Lean hematite technology combining dressing-fine screening and shaking table gravity separation

A technology of hematite and fine sieve, applied in the direction of solid separation, separation of solids from solids with air flow, chemical instruments and methods, etc., can solve the problems of high environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

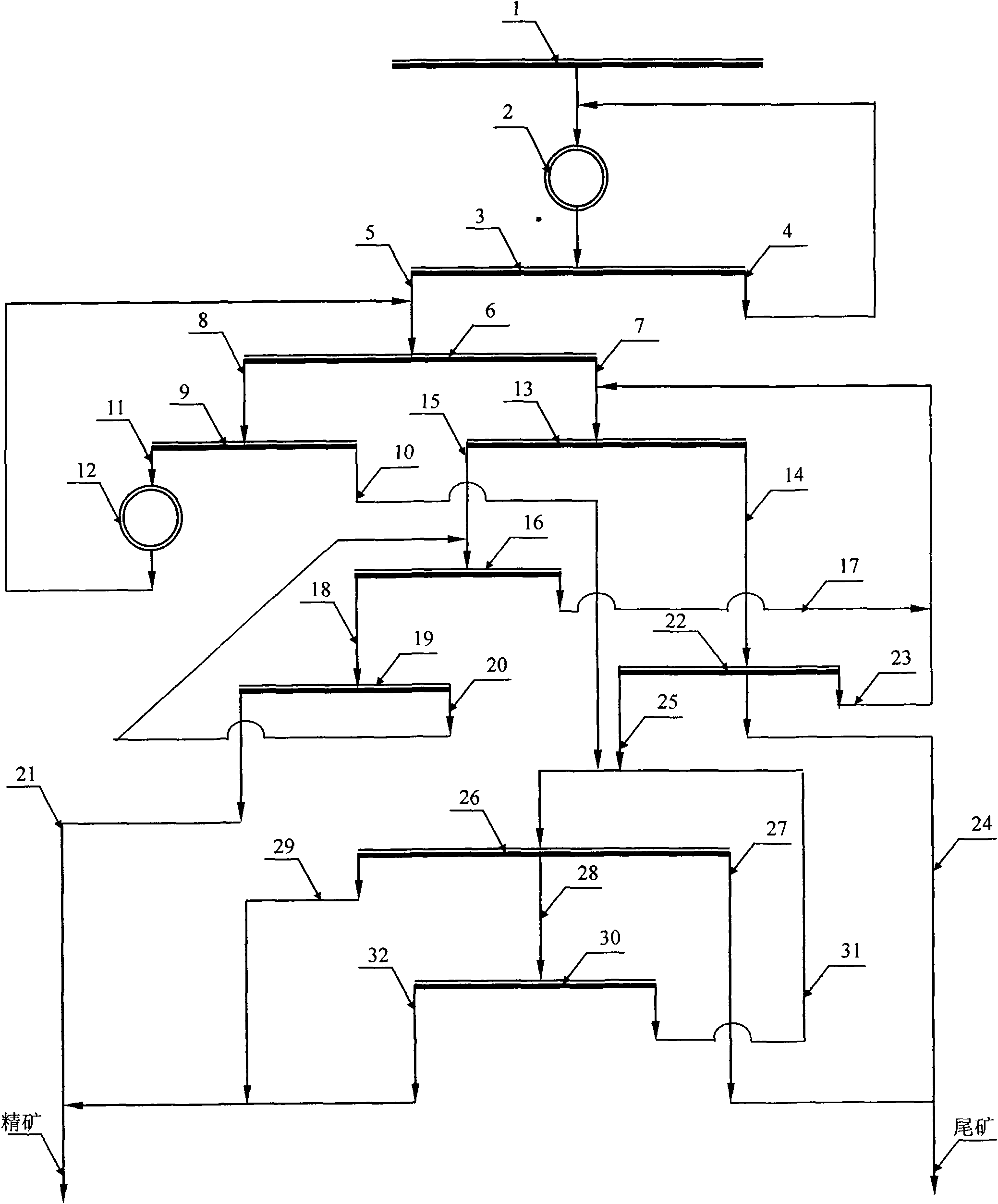

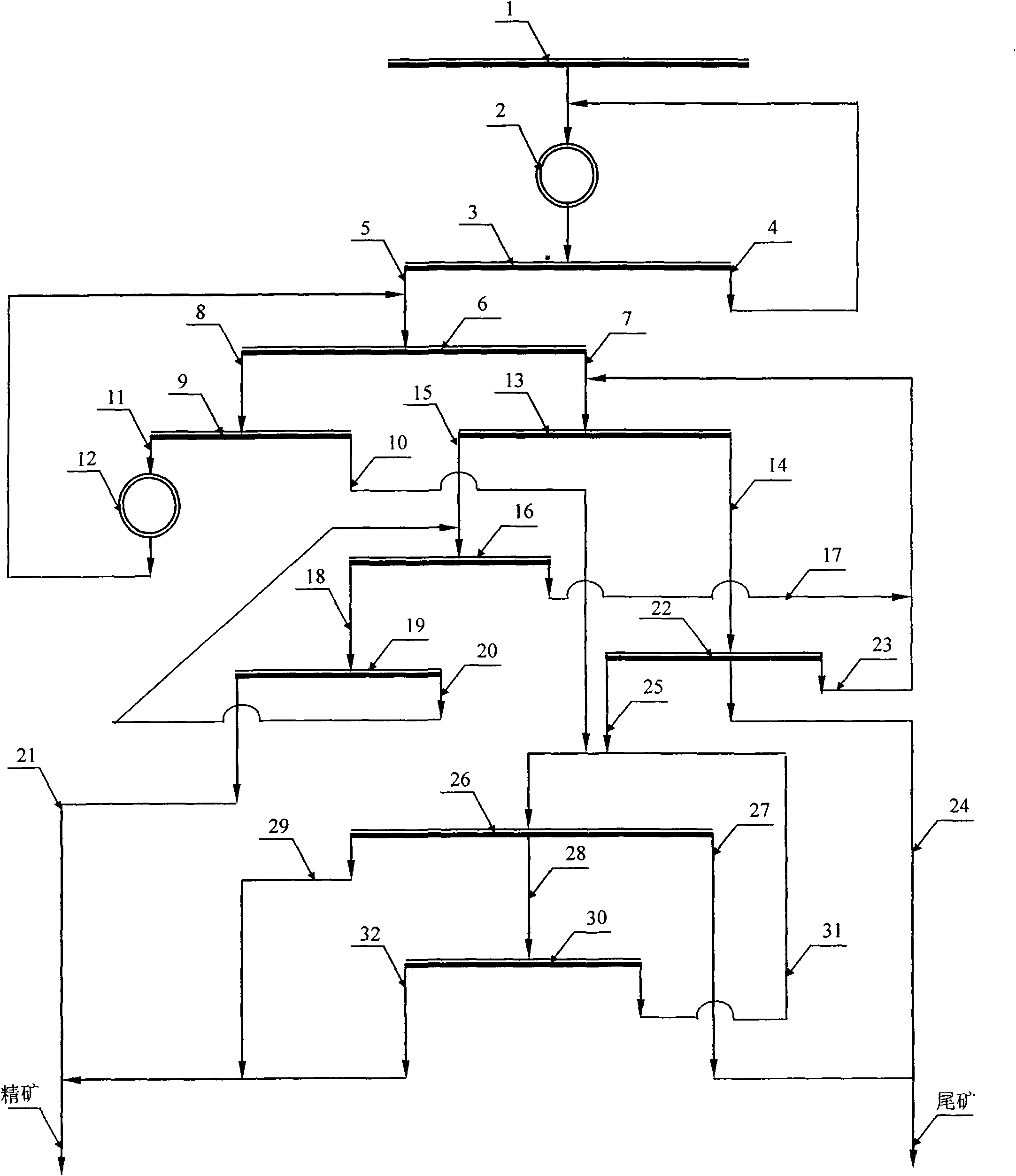

[0029] The specific implementation manner of the present invention will be further described below in conjunction with the examples given in the accompanying drawings.

[0030] Such as figure 1 As shown, a kind of lean hematite ore beneficiation fine screen-shaking table gravity separation process of the present invention is characterized in that the grinding product is inspected and graded by using the high-frequency vibrating screen fine screen 6, the roughing spiral flow tank 13, the selection spiral flow The trough, the sweeping spiral flow trough 22, the roughing shaker 26, and the selection shaker 30 are combined into a full-gravity separation beneficiation process, and the specific steps are as follows:

[0031] (1) Depleted hematite ore 1 carries out one-stage grinding operation 2;

[0032] (2) The product of one-stage grinding operation 2 enters classification operation 3, the separated sand-returning product 4 returns to one-stage grinding operation 2, and the separ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap