Buffer arrangement and buffer stop of an elevator

A shock absorber and elevator technology, which is applied to elevators, lifting equipment in mines, transportation and packaging, etc., can solve expensive and slow problems, achieve fast and easy actuation, avoid modification work, and improve work safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

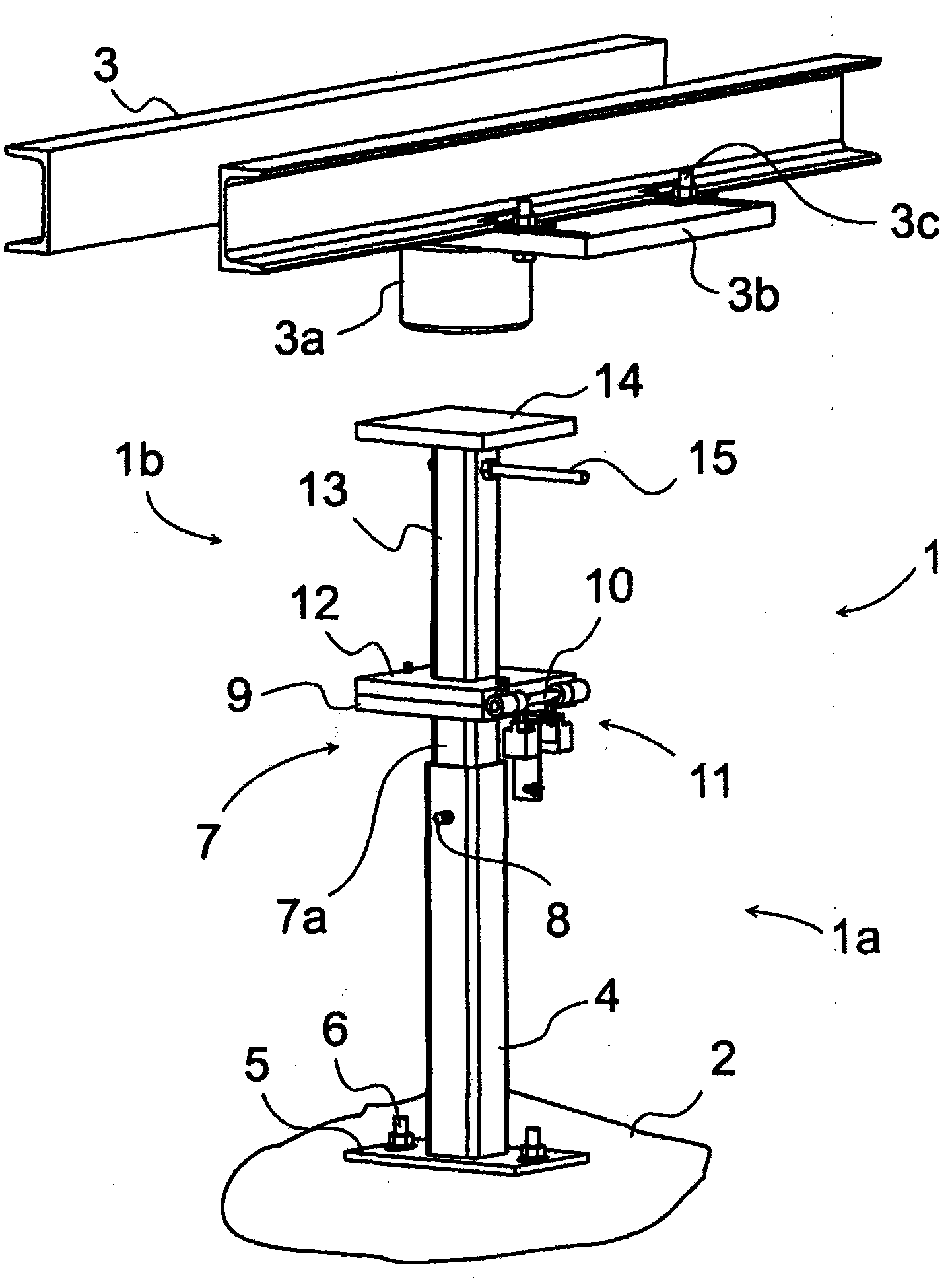

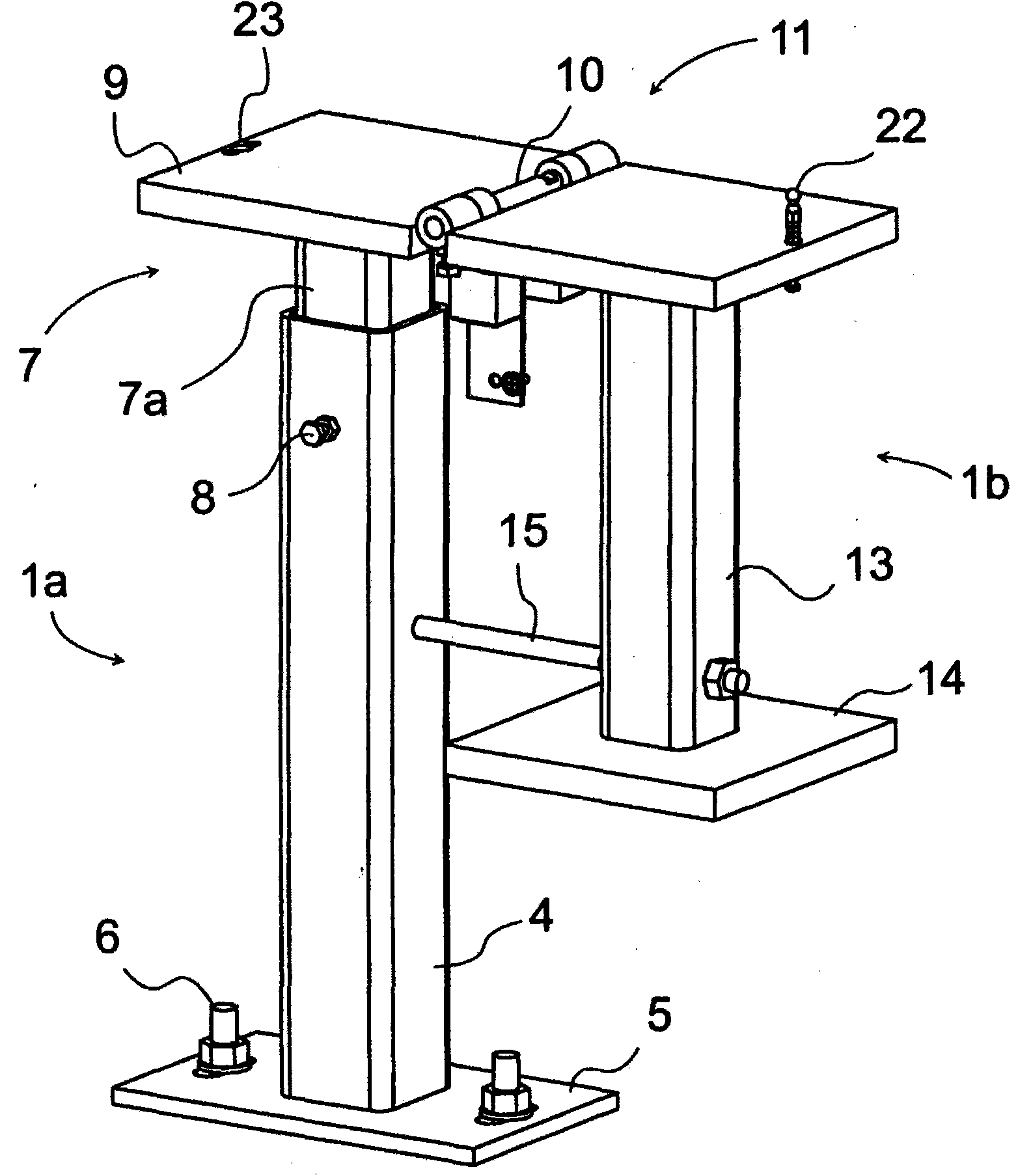

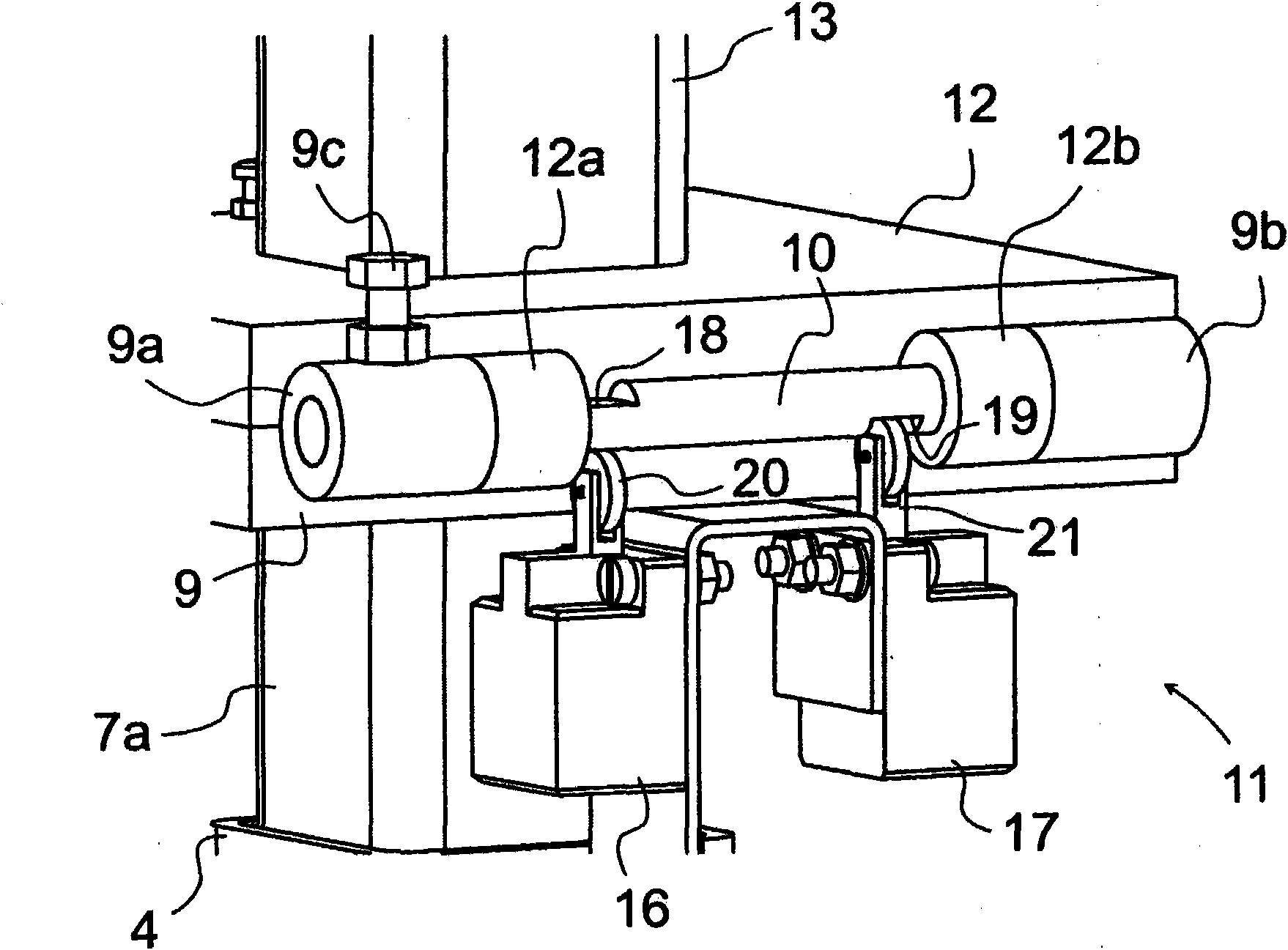

[0018] figure 1 One shock stop 1 is shown for use in the arrangement according to the invention when the elevator is in maintenance mode. In this solution, the shock stop 1 is fixed to the ground 2 of, for example, an elevator shaft and is arranged to point substantially vertically upwards. Other parts incorporated into the buffer configuration can be found in figure 1 Viewed above the breaker 1, these parts are fixed to the bottom beam 3 of the car hanger of the elevator car. These other parts are, among other things, the actual buffer 3a and the mounting base 3b of the buffer and the fixing means 3c by which the mounting base 3b is fixed to the bottom beam 3 of the car hanger. The bumper 3a may be an elastomeric bumper made of polyurethane, for example. The mounting base 3b of the buffer 3a is provided with e.g. an elongated fixing hole, thanks to which the mounting base 3b and at the same time the buffer 3a can be moved in a lateral direction into a better position, e.g....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com