Seal assembly and method of assembly thereof

A technology of sealing components and seals, which is applied in the direction of sealing devices, engine seals, vehicle parts, etc., can solve problems such as the inability to guarantee the sealing effect, the inability to achieve the installation effect, and the inability to guarantee the quality, so as to save design costs and products Cost, ease of disassembly and maintenance, and simple product structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Reference is made to the drawings wherein like reference numerals represent like parts.

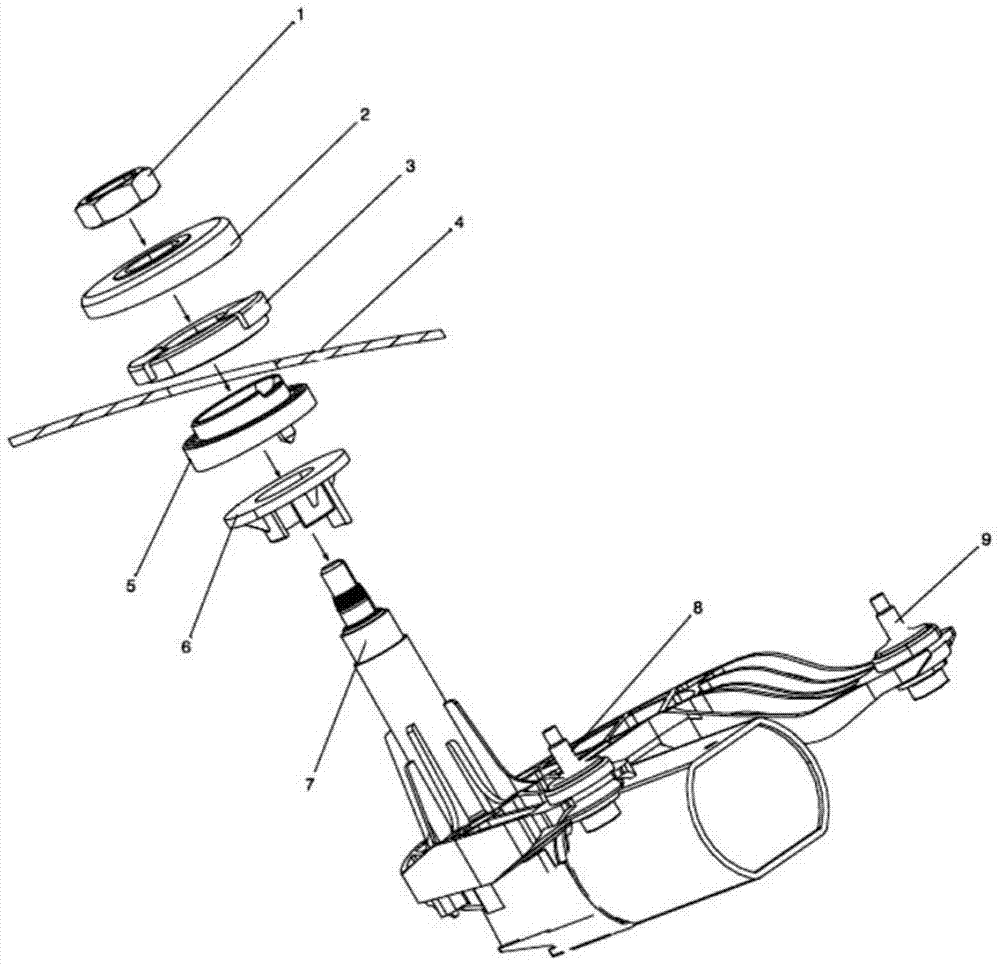

[0016] figure 1 It is an exploded illustration of a prior art double rubber pad type independent seal assembly. The seal assembly seals the joint of the shaft assembly passing through the window glass to said window glass. The shaft assembly may be an output shaft assembly 7 of a motor of a vehicle wiper (especially a rear wiper). For the traditional three-point fixed motor, two of the mounting points are located on the body sheet metal frame (not shown), that is, as figure 1 The first system structure fixed point 8 and the second system structure fixed point 9, the third installation point is realized by passing through the window glass hole. Wherein, the sealing assembly includes: a fastening nut 1, a shield cover 2, a glass outer sealing rubber pad 3, a vehicle window glass 4, a glass inner sealing rubber pad 5, and a rubber pad supporting base 6, and these components are as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com