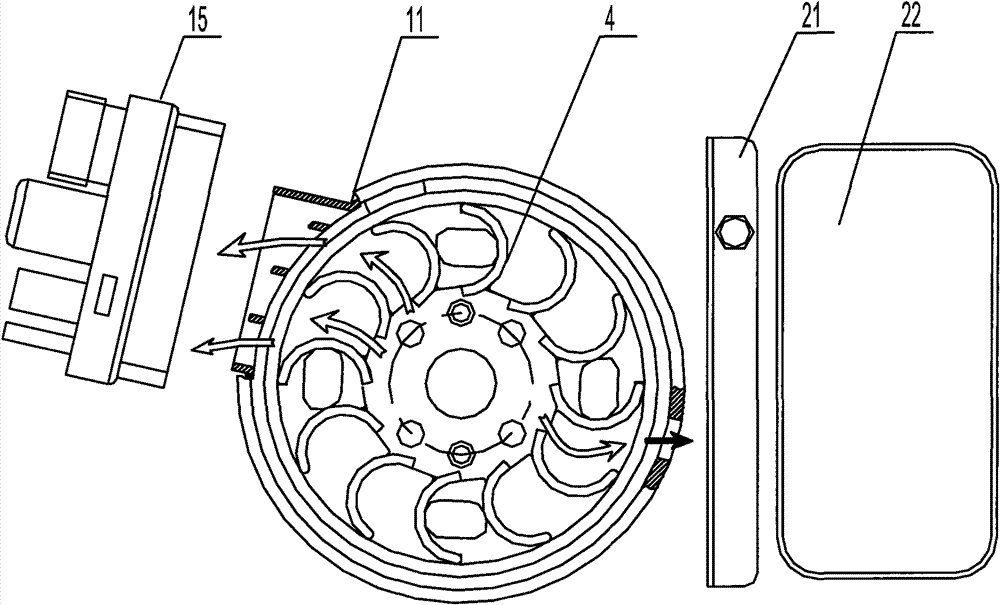

[0019] Such as Figure 1 to Figure 3 As shown, the cooling system of the frequency conversion generator of the present invention mainly includes an engine case 14, a generator 23, a generator casing 11, a fuel tank 12, fan blades 4, a generator rear cover 2, a heat shield 21, and an inverter controller 15 Wait. The generator includes a generator rotor 6 and a generator stator 8, the generator rotor 6 is installed on the engine crankshaft 13 with the second bolt 5, the generator casing 11 is fixed on the engine case 14, and the generator stator is fixed with the third bolt 7 On the generator housing 11 and inside the generator rotor 6 . The fan blade 4 is located between the generator rotor 6 and the generator rear cover 2 . The inverter controller 15 is installed on the panel rear cover 16 and is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com