Online recursive parameter estimation-based roll eccentricity compensation equipment

A technology of parameter estimation and eccentricity, applied in the direction of rolling force/roll gap control, etc., can solve the problem of lack of real-time operation time, and achieve the effect of improving thickness control accuracy and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

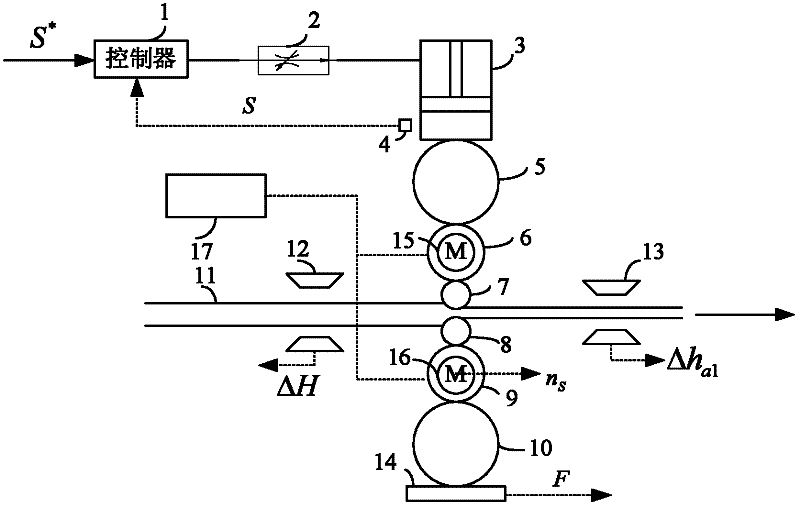

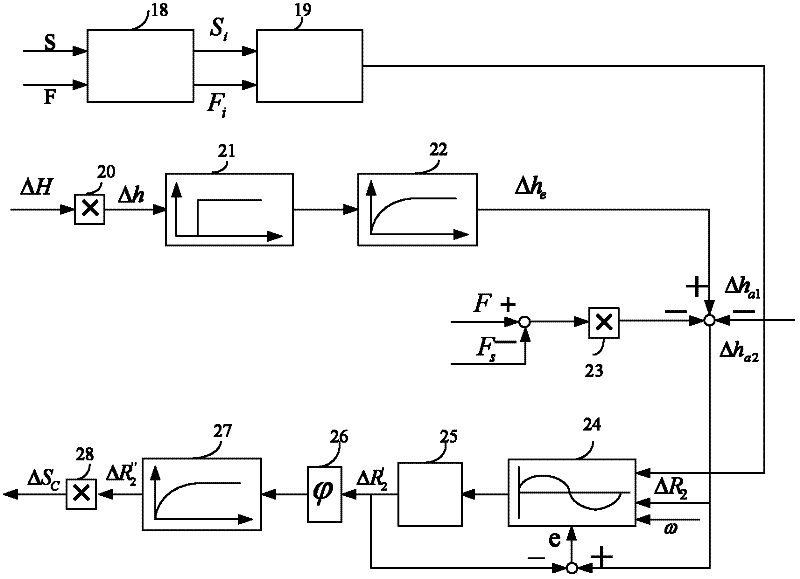

[0023] The roll eccentricity compensation device based on online recursive parameter estimation provided by the present invention has a structure such as figure 2 As shown, it includes a sampling device 18, a conversion device 19, a device for online sampling and calculation of roll eccentricity signals during the rolling process, a device for realizing online recursive parameter estimation, and a roll gap compensation device connected in sequence with electrical signals.

[0024] The sampling device 18 is a device for sampling and calculating the roll eccentricity signal in the eccentricity test, and the device is realized by programming on a programmable logic controller. The device is timed to sample data s i , F i The device and calculation of roll test eccentricity signal ΔR 1 installation. Among them, S i is the roll gap value at time i, F ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com