Sensor unit and manufacture method thereof

A manufacturing method and sensor technology, applied to instruments, electrical digital data processing, input/output process of data processing, etc., can solve problems such as increased difficulty of process, complexity of process and structure, overflow of glue, etc., and achieve cost saving , the effect of optimizing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

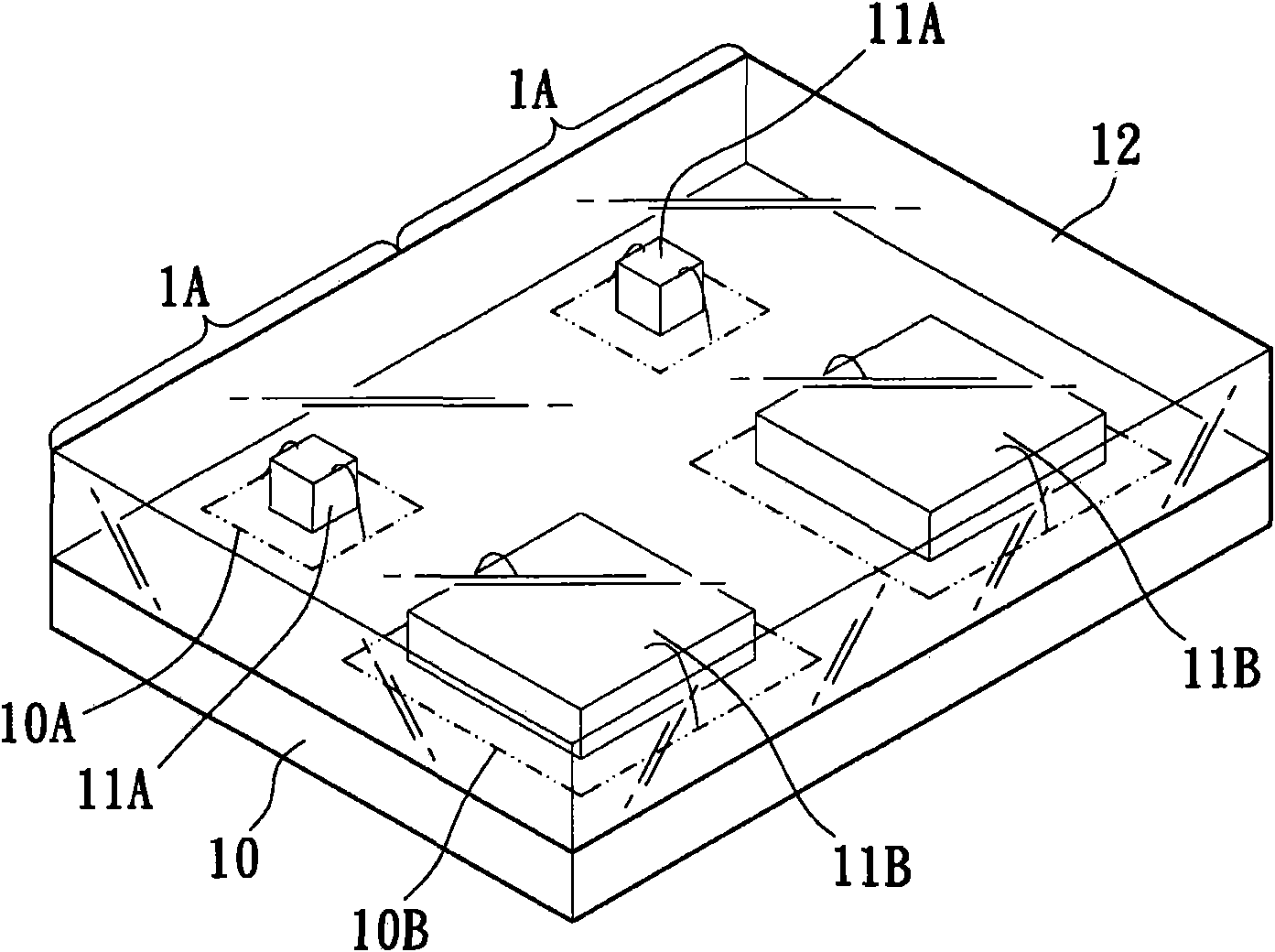

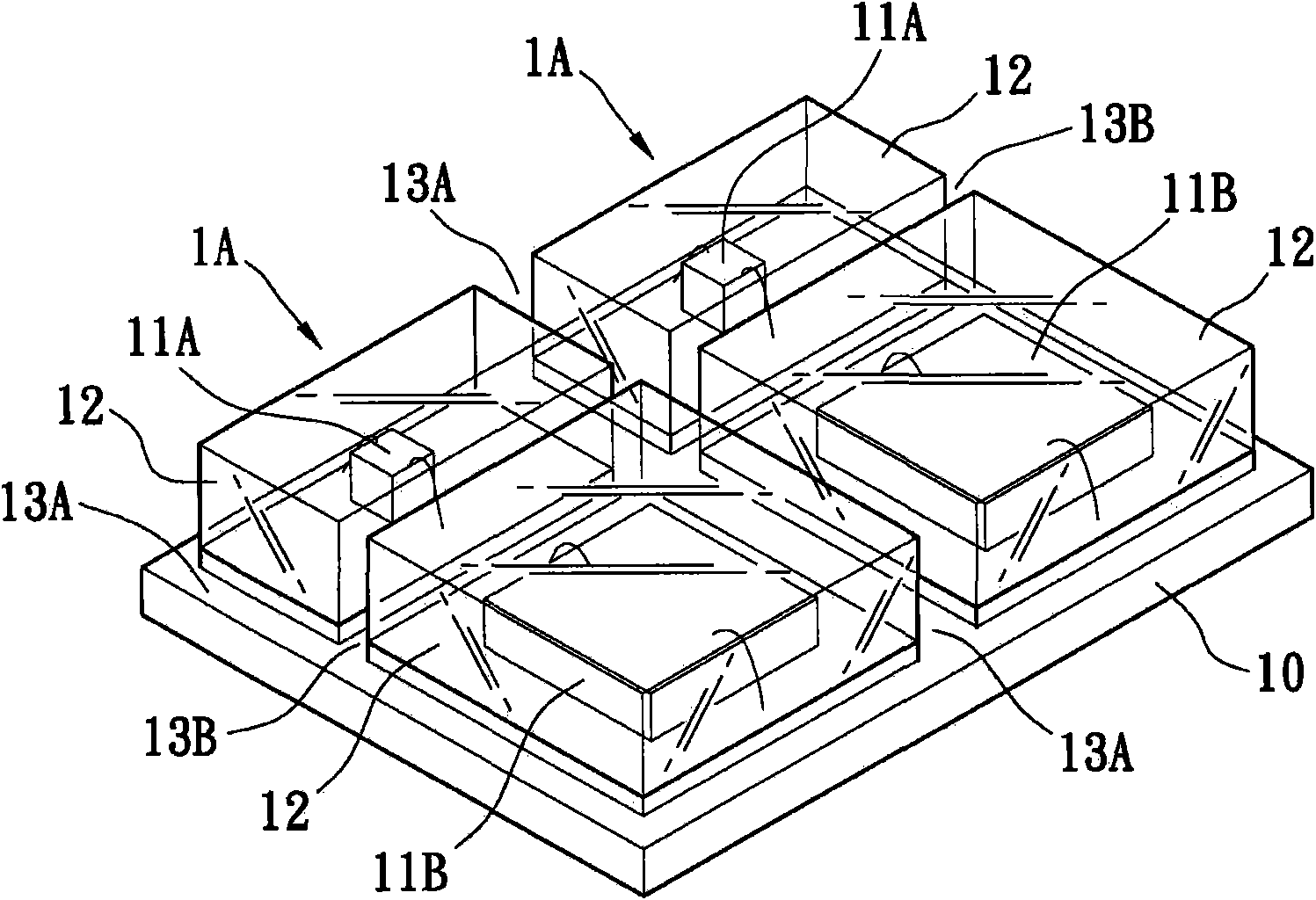

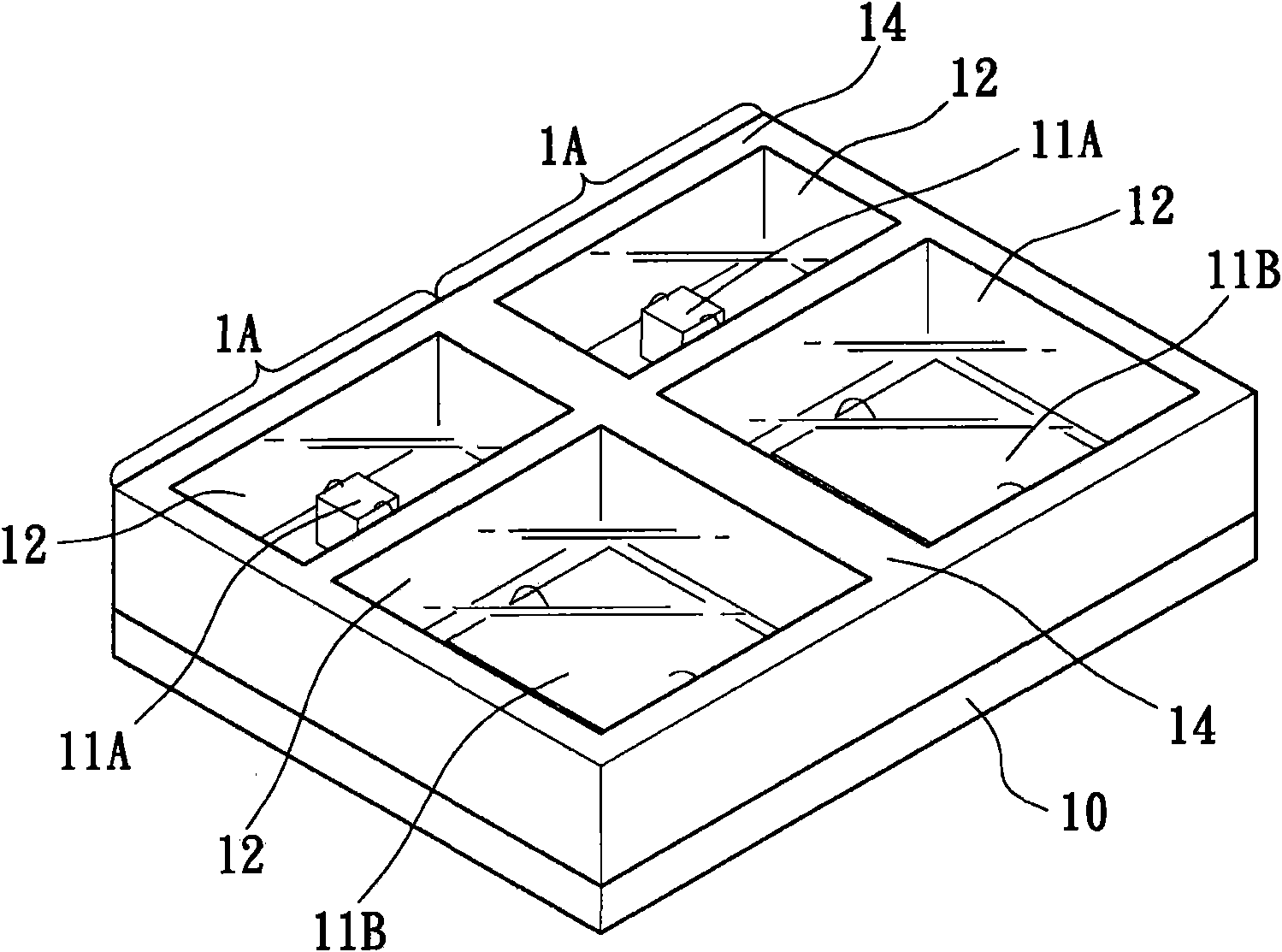

[0022] see Figure 1 to Figure 4 , the present invention provides a manufacturing method of the sensor unit 1, the manufacturing method is to use two molding methods to package and isolate the components of the sensor unit 1, which has the effect of reducing the process cost and can also solve the problem of traditional assembly The absence of the mode, its manufacturing method comprises the following steps:

[0023] The step (1) of the present invention is to provide a substrate 10 including a plurality of sensor regions 1A on the substrate 10 . Such as figure 1 As shown, in this specific embodiment, the substrate 10 includes two sensor regions 1A, and each sensor region 1A will form a sensor unit 1 (such as Figure 4 shown). Each sensor area 1A is provided with two independent circuit areas 10A, 10B on the surface and inside of the substrate 10 (but the number of the circuit areas can be more than two), and in this embodiment, the sensor unit 1 The signal transmitter 11A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com