Method for producing sensor unit

A manufacturing method and sensor technology, which are used in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of increased process difficulty, easy falling off or displacement, and overflow of glue, and achieve cost savings and excellent reliability. The effect of high degree and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

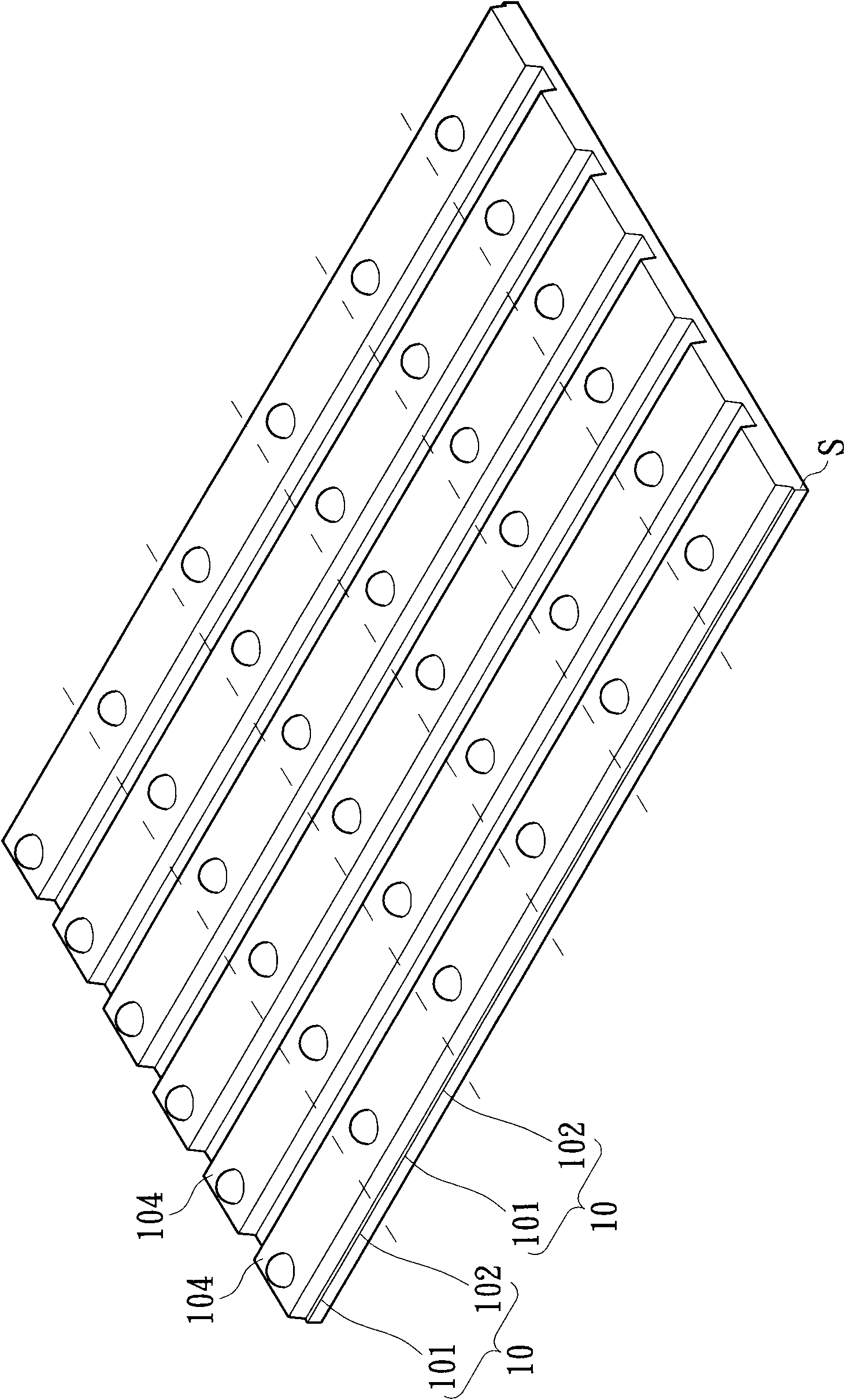

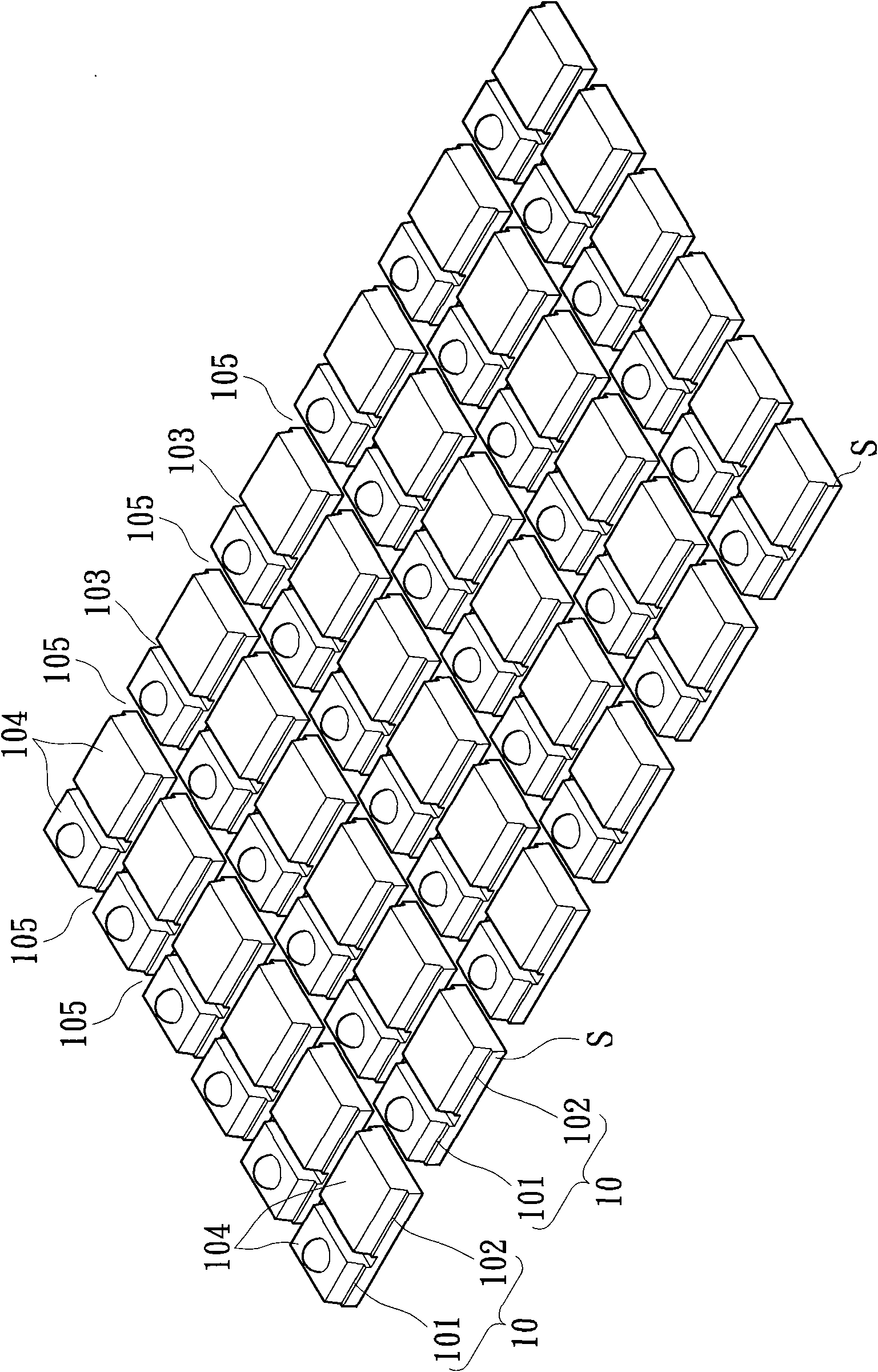

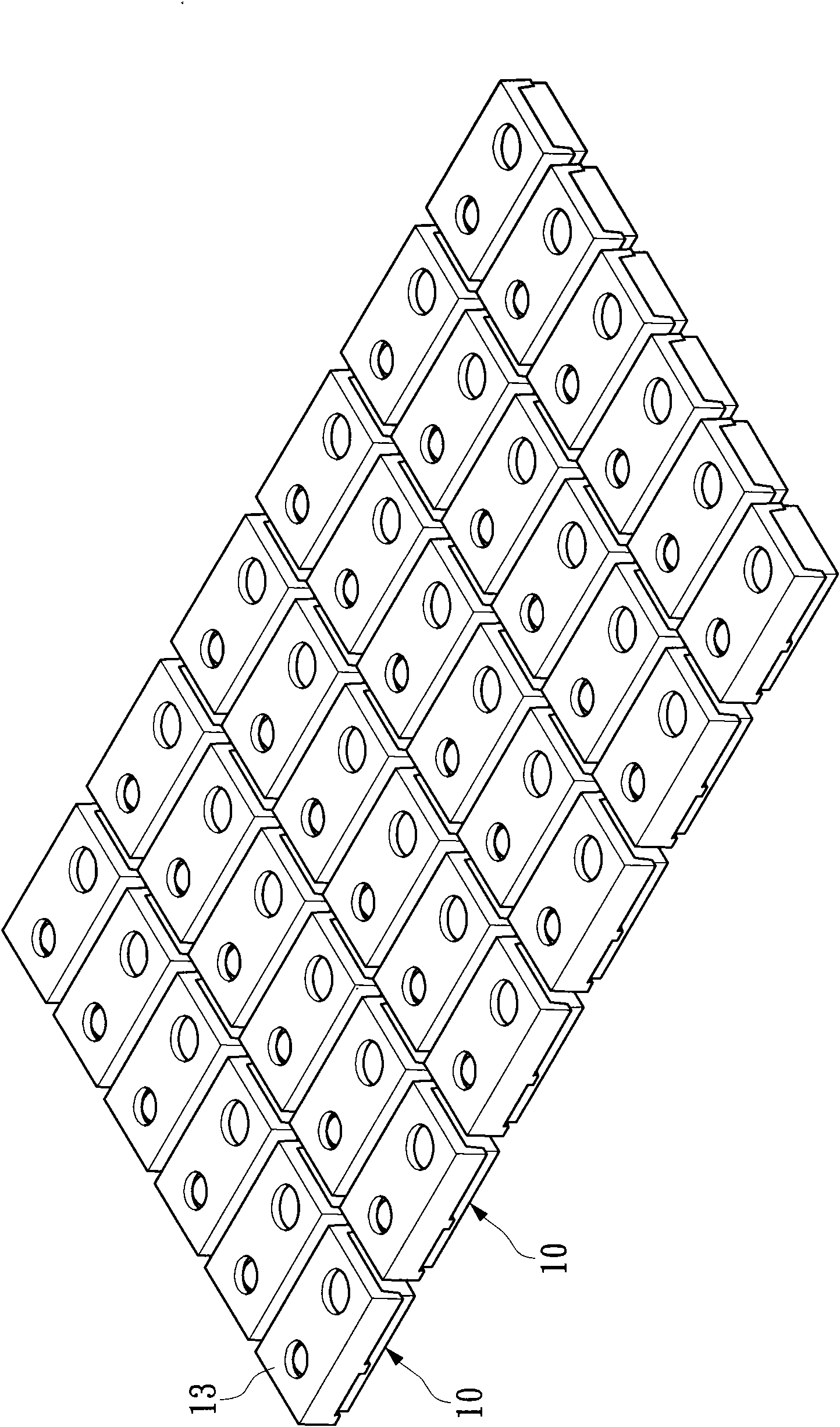

[0035] see Figure 1 to Figure 3 , and with Figure 4 The present invention provides a method for manufacturing the sensor unit 1. The manufacturing method utilizes a one-time modeling method and an assembly spacer 13 to package and isolate the sensor unit 1, which has the effect of reducing the process cost, and more The defect of the traditional assembly method can be solved, and its manufacturing method includes the following steps:

[0036] Step (1): A substrate S is provided, and the substrate S includes a plurality of sensor regions 10 . Such as figure 1 As shown, in this specific embodiment, the substrate S includes an array of 6 by 6 sensor regions 10, and each sensor region 10 will form a sensor unit 1 ( Such as Figure 4 , Figure 5 shown). Each sensor area 10 is provided with two independent circuit areas 101, 102 on the surface and inside of the substrate S (but the number of the circuit areas 101, 102 can be more than two), and in this embodiment, the sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com