Roll eccentricity compensation method based on on-line recursive parameter estimation and equipment thereof

A technology of parameter estimation and compensation method, applied in the direction of rolling force/roll gap control, etc., can solve the problem of lack of real-time operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1. A roll eccentricity compensation method based on online recursive parameter estimation:

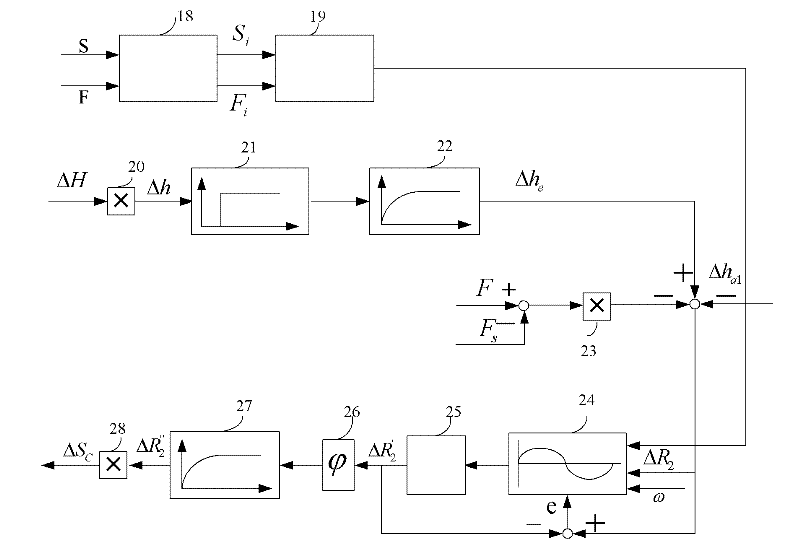

[0063] see figure 1 , figure 2 , the compensation method includes the following steps:

[0064] 1. Obtain the test roll eccentricity signal ΔR 1 :

[0065] Conduct eccentricity compensation test, sample and calculate the test roll eccentricity signal ΔR in the test 1 ,Specifically:

[0066] (1) Adjust the main drive speed n of the rolling mill s , stably reaching the speed of eccentric signal measurement.

[0067] Use the main transmission control system 17 of the rolling mill to control the main transmission of the rolling mill to rotate at the speed of the eccentric compensation test, which is generally 20% of the maximum rotating speed. s After reaching the set speed (such as 20% of the maximum speed) and stabilizing, start the next step.

[0068] (2) Adjust the pressing down system of the rolling mill so that the roll is pressed against the eccentric sign...

Embodiment 2

[0115] Embodiment 2. Roll eccentricity compensation device based on online recursive parameter estimation:

[0116] The structure of the roll eccentric compensation device is as follows: figure 2 As shown, it includes a sampling device 18, a conversion device 19, a device for online sampling and calculation of roll eccentricity signals during the rolling process, a device for realizing online recursive parameter estimation, and a roll gap compensation device connected in sequence with electrical signals.

[0117] The sampling device 18 is a device for sampling and calculating the roll eccentricity signal in the eccentricity test, and the device is realized by programming on a programmable logic controller. The device is timed to sample data s i , F i The device and calculation of roll test eccentricity signal ΔR 1 installation. Among them, S i is the roll gap value at time i, Fi is the total rolling force value at time i, 1≤i≤n, n is a natural number.

[0118] The trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com