Gravity brake wheel

A braking wheel and gravity technology, which is applied to casters, wheels, transportation and packaging, etc., can solve the problems of incompatibility of the structure of the universal wheel and the caster, and the braking force is small, so as to achieve the effect of easier unification of design and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

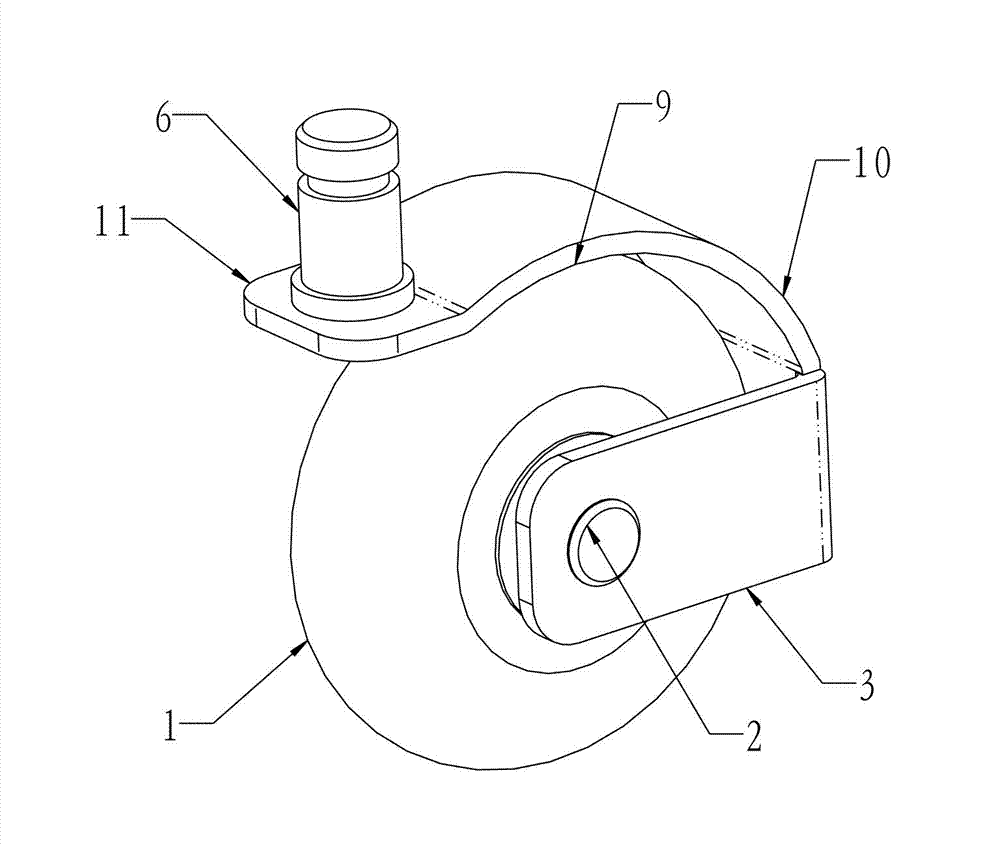

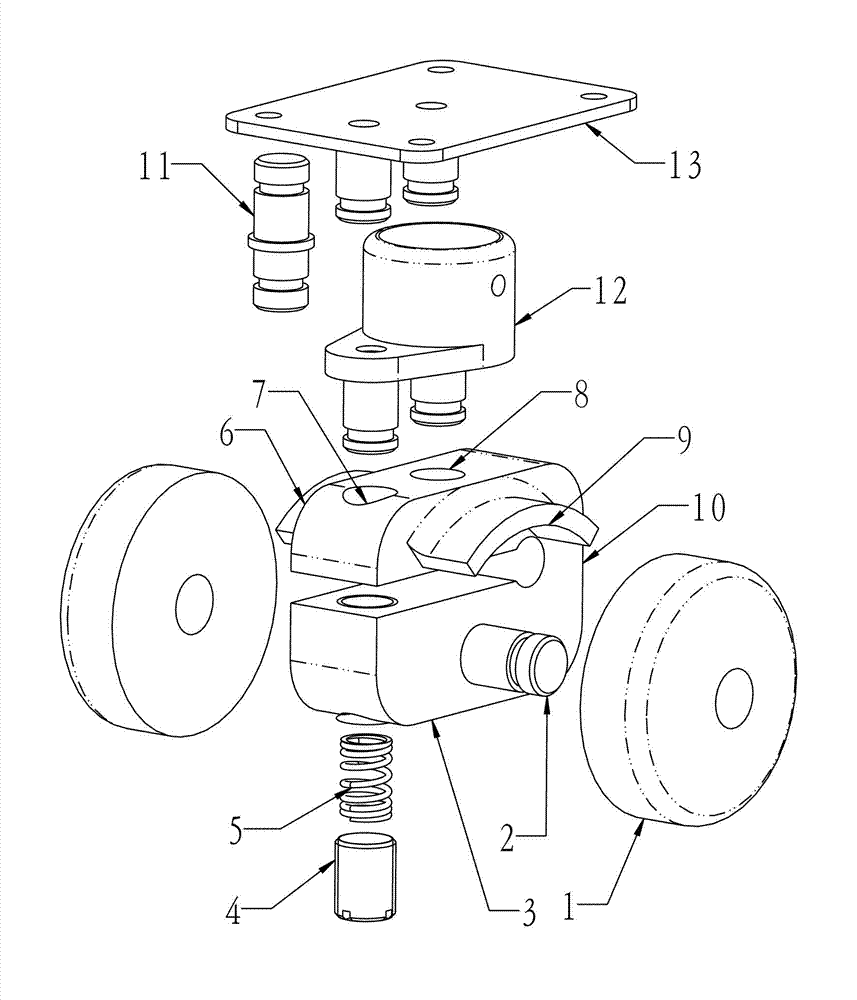

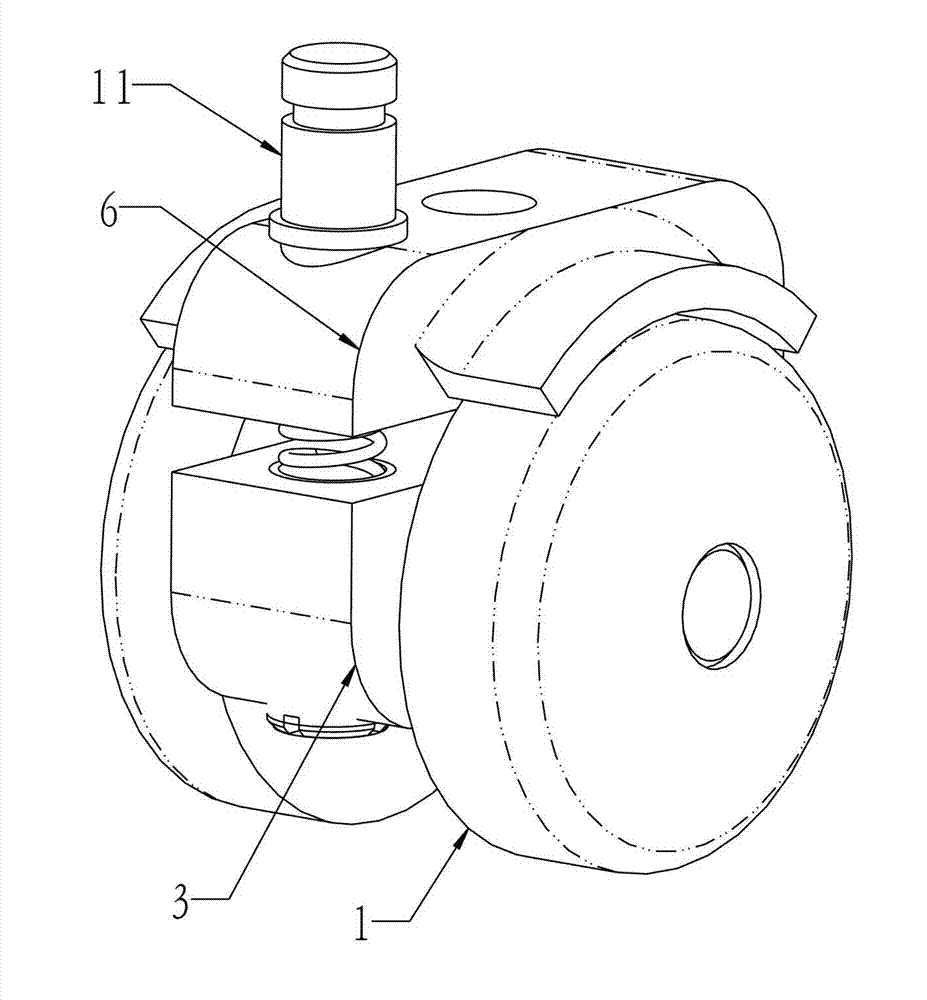

[0013] Detailed ways: figure 1 Middle is the gravity brake wheel, the exploded diagram of the gravity brake wheel accessories of plastic parts. In the figure, the accessories of plastic and double-wheel gravity braking wheels are used as an example. The rollers (1) are pulled out from both sides of the horizontal shaft (2). The horizontal shaft (2) can be made of metal, and the horizontal shaft (2) is installed on the horizontal shaft. on the seat (3). The spring (4) can adjust the pre-tightening force by adjusting the screw (5). There are positioning holes A (7) and positioning holes B (8) on the bearing seat (6). The brake part (9) is fixed on the load-bearing seat (6). The curved elastic section (10) uses the elasticity of the material itself as an elastic part to play the same function as the spring (4). The vertical shaft (11) is assembled Universal wheel is used, and circle sleeve seat (12) is that the caster wheel of assembling band circle sleeve seat is used, and fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com